A coil automatic winding device

An automatic winding and coil technology, applied in coil manufacturing, electrical components, inductor/transformer/magnet manufacturing, etc., can solve the problem of low automation of winding devices, achieve high production efficiency, prevent coils from loosening, and work reliably. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

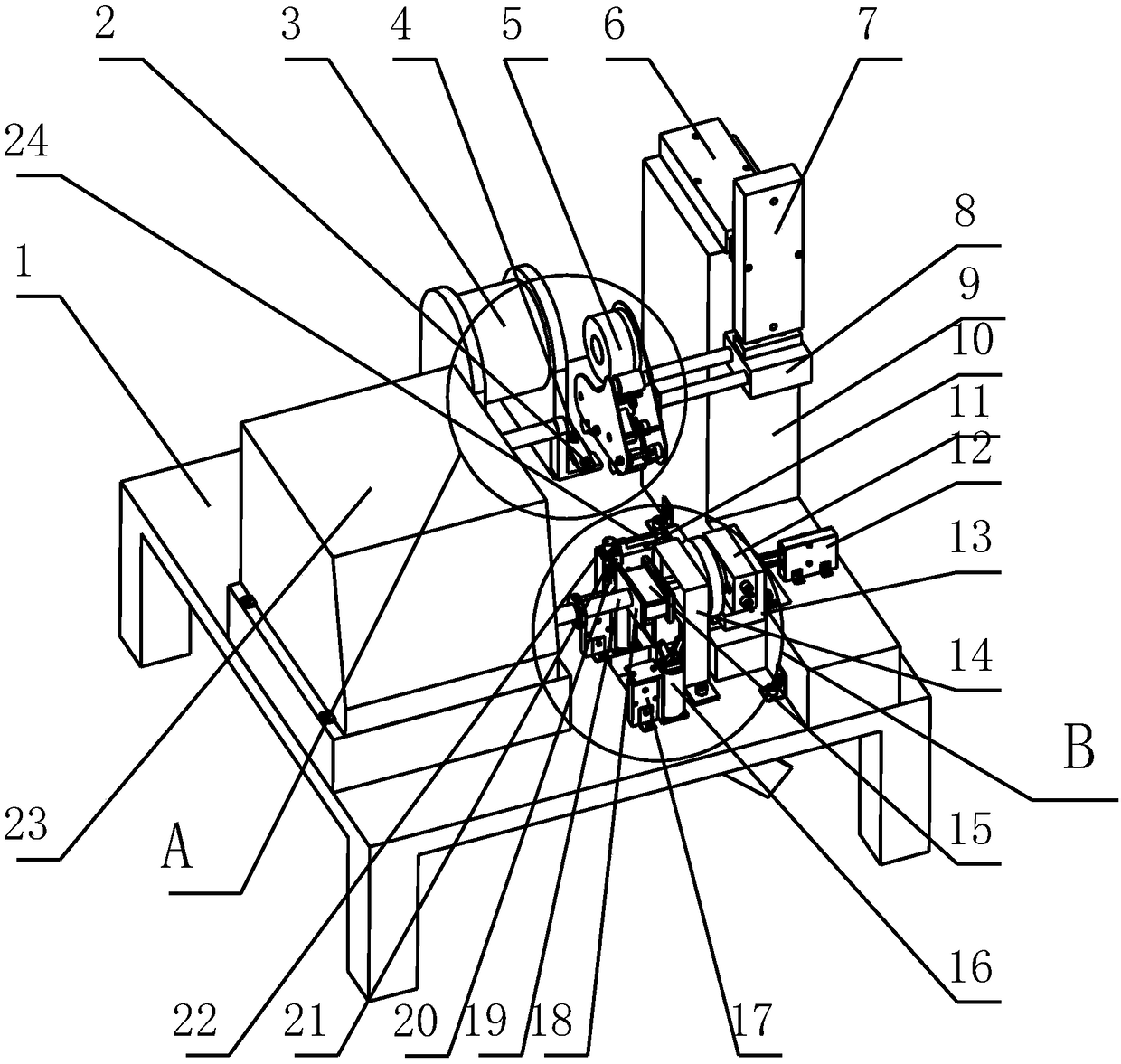

[0032] Such as Figure 1-3 , an automatic coil winding device, comprising a frame 1, a winding main shaft 19 and a winding skeleton 15 fixed on the winding main shaft 19, the winding main shaft 19 is driven by a main shaft drive box 23;

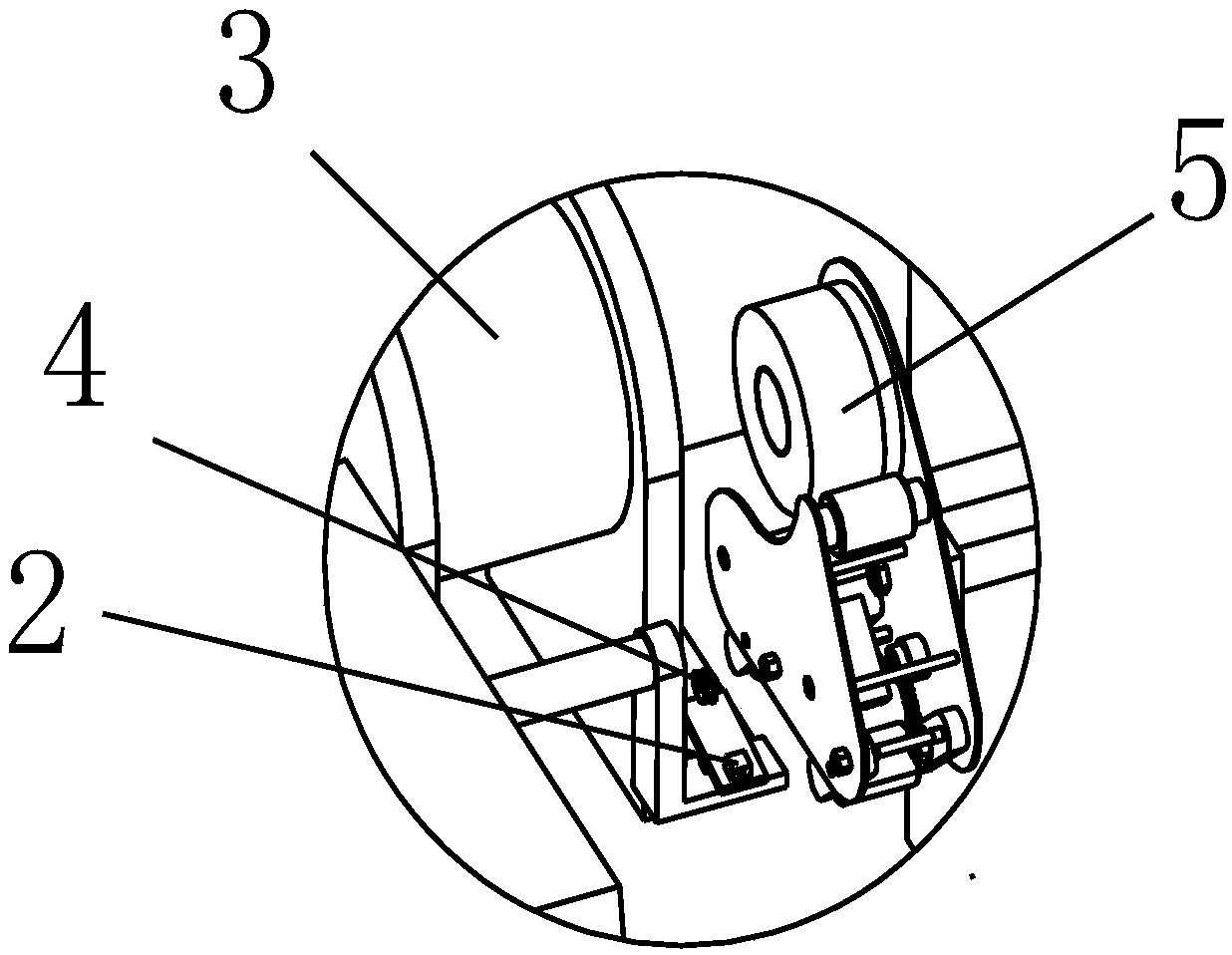

[0033] One side of the winding main shaft 19 is provided with a wire barrel 3 and a lead-in mechanism for supplying wire rods, and the lead-in mechanism includes a fixing mechanism and a driving fixing mechanism that fixes the thread ends extracted from the bobbin 3 from one side of the main shaft to the other side the first drive mechanism;

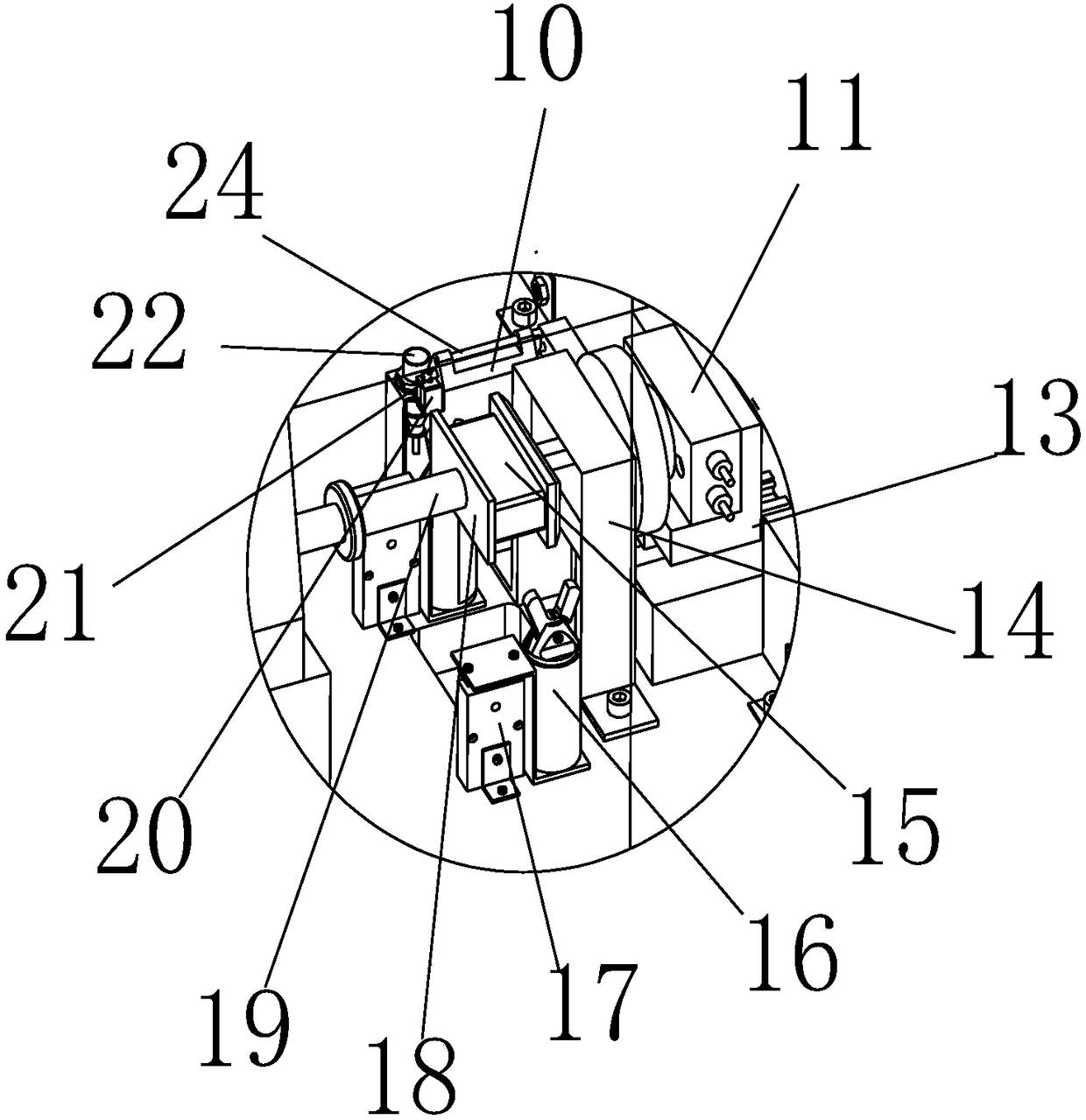

[0034] On the other side of the main shaft, there is a clamping mechanism for clamping the thread ends sent by the fixing mechanism;

[0035] The winding device also includes a tape sealing mechanism for fixing the wire on the winding frame 15 and a controller for controlling the lead mechanism and the clamping mechanism;

[0036] A photoelectric sensor 22 for detecting whether the wire rod is used up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com