Stiffness-adjustable grinding device and using method

A kind of rigidity and grinding wheel technology, applied in the direction of grinding machine, abrasive belt grinder, grinding/polishing equipment, etc., can solve the problems of damage to the grinding machine and grinding materials, different shapes of materials, and inability to grind in depressions, etc., to improve the degree of automation , The grinding effect is outstanding, the effect of increasing the friction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

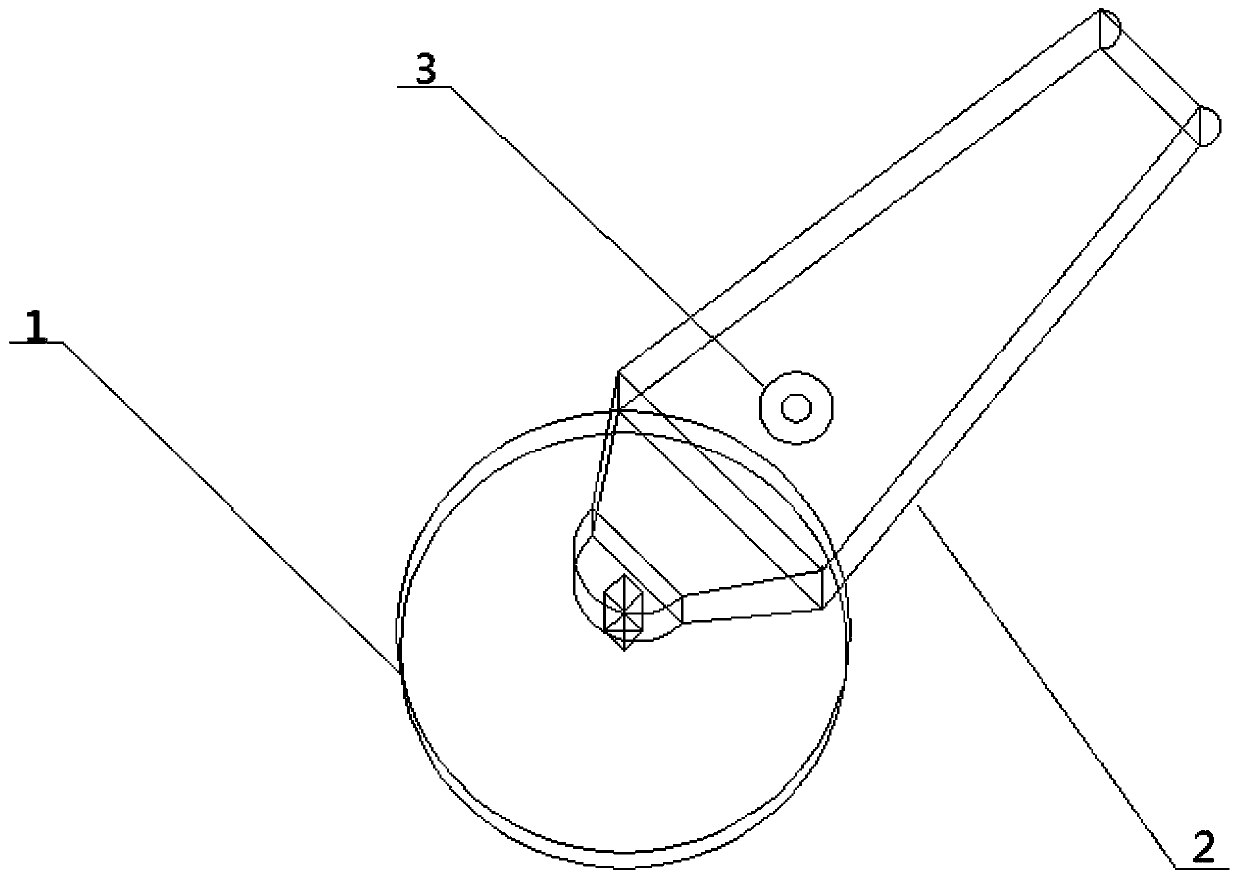

[0058] see Figure 1-9 , a grinding device with adjustable stiffness, which includes a motor 2 for providing power, a switch 3 for controlling its opening is installed on the motor 2, and a grinding wheel 1 for grinding is installed on the output shaft of the motor 2 Or grinding belt 7; the grinding area on the grinding wheel 1 and grinding belt 7 adopts rubber material to be divided into multiple layers, and the middle layer adopts a hydraulic layer or pulse layer 9 that can produce instantaneous force, and all the other layers are able to provide different grinding Rigidity layer 11 of rigidity; The hydraulic layer or pulse layer 9 is respectively connected with hydraulic device or pulse device 12; The outer surface is wrapped with a layer of flexible material 10; by changing the grinding material of the rigidity layer 11 in real time, finely adjust the appropriate stiffness to polish the object. By using the above-mentioned grinding device, it can adjust or change the grin...

Embodiment 2

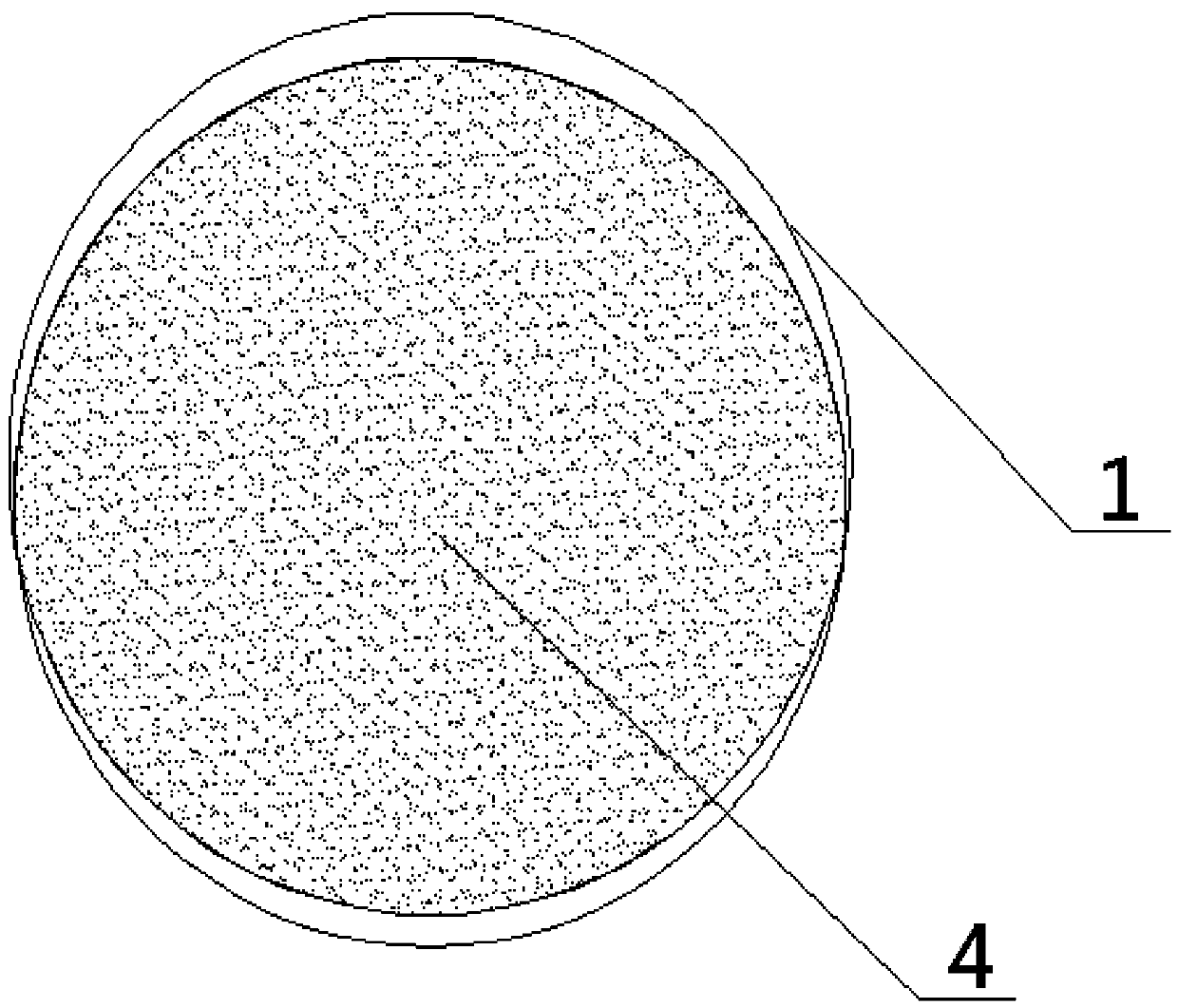

[0070] When adopting water and solid mixture 4, its usage method is:

[0071] Step1: Understand the stiffness of the grinding material and determine the approximate required grinding stiffness;

[0072] Step2: Considering the rigidity and diameter of the solid, select a suitable solid material; adjust the ratio of water and solid to obtain a mixture of water and solid with the required rigidity 4;

[0073] Step3: Add water and solid mixture 4 to the grinding wheel through the drain pipe 13, and install a water filter 15 at the front end of the drain pipe 13 after injection, so that water can flow out through the water filter 15, and further accurately adjust the ratio of water and solids to suit grinding ;

[0074] Step4: Start switch 3;

[0075] Step5: Facing the concave hole, turn off the switch 3, install the telescopic rod 21 on the axle 18, adjust the grinding distance according to the actual situation, and install a small grinding machine at the end of the telescopic r...

Embodiment 3

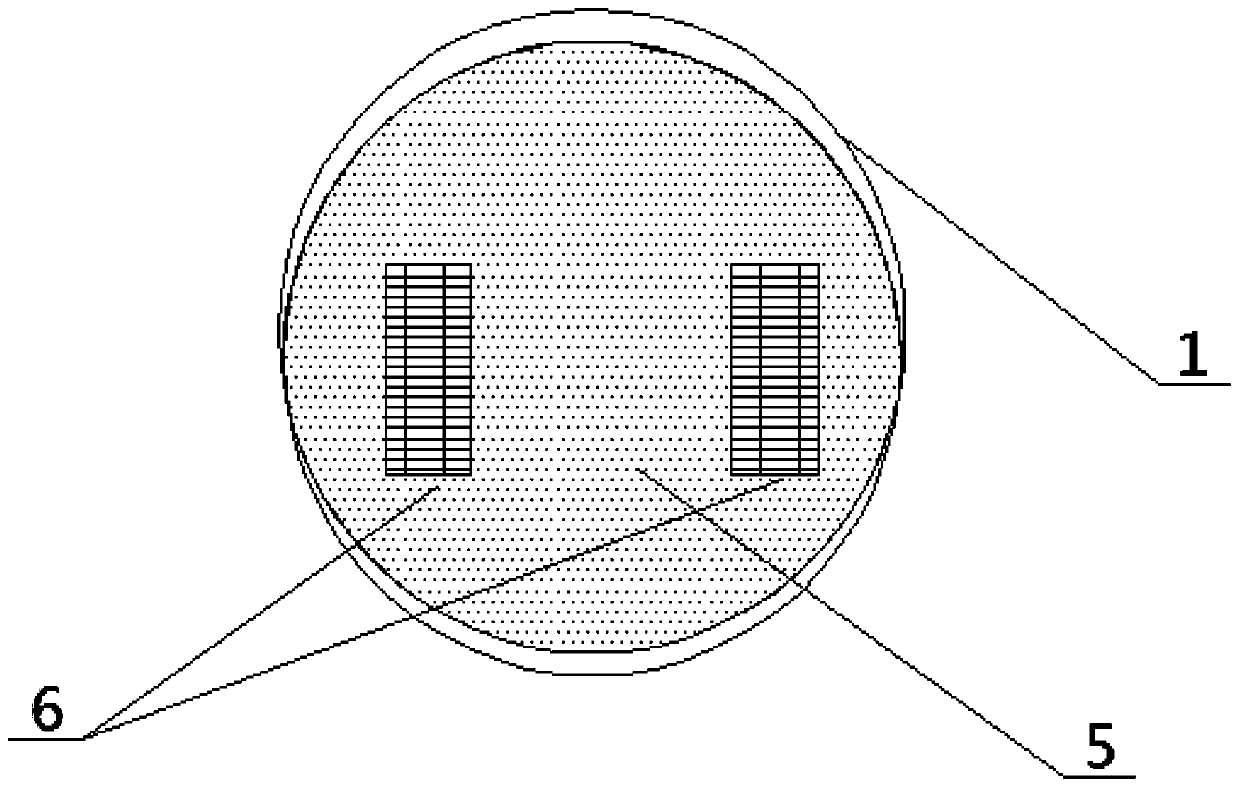

[0078] When adopting ferrofluid reinforced solid mixture 5, its usage method is:

[0079] Step1: Understand the stiffness of the grinding material and determine the approximate required grinding stiffness;

[0080] Step2: Consider the magnetism of the magnetic fluid, solid diameter and stiffness, select the appropriate magnetic fluid material and solid material, adjust the ratio of the magnetic fluid and the solid, and obtain the required rigidity of the magnetic fluid plus solid mixture 5;

[0081] Step3: Add the magnetic fluid-added solid mixture 5 to the grinding wheel through the drain pipe 13, adjust the current intensity of the grinding device, that is, the magnetic field strength of the surrounding electromagnet 6, and then change the viscosity of the magnetic fluid-added solid mixture 5 to adapt to grinding;

[0082] Step4: Start switch 3;

[0083] Step5: Facing the concave hole, turn off the switch 3, install the telescopic rod 21 on the axle 18, adjust the grinding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com