Patents

Literature

54 results about "Reinforced solid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

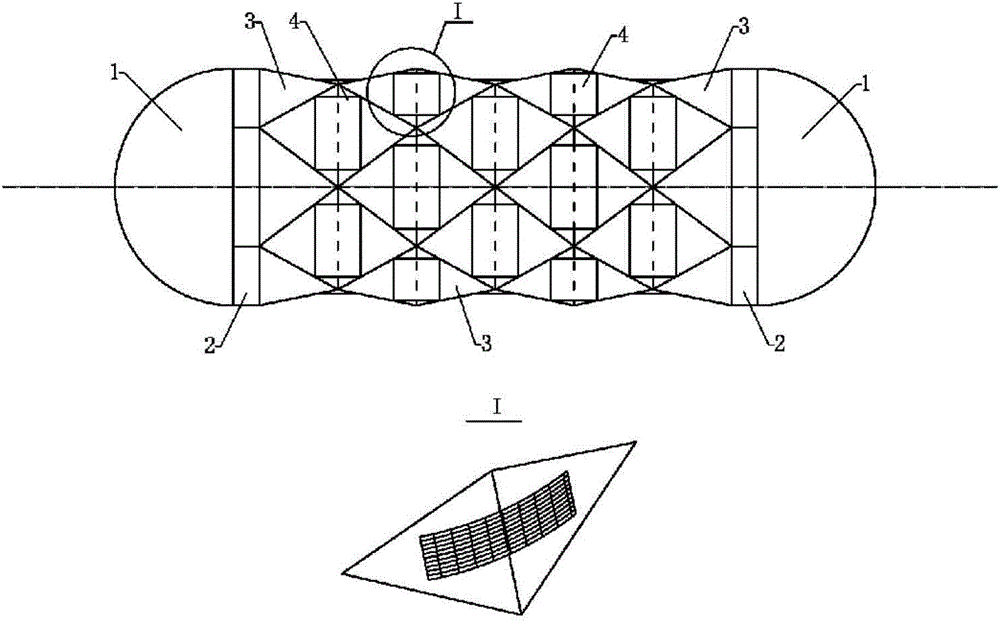

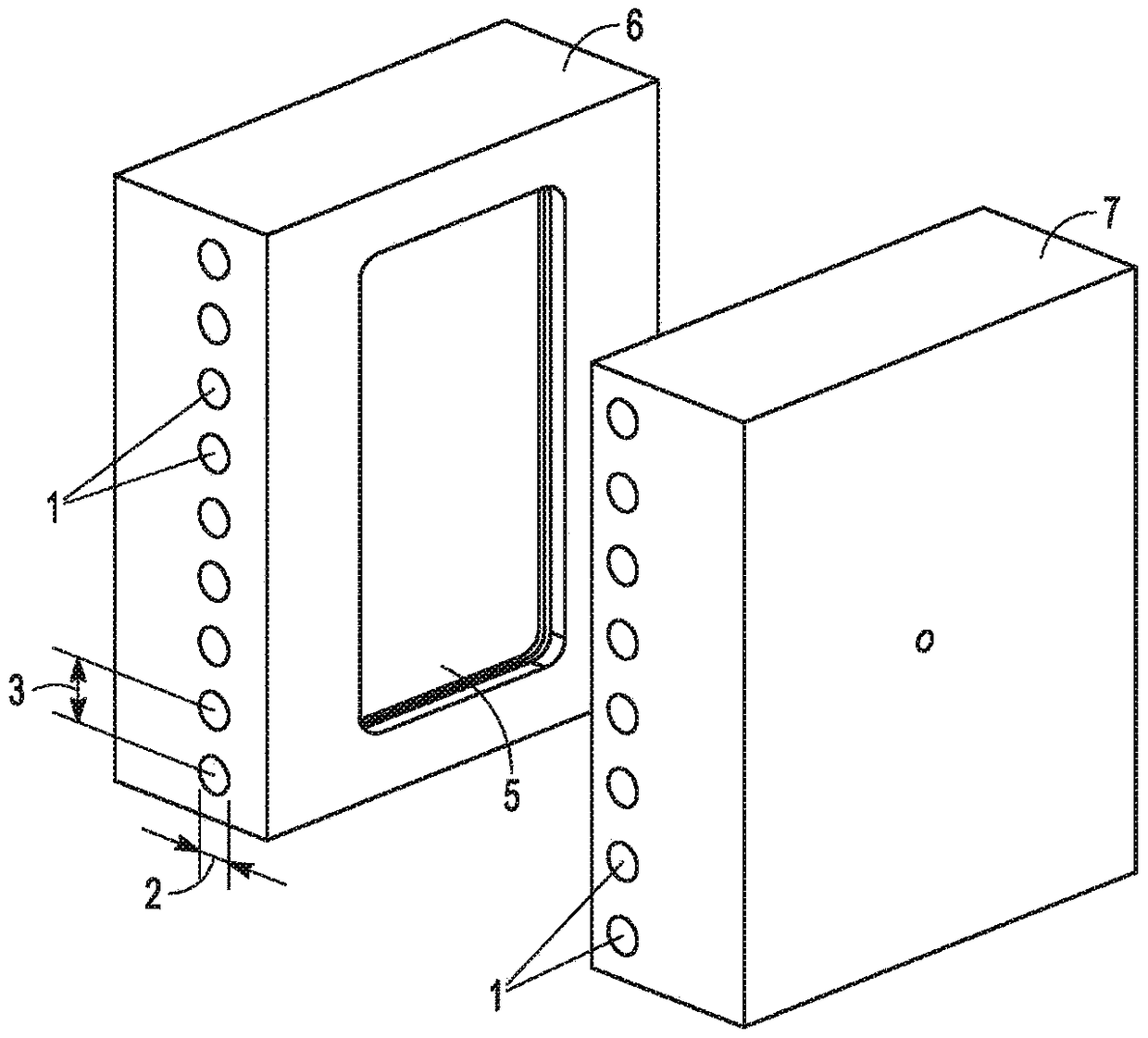

In solid mechanics, a reinforced solid is a brittle material that is reinforced by ductile bars or fibres. A common application is reinforced concrete. When the concrete cracks the tensile force in a crack is not carried any more by the concrete but by the steel reinforcing bars only. The reinforced concrete will continue to carry the load provided that sufficient reinforcement is present. A typical design problem is to find the smallest amount of reinforcement that can carry the stresses on a small cube (Fig. 1). This can be formulated as an optimization problem.

Surface reinforced solid wood section material, floor board and manufacturing method thereof

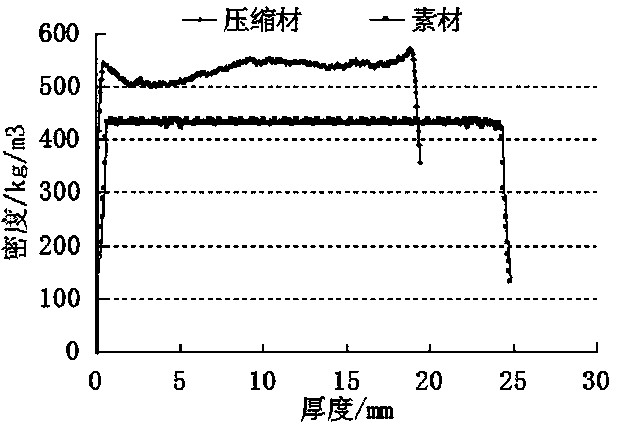

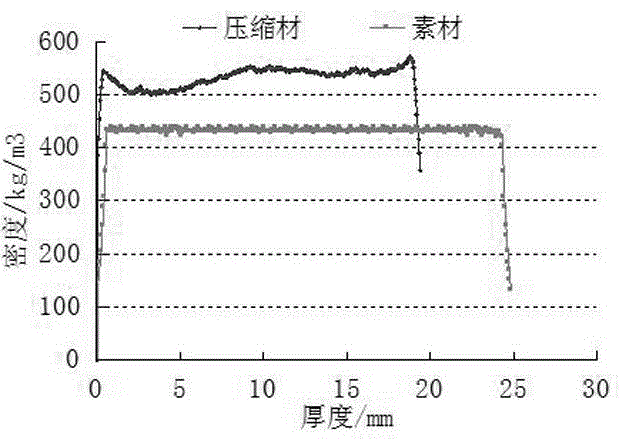

ActiveCN101603623AReduce pollutionStable moisture contentWood compressionFurniture partsSolid woodVolumetric Mass Density

Owner:ZHEJIANG SHIYOU TIMBER +1

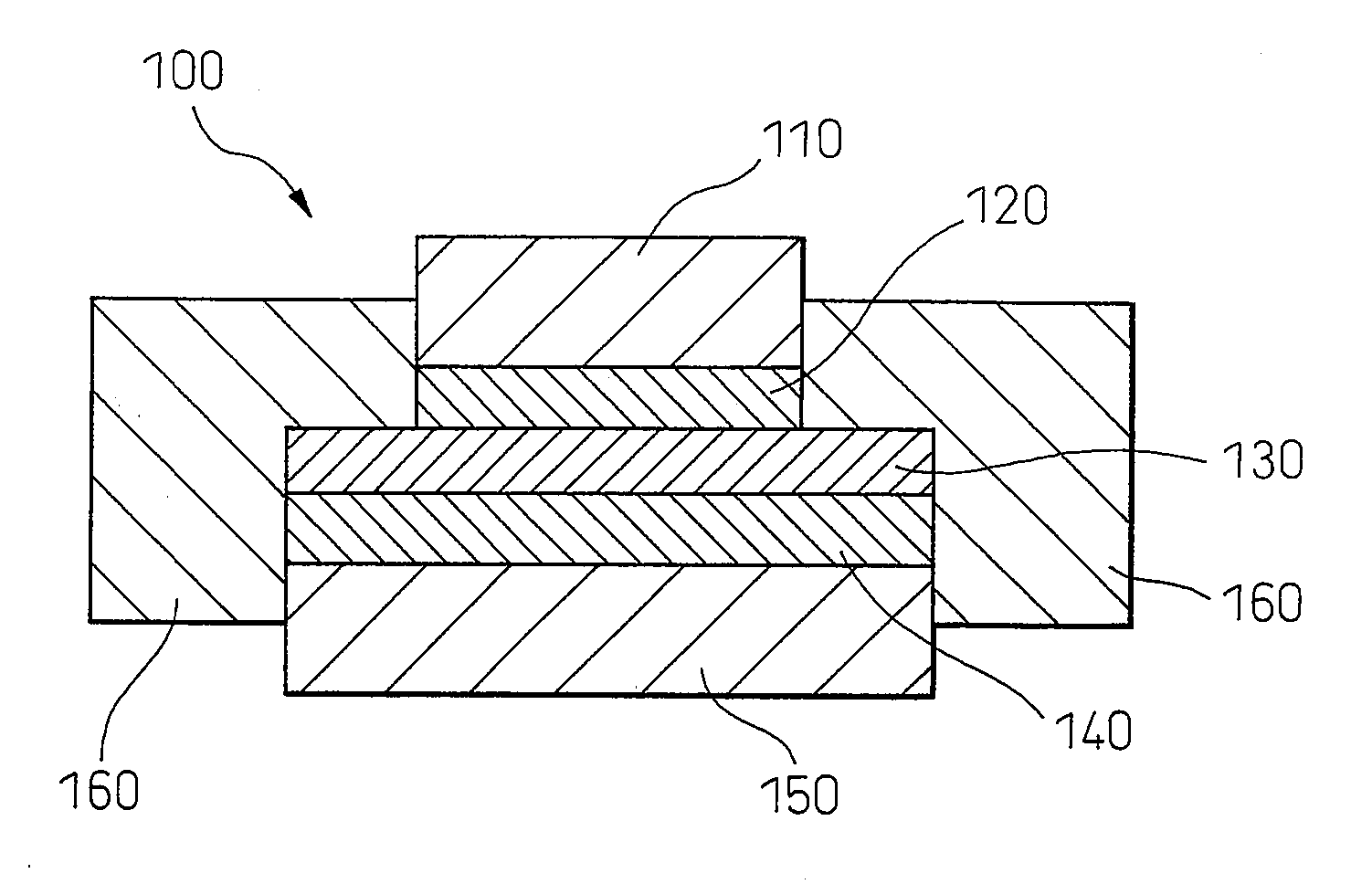

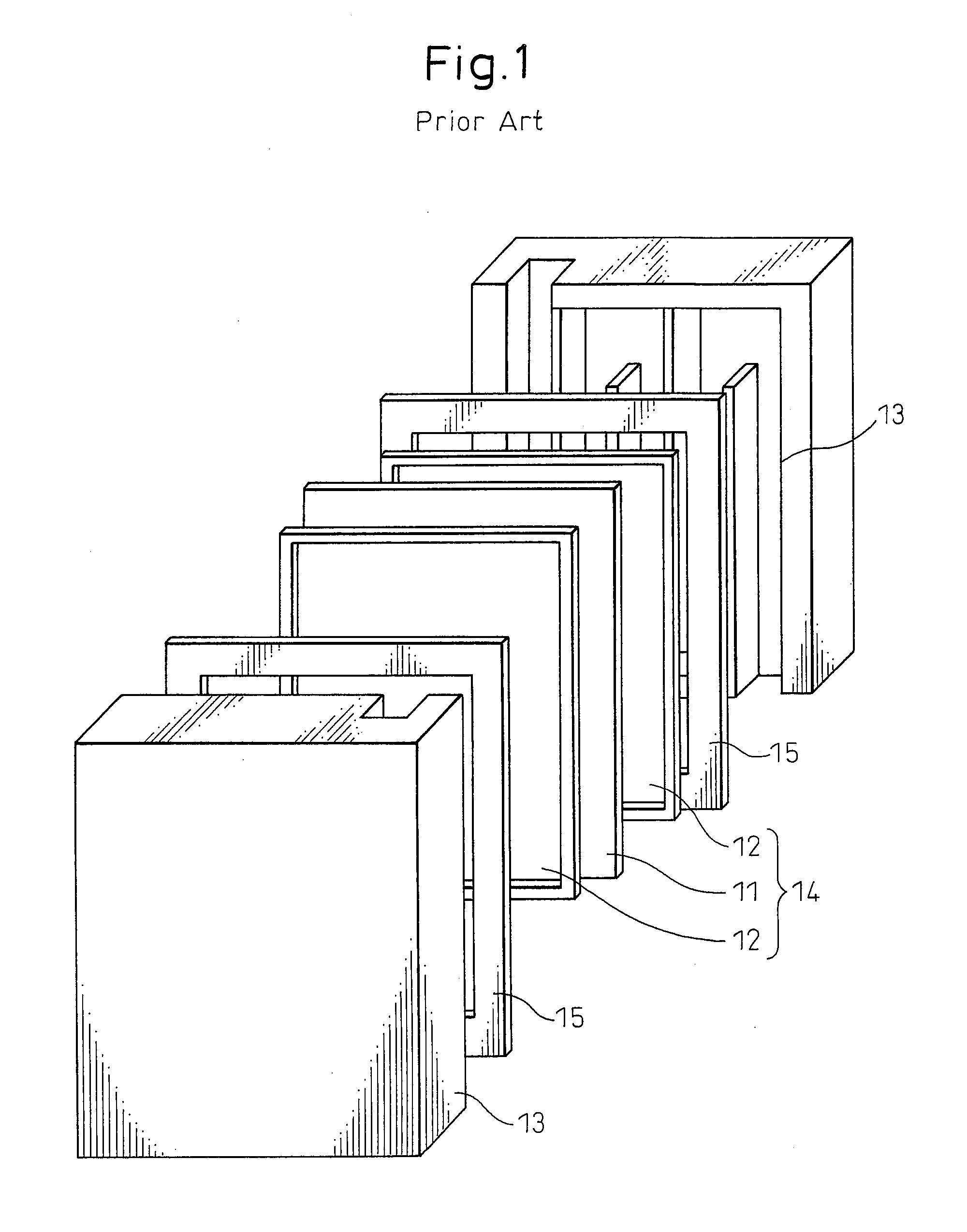

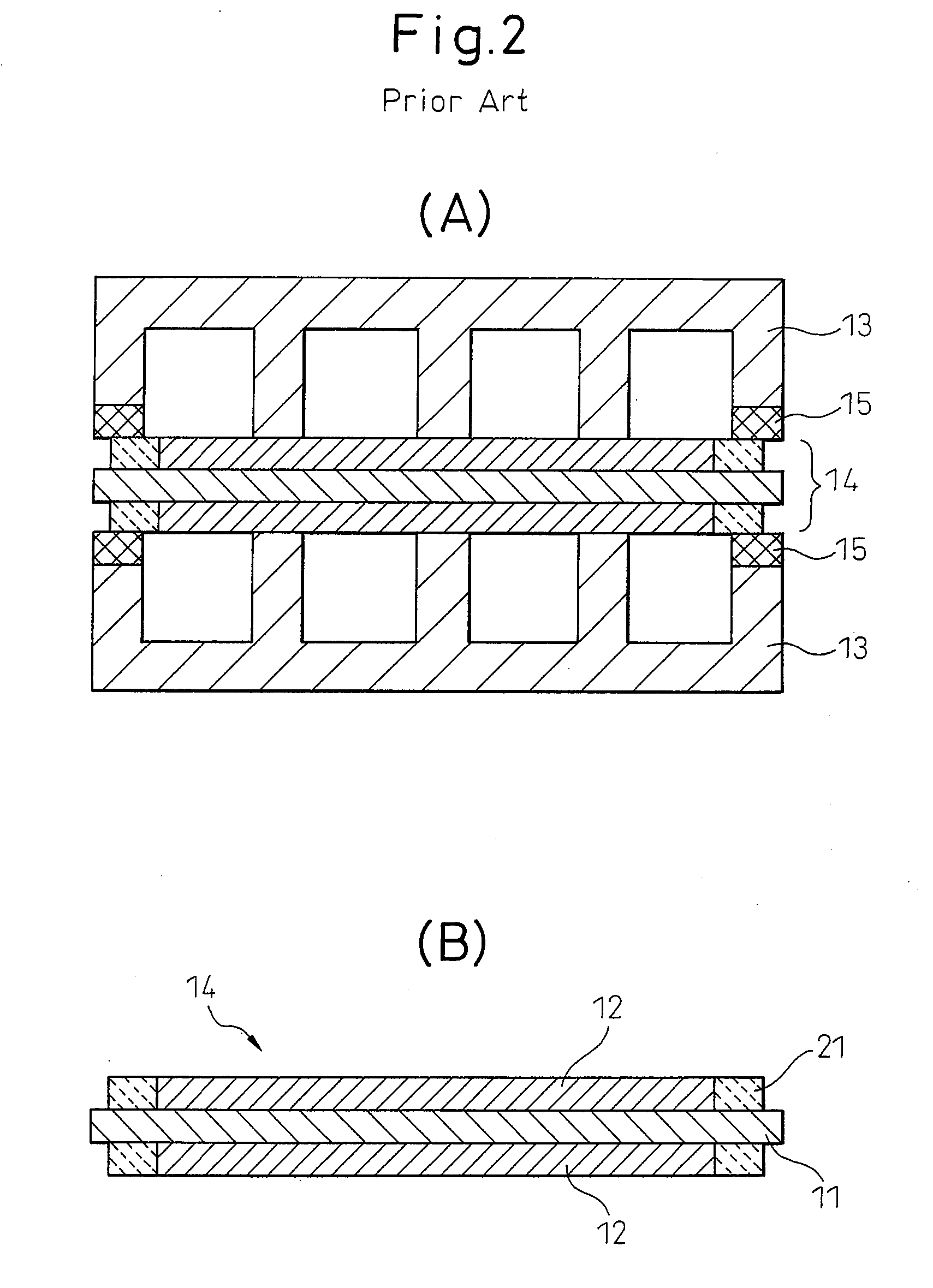

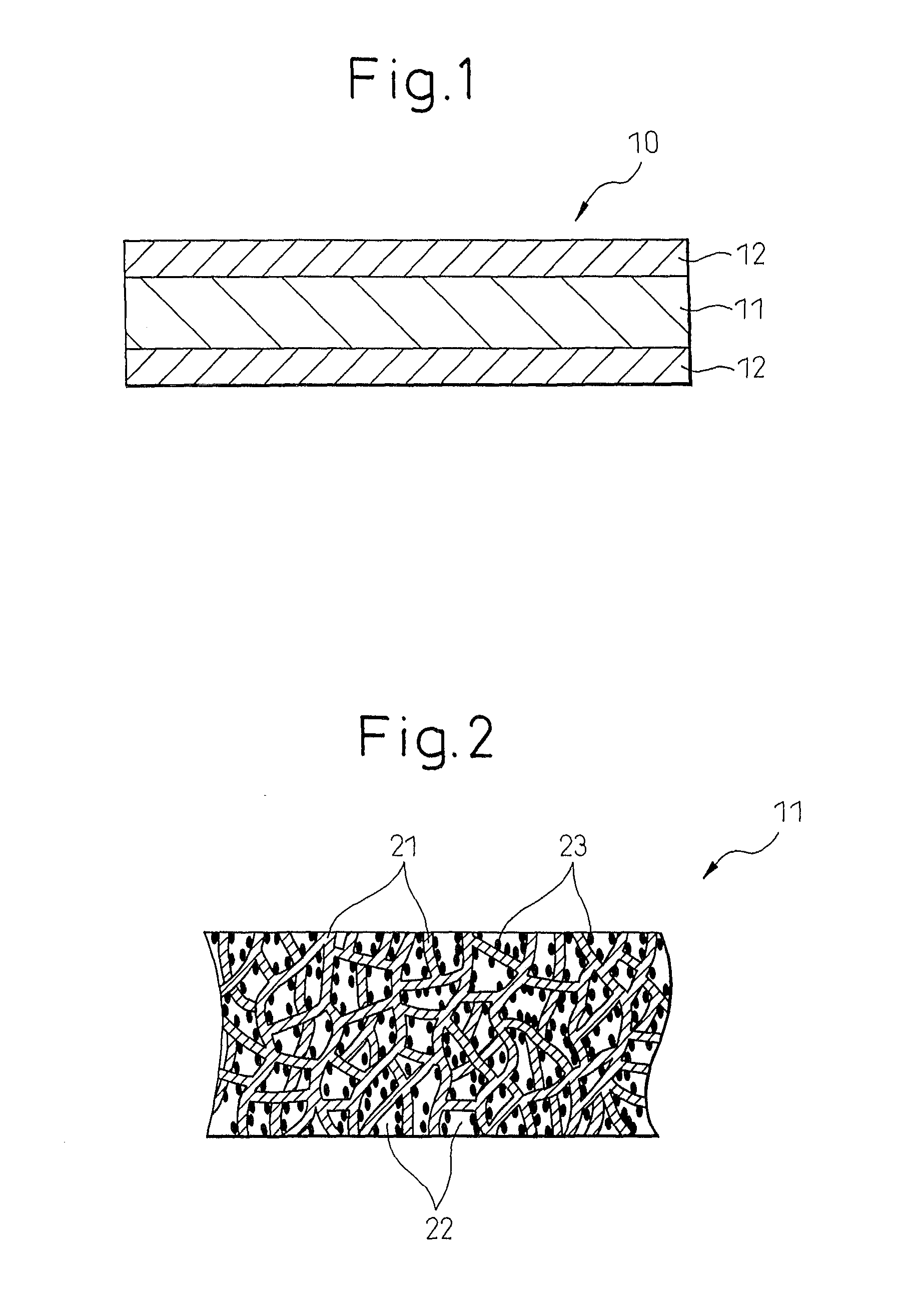

Membrane Electrode Assembly, Method For Producing The Same, and Solid Polymer Fuel Cell Using The Same

ActiveUS20100047649A1Improve accuracySimple wayCell electrodesFinal product manufacturePolymer electrolytesFuel cells

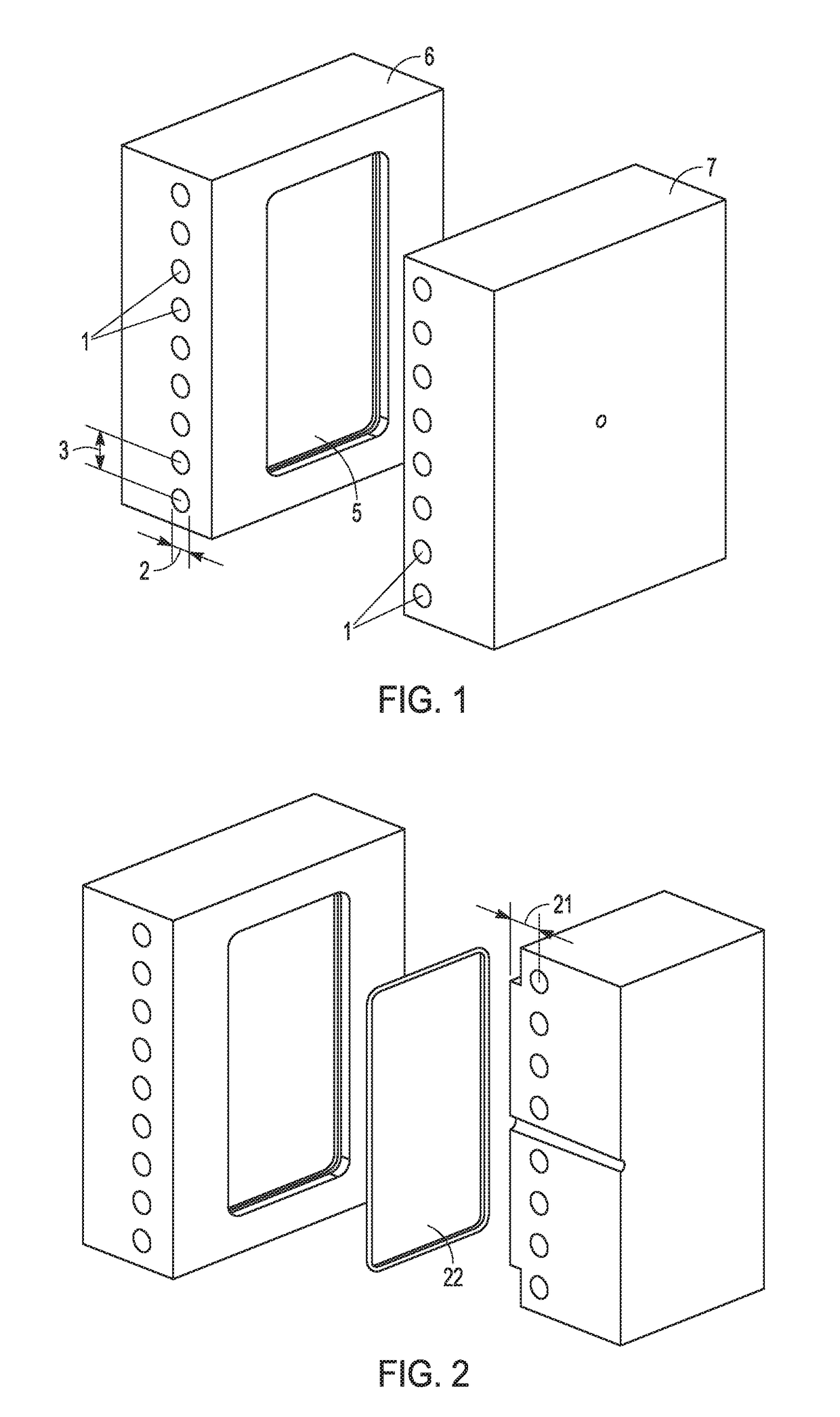

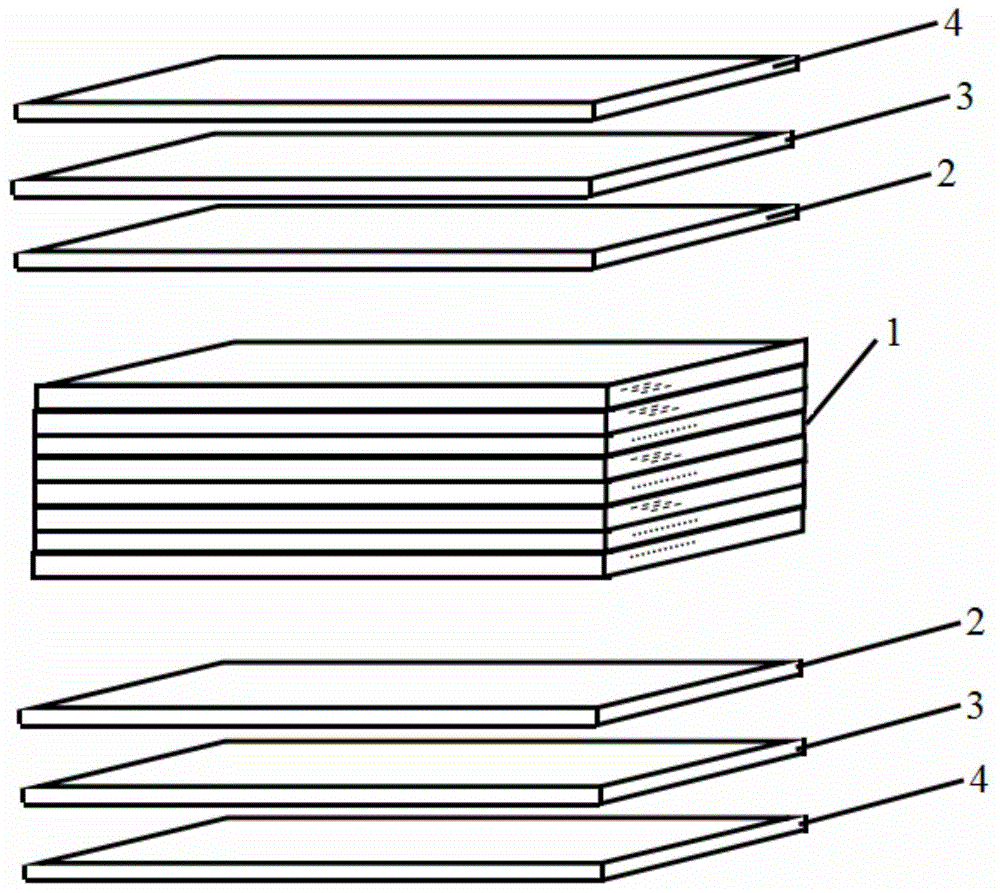

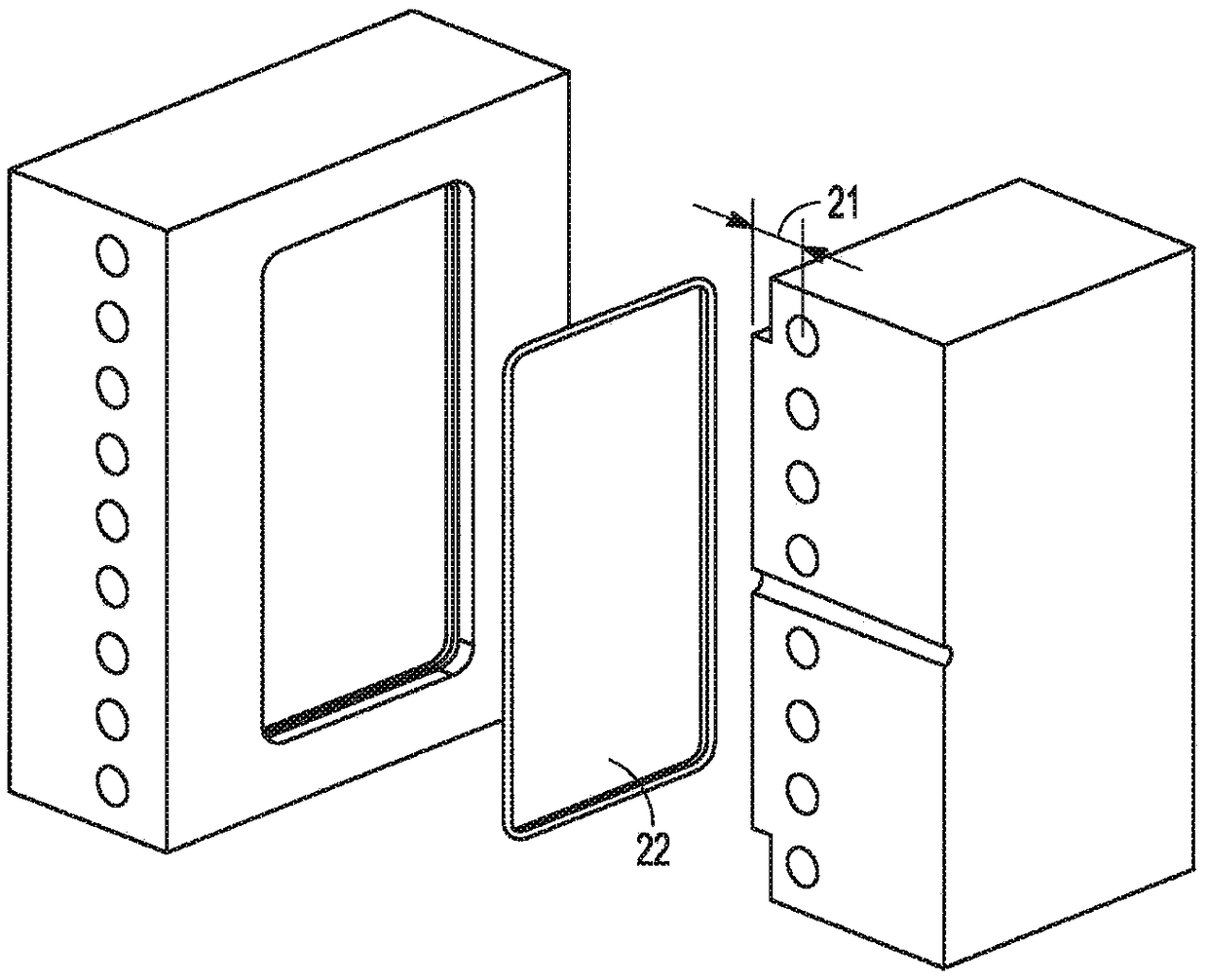

The present invention provides a membrane electrode assembly that enhances the reliability, mechanical strength, and handling characteristics of a seal in a solid polymer electrolyte fuel cell. The membrane electrode assembly of the present invention comprises a membrane-electrode structure having electrode layers and gas diffusion layers on both sides of a polymer electrolyte membrane, and a resin frame provided in such a manner as to fully enclose the outer periphery of the electrolyte membrane and to enclose at least portions of the outer peripheries of the gas diffusion layers, the resin frame being provided so as to enclose the electrolyte membrane side. The gas diffusion layer and electrode layer on one side are stacked on a surface of the electrolyte membrane so that a surface region of the electrolyte membrane is left exposed. The gas diffusion layer on the opposite side extends all around the outer periphery of the electrolyte membrane. The resin frame is attached fixedly to at least a portion to the surface region.

Owner:W L GORE & ASSOC GK

Periodical stimulation and solid fermentation process of producing marsh gas with straw and city refuse

InactiveCN1403396AIncrease profitEfficient use ofSolid waste disposalWaste based fuelGas phaseEngineering

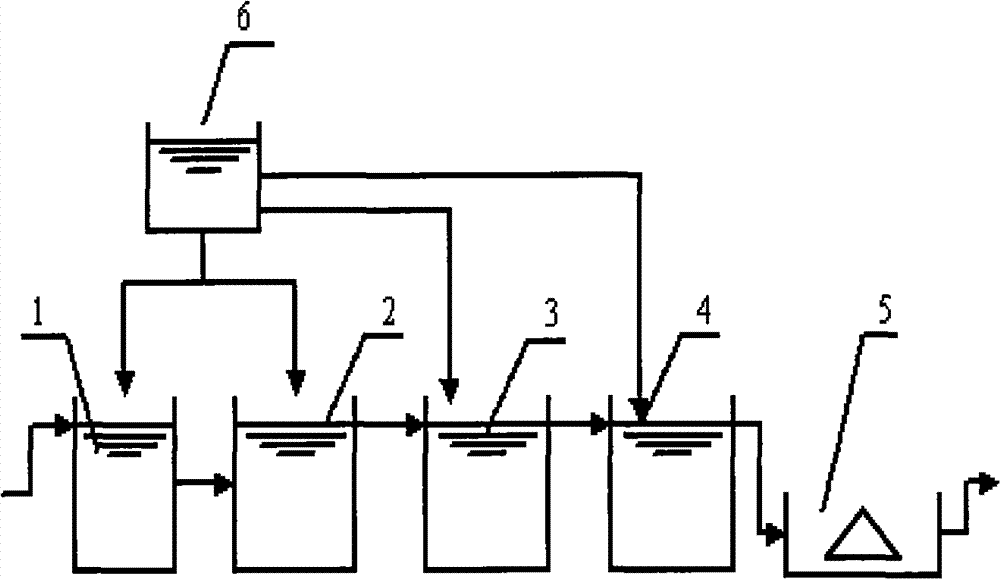

The present invention relates to biological marsh gas fermentation, and is especially the periodical stimulation and solid marsh gas fermentation process of straw and city refuse. The said process includes steam blasting dry straw and organic refuse; fast mixing of the steam blasted material and marsh gas and solid fermentation in a sealed fermenting tank; introducing fermented marsh gas to eliminate air from the tank and applying pressure periodically to reinforce solid fermentation; and collecting marsh gas. The said process has raised fermentation temperature and humidity, high marsh gas yield and easy to use fermented residue.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

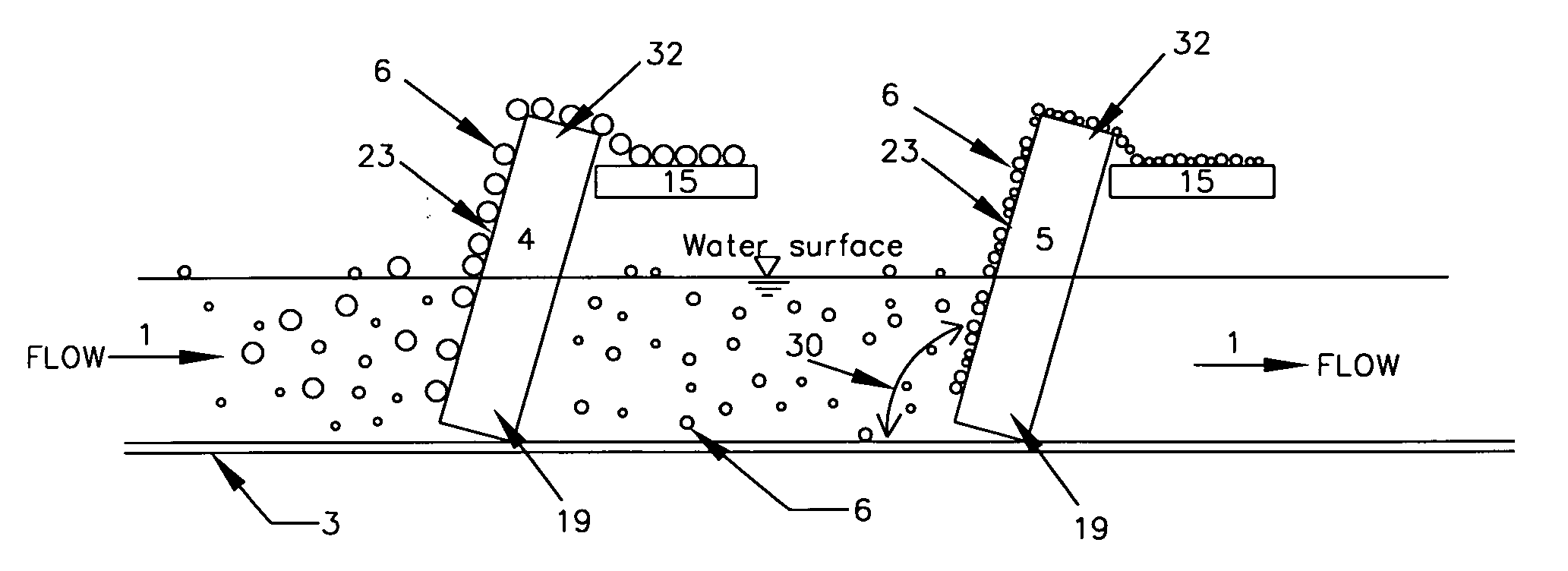

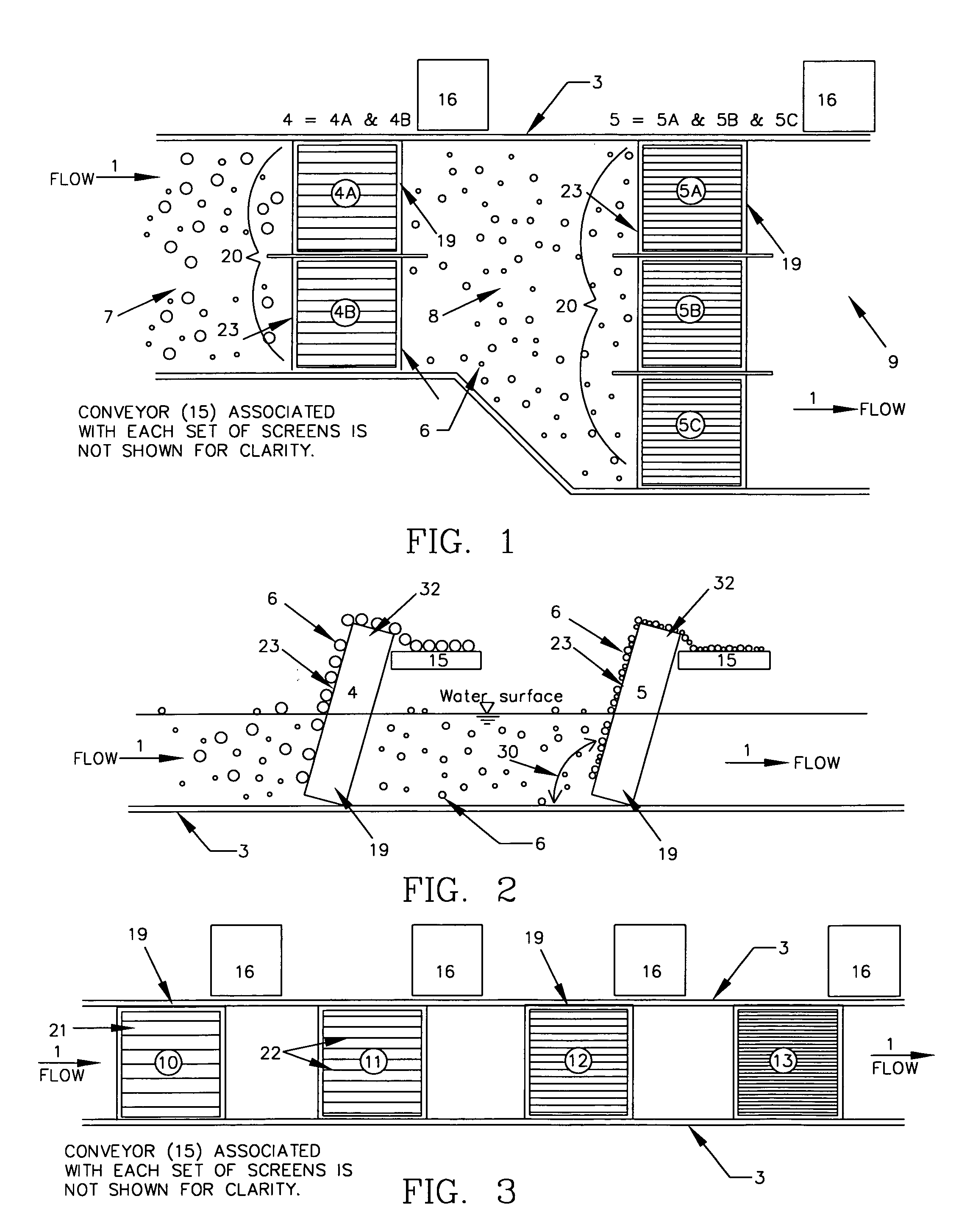

Methods of removing solids from liquids

A method of removing solid matter from liquid using two or more sets of screening devices installed in series. Each set of screening devices consists of one or more identical or nearly identical screening devices. Each downstream set of screening devices has smaller openings than the preceding upstream set of screening devices. Solid matter collected by the screening devices is automatically discharged onto two or more conveyor systems that deposit the material onto one or more central collection areas for final removal and disposal. The present invention uses screening devices in a special configuration to achieve enhanced removal of solid matter from liquid (i.e. a series installation with screen opening size decreasing in a downstream direction).

Owner:SUTHARD CLIFFORD JAMES +1

Reinforced-resin coated plant food granules

InactiveUS6045810AGuaranteed economic efficiencyImprove the immunityBiocidePowder deliveryControl releaseWater insoluble

A reinforced-resin coated, attrition resistant controlled release plant food containing water soluble central spheroids of plant nutrients amounting to between 75 and 98 percent and water insoluble resin coatings amounting to between 2 and 25 percent covering the central spheroids with the insoluble resin coatings reinforced with finely divided water insoluble plant nutrients formed in-situ by the chemical coreaction of a plurality of water soluble plant nutrients. The reinforcing nutrients amount to between 5 and 25 percent of the resin coating. A method is provided for preparing the new reinforced-resin coated plant foods with the reinforcing solids distributed throughout the insoluble resins or between thin layers of resins.

Owner:B & B INT LLC

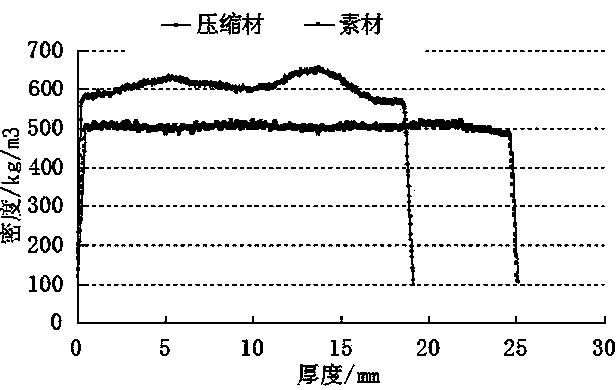

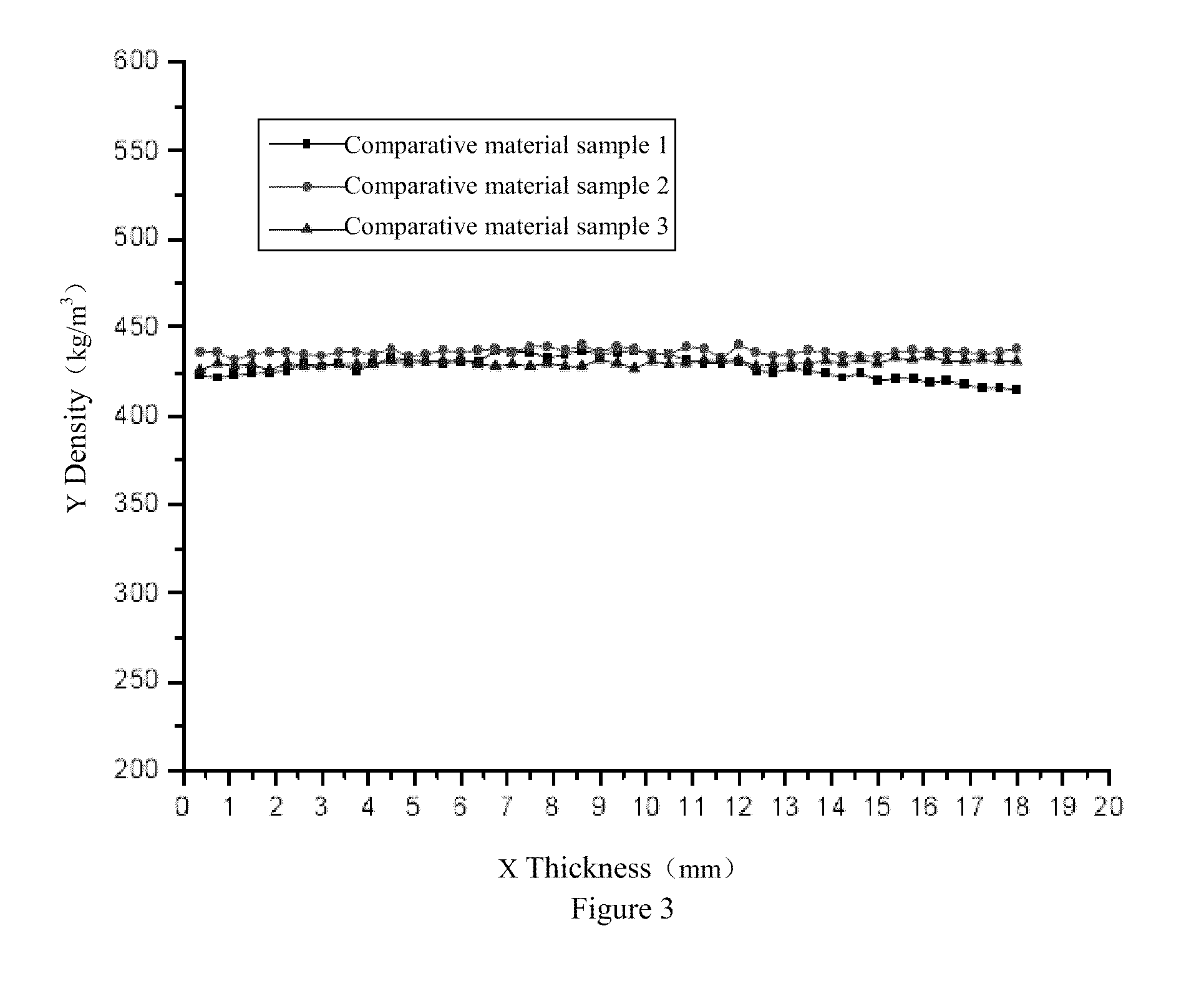

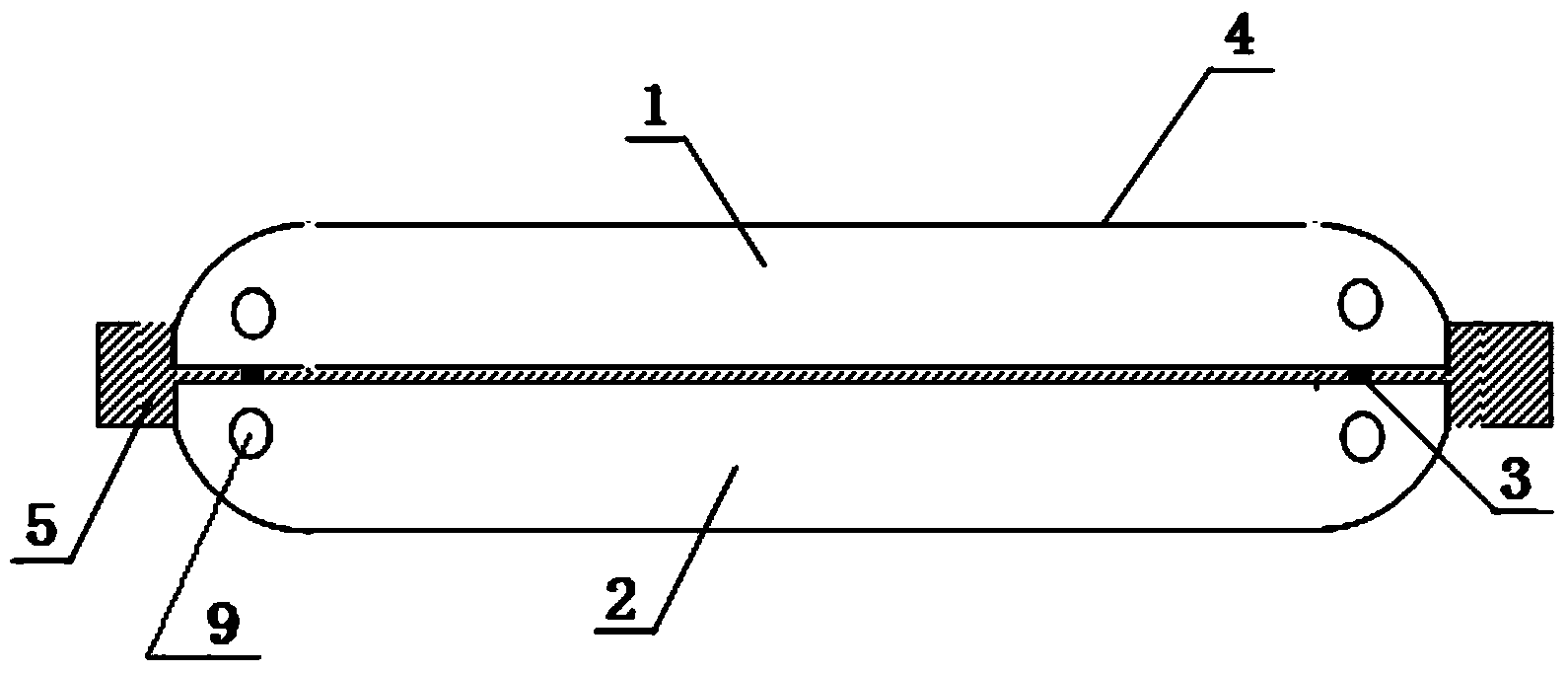

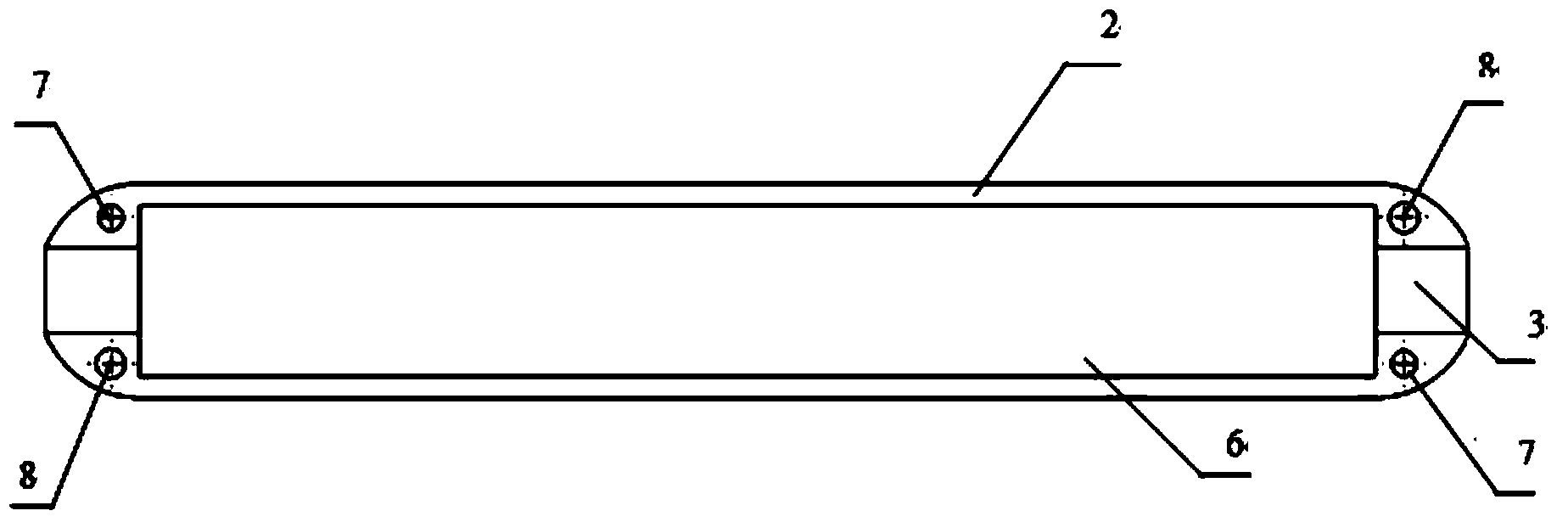

Integral reinforced solid wood section bar and manufacturing method thereof

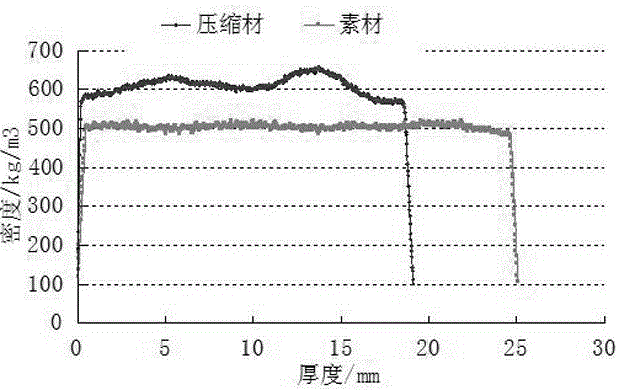

ActiveCN103481348ASmall volume lossHigh strengthWood working apparatusDomestic articlesSolid woodThermal insulation

The invention belongs to the technical field of function improving and machining of wood and particularly discloses an integral reinforced solid wood section bar and a manufacturing method thereof. The method comprises the steps of under the condition of lower water content (1-3%), adopting a single heating softening molding technology to perform low-compression rate integral compressing treatment on the wood to obtain an integral staypak with the section being uniform in density. According to the method, bursting and bubbling phenomena generated by overhigh steam pressure in the wood can be effectively reduced, the thermal insulation time can be greatly shortened, and the work efficiency is improved. The integral compression wood section bar generated by the method is good in size stability, environment-friendly and healthy, and can be used for manufacturing solid wood floors and solid wood furniture and as indoor decoration materials.

Owner:江门健威家具装饰有限公司

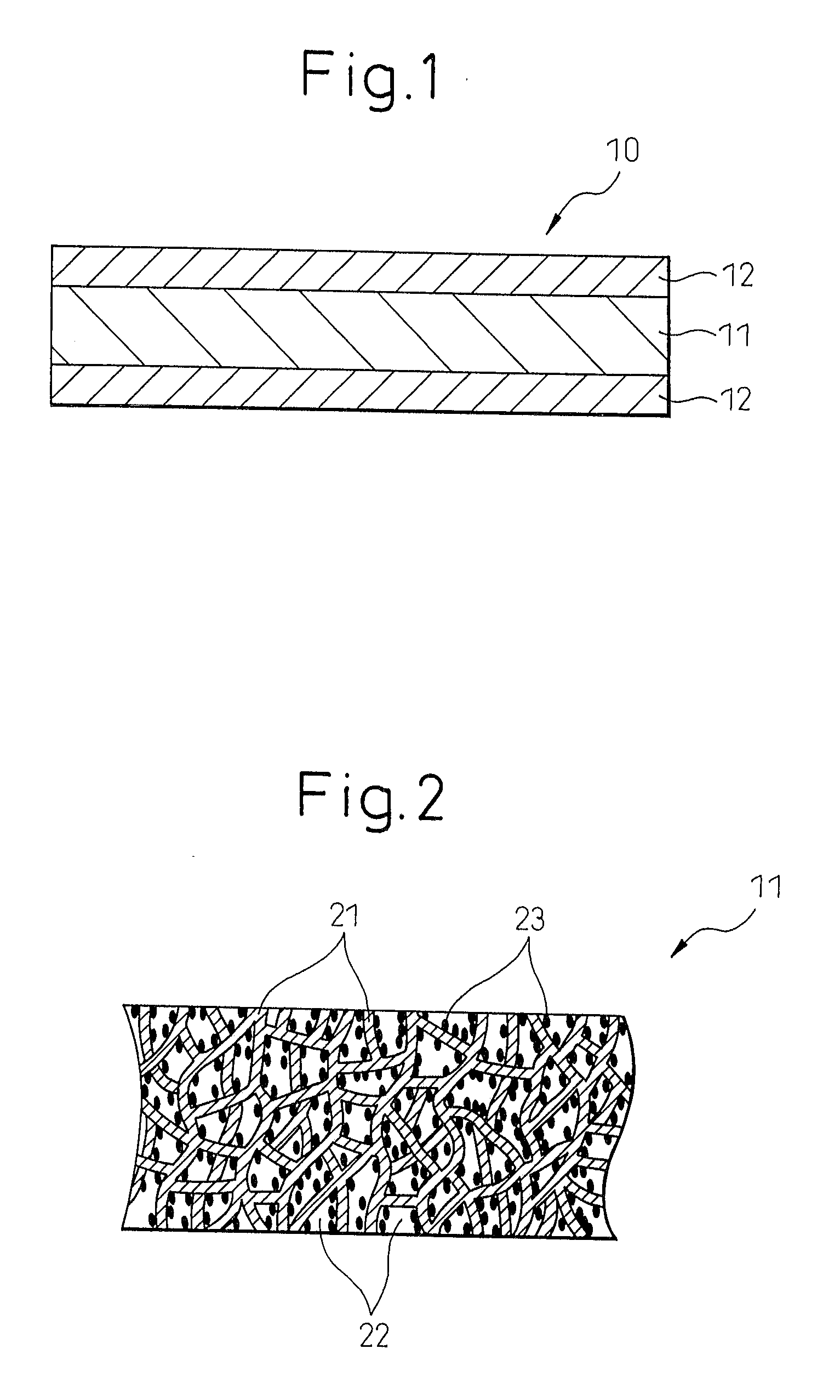

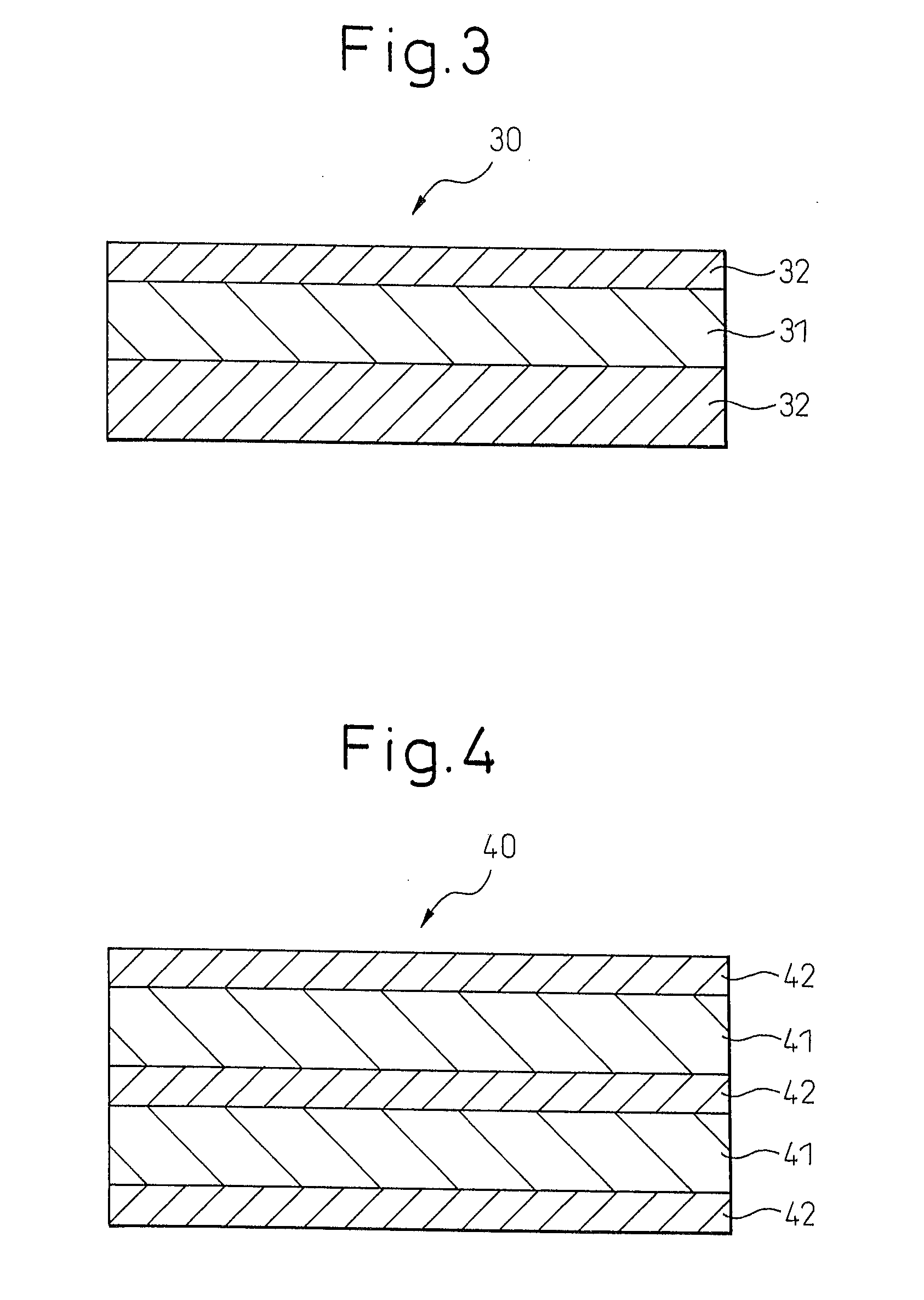

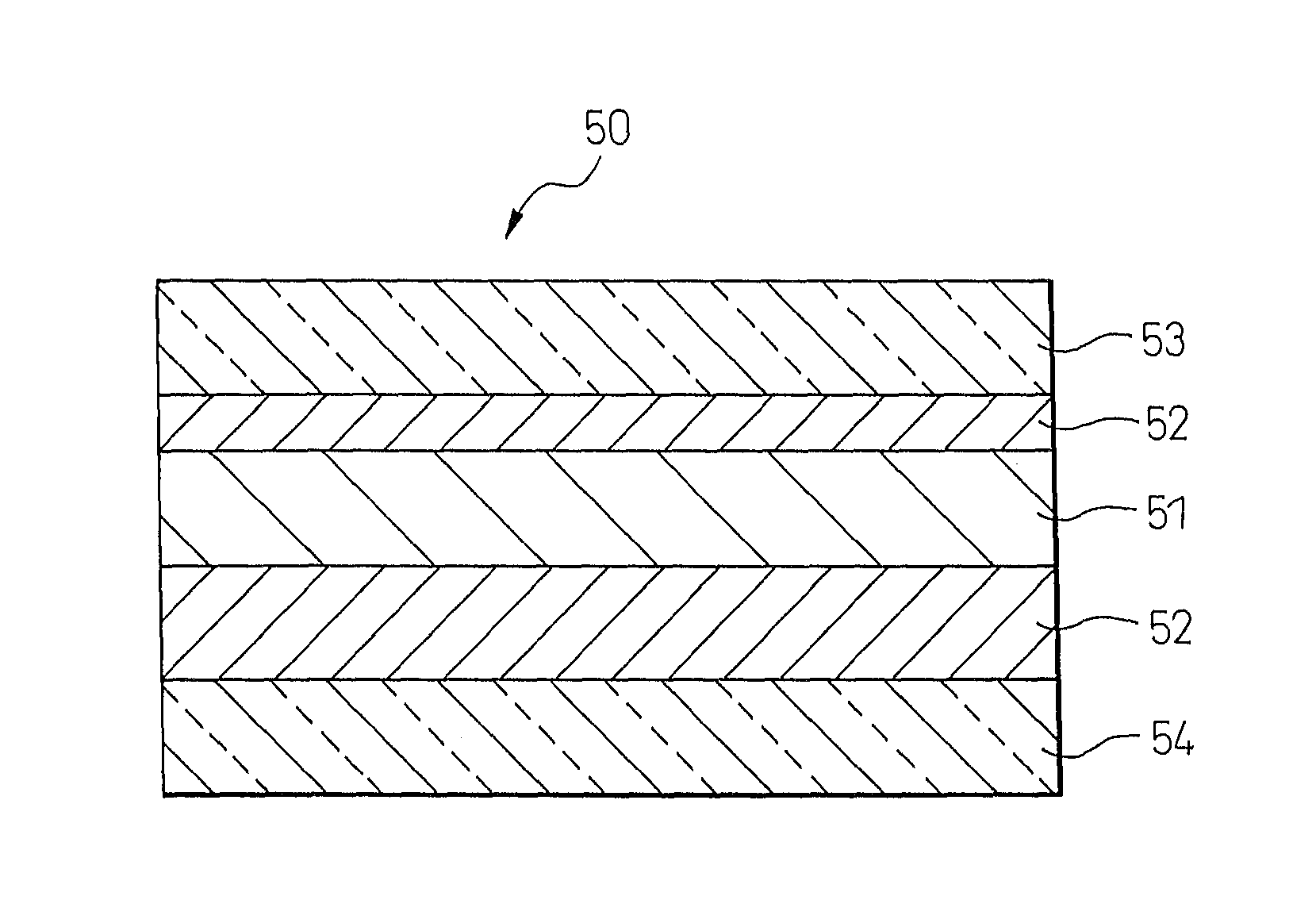

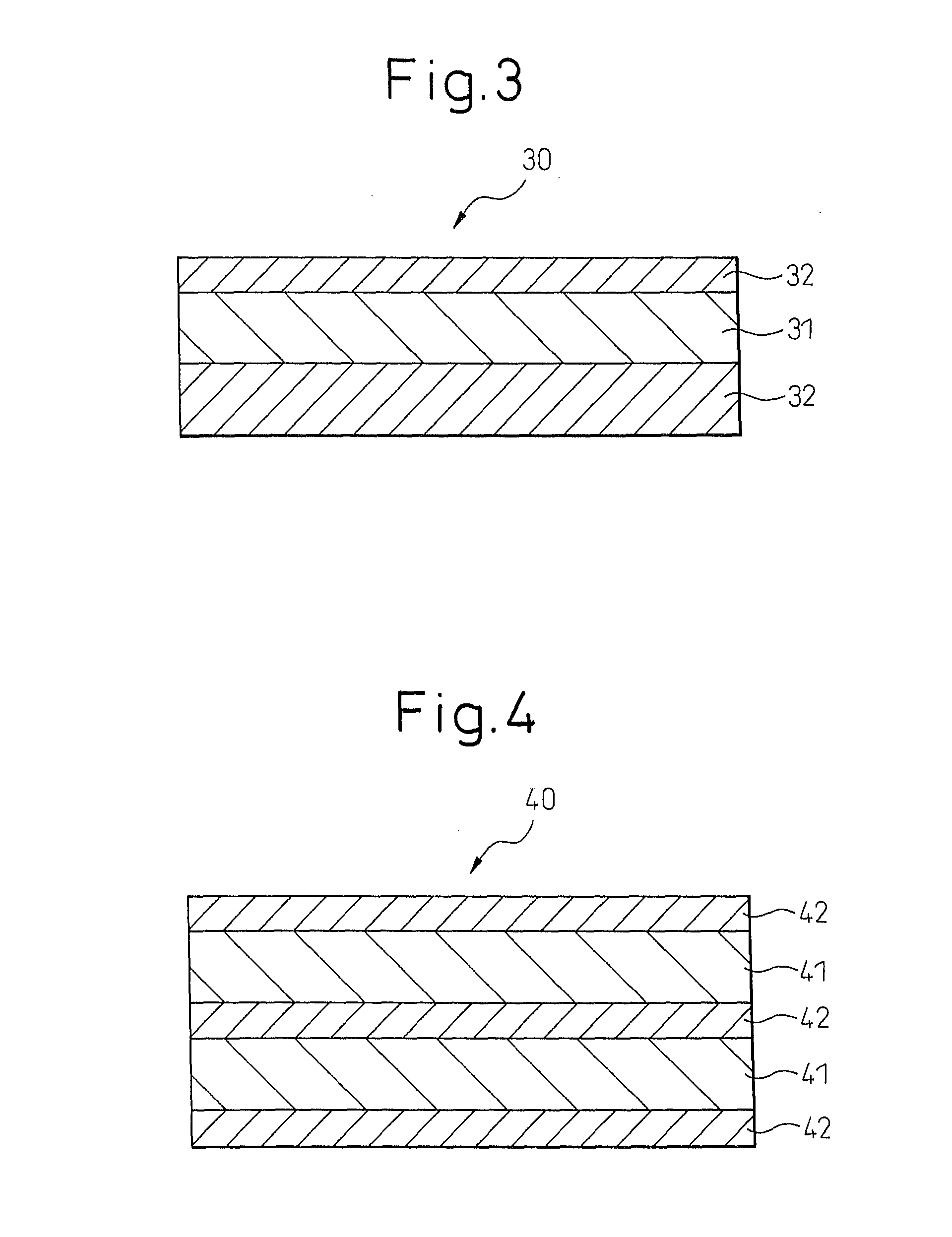

Reinforced Solid Polymer Electrolyte Composite Membrane, Membrane Eelctrode Assembly For Solid Polymer Fuel Cell, and Solid Polymer Fuel Cell

ActiveUS20110070521A1Easy to operateImprove mechanical durabilityElectrolyte holding meansElectrolytesPolymer electrolytesPolymer science

The invention provides a solid polymer fuel cell whose operational stability over time has been enhanced. A reinforced solid polymer electrolyte composite membrane for a solid polymer fuel cell according to the present invention comprises two or more polymer electrolyte membranes and one or more layers of a sheet-like porous reinforcing member, wherein the polymer electrolyte membranes provide both the upper and lower surfaces of the composite membrane, and pores in the sheet-like porous reinforcing member are substantially filled with the electrolyte from the polymer electrolyte membranes, and wherein the sheet-like porous reinforcing member contains a peroxide decomposition catalyst.

Owner:W L GORE & ASSOC GK

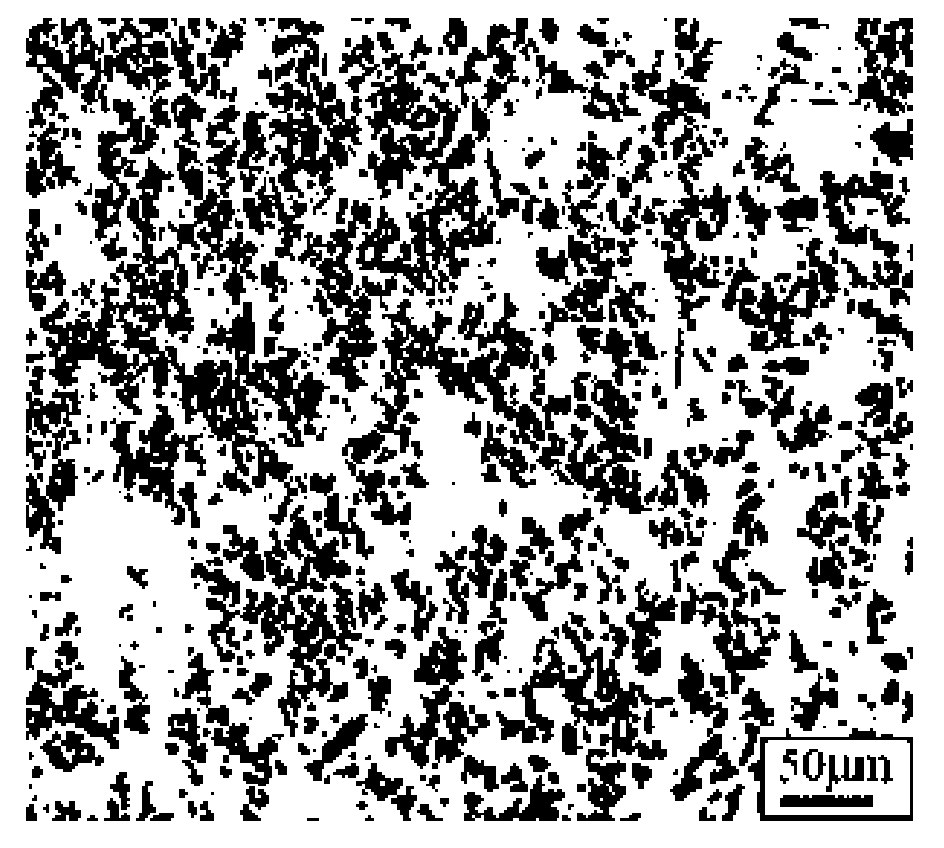

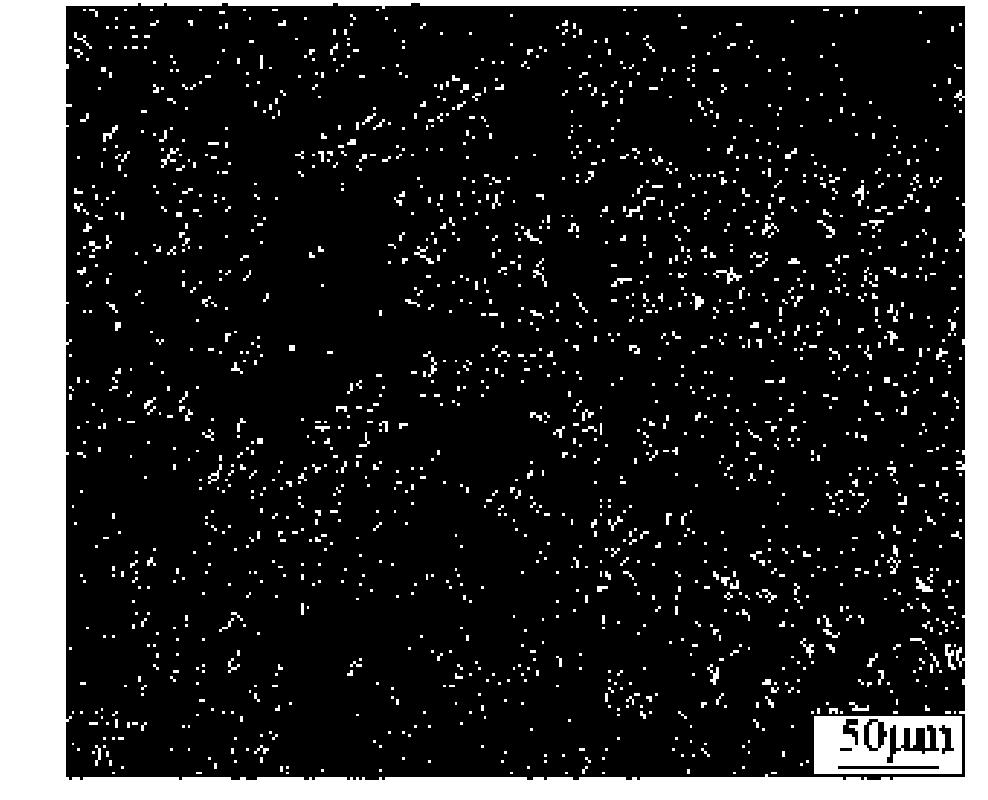

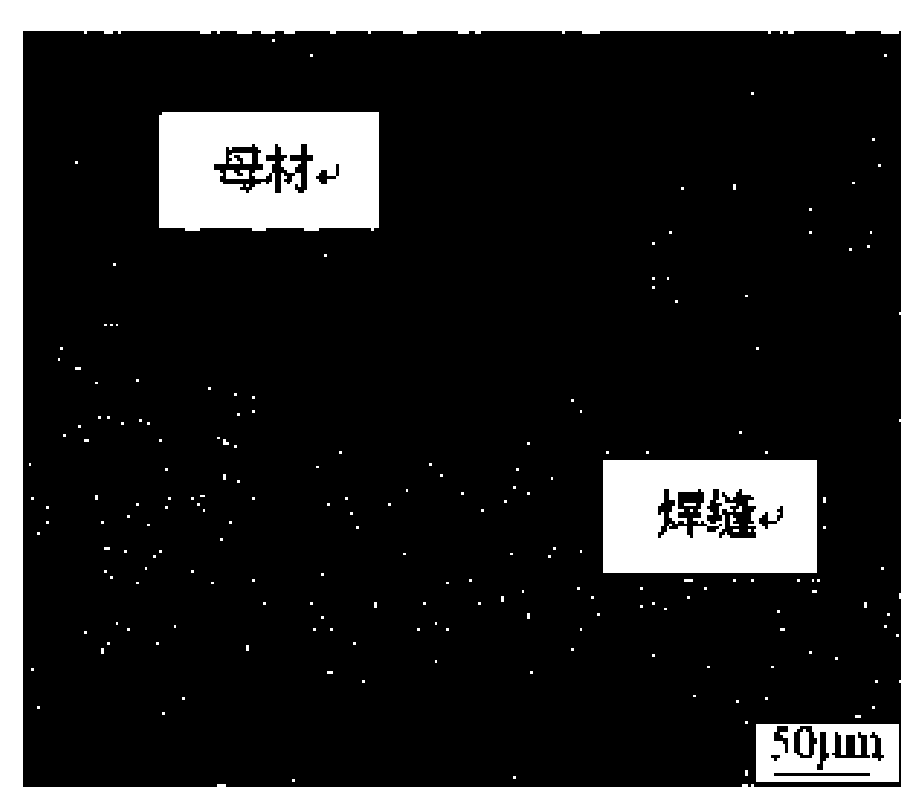

In-situ reinforced solid welding wire for welding a welding seam by melting SiC particle reinforced aluminum-based composite material

ActiveCN101628364AWell formed weldHigh tensile strengthWelding/cutting media/materialsSoldering mediaWeld seamMaterials science

The invention provides an in-situ reinforced solid welding wire for welding a welding seam by melting SiC particle reinforced aluminum-based composite material, which relates to a solid welding wire for welding by melting the SiC particle reinforced aluminum-based composite material. The invention solves the problem that the strength of the welding seam obtained by welding the particle reinforced aluminum-based composite material by using the prior welding wire only can reach about 40% of that of base material. The in-situ reinforced solid welding wire for welding the welding seam by melting the SiC particle reinforced aluminum-based composite material comprises the following components according to the mass percent: 4-8% of SiC, 5-10% of Si, 1.0-1.8% of Ti, 0.1-0.3% of Sc, 0.05-0.15% of Y, 0.1-0.3% of B, 0.3-0.8% of Mg and Al as the rest. The welding wire of the invention has the advantages of good formation of the appearance of the welding seam, increased tensile strength and wide application range. The welding wire can be used as the stuffing for TIG, MIG, plasma arc welding, electron beam welding and laser welding. The strength of the welding seam obtained by welding the particle reinforced aluminum-based composite material by using the welding wire of the invention can reach 70% of that of the base material.

Owner:HARBIN INST OF TECH

Surface reinforced solid wood profiles, flooring and manufacturing method

The present invention relates to the technical filed of wood processing, in particular to the method for strengthening the wood surface, the profiles and the solid wood flooring of the same. The density of the surface-strengthened solid wood profiles are 300˜580 Kg / m3, the reinforced surface is 1˜5 mm thick, the hardness of the paint film of the reinforced surface is 2H˜8H, the overall moisture content of the profiles are 6˜9%. The hardness of the paint film on the reinforced surface of the inventive solid wood profiles is higher, and the overall moisture content is stable, which is suitable for wider range of climate conditions.

Owner:ZHEJIANG SHIYOU TIMBER

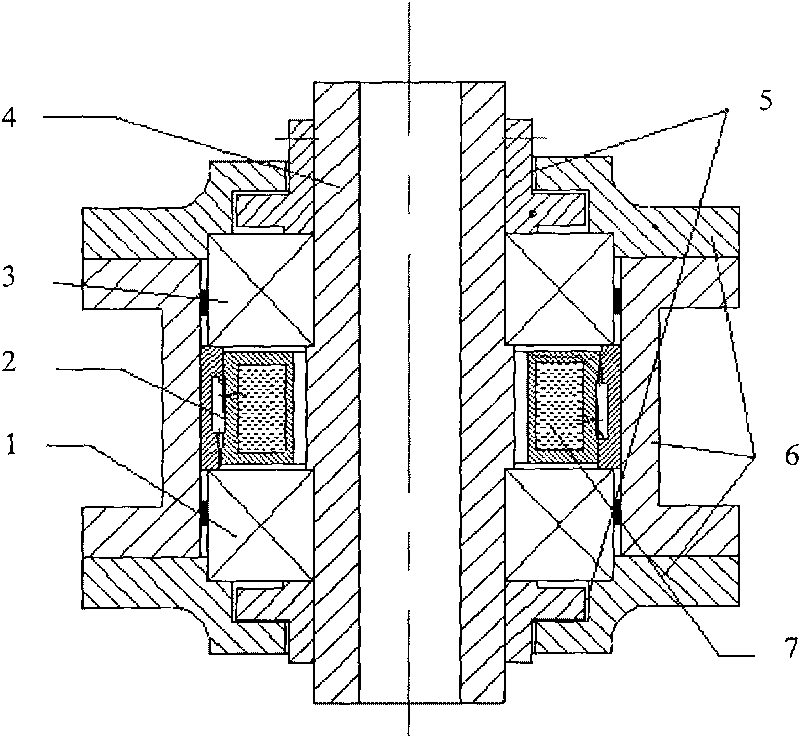

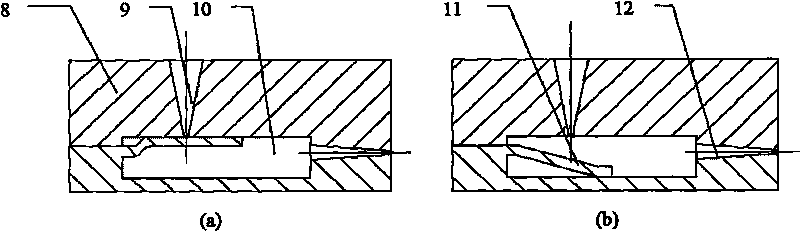

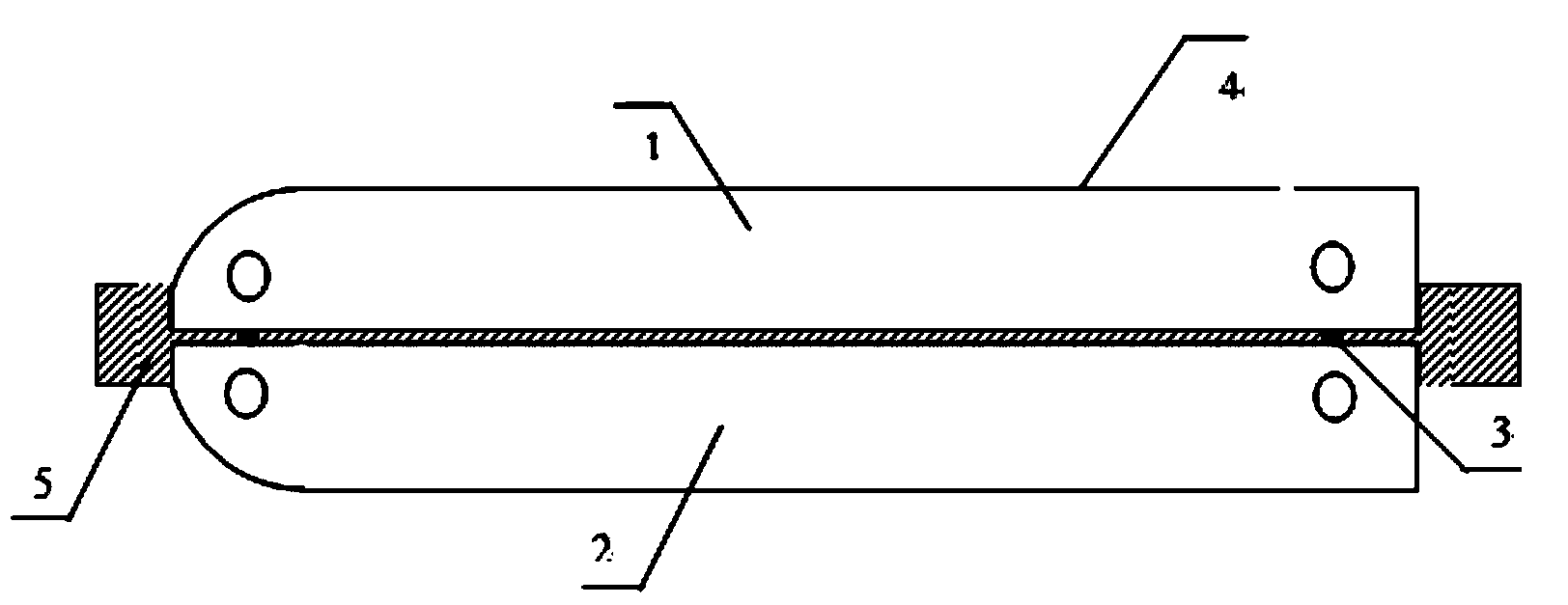

MEMS micropump-based solid-liquid composite lubricated shafting for flywheel

InactiveCN101699125AHigh control precisionImprove featuresSpacecraft guiding apparatusEngine lubricationLow speedEngineering

The invention belongs to the technical field of space tribology, and relates to an MEMS micropump-based solid-liquid composite lubricated shafting for a flywheel. The shafting comprises a first MEMS micropore reinforced solid film lubricated ceramic bearing, an MEMS micropump oil storage-oil supply system, a second micropore reinforced solid film lubricated ceramic bearing, a main shaft, an internal support sleeve, an external support sleeve and an oil reservoir. The shafting can provide effective support and lubrication for an internal rotor motor and an outer rotor motor, and utilizes a liquid composite lubrication mode that the MEMS micropore reinforced solid film lubricated ceramic bearings and an MEMS micropump supply oil accurately. A shafting lubricating system adopts an oil storage device, an oil supply device and a maintaining device which consist of a cavity oil reservoir, the MEMS micropump and a labyrinth seal to make the shafting have excellent lubrication properties and friction properties within the wide rotating speed range from static starting to high-speed operation, so that the initial running is improved effectively, the starting occlusion is prevented, and simultaneously, the control accuracy, service life and reliability of the shafting are improved at low speed.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

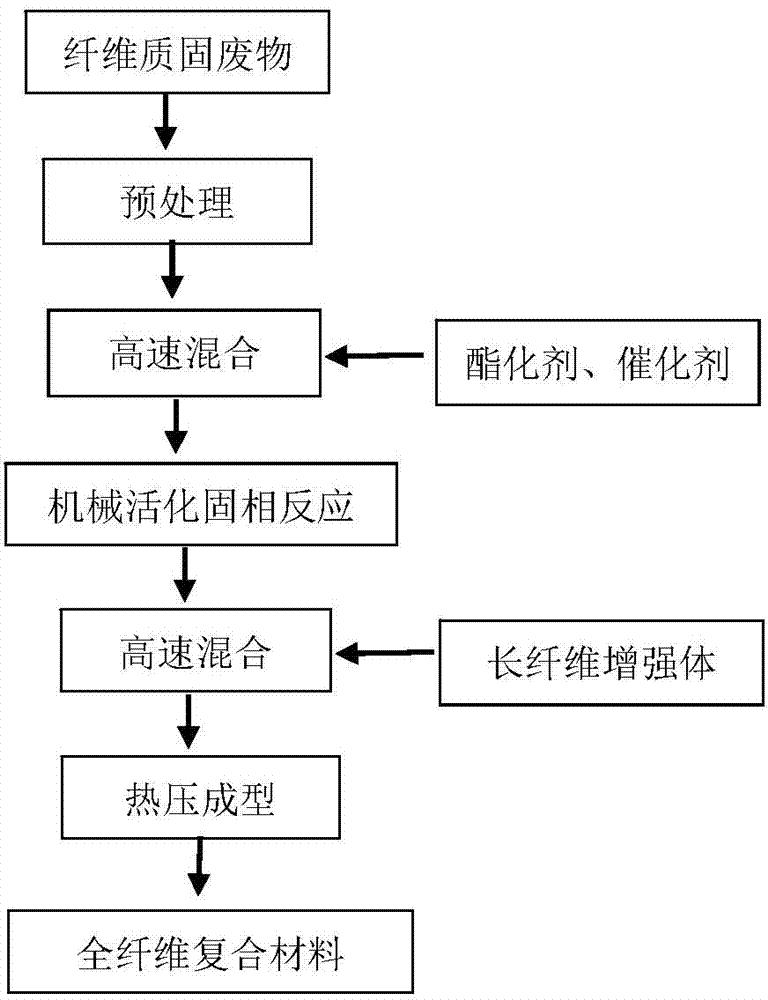

Preparation method of all-fiber degradable composite material

The invention discloses a preparation method of an all-fiber degradable composite material, which comprises the following steps: 1) raw material pretreatment: drying fiber solid waste, and pulverizing to obtain fiber solid waste powder; 2) high-speed mixing: uniformly mixing the fiber solid waste powder, an esterifying agent and a catalyst in a mixing machine to obtain a reactant mixture; 3) mechanical activation solid-phase reaction: adding the reactant mixture into a mechanical activation reactor to carry out solid-phase reaction, thereby obtaining an esterification modified fiber; 4) high-speed mixing: carrying out high-speed mixing on the esterification modified fiber and long fiber reinforcer to obtain a mixture; and 5) putting the mixture into a mold, and carrying out hot pressing on a flat vulcanizing machine under the conditions of certain temperature and pressure to prepare the all-fiber composite material. The solid-phase reaction is adopted to overcome the defect in the solvent process, and the mechanical activation reinforced solid-phase esterification is adopted to prepare the thermoplastic plant fiber, so that the method has the advantages of simple technique, no pollution, low cost and the like and is simple to operate.

Owner:GUANGXI UNIV +1

Surface reinforced solid wood profiles, flooring and manufacturing method

The present invention relates to the technical filed of wood processing, in particular to the method for strengthening the wood surface, the profiles and the solid wood flooring of the same. The density of the surface-strengthened solid wood profiles are 300˜580 Kg / m3, the reinforced surface is 1˜5 mm thick, the hardness of the paint film of the reinforced surface is 2H˜8H, the overall moisture content of the profiles are 6˜9%. The hardness of the paint film on the reinforced surface of the inventive solid wood profiles is higher, and the overall moisture content is stable, which is suitable for wider range of climate conditions.

Owner:ZHEJIANG SHIYOU TIMBER

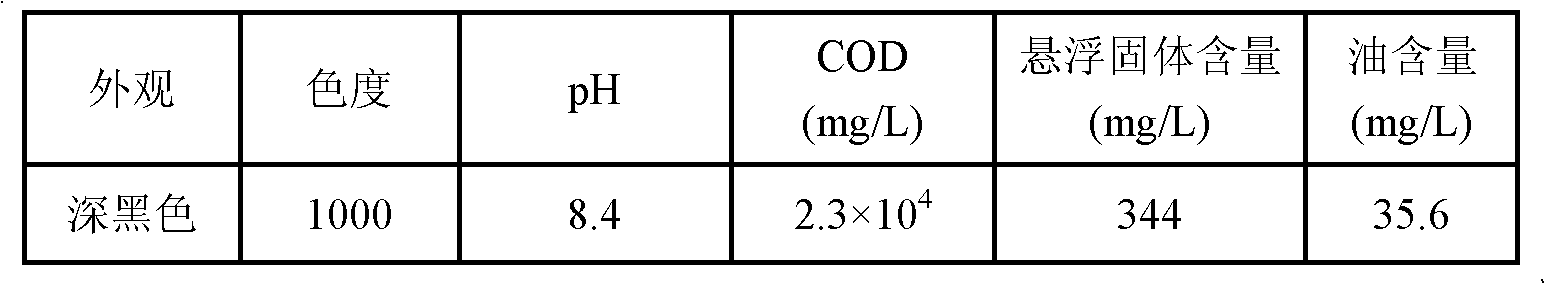

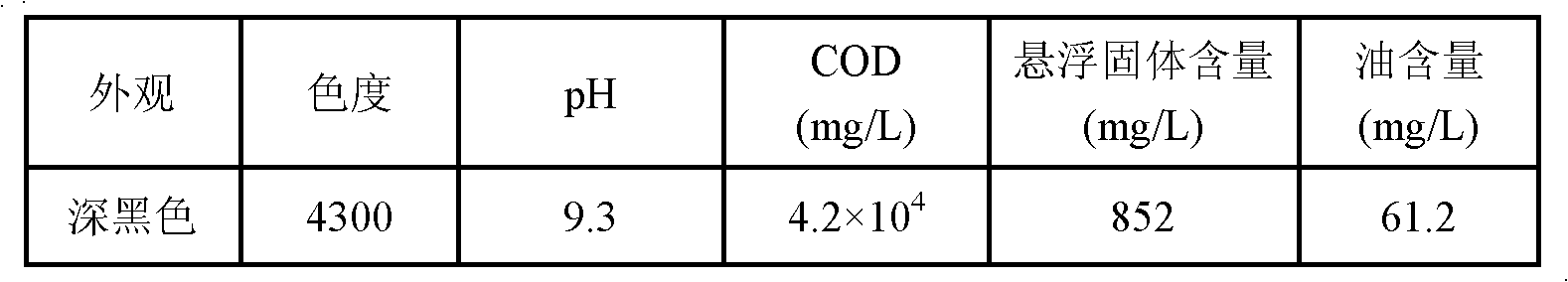

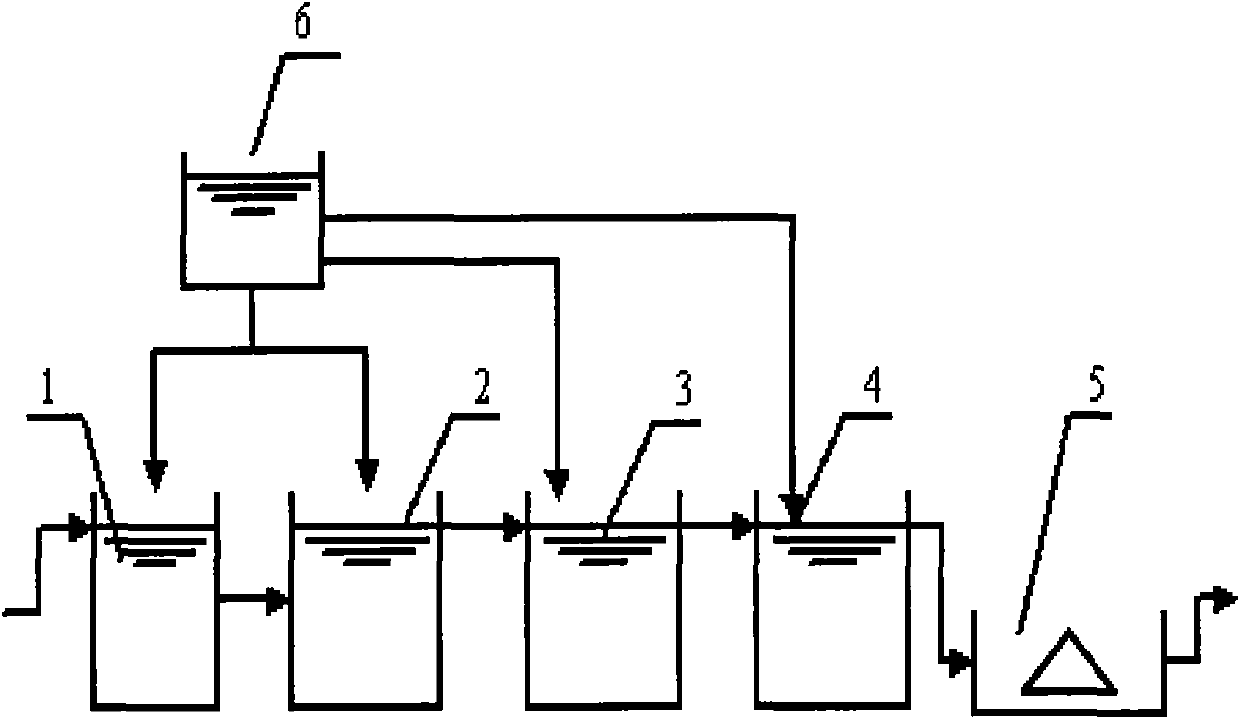

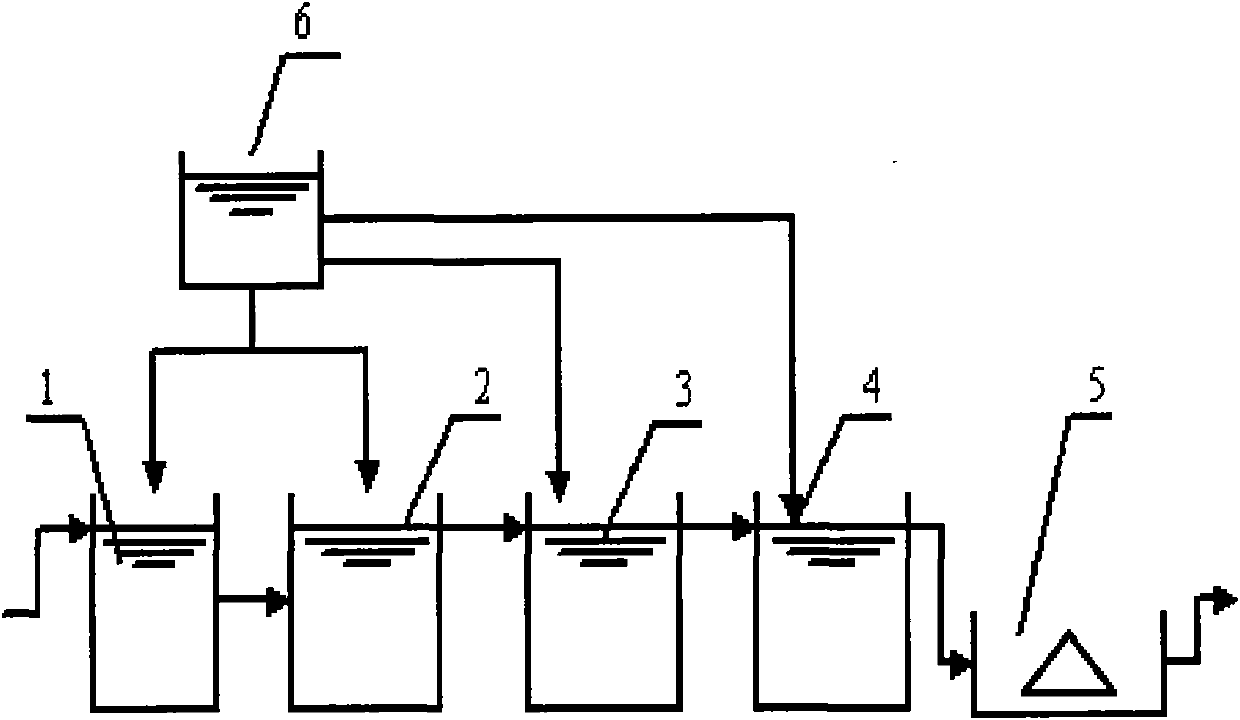

New reinjection treatment method of polysulfonate drilling wastewater

InactiveCN102086071AReduce pollutionAlleviate water scarcityMultistage water/sewage treatmentFiltrationWater quality

The invention provides a reinjection treatment method of polysulfonate drilling wastewater. The method comprises the following steps: adding inorganic acid in the drilling wastewater to adjust the pH value to 1-2, reacting for 20-30min to ensure that the suspended matter in water is destabilized and precipitated; then centrifuging to remove the precipitated suspended matter, adjusting the pH value again to 7-8, adding coagulant and coagulant aid to ensure that the coagulant and the suspended matter in water are coagulated to form flocs, removing the flocs, adding oxidant to perform oxidation treatment, and filtering to further remove the suspended matter in water and reduce the medium value of particle size. The invention adopts the treatment technology mainly containing acidification, coagulating sedimentation and secondary filtration and combines the reinforced solid-liquid separation measures such as acid-base regulation and centrifugal separation; and the effluent can meet the C1 grade injected water quality standards of the recommendation quota for injection water quality of fragmental rock fragmental rock oil field (SY / T 5329-94). By adopting the reinjection treatment method of the invention, the environmental pollutions caused by drilling wastewater can be greatly reduced and the situation that the oil field is lack of water resources can be alleviated.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

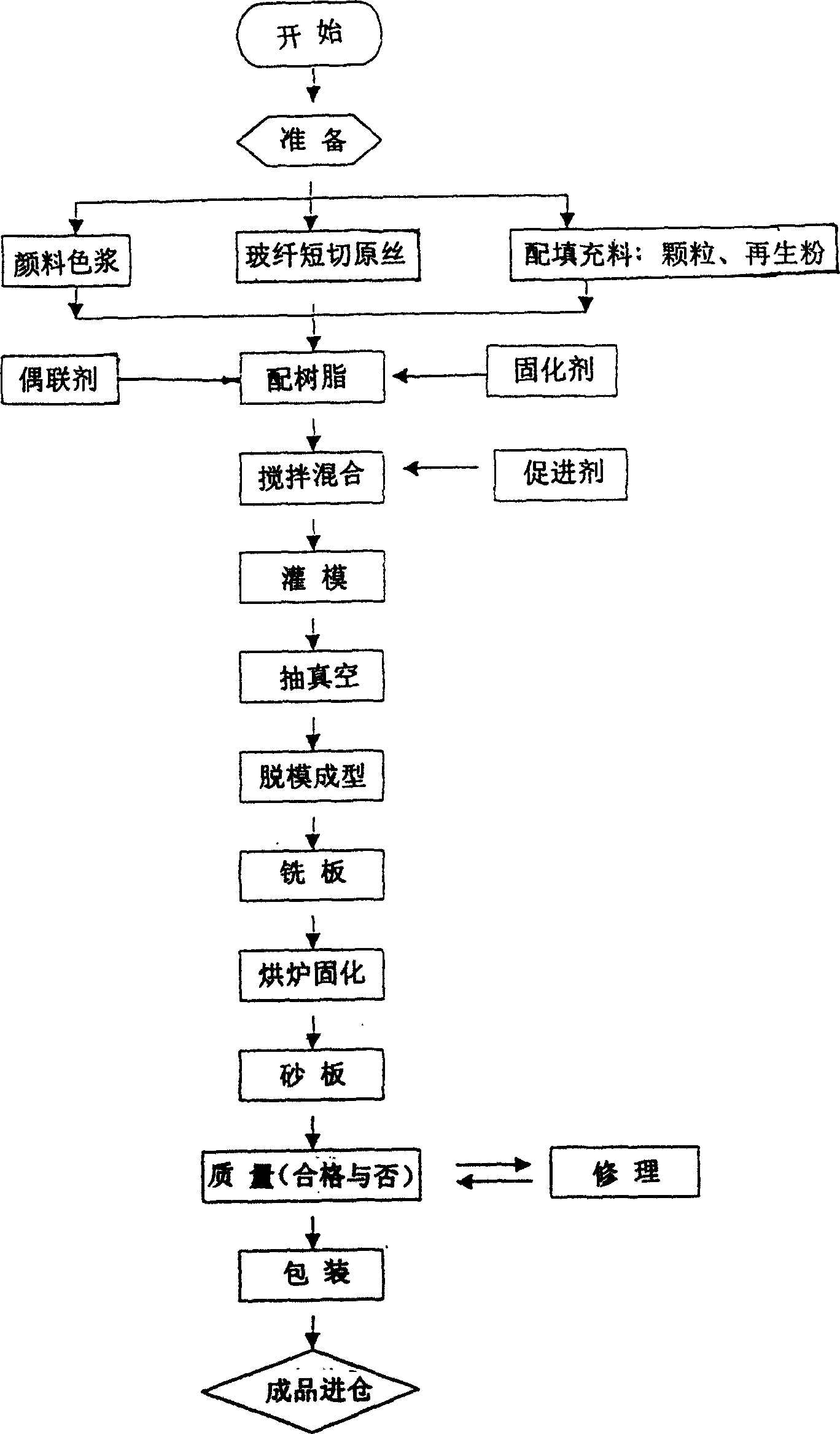

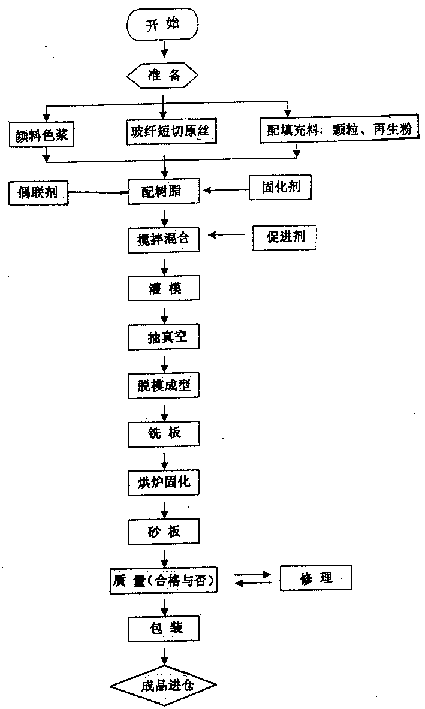

Reinforced solid surface materials

The invention discloses a reinforced solid surface material which comprises the components of, A. one or mixture of two selected from unsaturated polyester resin or modified unsaturated polyester resin, or base material of acrylic resin, B. any one or mixture of several filling materials selected from aluminium hydroxide powder, calcium carbonate powder, natural stone powder, and magnesium hydroxide powder, C. auxiliary agent including methyl-ethyl ketone curing agent, colorless cobalt promoter, or oxidation dibenzoyl initiating agent, silicane coupling agent, pigment, D. fiber glass raw filament.

Owner:冯伟康

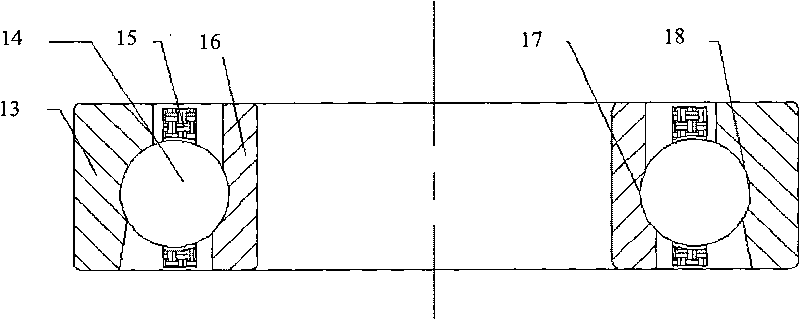

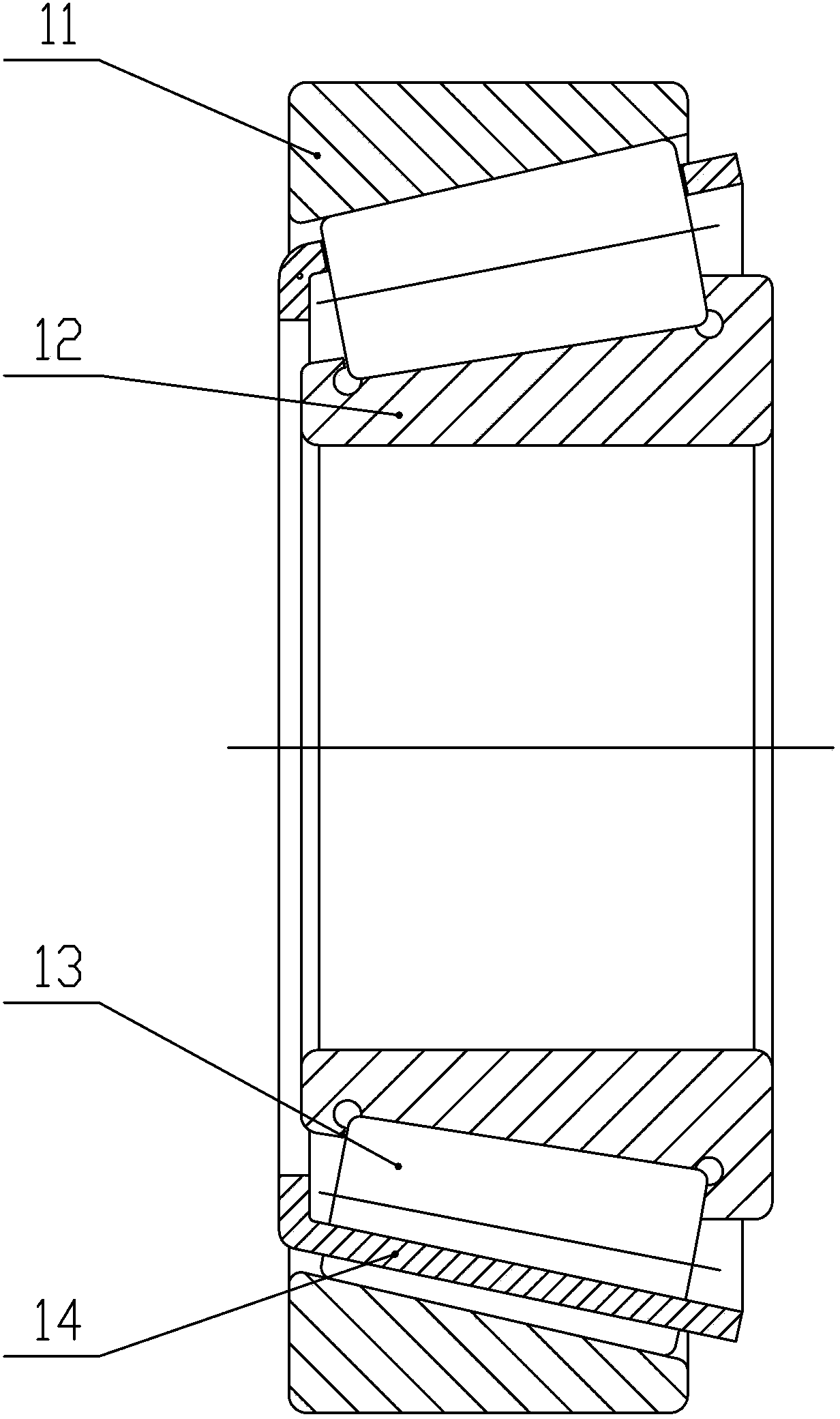

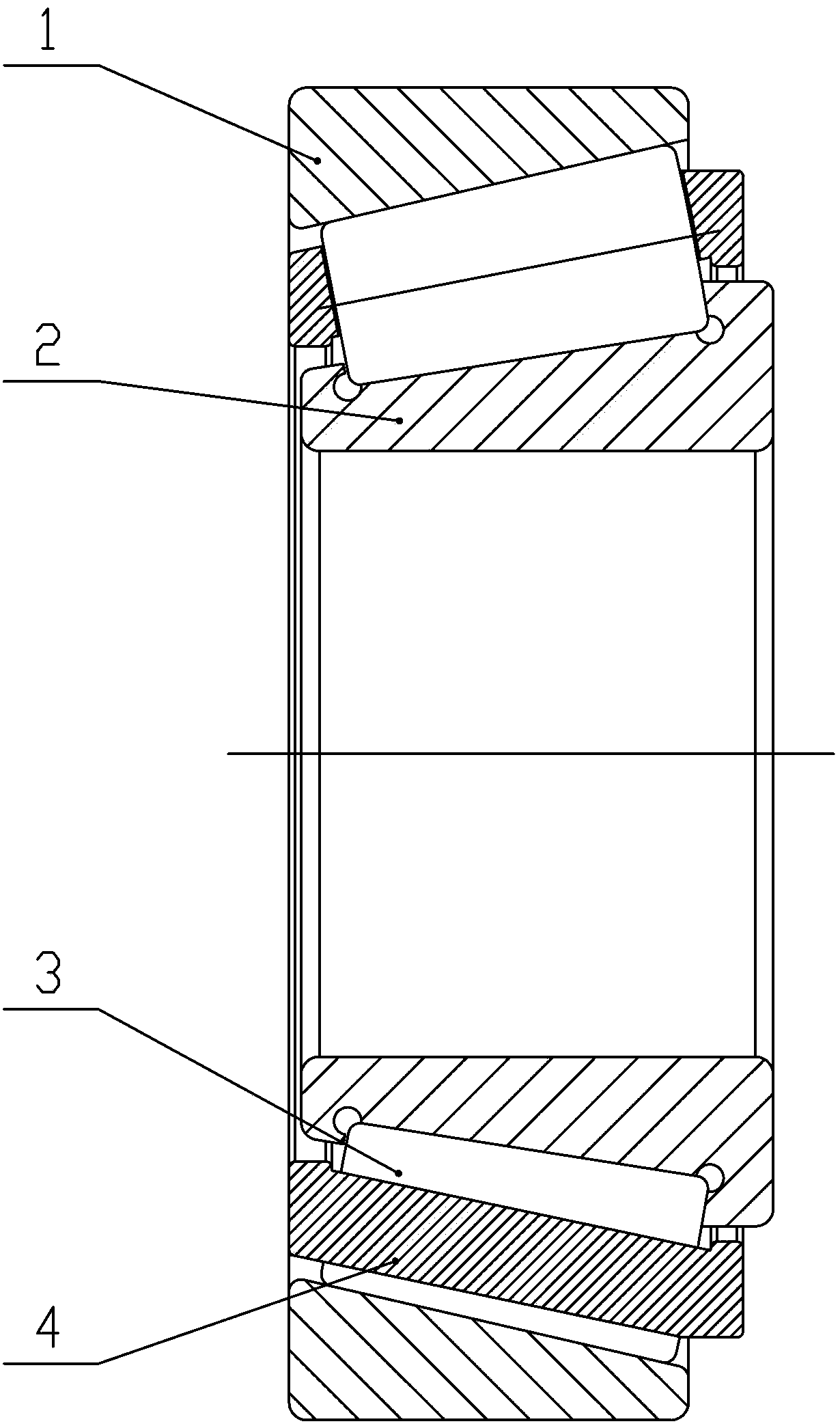

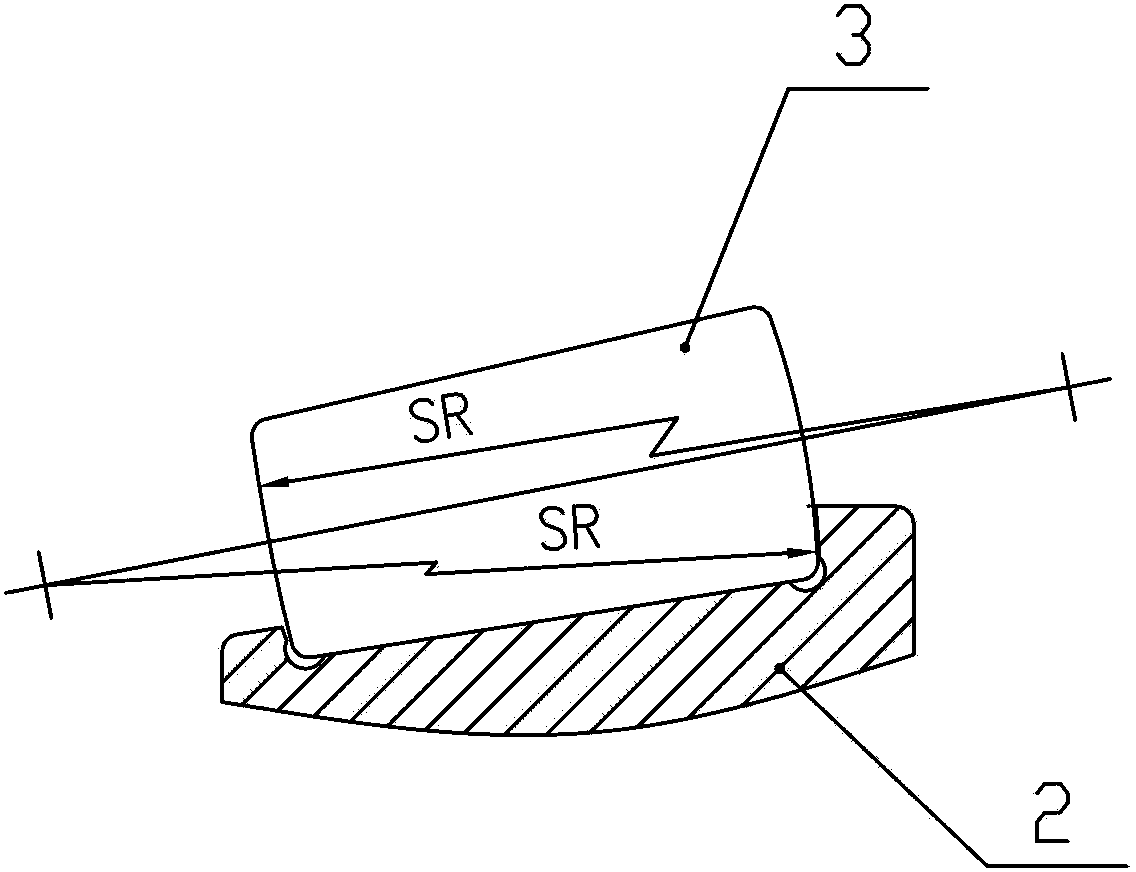

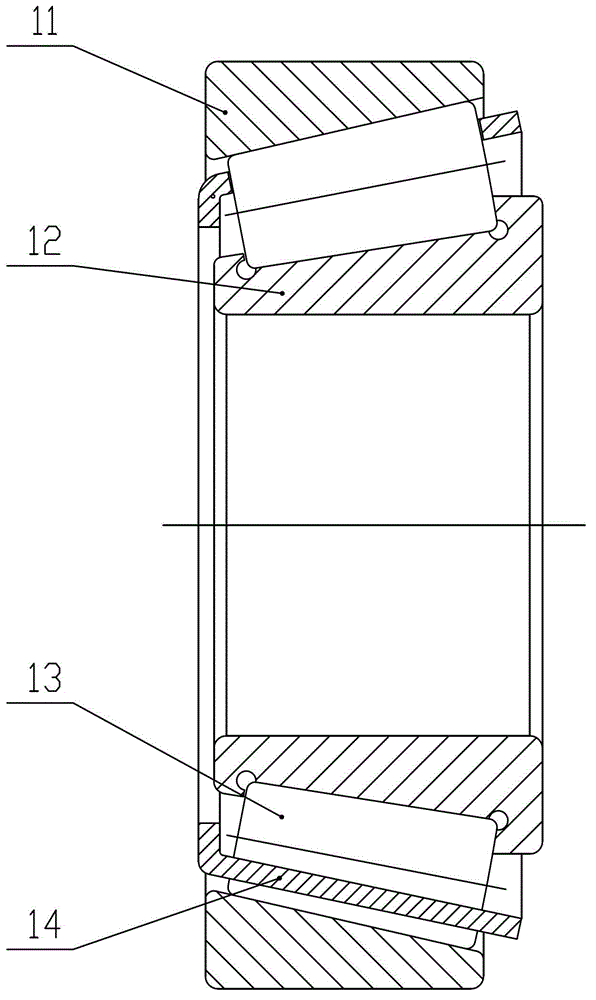

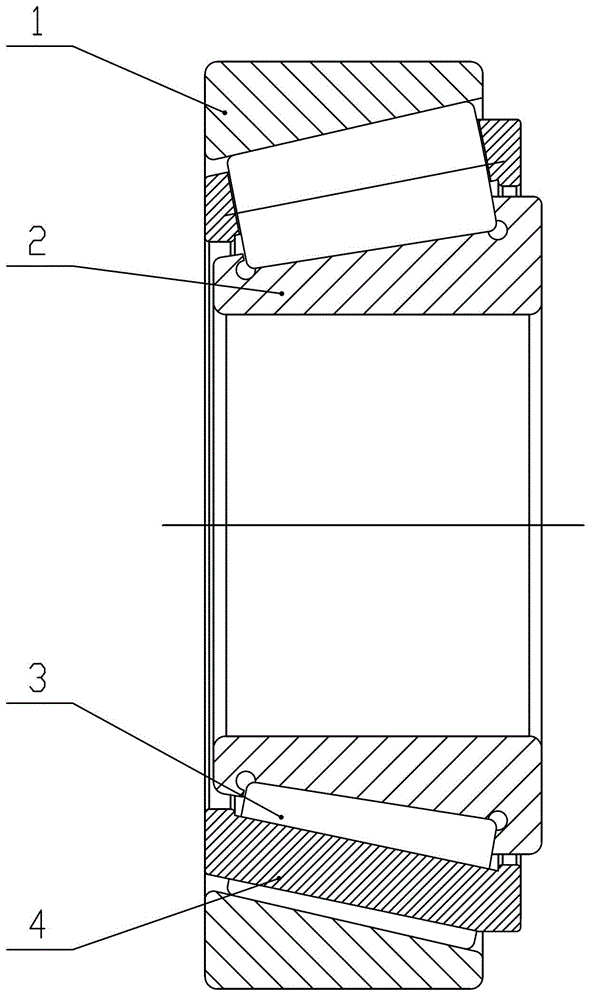

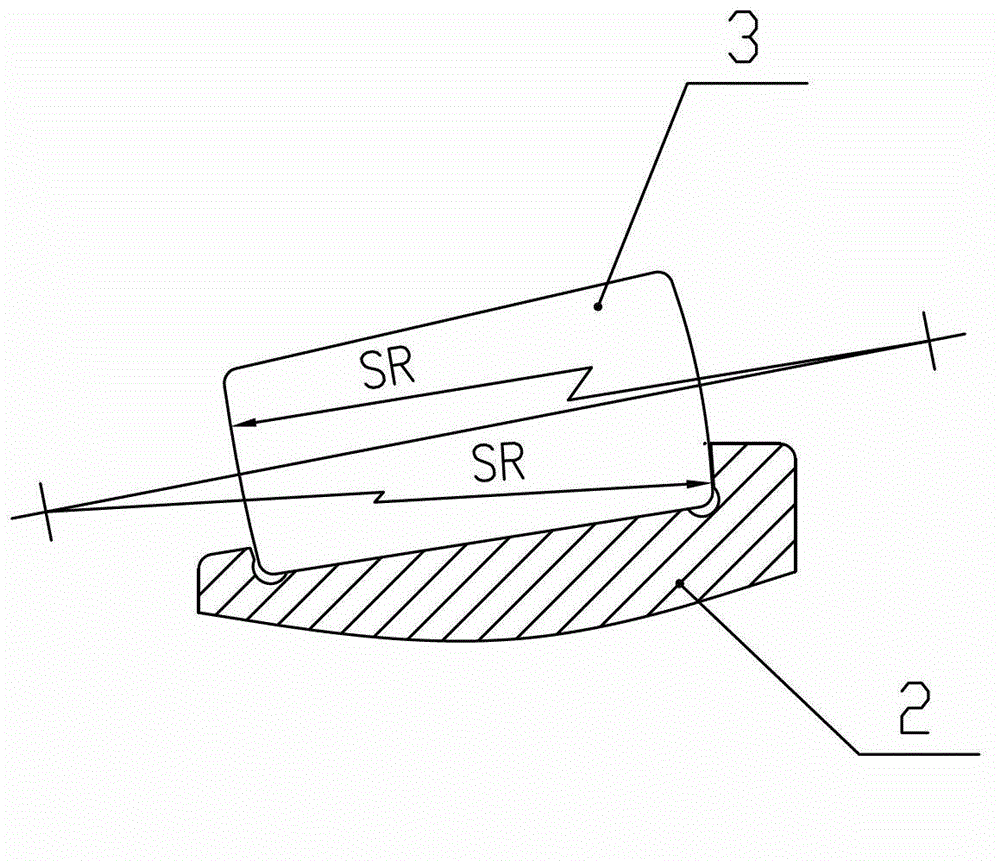

Solid cage and reinforced solid tapered roller bearing

ActiveCN103352919AHigh strengthIncrease loading capacityRoller bearingsBearing componentsNumerical controlEngineering

The invention provides a solid cage and a reinforced solid tapered roller bearing. The bearing comprises an inner ring, an outer ring, a tapered roller and a solid cage, wherein a plurality of roller mounting holes are milled by a numerical control milling machine along the circumference of the solid cage, the mounting holes are in the shape of a radial straight hole having an angle same as a contact angle of the roller, solid parts of the solid cage comprises two side rings and a plurality of lintels between the rings, the side surface of each lintel is respectively provided with two symmetrical lock points, each lock point is a square neck formed by two square bumps, an arc surface cooperating with the roller is milled inwardly in the square neck, the tapered roller guides rotation of the solid cage in virtue of the lock points on the solid cage, the external surface of the inner ring is provided with a U-shaped neck cooperating with the tapered roller, and the tapered roller is mounted through an outer mounting hole in the solid cage and is assembled with the inner ring to form an inner ring assembly. The bearing provided by the invention has the advantages great bearing capability, a long service life, smooth operation, low friction, good lubrication performance, good vibration resistance, etc.

Owner:SHANDONG KAIMEIRUI BEARING TECH CO LTD

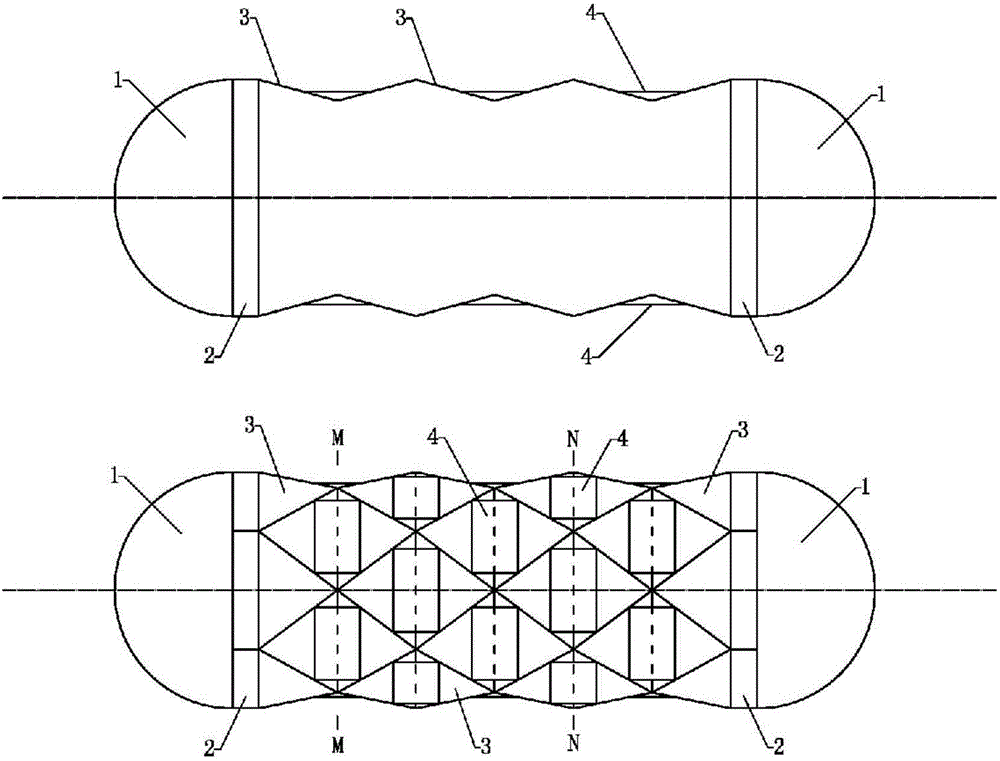

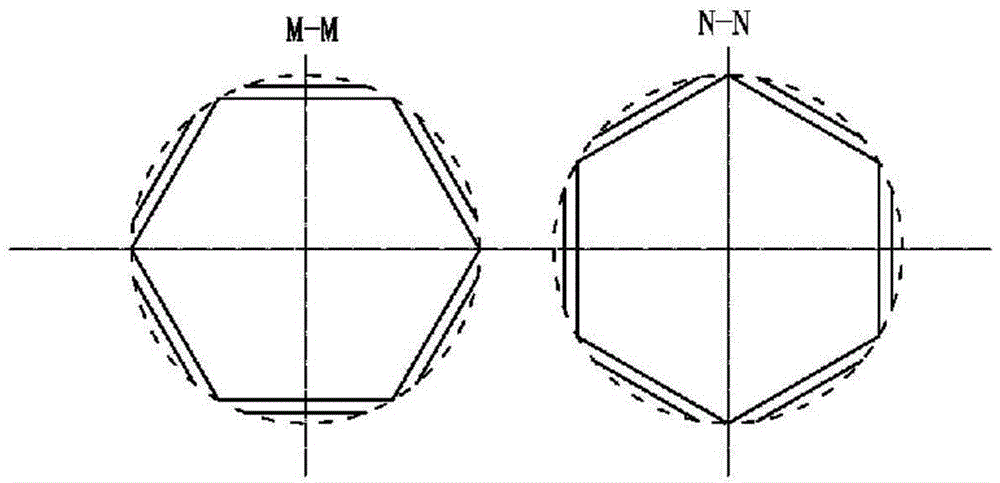

Multi-plane cylindrical shell structure with reinforced folded corners

ActiveCN103603372AImprove axial stiffnessImprove pressure resistanceArtificial islandsUnderwater structuresStructural engineeringReinforced solid

The invention discloses a multi-plane cylindrical shell structure with reinforced folded corners. The multi-plane cylindrical shell structure comprises spherical seal heads, transition sections, polygonal spatial plates and reinforcing plates or reinforcing rods or reinforcing solid structures. The reinforcing plates or the reinforcing rods or the other reinforcing solid structures are arranged on folded corner sunken portions on a cylindrical shell structure, and the folded corner sunken portions are formed by the polygonal spatial plates. Compared with a multi-plane cylindrical shell structure in the prior art, the multi-plane cylindrical shell structure with the reinforced folded corners has the advantages that the multi-plane cylindrical shell structure is good in pressure-resistant property, can bear high ultimate pressure as compared with the multi-plane cylindrical shell structure in the prior art under the condition of identical geometry and material parameters, and is applicable to manufacturing pressure-resistant structures in underwater or underground systems.

Owner:HUAZHONG UNIV OF SCI & TECH

Reinforced solid polymer electrolyte composite membrane, membrane electrode assembly for solid polymer fuel cell, and solid polymer fuel cell

ActiveUS8906573B2Easy to operateImprove mechanical durabilityElectrolyte holding meansElectrolytesPolymer electrolytesPolymer science

The invention provides a solid polymer fuel cell whose operational stability over time has been enhanced. A reinforced solid polymer electrolyte composite membrane for a solid polymer fuel cell according to the present invention comprises two or more polymer electrolyte membranes and one or more layers of a sheet-like porous reinforcing member, wherein the polymer electrolyte membranes provide both the upper and lower surfaces of the composite membrane, and pores in the sheet-like porous reinforcing member are substantially filled with the electrolyte from the polymer electrolyte membranes, and wherein the sheet-like porous reinforcing member contains a peroxide decomposition catalyst.

Owner:W L GORE & ASSOC GK

Chemically reinforced solid-liquid separation method for well drilling waste liquid

The invention relates to a chemically reinforced solid-liquid separation method for a well drilling waste liquid, comprising the following steps of: mixing the well drilling waste liquid with clear water, regulating the solid content of the well drilling waste liquid to 5%-10%, and then carrying out capillary pumping for not more than 2500s; adding a destabilizing agent comprising 0.3%-0.5% of sulfuric acid or nitric acid, 0.4%-1.0% of polyaluminium silicate chloride and 0.2%-0.3% of polyferric sulfate; adding adsorbents comprising 1%-1.5% of quick lime and 0.5%-1% of calcium chloride; adding a flocculating agent comprising 0.005%-0.015% of cationic polyacrylamide, anionic polyacrylamide or amphoteric polyacrylamide; accomplishing solid-liquid separation by using a centrifugal machine and then respectively discharging separated solid phase and liquid phase, wherein the centrifugal factor of the centrifugal machine is 2000-2200g, the water content of discharged mud is not greater than 70%, the solid content of the discharged water is not greater than 0.5%, and the recovery rate of the solid phase is not less than 90%. The chemically reinforced solid-liquid separation method reduces the difficulty in subsequent advanced treatment on the well drilling waste liquid, thereby creating the favorable conditions for resource recycling of the liquid phase.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

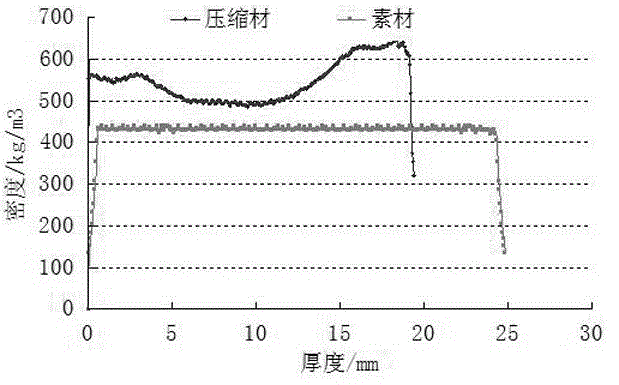

Integral reinforced solid wood section bar and manufacturing method thereof

ActiveCN103481348BSmall volume lossHigh strengthWood working apparatusFlat articlesSolid woodProcess engineering

The invention belongs to the technical field of wood function improvement and wood processing, and specifically discloses an integral reinforced solid wood profile and a manufacturing method thereof. The method comprises the following steps: under the condition of low moisture content (1-3%), the wood is subjected to integral compression treatment with low compression rate by adopting a heating and softening forming technology, so as to obtain an integral compressed material with uniform cross-sectional density. The method can effectively reduce the phenomenon of blasting and bubbling caused by excessive steam pressure inside the wood, greatly shorten the heat preservation time, and improve work efficiency. The overall compressed timber profile obtained by the method of the invention has good dimensional stability, is environmentally friendly and healthy, and can be used for manufacturing solid wood floors, solid wood furniture and as interior decoration materials.

Owner:江门健威家具装饰有限公司

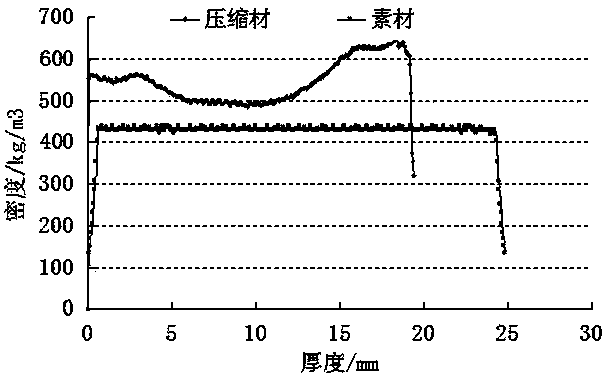

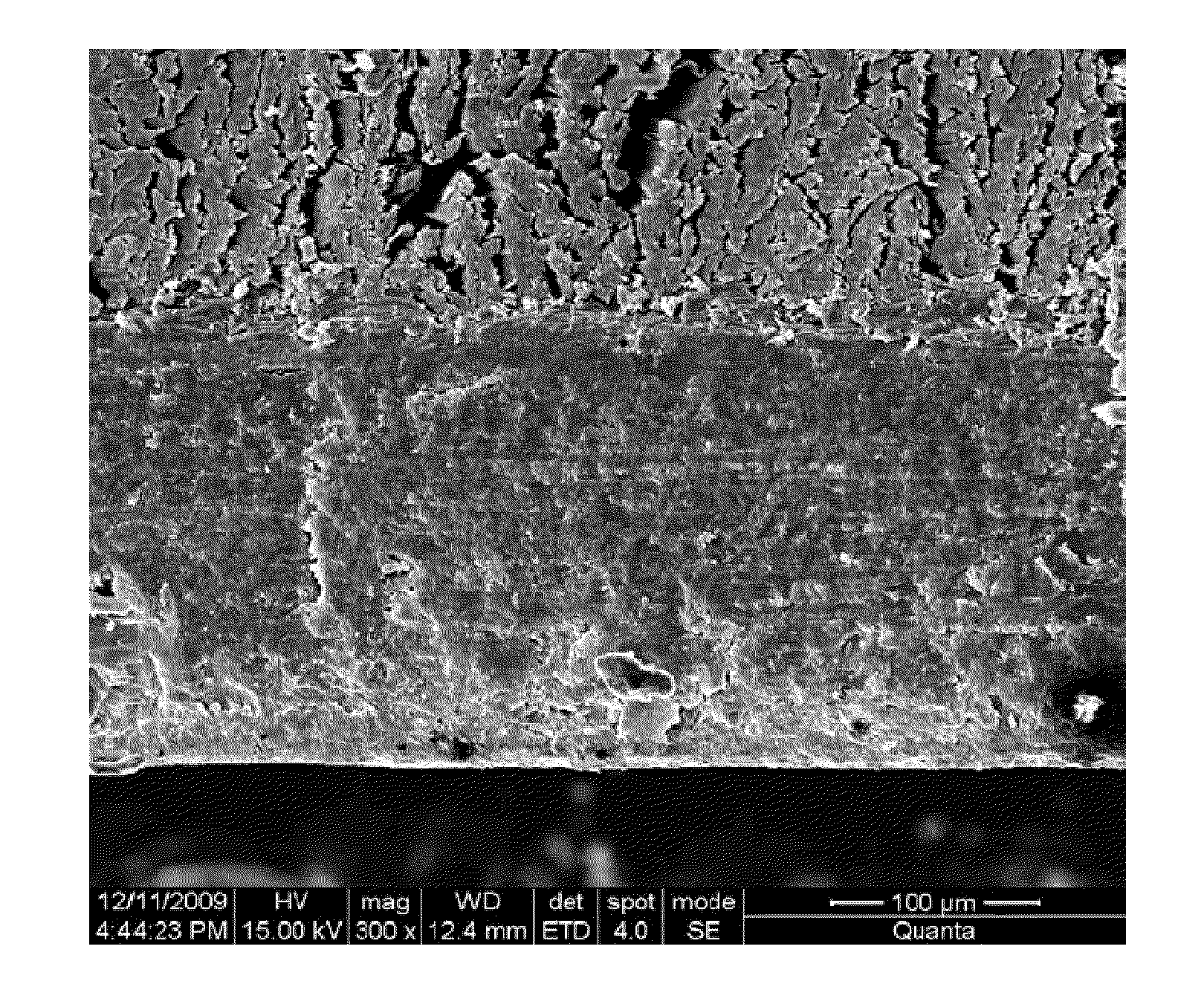

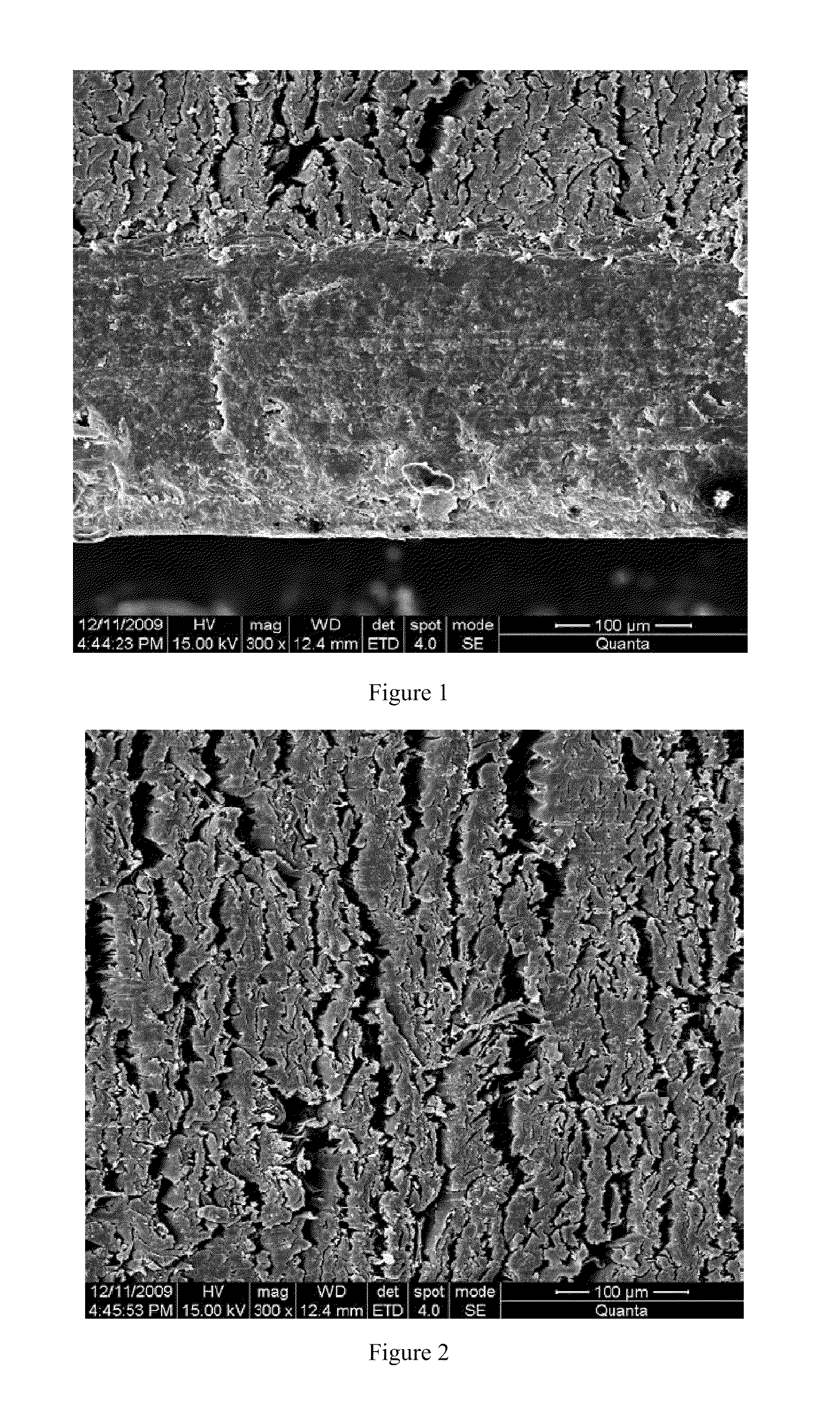

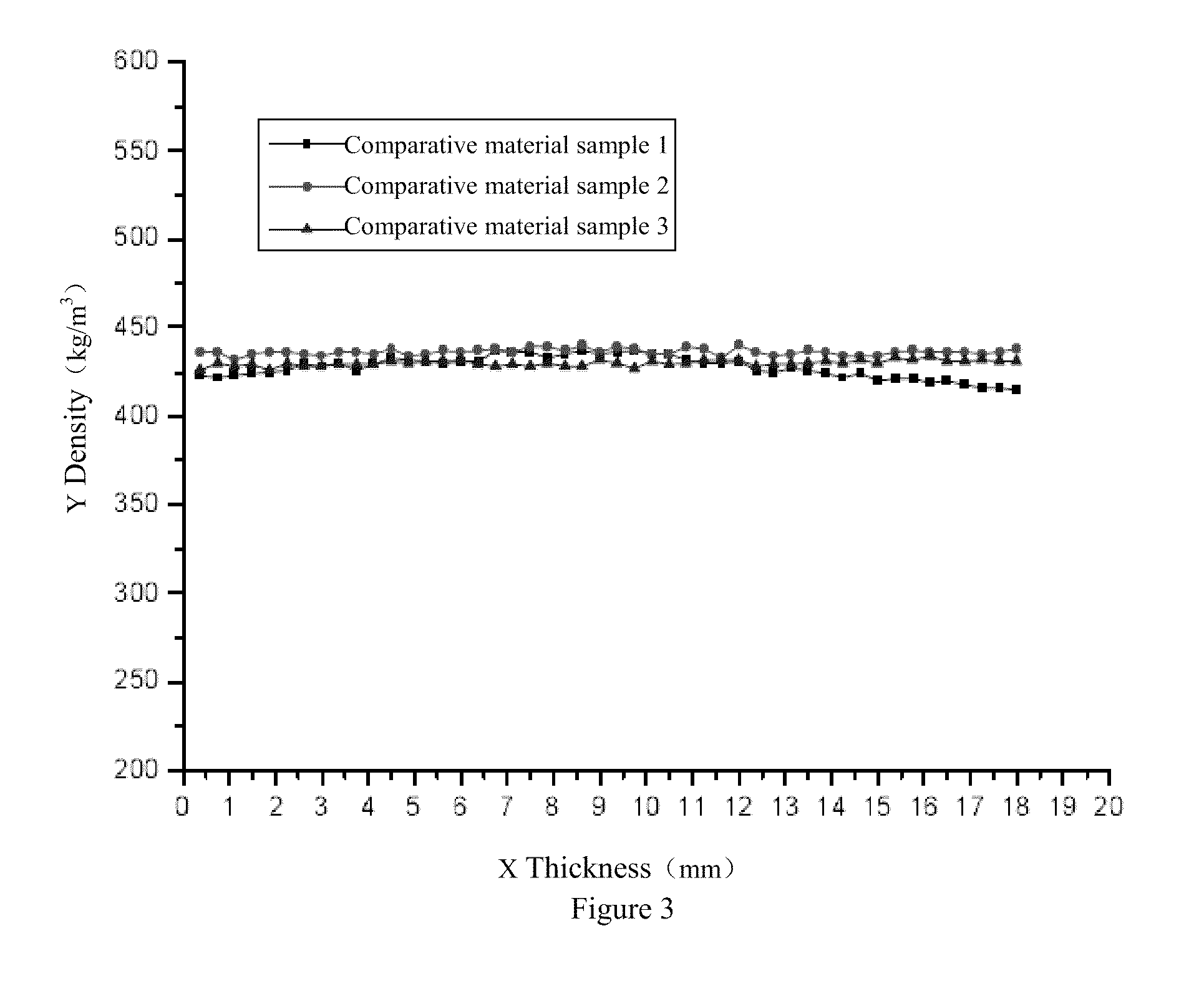

Type of surface-reinforced solid wood section material and its manufacturing method

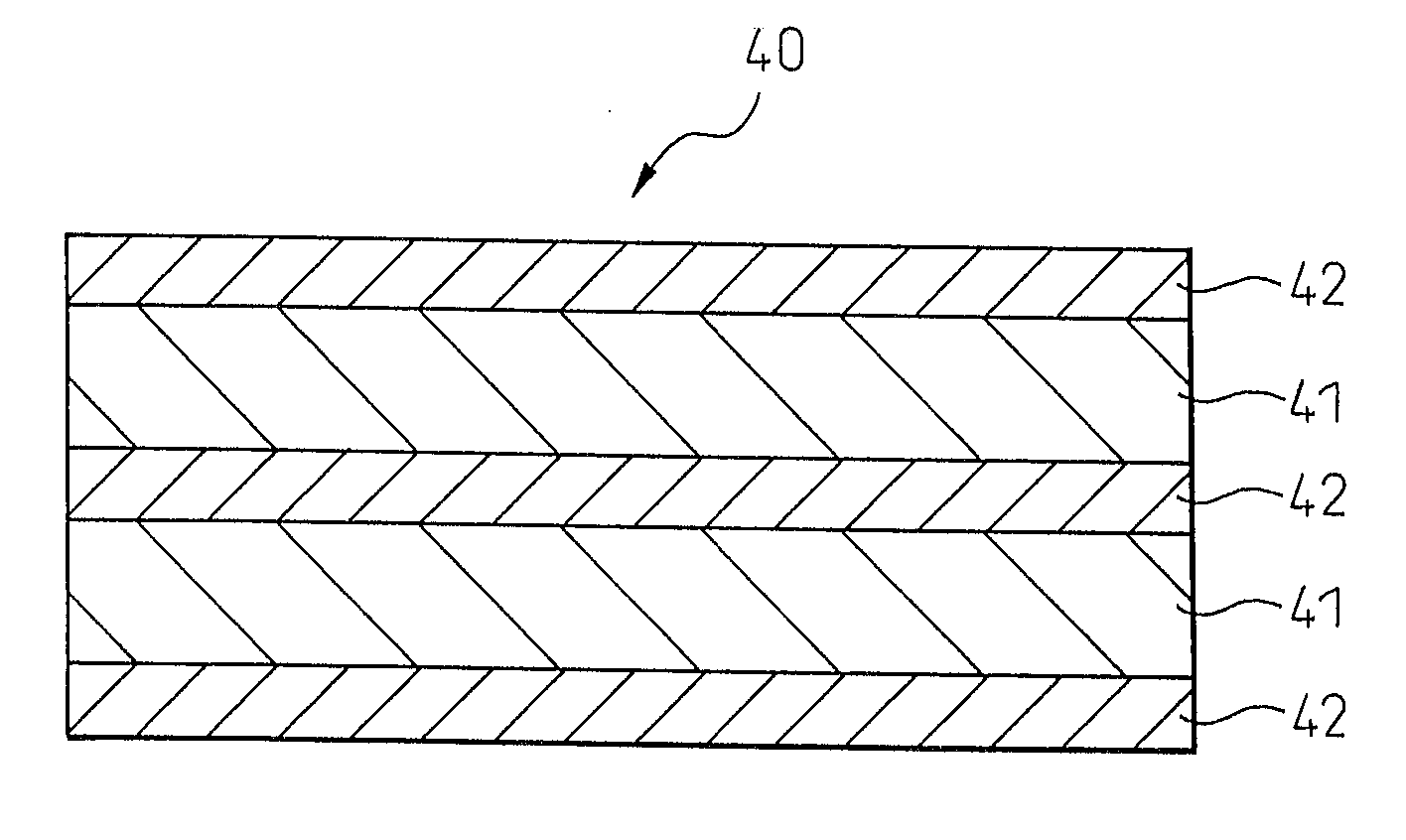

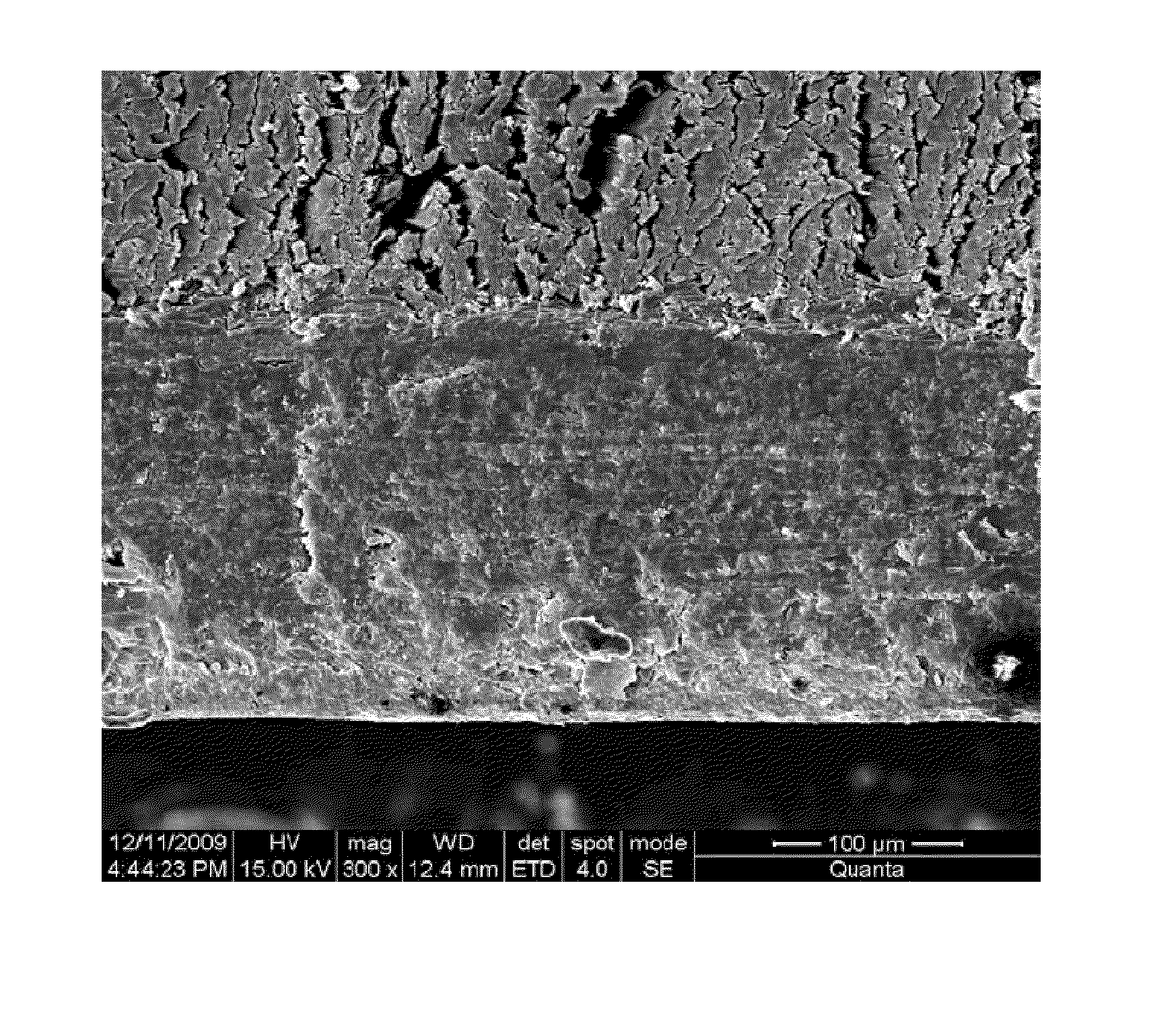

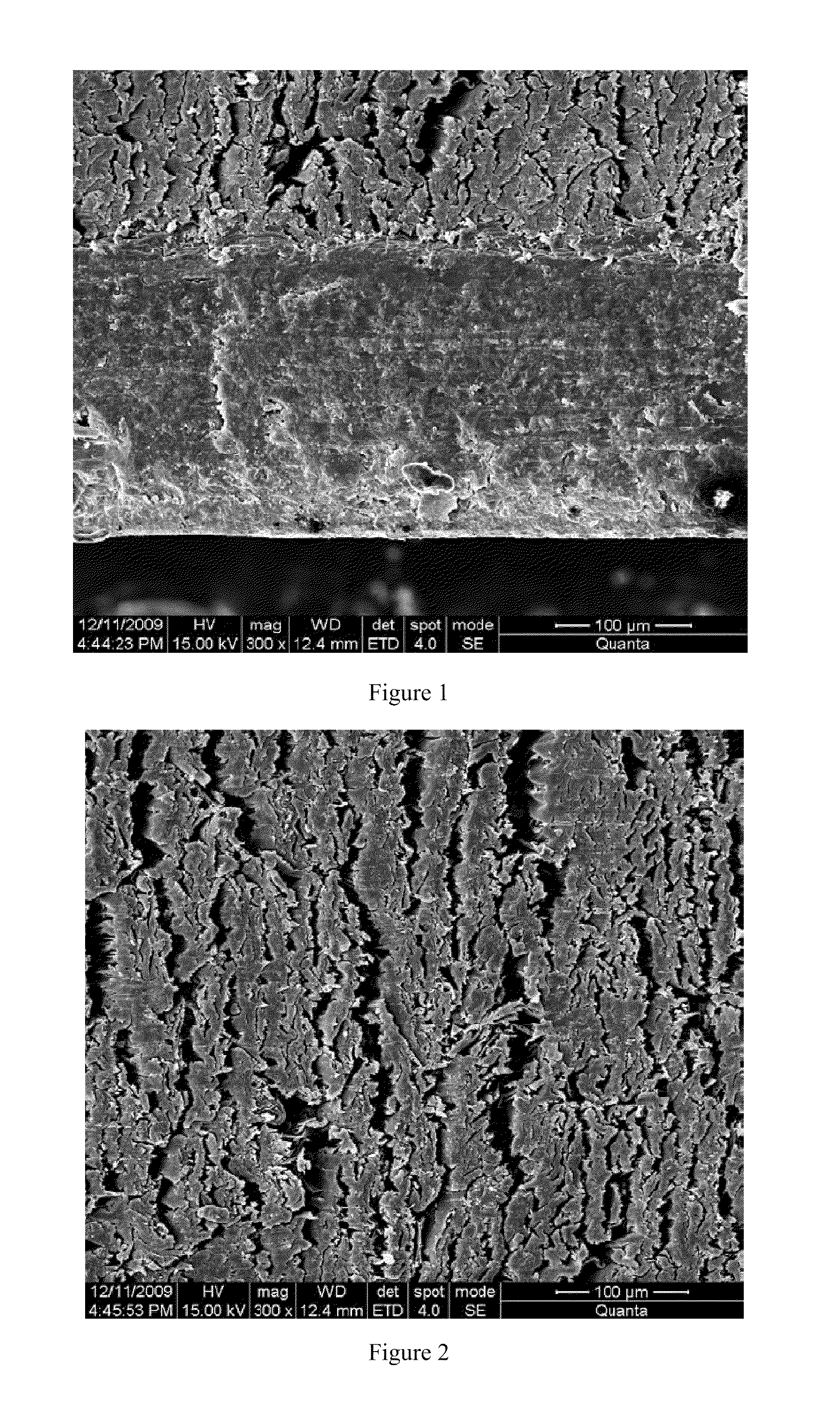

ActiveUS20110262685A1Short processing timeSave energyWood compressionCeramic shaping apparatusFiberSolid wood

The present invention relates to a solid wood section material and its manufacturing method. This invention is achieved by the following technical plans: a type of surface-reinforced solid wood product, including a compacted layer and a natural layer connected with fibre, has total density of between 350 and 750 kg / m3, moisture content between 5 and 12%, corrosion grade greater than II and weight loss less than or equal to 24%. This invention is particularly suitable to make floor boards.

Owner:TU DENGYUN +1

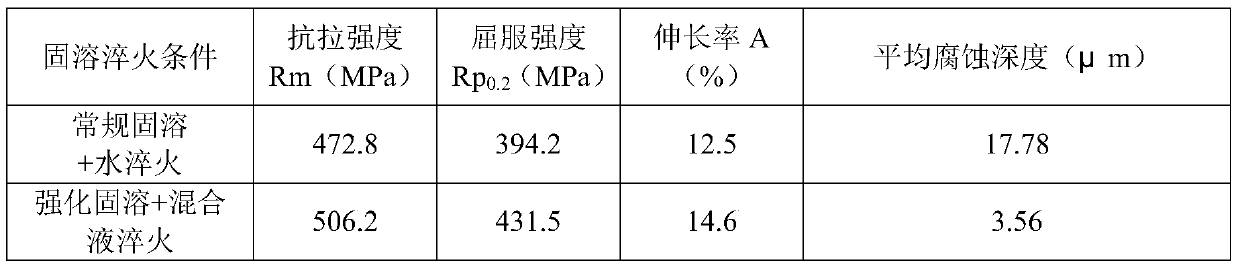

Production process of 2-series aluminum alloy thin-wall profile machining part

The invention belongs to the field of aluminum alloy preparation and relates to a production process of a 2-series aluminum alloy thin-wall profile machining part. The machining part is a thin-wall profile and comprises steps that aluminum alloy is proportioned according to a certain mass percent; the prepared aluminum alloy is smelted, degassing and deslagging are thorough, and an aluminum alloycast ingot with qualified components and structures is cast; the aluminum alloy cast ingot is extruded at an extrusion ratio of 9 / 1 to obtain an aluminum alloy thin-wall profile; the aluminum alloy thin-wall profile is subjected to solution treatment, the solution temperature is freely increased to 485 DEG C, heat preservation is conducted for 3 h, then the temperature is increased to 505 DEG C atthe heating speed of 10 DEG C / h, heat preservation is conducted for 15-18 min, and the aluminum alloy thin-wall profile subjected to solution treatment is quenched through mixed liquid. The method isadvantaged in that the reinforced solid solution with relatively higher temperature is adopted, so performance of the material is facilitated, the size and quantity of the second phase can be greatlyreduced, the structure is more uniform, and mechanical property of the material is improved.

Owner:CHINA ZHONGWANG

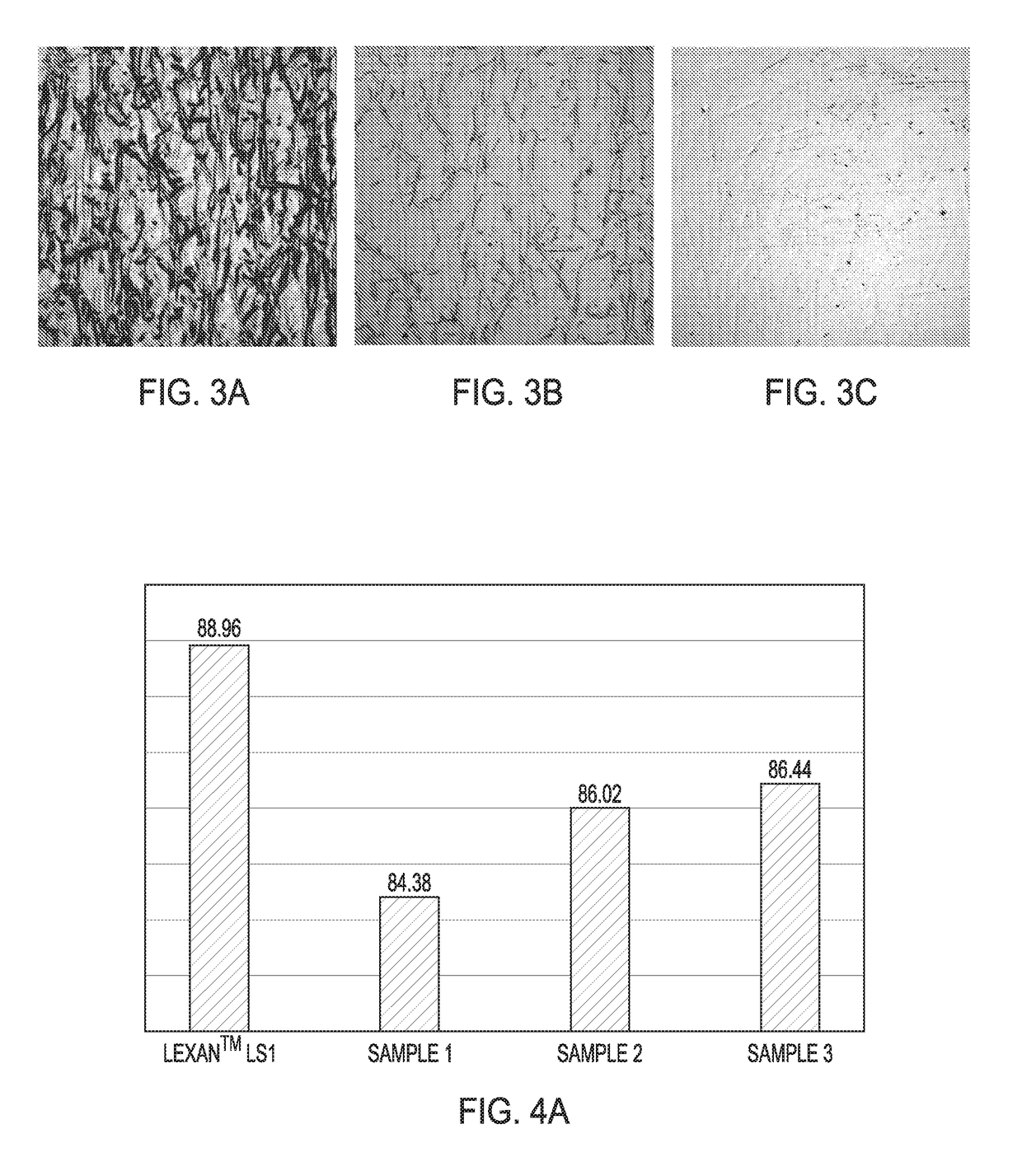

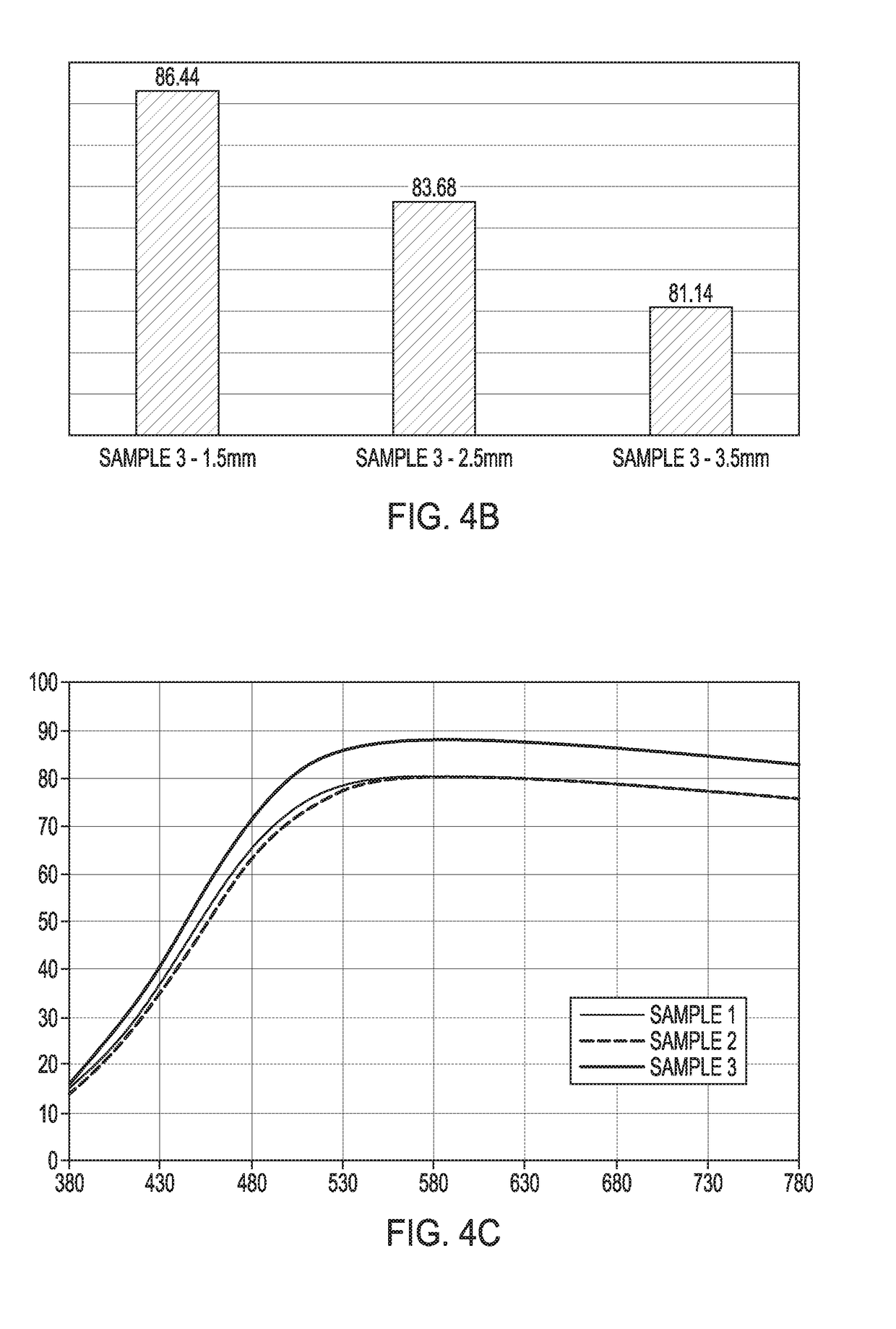

Glass filler-reinforced solid resin

InactiveUS20190077060A1Improve transmittanceReduce transmittanceCoatingsShell moldingRefractive index

Glass filler-reinforced solid resins and methods of making the same. The method includes contacting a flowable resin composition and a tool. The flowable resin composition includes a flowable resin and glass filler. The method includes molding or forming the flowable resin composition with the tool. The method includes curing the flowable resin composition, to form the glass filler-reinforced solid resin. Substantially all the surface of the tool that contacts the flowable resin composition during the curing thereof has a surface roughness Ra of about 2 microns or less. A refractive index of the glass filler is within about 0.100 of a refractive index of a cured product of the flowable resin in the glass filler-reinforced solid resin.

Owner:SABIC GLOBAL TECH BV

Chemically reinforced solid-liquid separation method for well drilling waste liquid

ActiveCN102019110BReduce contentFacilitate subsequent in-depth processingFiltration circuitsLiquid wasteSorbent

The invention relates to a chemically reinforced solid-liquid separation method for a well drilling waste liquid, comprising the following steps of: mixing the well drilling waste liquid with clear water, regulating the solid content of the well drilling waste liquid to 5%-10%, and then carrying out capillary pumping for not more than 2500s; adding a destabilizing agent comprising 0.3%-0.5% of sulfuric acid or nitric acid, 0.4%-1.0% of polyaluminium silicate chloride and 0.2%-0.3% of polyferric sulfate; adding adsorbents comprising 1%-1.5% of quick lime and 0.5%-1% of calcium chloride; adding a flocculating agent comprising 0.005%-0.015% of cationic polyacrylamide, anionic polyacrylamide or amphoteric polyacrylamide; accomplishing solid-liquid separation by using a centrifugal machine and then respectively discharging separated solid phase and liquid phase, wherein the centrifugal factor of the centrifugal machine is 2000-2200g, the water content of discharged mud is not greater than 70%, the solid content of the discharged water is not greater than 0.5%, and the recovery rate of the solid phase is not less than 90%. The chemically reinforced solid-liquid separation method reduces the difficulty in subsequent advanced treatment on the well drilling waste liquid, thereby creating the favorable conditions for resource recycling of the liquid phase.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Surface reinforced solid wood section material, floor board and manufacturing method thereof

ActiveCN101603623BLow compression recoveryHigh hardnessWood compressionFurniture partsSolid woodHardness

The present invention relates to the technical field of wood processing, in particular to the method for strengthening the wood surface, the profiles and the solid wood flooring of the same. The density of the surface-strengthened solid wood profiles are 300-580Kg / m 3 the reinforced surface is 1-5mm thick, the hardness of the paint film of the reinforced surface is 2H-8H, the overall moisture content of the profiles are 6-9%. The hardness of the paint film on the reinforced surface of the inventive solid wood profiles is higher, and the overall moisture content is stable, which is suitable for wider range of climate conditions.

Owner:ZHEJIANG SHIYOU TIMBER +1

Method for preparing fiber cement slab from industrial tailing slag

The invention discloses a method for preparing a fiber cement slab from industrial tailing slag. The preparation method comprises the following steps of putting 5-10 parts by weight of wood pulp fibers, 15-50 parts by weight of cement, 20-55 parts by weight of lithium slag, 10-30 parts by weight of graphite tailings and 3-5 parts by weight of an additive into a crusher and crushing the raw materials into a powdery mixed raw material. According to the method for preparing a fiber cement slab from industrial tailing slag, an intermediate chelating agent is adopted, the chelating effect of heavymetal is utilized, a capillary energy conveying channel is blocked, the activated state of the intermediate chelating agent is converted into a stable state, and then the long-term stability of a stabilized product is improved; and after the solid waste is modified, the kinetic energy of chemical reaction is reduced, the reaction activity of the material is reduced, the weather resistance of the solid waste (graphite tailings, lithium slag and the like) material is improved, and different types of green building construction new materials can be formed according to requirements by using a multistage super-strong consolidation material and a graded reinforced solid waste sealing technology.

Owner:SICHUAN OUXUN ENERGY ENG TECH

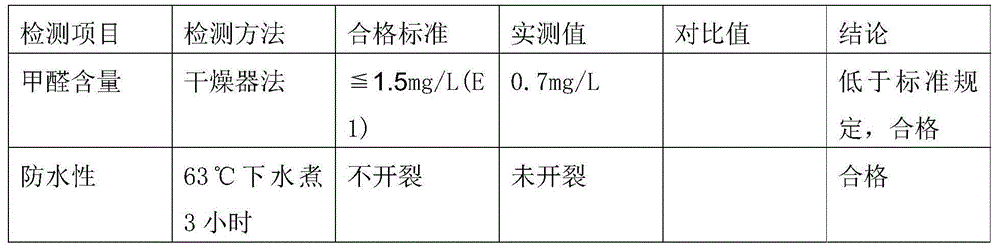

Fiberboard manufacturing method

InactiveCN105690534AImprove flatnessAvoid the disadvantage of not being waterproofDomestic articlesLignocellulosic moulding material treatmentSolid woodFiber bundle

The invention discloses a fiberboard / particle board manufacturing method. Before pressing the synthetic fiberboard / particle board, the separated wood fibers or fiber bundles are treated with waterproof glue, and the waterproof glue treatment is firstly mixed with waterproof glue and fiber glue to form Sprayable thin glue, and then spray it on the filamentous fiber with a nozzle at room temperature, stir the fiber to make it uniform; then press the above-mentioned treated fiber into fiberboard / particle board; the waterproof glue is acidified extraction A mixture of alkali lignin and urea-formaldehyde resin adhesive. Due to the use of special waterproof glue to waterproof the fiberboard / particle board layer, the fiberboard / particle board layer has waterproof properties, and its formaldehyde content has been tested to be lower than the value required by the national standard. This kind of waterproof fiberboard / particle board has high flatness, which can greatly improve the flatness of the surface of the solid wood composite board, reaching the same level as the reinforced composite board, while retaining various advantages of the solid wood reinforced board.

Owner:广西南宁绿园北林木业有限公司

Type of surface-reinforced solid wood section material and its manufacturing method

ActiveUS8221660B2Low densityHigh surface hardnessWood compressionCeramic shaping apparatusFiberSolid wood

The present invention relates to a solid wood section material and its manufacturing method. This invention is achieved by the following technical plans: a type of surface-reinforced solid wood product, including a compacted layer and a natural layer connected with fibre, has total density of between 350 and 750 kg / m3, moisture content between 5 and 12%, corrosion grade greater than II and weight loss less than or equal to 24%. This invention is particularly suitable to make floor boards.

Owner:TU DENGYUN +1

Overhead bare conductor expanding and reinforced insulation structure

InactiveCN103971798AEliminate coronaLarge equivalent radiusInsulated cablesInsulated conductorsElectrical conductorInsulation layer

An overhead bare conductor expanding and reinforced insulation structure comprises an upper expanding component, a lower expanding component and an elastic buckle for connecting the upper expanding component and the lower expanding component, wherein the upper expanding component and the lower expanding component are the same in structure and are clamped on the surface of the positions, needing to be protected, of an overhead bare conductor in a longitudinal symmetry mode; the outer surface of the upper expanding component and the outer surface of the lower expanding component are coated with modified epoxy insulation layers. The expanded conductor is of a hollow structure. The structure shields the single-line curvature and burrs on the surface of the overhead bare conductor, the equivalent radius of the smooth and large conductor is obtained, the corona on the surface of the bare conductor is thoroughly eliminated, and the safety distance is greatly reduced. The almost permanent safety protection effect can be obtained due to the strategy of the expanded conductor and an external reinforced solid insulation layer.

Owner:STATE GRID CORP OF CHINA +3

Solid cage and reinforced solid tapered roller bearing

ActiveCN103352919BHigh strengthIncrease the diameterRoller bearingsBearing componentsNumerical controlEngineering

The invention provides a solid cage and a reinforced solid tapered roller bearing. The bearing comprises an inner ring, an outer ring, a tapered roller and a solid cage, wherein a plurality of roller mounting holes are milled by a numerical control milling machine along the circumference of the solid cage, the mounting holes are in the shape of a radial straight hole having an angle same as a contact angle of the roller, solid parts of the solid cage comprises two side rings and a plurality of lintels between the rings, the side surface of each lintel is respectively provided with two symmetrical lock points, each lock point is a square neck formed by two square bumps, an arc surface cooperating with the roller is milled inwardly in the square neck, the tapered roller guides rotation of the solid cage in virtue of the lock points on the solid cage, the external surface of the inner ring is provided with a U-shaped neck cooperating with the tapered roller, and the tapered roller is mounted through an outer mounting hole in the solid cage and is assembled with the inner ring to form an inner ring assembly. The bearing provided by the invention has the advantages great bearing capability, a long service life, smooth operation, low friction, good lubrication performance, good vibration resistance, etc.

Owner:SHANDONG KAIMEIRUI BEARING TECH CO LTD

Glass filler-reinforced solid resin

Glass filler-reinforced solid resins and methods of making the same. The method includes contacting a flowable resin composition and a tool. The flowable resin composition includes a flowable resin and glass filler. The method includes molding or forming the flowable resin composition with the tool. The method includes curing the flowable resin composition, to form the glass filler-reinforced solid resin. Substantially all the surface of the tool that contacts the flowable resin composition during the curing thereof has a surface roughness Ra of about 2 microns or less. A refractive index of the glass filler is within about 0.100 of a refractive index of a cured product of the flowable resin in the glass filler-reinforced solid resin.

Owner:SABIC GLOBAL TECH BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com