Multi-plane cylindrical shell structure with reinforced folded corners

A cylindrical shell structure and multi-plane technology, applied in underwater structures, infrastructure engineering, buildings, etc., can solve the problems of bending stress at knuckles, stress concentration at sharp points, insufficient axial stiffness, etc., and achieve weak stress concentration , Large axial stiffness and good pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

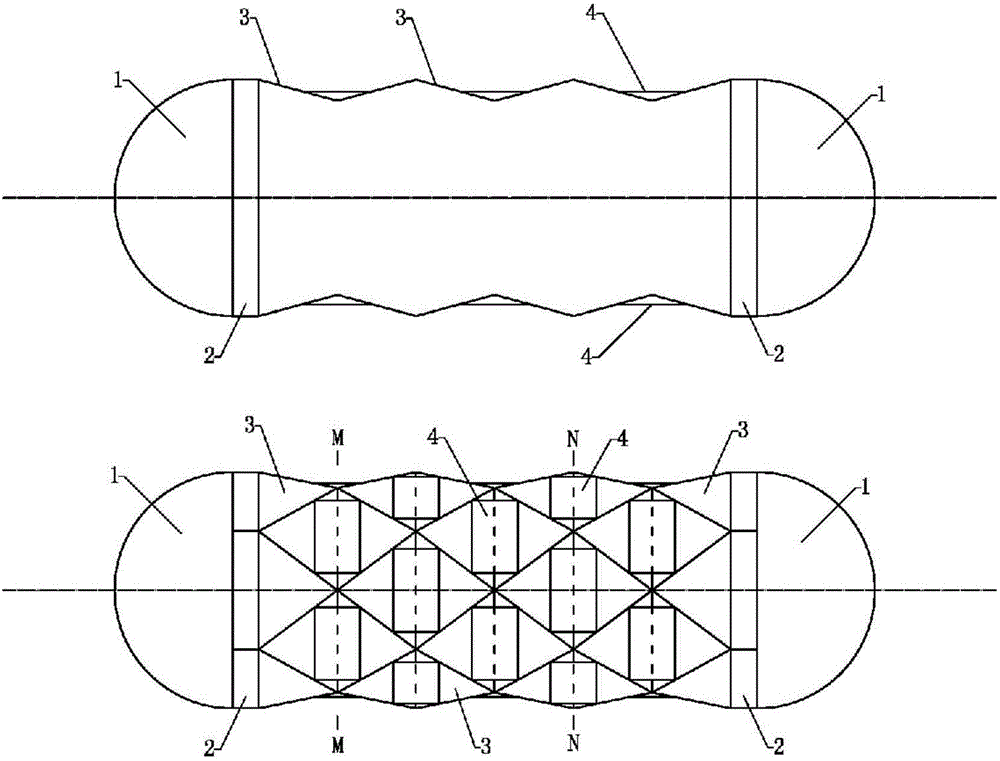

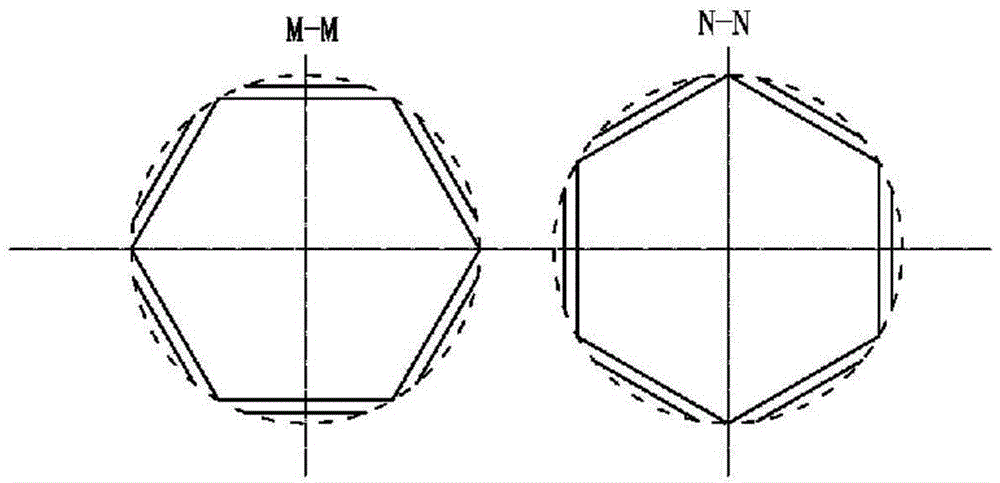

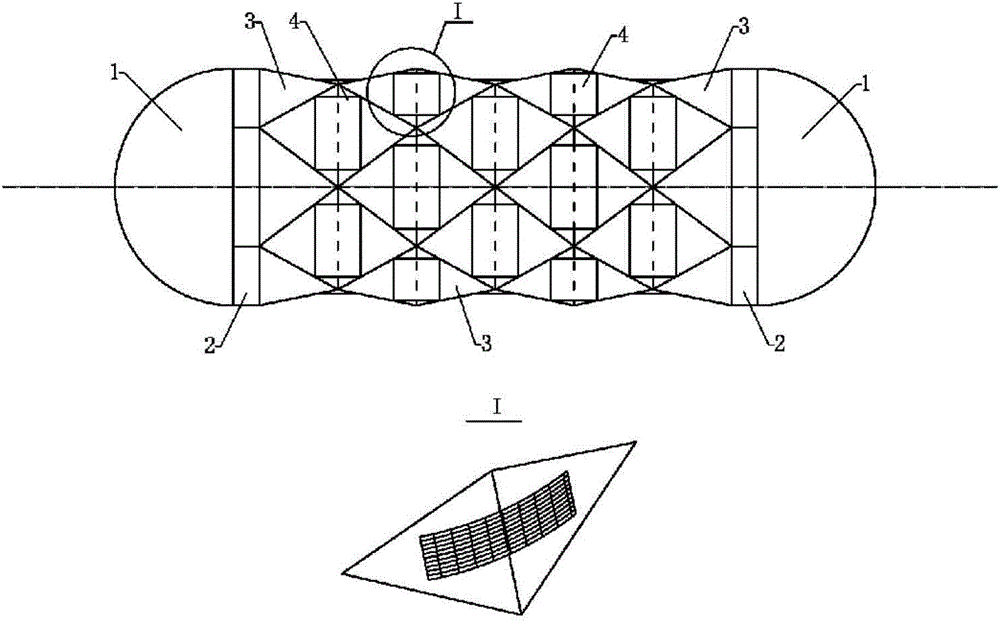

[0021] figure 1 is a schematic diagram of the partially reinforced multi-planar cylindrical shell structure of the present invention, figure 2 is along figure 1 M-M, N-N partial cross-sectional profile, Figure 3-5 The locally reinforced multiplanar cylindrical shell structures according to the invention are shown respectively.

[0022] like image 3 As shown, the partially reinforced multi-plane cylindrical shell structure according to the first embodiment of the present invention is composed of a spherical head 1 , a transition section 2 , a polygonal space plate 3 , and a reinforced curved plate 4 .

[0023] like Figure 4 As shown, the partially reinforced multi-plane cylindrical shell structure according to the second embodiment of the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com