Glass filler-reinforced solid resin

A glass filler and solid resin technology, the optical properties of the material-reinforced resin have not yet been reached, and the rate is in the field of the glass filler, which can solve the problems such as the optical properties not reaching an acceptable level, and achieve good optical properties and high performance. Transmittance, high brightness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] Example 1. Formation of samples

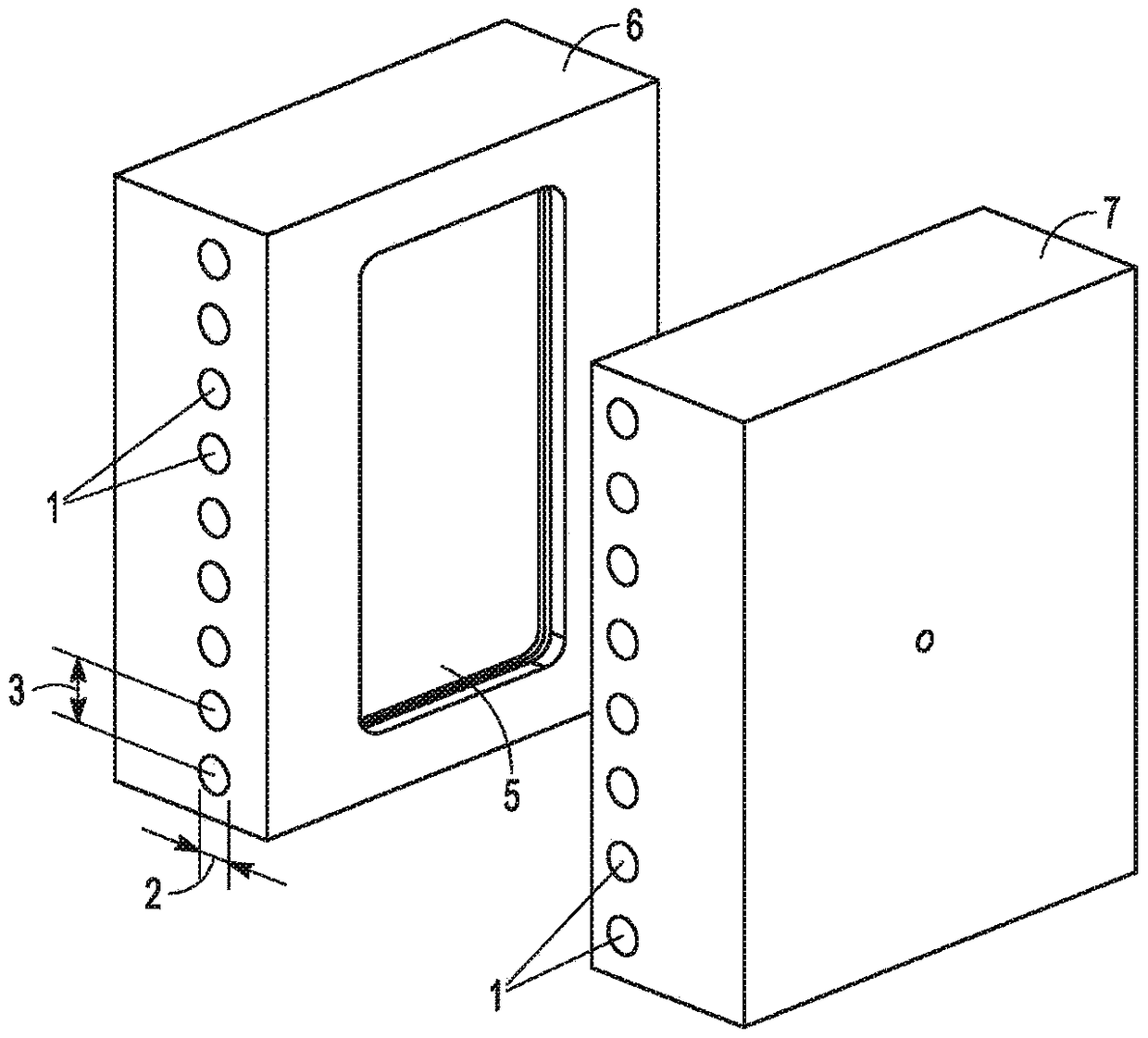

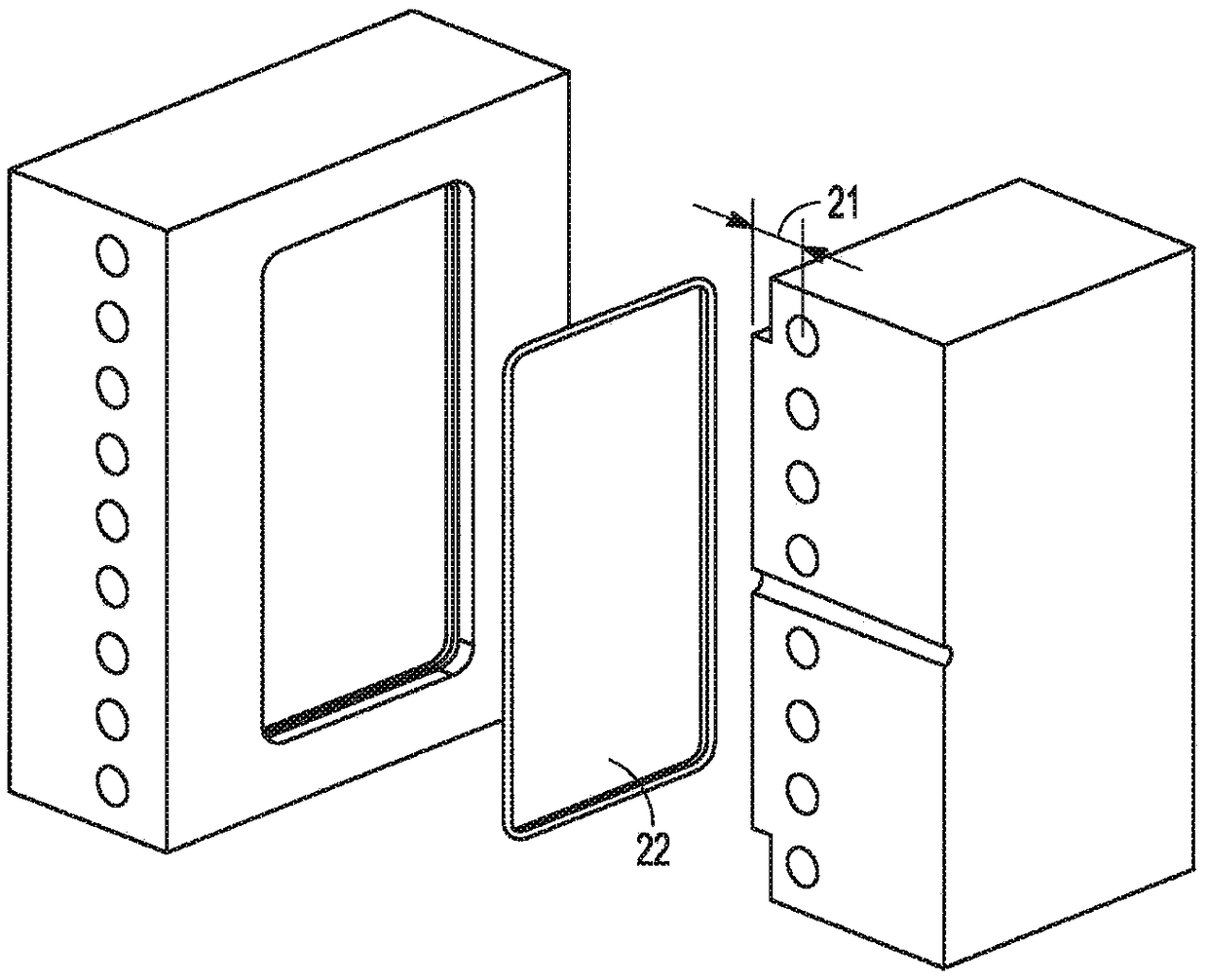

[0083] Double-sided dynamic temperature-controlled injection molding tools are machined using a grinder or end-mill, polishing wetstone (rough to smooth (from #1500 to #3000), then polished with Sandpaper was polished from (coarse to smooth (from #2000 to #3000)), and finally Diamond Compound #2 from Universal Superabrasives, USA. The final polished tool had about R a 6.5 nm smoothness. The tools such as figure 1 Shown in , with sides 6 and 7. The diameter 2 of the heating / cooling channel 1 is about 8 mm. The center of the heating / cooling channel 1 is located approximately 8 mm from the tool core surface 5 . The distance 3 between the heating / cooling channels is about 16 mm. figure 2 A cross-section of the molding tool is shown showing the molded part 22 . Said distance 21 is about 8 mm.

[0084] The injection molding tool was used for bisphenol-A based polycarbonate (refractive index 1.586) and poly(1,4-cyclohexylidenecycloh...

Embodiment 2

[0086] Example 2. Characterization of samples

[0087]Total transmittance, diffuse transmittance and haze were measured using a HM-150 from Murakami Color Research Laboratory, all using a halogen D65 (CIE standard) light source from 380 nm to 780 nm. Brightness was measured with an SR-3A supplied by Topcon, which irradiates the sample onto a white board using a xenon light source, and detects reflected light from the sample and from the white board through the sample. Surface roughness was measured using a Contour Elite I from Bruker.

[0088] Figure 4A The diagram illustrates how to communicate with the Lexan TM Total transmittance at 380-780 for samples 1-3 at 1.5 mm thickness compared to LS1. The overall transmittance was improved for samples 2 and 3, with double-sided heating and cooling of sample 3 providing the best results. Figure 4B The graph illustrates the total transmission of Sample 3 at thicknesses of 1.5mm, 2.5mm and 3.5mm. As the thickness decreases, th...

Embodiment approach

[0103] The following exemplary embodiments are provided herein, the numbering of which should not be construed as indicating a level of importance:

PUM

| Property | Measurement | Unit |

|---|---|---|

| luminance | aaaaa | aaaaa |

| luminance | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com