New reinjection treatment method of polysulfonate drilling wastewater

A technology for drilling wastewater and treatment methods, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., which can solve the damage of oil-producing formations, increase the difficulty of wastewater treatment, and increase the treatment cost. It can reduce pollution and alleviate the shortage of water resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

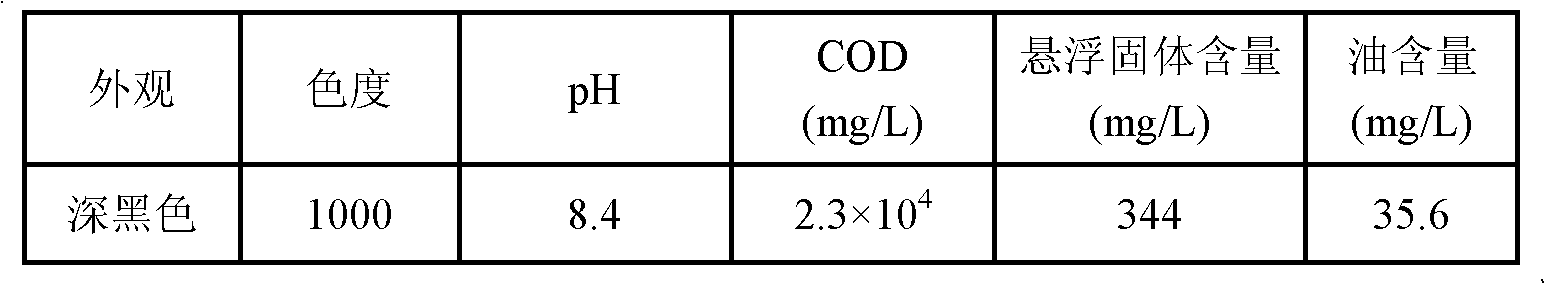

[0035] This embodiment is aimed at the polysulfonate mud system 1# drilling wastewater produced at a depth of 3000 meters in a certain well in Shengli Oilfield. The water quality of this wastewater is as shown in Table 1. The specific operations are as follows:

[0036] Table 11# Drilling wastewater quality

[0037]

[0038] First, add 28mL / L (1+1) hydrochloric acid (diluted by adding an equal volume of water to 36%-38% concentration of hydrochloric acid) to 1# drilling wastewater to adjust the pH to 2, and mix slowly to make it React for 20 minutes; then enter the centrifuge for centrifugation to remove the suspended solids that have settled, the centrifugal speed is 2500r / min, and the centrifugation time is 3min;

[0039]Then add 8g / L quicklime to adjust the pH to 7.0, add 625mg / L coagulant polyaluminum chloride and 6mg / L coagulant cationic polyacrylamide, its relative molecular weight is 800-10 million, and carry out coagulation treatment. Further remove the suspended s...

Embodiment 2

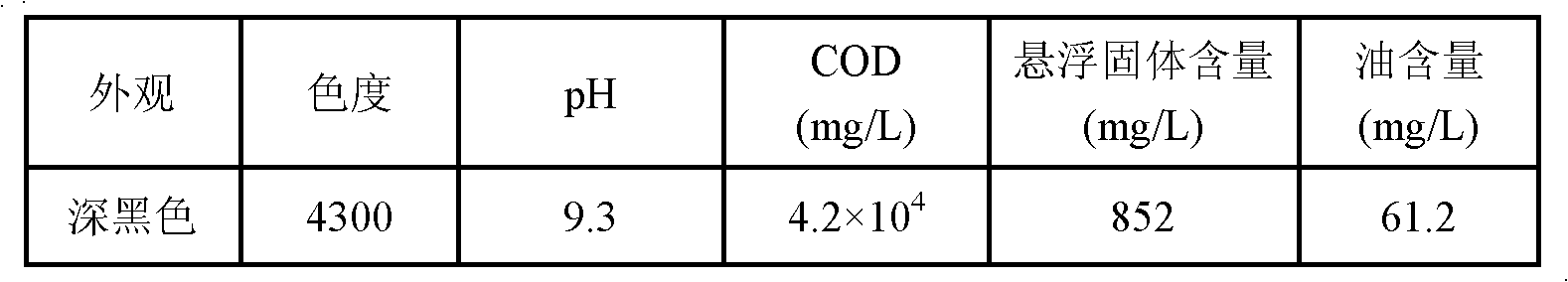

[0043] This embodiment is aimed at the 2# polysulfide mud system drilling wastewater produced at a depth of 4100 meters in a certain well in Shengli Oilfield. The water quality of this wastewater is shown in Table 2. The specific operations are as follows:

[0044] Table 22# Drilling wastewater quality

[0045]

[0046] First, add 35mL / L (1+1) hydrochloric acid (diluted by adding an equal volume of water to 36%-38% hydrochloric acid) into 2# drilling wastewater to adjust the pH to 1, and mix slowly to make it React for 30 minutes; then enter the centrifuge for centrifugation to remove the suspended solids that have settled, the centrifugal speed is 3000r / min, and the centrifugation time is 5min;

[0047] Then add 10g / L quicklime to adjust the pH to 8, add 950mg / L coagulant polyaluminium chloride and 10mg / L coagulant cationic polyacrylamide, its relative molecular weight is 800-10 million, and carry out coagulation treatment. Further remove the suspended solids in the water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com