Reinforced solid surface materials

An enhanced, solid technology, applied in the field of enhanced solid surface materials, can solve the problems of affecting the application effect, high brittleness, low toughness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] (Take pearl black solid surface material as an example) The following components are weighed according to the following proportions (Kg):

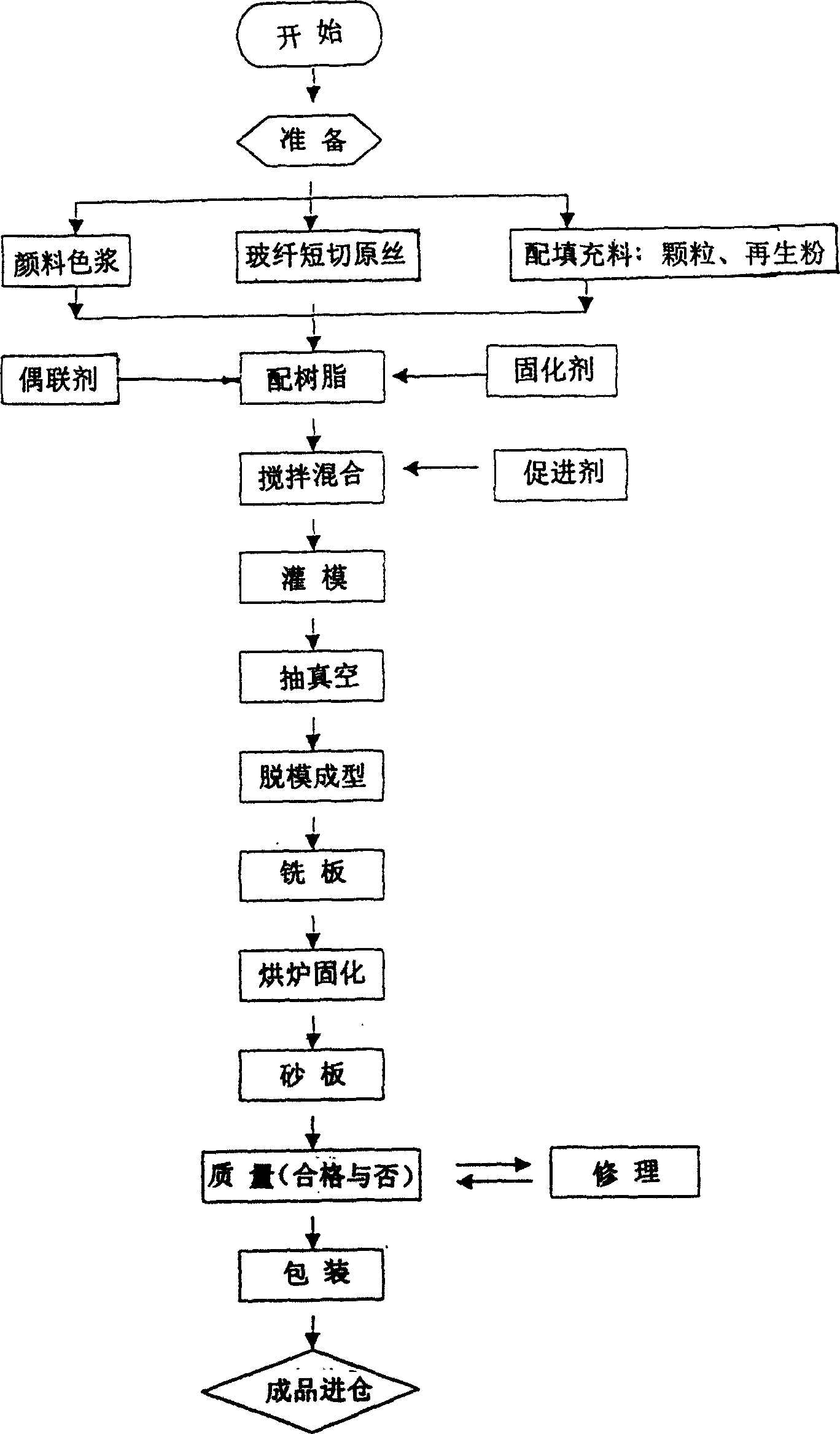

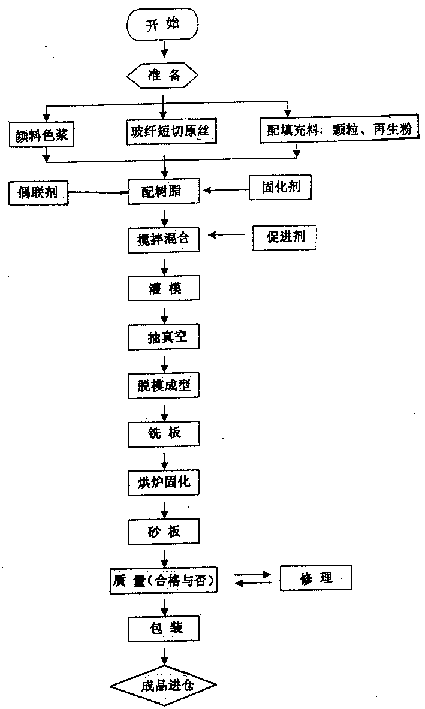

[0041] Unsaturated polyester resin 17.4Kg, aluminum hydroxide powder 28Kg, black color paste 0.092Kg, glass fiber chopped strand 0.25Kg, methyl ethyl ketone peroxide 0.204Kg, colorless cobalt 0.048Kg, organosiloxane 0.136Kg, white color 0.2Kg of unsaturated polyester resin pellets, 3Kg of black regenerated powder. Produce according to the following method, refer to figure 1 , start, prepare, in order to make pigment paste, coupling agent, glass fiber chopped strands, curing agent, recycled powder, unsaturated polyester resin of various colors as granules, aluminum hydroxide powder, while stirring Add it into the unsaturated polyester resin, under high-speed stirring, fully stir evenly, finally add the accelerator and stir evenly, pour the mixed slurry into the plate mold, level it, and then send it into the vacuum box for vacuuming...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com