Methods of removing solids from liquids

a liquid solids and liquid technology, applied in the direction of filtration separation, moving filter element filtering, separation process, etc., can solve the problems of damage to the equipment in the treatment unit, easy apparent damage to the nation's waters and their ecosystems, fish kills and other harm, etc., to achieve the effect of simplifying the removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

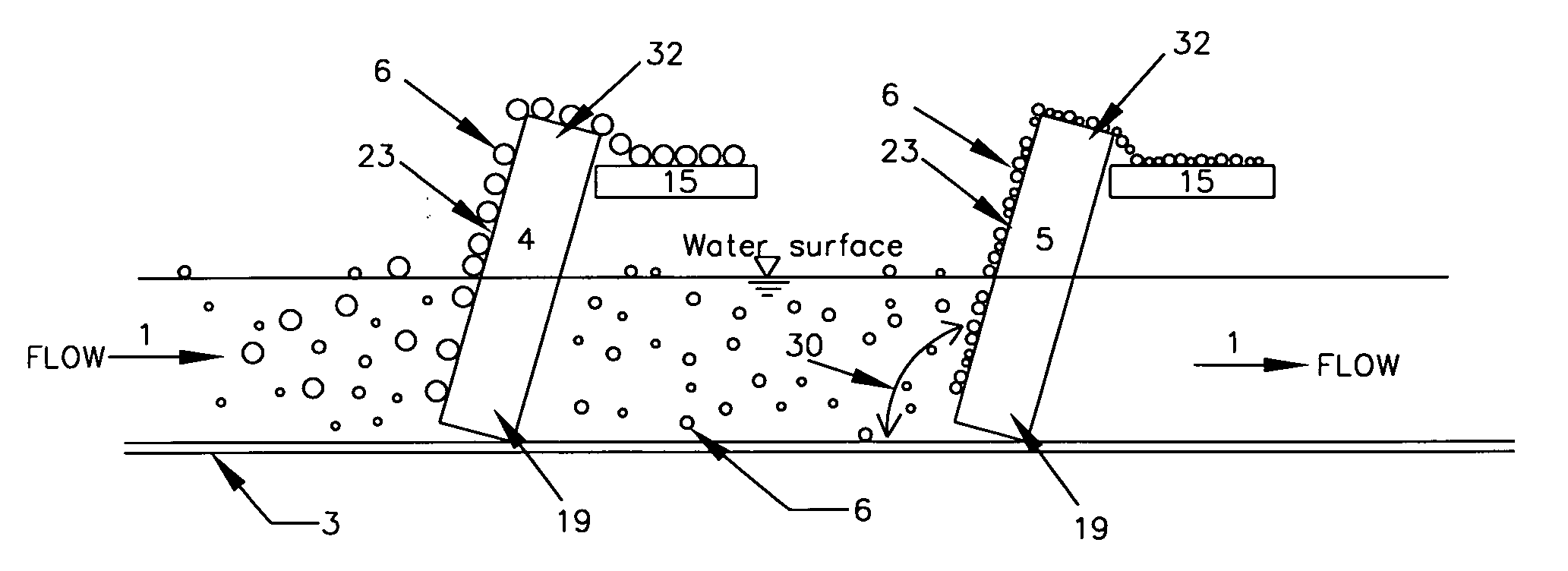

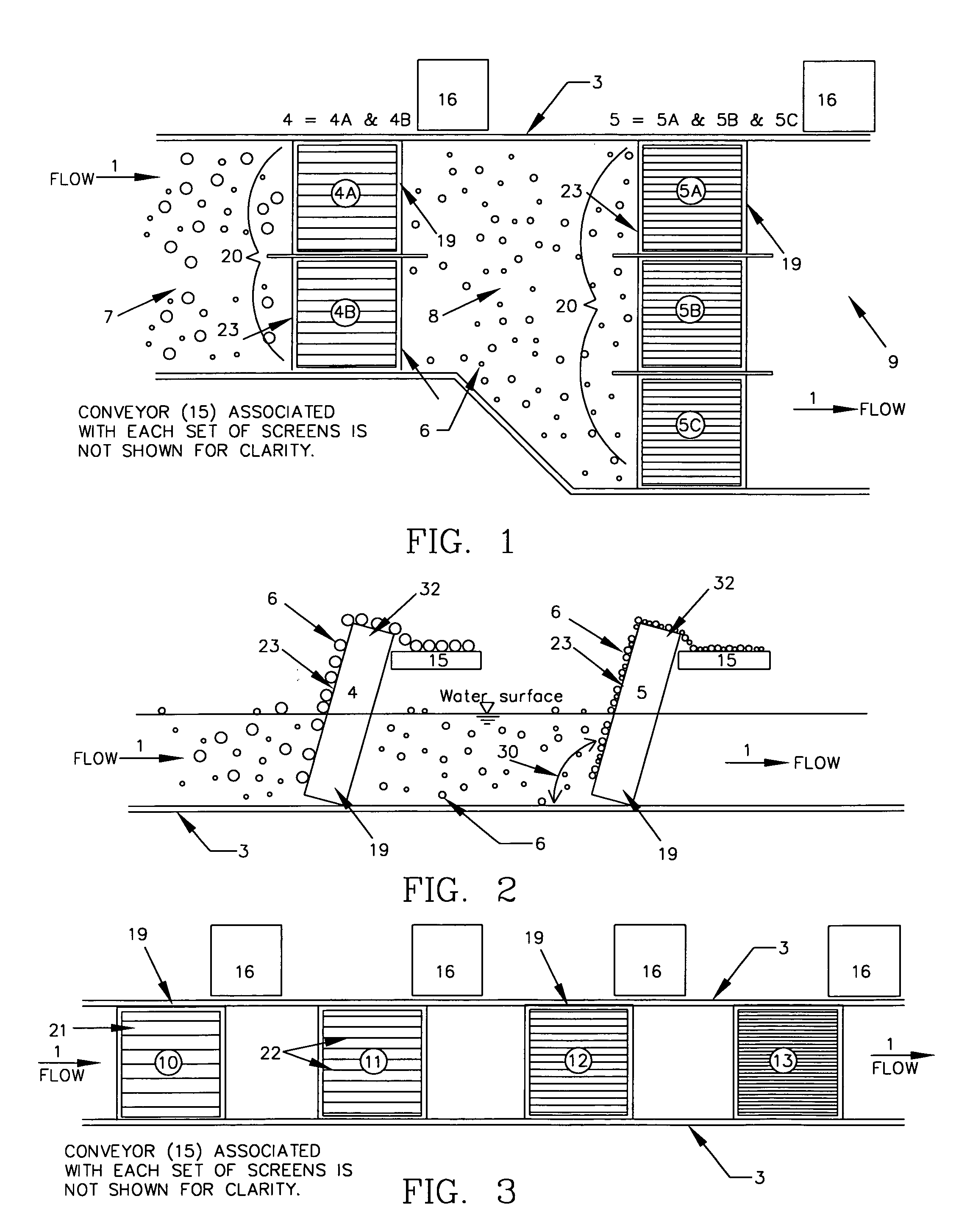

Use of Method for Canal Pollution Control System

[0038]The Indian River Farms Water Control District (IRFWCD) in Indian River County (IRC), FL is an area of over 53,000 acres that is drained by an extensive network of man-made canals. The IRFWCD discharges into the Indian River Lagoon, an Estuary of National Significance and a St. Johns River Water Management District (SJRWMD) Surface Water Improvement and Management (SWIM) program priority water body. In the East Indian River County Master Stormwater Management Plan, a pollutant loading analysis showed that the three discharge canals of the IRFWCD convey large amounts of suspended solids, nutrients, and floating vegetative debris into the lagoon.

[0039]The Main Relief Canal drainage basin has a continuous flow discharge to the Indian River Lagoon that averages approximately 50 million gallons per day. During storm event periods, radial control gates are opened to release flood waters stored in approximately 150 miles of canal and dit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angles | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com