Coal mining solid filling method

A technology of solid filling and solid objects, which is applied in the direction of filling, ground mining, mining equipment, etc., can solve the problems of low degree of mechanization, in the research stage, and high production cost, and achieve high production efficiency, improved recovery rate, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

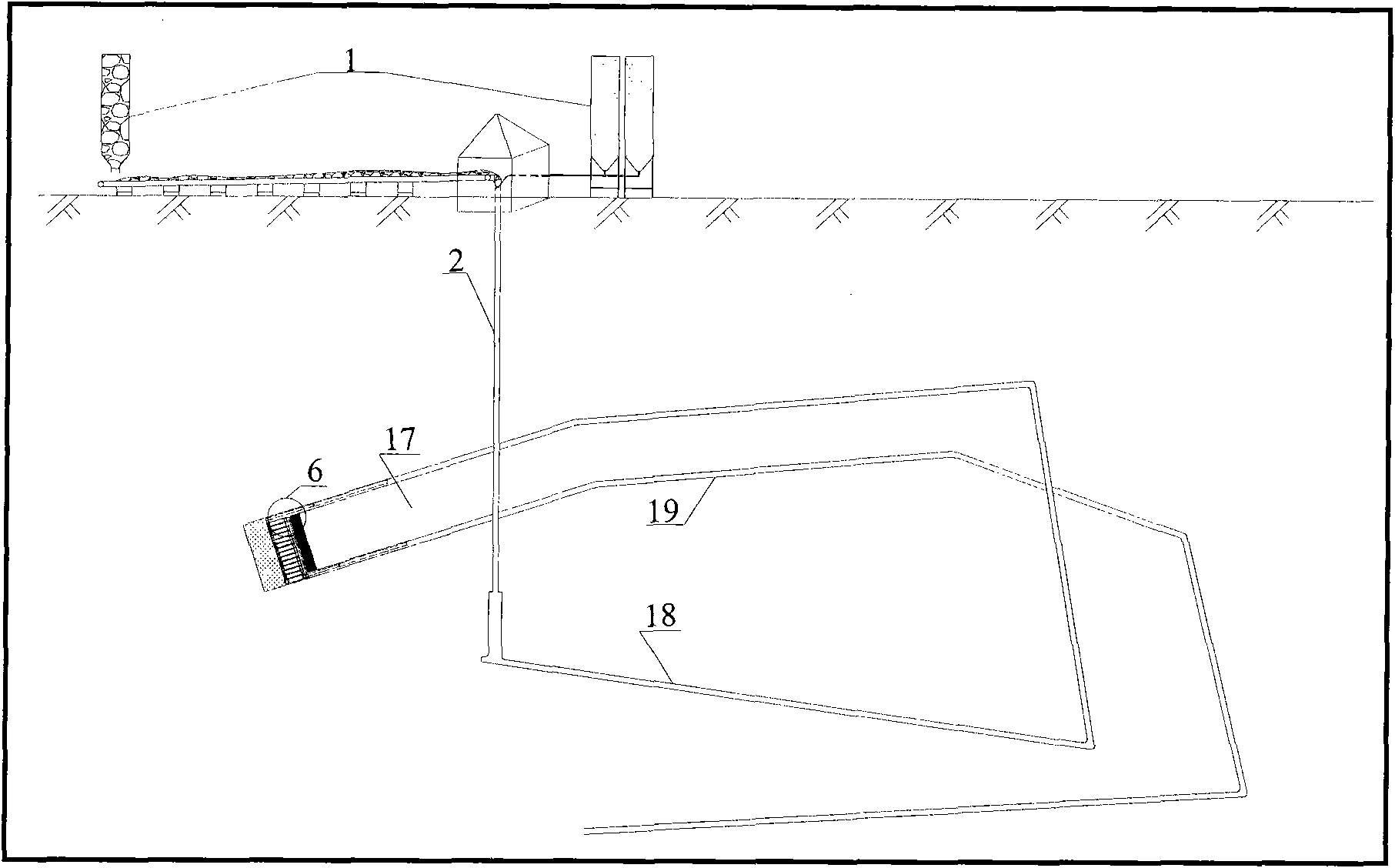

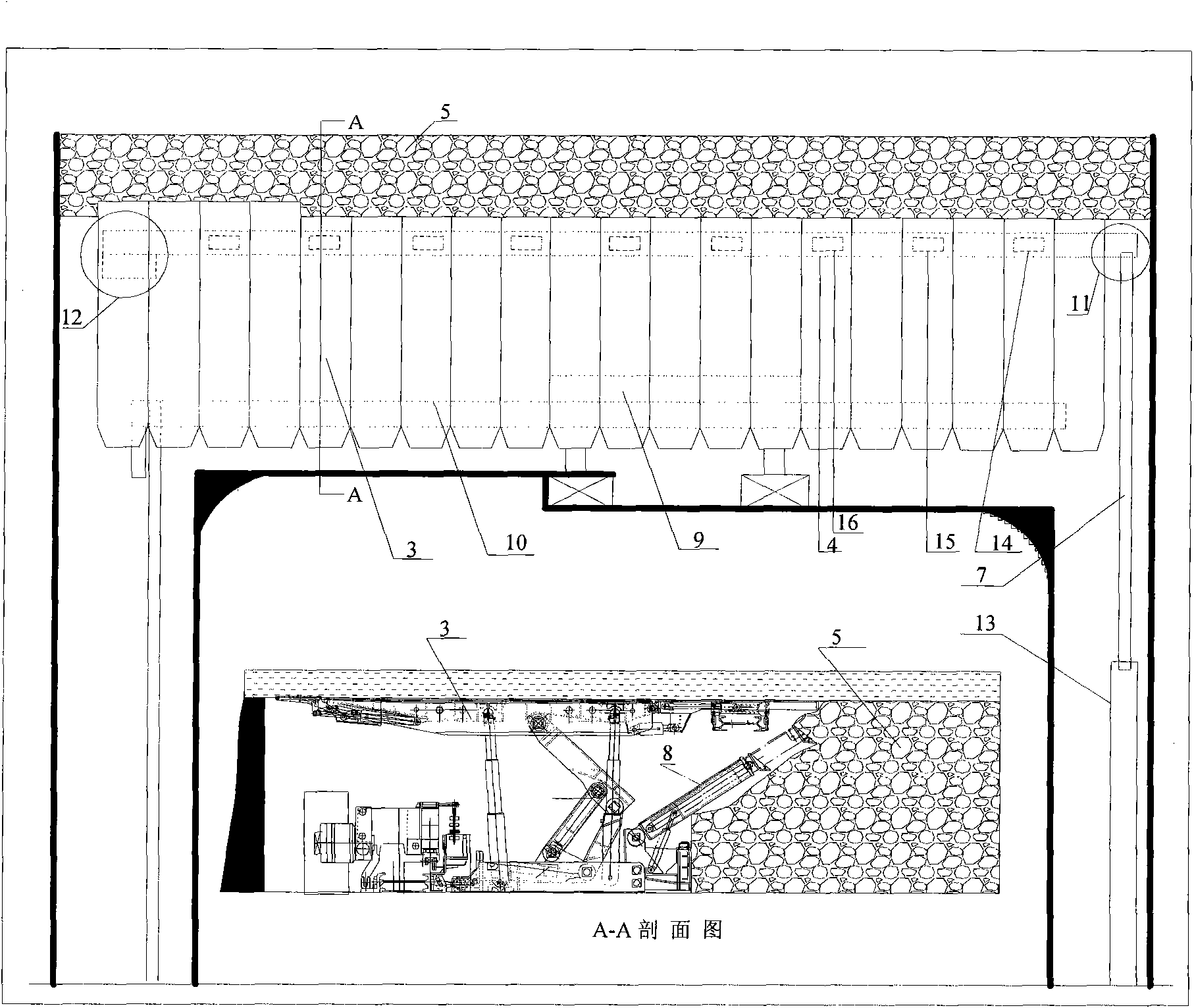

[0025] 1. Set the depth of the vertical feeding well 2 to 350m. Use Φ510×12mm wear-resistant steel pipe as the feeding pipe of the feeding well. Capacity greater than 450t / h;

[0026] (2) Set the length of the solid filling mining face 17 to be 50m, the daily cycle is 6 knives, two shifts of production, one shift of maintenance, the cycle progress is 0.6m, the daily cycle progress is 3.6m, that is, the advancing speed of the working face is 3.6m / d; based on 25 days per month, the monthly advance rate is 90m / month; based on 300 days per year, the annual advance rate is 1080m;

[0027] (3) The main equipment of solid filling mining face 17 are: MG200 / 466-WDH coal shearer; ZZC4800 / 16 / 32 self-ramming filling hydraulic support 3; SGB630 / 150 solid filling mining conveyor 4; SZZ-764 / 132 Self-moving filling material transfer machine 7; SDJ-150 coal transport belt conveyor 13 and SGZ gangue and fly ash belt conveyor 13.

[0028] (4) The solid filling mining face 17 adopts the compre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com