Secondary bottom sealing structure of open caisson and construction method

A construction method and bottom sealing technology, which are applied in basic structure engineering, caisson, construction, etc., can solve the problems of complex bottom sealing construction, difficult adjustment of the subsidence process, and construction quality easily affected by the bottom hole environment, etc., and achieve the effect of ensuring quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

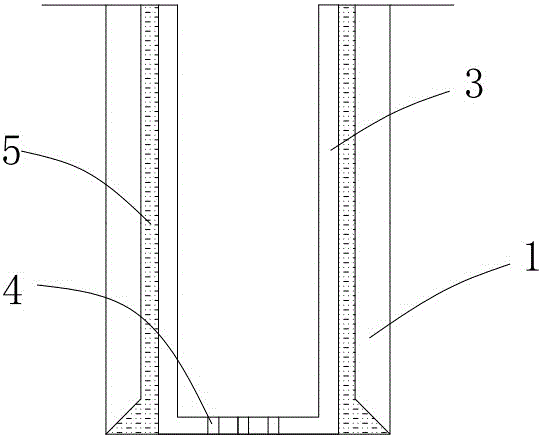

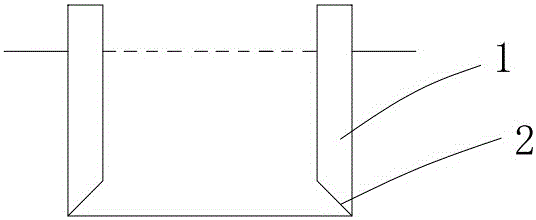

[0025] Embodiment: a kind of caisson secondary bottom sealing structure, as figure 1 shown. The device includes a casing 1 and an inner container 3 buried below the ground, the casing is straight cylindrical with upper and lower openings, and a blade foot 2 is provided at the bottom of the casing. The inner tank is cylindrical, and the outer wall of the inner tank is consistent with the inner wall of the shell with a gap. The top of the inner tank is open, and the bottom is provided with a bottom plate 4. The bottom plate is provided with a mud hole, and the mud hole 5 is closed after the inner tank sinks to the bottom. The gap between the shell and the liner is consolidated by grouting to form a consolidation layer 6 .

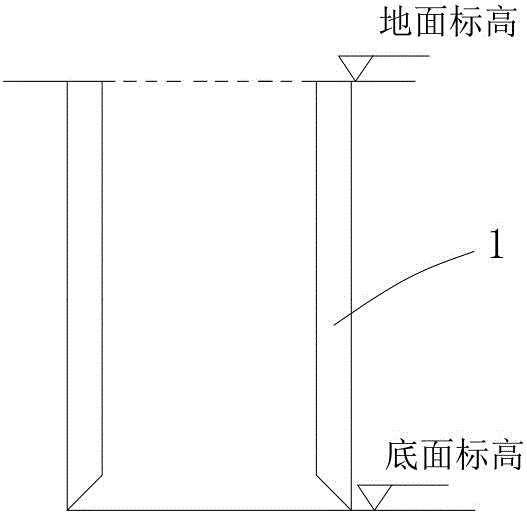

[0026] A construction method for a caisson secondary bottom sealing structure, such as Figure 2-5 shown. Include the following steps:

[0027] a. The shell sinks to the design elevation;

[0028] b. The liner sinks inside the shell to the design elevati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com