Method for analyzing pore structure of solid material based on microscopic image

A solid material and pore structure technology, applied in 3D image processing, image data processing, permeability/surface area analysis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

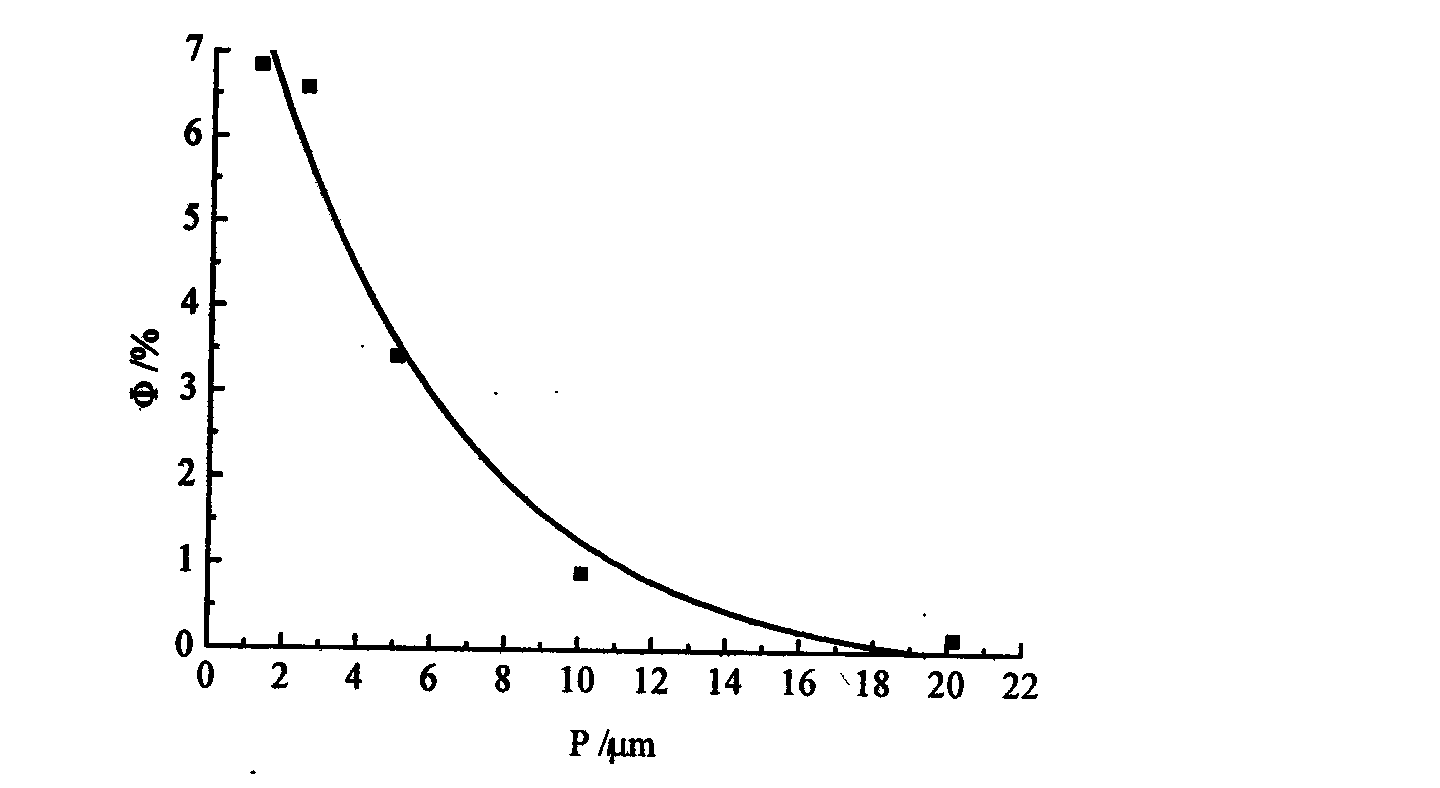

[0032] The mudstone is scanned by the micro-CT X-ray imaging system, and the computer system reconstructs the scanned CT image to generate a single CT cross-sectional image. Digital image processing and three-dimensional reconstruction are performed based on the micro-CT image. The purpose is to calculate Mudstone pore size, porosity and their variation. The calculation process is:

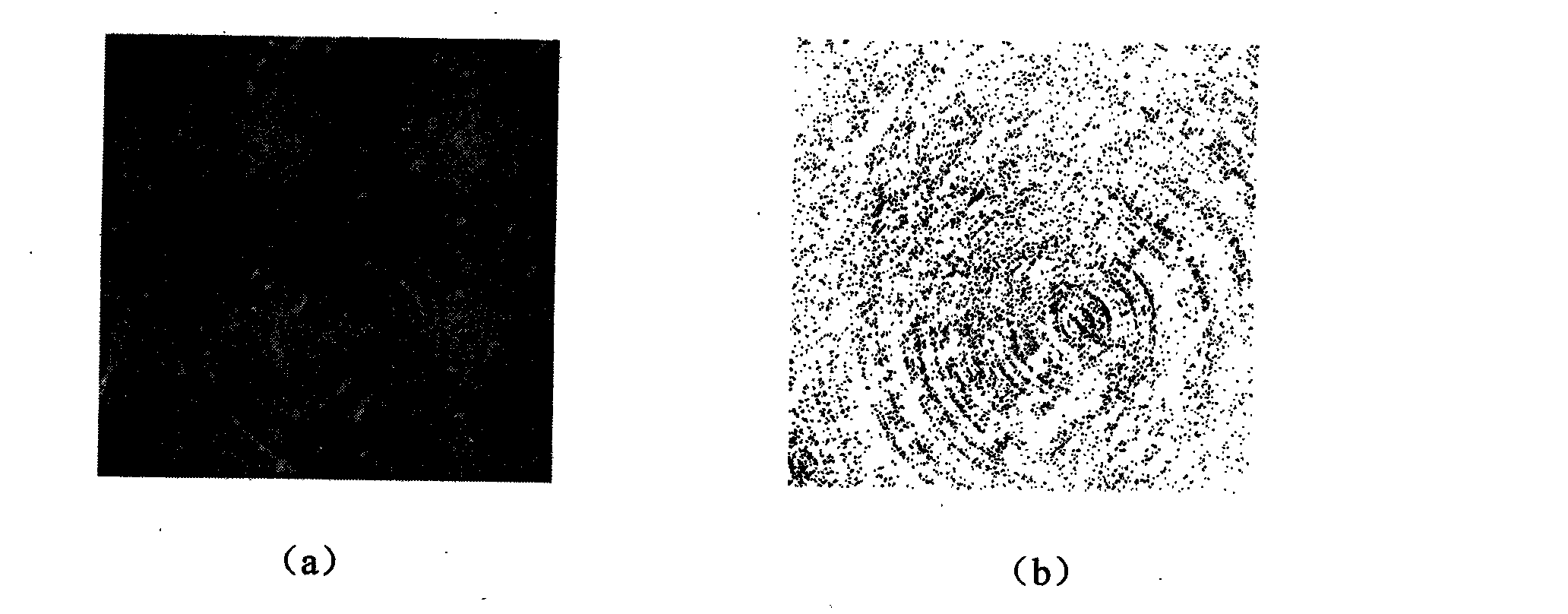

[0033] I. Acquisition of a single cross-sectional image of micro-CT. The micro-CT single image comes from the micro-CT test system, figure 1 It is a randomly selected cross-sectional image in bmp bitmap format, the image type is index image, the image size is 2001×2001 pixels, the number of bits per pixel is 8 bits, and the grayscale range is 0 to 255. The size is 1.26 μm, that is, the pore diameter is 1.26 μm. The black dots in the figure indicate the lower density of the material, the white dots indicate the higher density of the material, and the change from black to white indicates the dens...

Embodiment approach 2

[0044] Embodiment 2: The solid material coal is scanned by the micro-CT X-ray imaging system, and the pore structure of the coal is analyzed. The pore size is in the range of 0.8 μm to 7 μm, and the porosity is in the range of 22% to 4%. The law of decrement. Others are the same as Embodiment 1.

Embodiment approach 3

[0045] Embodiment 3: The solid material sandstone is scanned by the micro-CT X-ray imaging system, and the pore structure of the sandstone is analyzed. The pore size is in the range of 0.4 μm to 4 μm, and the porosity is in the range of 2% to 14%. The law of decrement. Others are the same as Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com