MEMS micropump-based solid-liquid composite lubricated shafting for flywheel

A technology of solid-liquid compounding and lubricating shafts, which is applied in the direction of engine lubrication, bearing components, shafts and bearings, etc., can solve the problems of large friction torque and low control precision, improve the initial running-in, improve control precision, and improve the prevention of starting bite effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

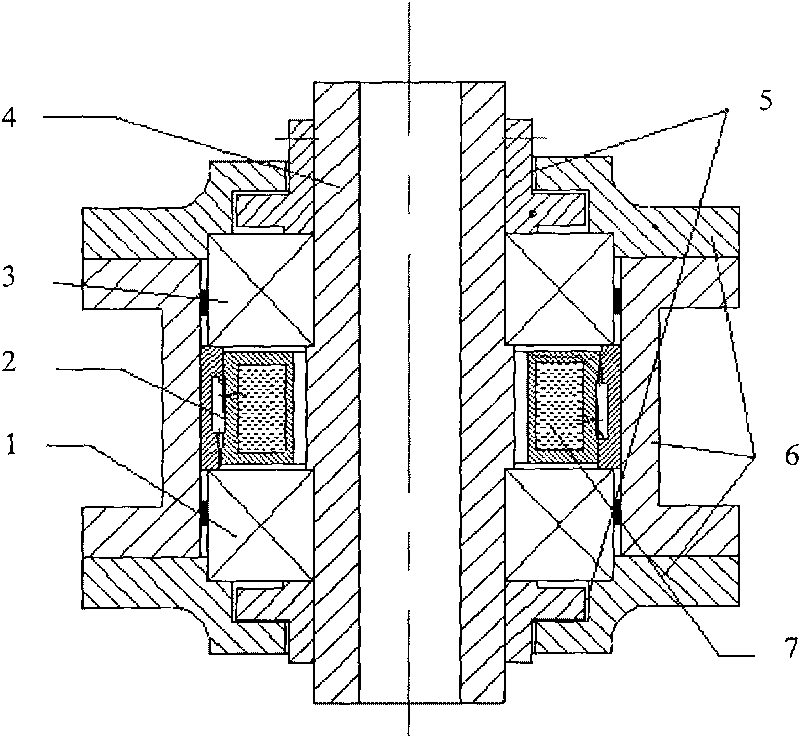

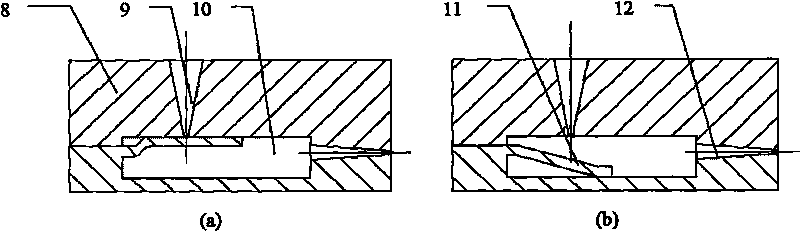

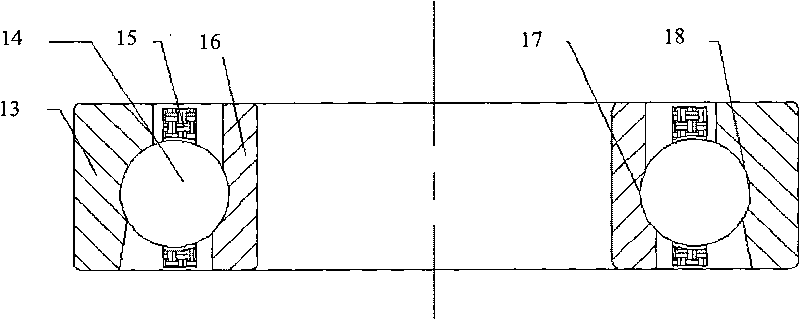

[0013] Such as figure 1 As shown, the inner rings of the first MEMS micropore-reinforced solid film lubricated ceramic bearing 1 and the second MEMS micropore-reinforced solid film lubricated ceramic bearing 3 of the key supporting parts of the shaft system are respectively tightly mounted on the shaft shoulders, and both ends are supported by inner rings. The support sleeve 5 is fixed, and the outer support sleeve 6 preloads the bearing; it is applied to the inner rotor flywheel motor, and the motor rotor is connected to the inner support sleeve 5; it is applied to the outer rotor flywheel motor, and the motor rotor is connected to the outer support sleeve 6. MEMS micro-pump oil storage-oil supply system 2 can accurately control the oil supply volume and oil supply speed through the wedge-shaped micro-oil inlet 9 and micro-valve 11 made by MEMS technology by virtue of the centrifugal force during work. Improve the utilization rate of lubricating oil and increase the lubricati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com