Solid cage and reinforced solid tapered roller bearing

A tapered roller bearing and solid cage technology, applied in the field of bearings, can solve the problems of poor lubrication performance, low bearing capacity, high noise, etc., and achieve the effects of good lubrication performance, high bearing capacity and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Specific embodiments of the present invention are described with reference to the accompanying drawings.

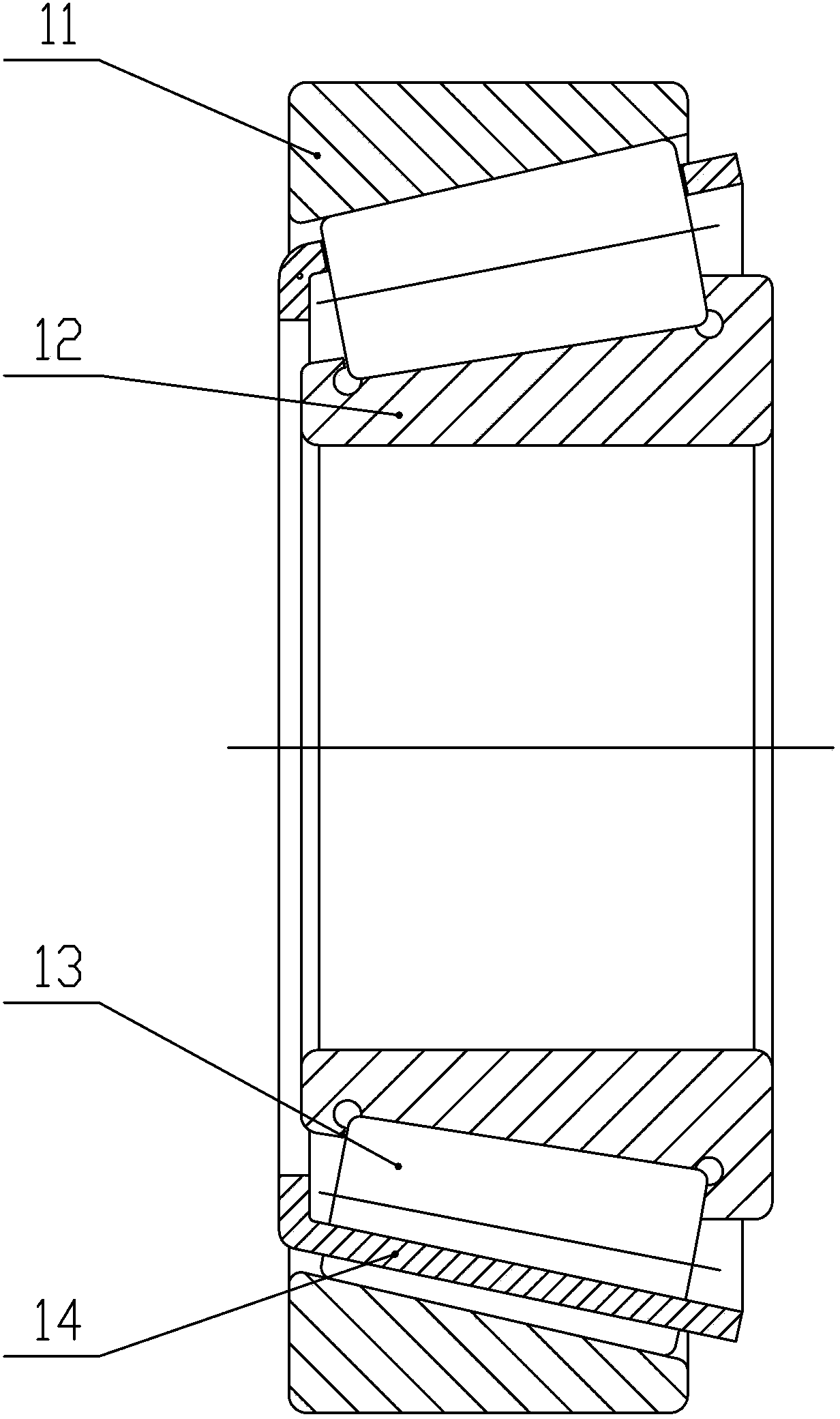

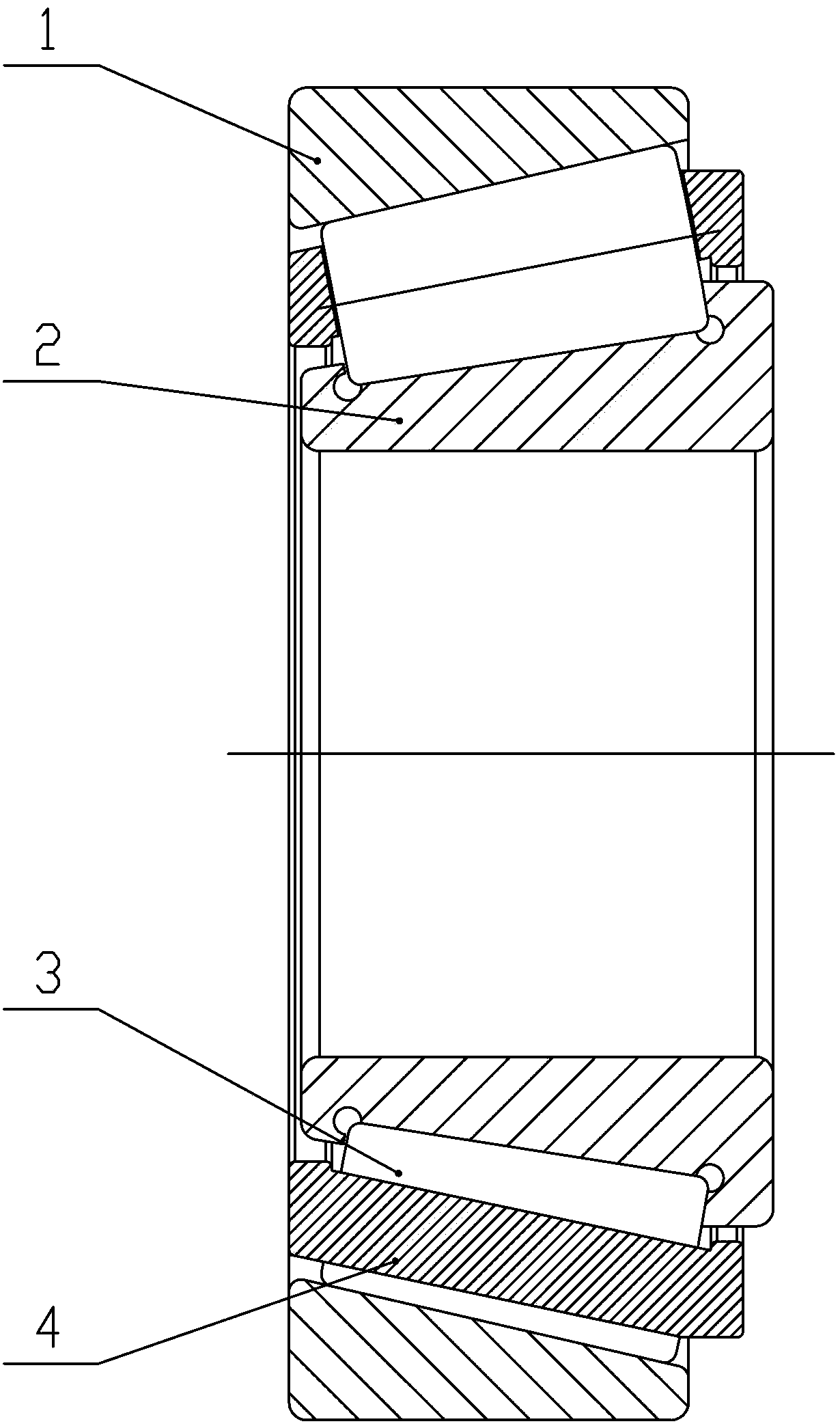

[0019] as attached figure 2 Shown: its part of bearing of the present invention comprises outer ring 1, inner ring 2, tapered roller 3, entity cage 4 four big parts. The outer surface of the inner ring is provided with a U-shaped groove that fits with the tapered rollers. The tapered rollers are loaded into the outer mounting holes of the solid cage and combined with the inner ring to form an inner ring assembly.

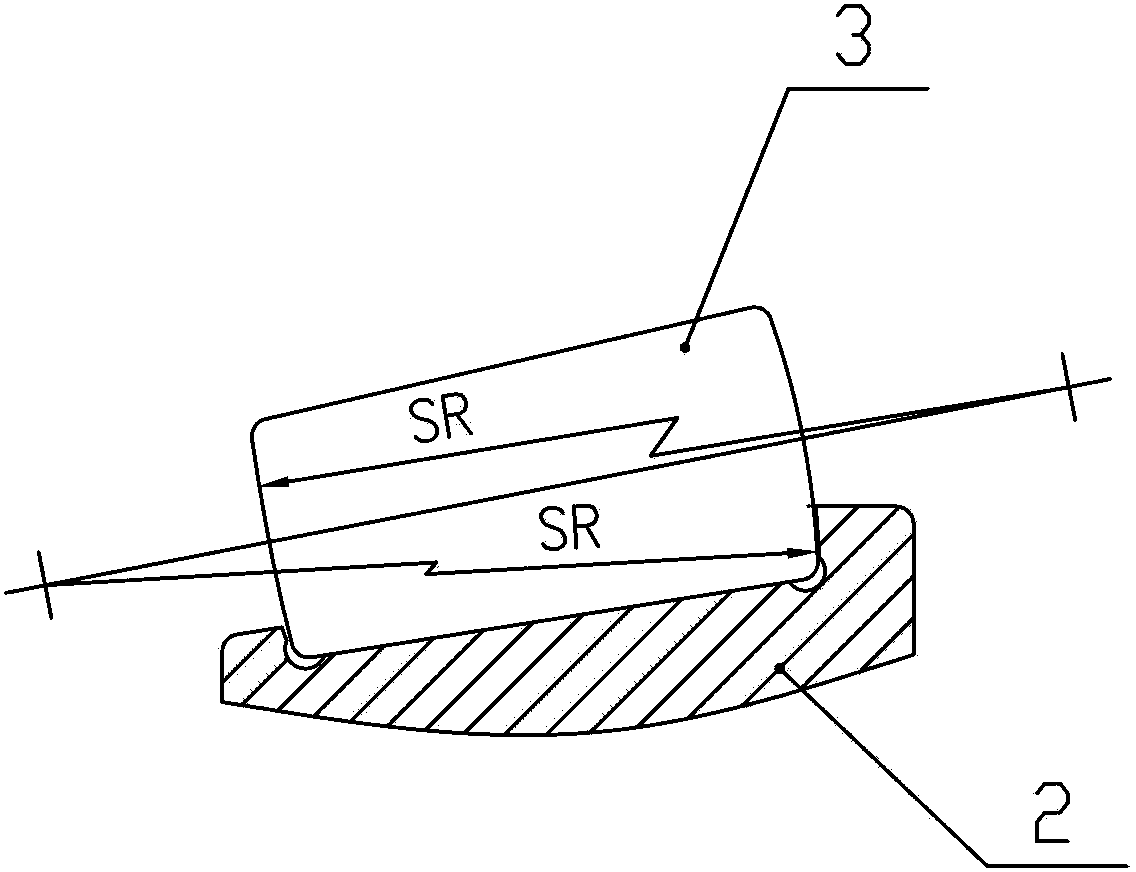

[0020] as attached image 3 As shown: the end faces on both sides of the tapered roller 3 are convex spherical SR design (SR is marked with a spherical body, indicating the radius of the ball), and the end faces of the U-shaped card slot and the square card slot that cooperate with the tapered roller are concave. The spherical SR design optimizes the contact state between the rollers, the inner ring and the cage, significantly reduces the contact stre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com