Chemically reinforced solid-liquid separation method for well drilling waste liquid

A technology for separation of drilling waste fluid and solid-liquid, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problem of difficulty in effectively separating drilling waste fluid, and achieve harmless treatment with reduced difficulty and high-efficiency solid-liquid The effect of separation and difficulty reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The following components are based on the quality of drilling waste fluid 100%;

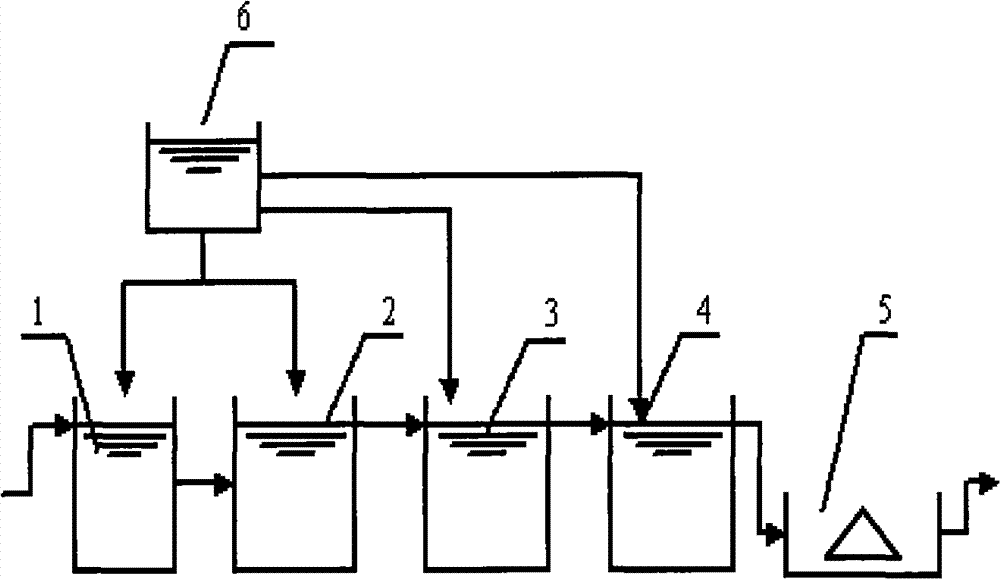

[0025] The buffer adjustment pool 1 handles a liquid-solid mass content of 5%, and a capillary suction time (CST)≤2500s.

[0026] The destabilizing agent formula (mass percentage, the same below) added to the destabilizing reaction tank 2 is 0.3% of nitric acid, 0.4% of polysilicon aluminum chloride and 0.2% of polyferric sulfate.

[0027] The adsorbent formula added to the adsorption reaction pool 3 is 1% quicklime and 0.5% calcium chloride.

[0028] The flocculant formula added to the flocculation reaction tank 4 is 0.015% cationic polyacrylamide.

[0029] The centrifugal factor of the centrifuge 5 is 2000-2200g, the water content of the effluent mud is ≤70%, the solid content of the effluent water is ≤0.5%, and the recovery rate of the solid phase is ≥90%.

[0030] The residence time of the whole process is 21-28 minutes, of which the dilution buffer stage is 3-4 minutes, the destabil...

Embodiment 2

[0032] The following components are based on the quality of drilling waste fluid 100%;

[0033] The buffer regulating pool 1 treats the effluent with a solid content of 10%, and a capillary suction time (CST)≤2500s.

[0034] The destabilizing agent formula (mass percentage, the same below) added to the destabilizing reaction tank 2 is 0.3% of sulfuric acid, 1.0% of polysilicon aluminum chloride and 0.3% of polyferric sulfate.

[0035] The adsorbent formula added to the adsorption reaction pool 3 is 1.5% quicklime and 1% calcium chloride.

[0036] The flocculant formula added to the flocculation reaction tank 4 is 0.015% of anionic polyacrylamide.

[0037] The centrifugal factor of the centrifuge 5 is 2000-2200g, the water content of the effluent mud is ≤70%, the solid content of the effluent water is ≤0.5%, and the recovery rate of the solid phase is ≥90%.

[0038] The residence time of the whole process is 21-28 minutes, of which the dilution buffer stage is 3-4 minutes, th...

Embodiment 3

[0040] The following components are based on the quality of drilling waste fluid 100%;

[0041] The solid content of the effluent treated by the buffer regulating tank 1 is 7%, and the capillary suction time (CST) is ≤2500s.

[0042] The destabilizing agent formula (mass percentage, the same below) added to the destabilizing reaction tank 2 is 0.5% nitric acid, 0.6% polysilicon aluminum chloride and 0.3% polyferric sulfate.

[0043] The adsorbent formula added to the adsorption reaction pool 3 is 1% quicklime and 0.8% calcium chloride.

[0044] The flocculant formula added to the flocculation reaction tank 4 is 0.005% amphoteric polyacrylamide.

[0045] The centrifugal factor of the centrifuge 5 is 2000-2200g, the water content of the effluent mud is ≤70%, the solid content of the effluent water is ≤0.5%, and the recovery rate of the solid phase is ≥90%.

[0046] The residence time of the whole process is 21-28 minutes, of which the dilution buffer stage is 3-4 minutes, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com