Double-surface ceramic plate polisher

A ceramic chip and polishing machine technology, which is applied to surface polishing machine tools, grinding/polishing equipment, grinding racks, etc., can solve the problems of finger injuries, waste, and difficult handling of experimental operators, and achieve small batches, Small size, easy to carry effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation of the invention will be further described below in conjunction with the accompanying drawings.

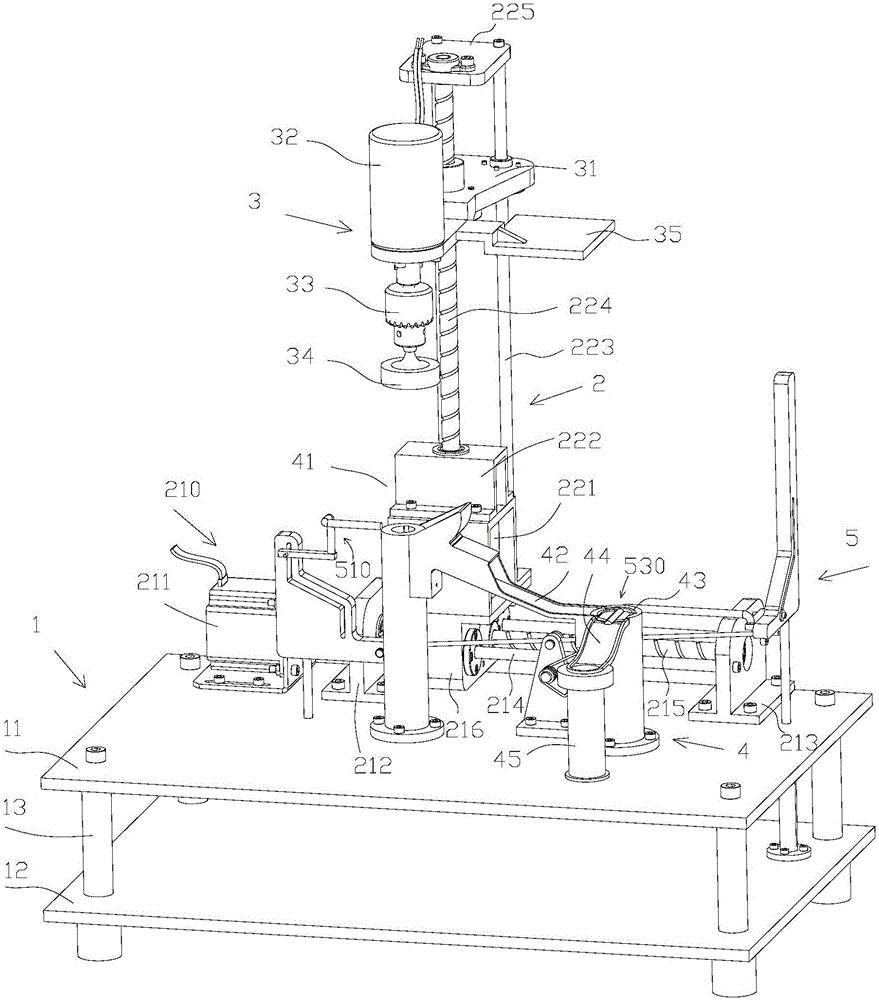

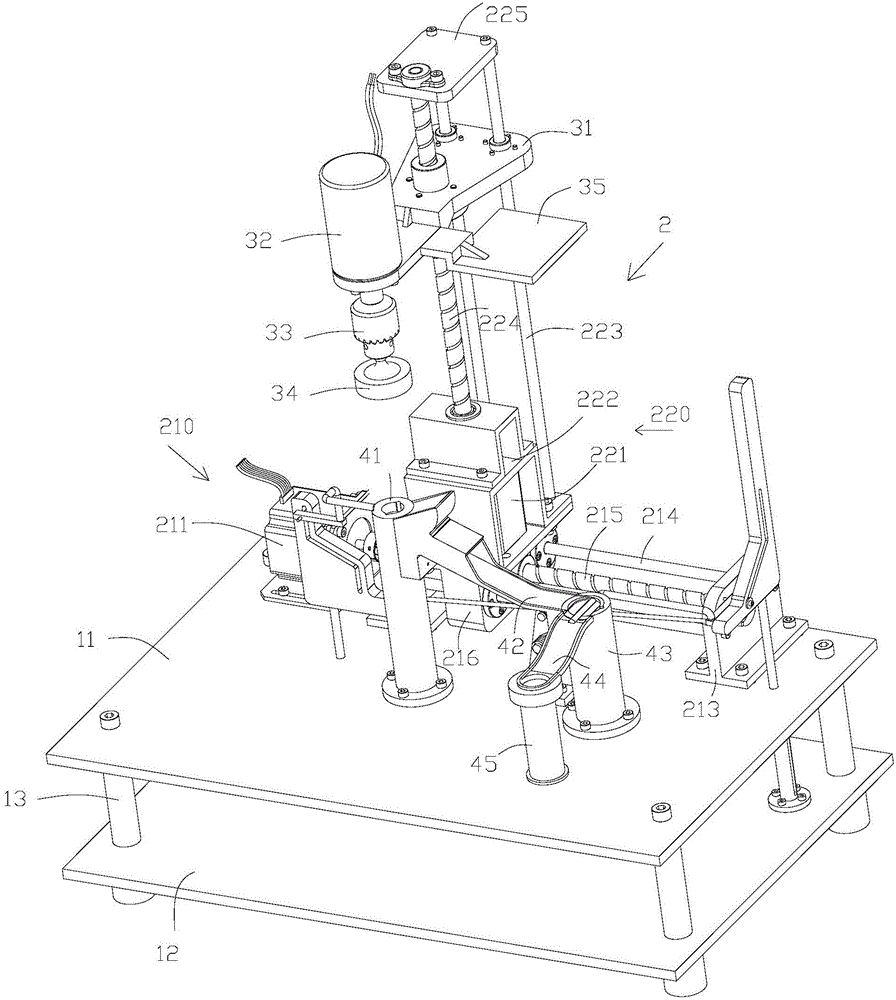

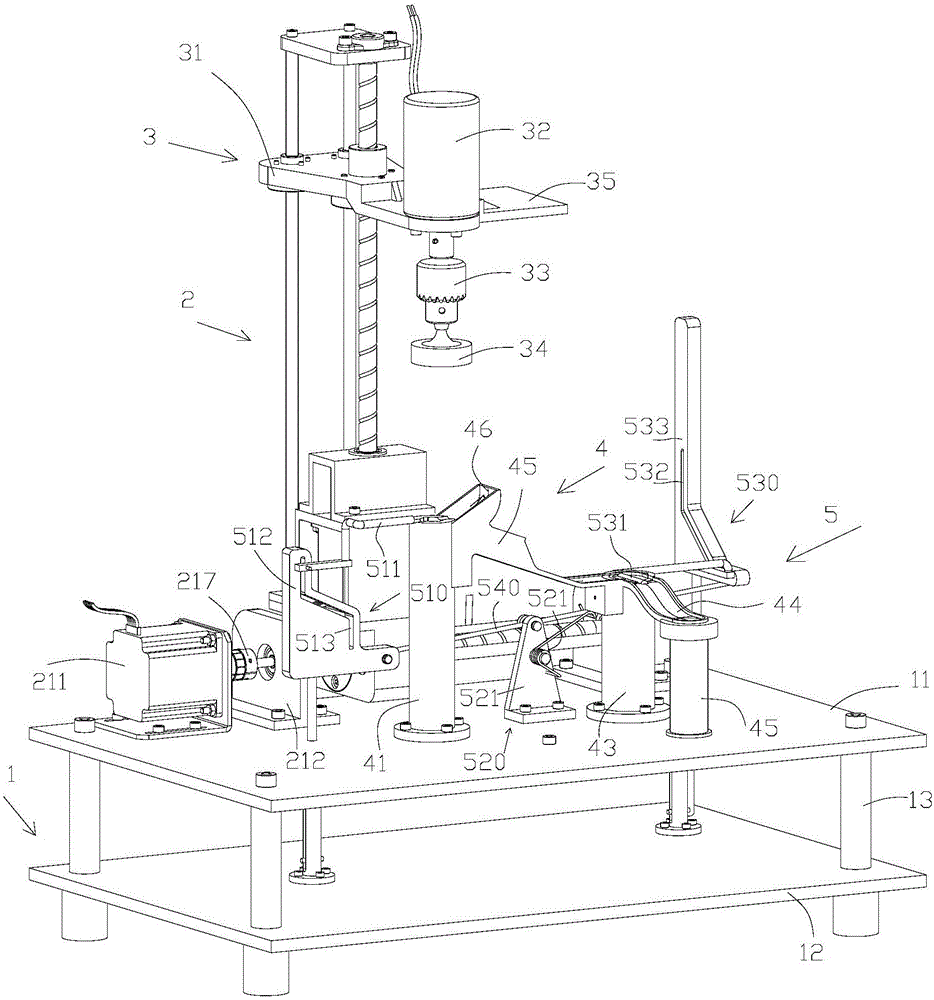

[0034] Such as Figure 1-5 As shown, a preferred embodiment is disclosed. The double-sided ceramic wafer polishing machine includes a base 1, a mobile platform 2 installed on the upper end surface of the base 1, a polishing assembly 3 installed on the mobile platform 2, and a workpiece placement table assembly installed on the upper end surface of the base 1 and corresponding to the polishing assembly 3 4 and the controller. The mobile platform 2 includes a first mobile mechanism 210 for lateral movement, and a second mobile mechanism 220 mounted on the first mobile mechanism 210 for longitudinal movement, and the second mobile mechanism 220 is driven by the first mobile mechanism 210 to move laterally. The polishing assembly 3 includes a lifting platform 31 installed on the second moving mechanism 220 and driven by the second moving mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com