Wax-changing device of polishing machine

A polishing machine and power device technology, which is applied in the direction of grinding/polishing safety devices, surface polishing machine tools, grinding/polishing equipment, etc., can solve the problems of unsafe manual operation and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

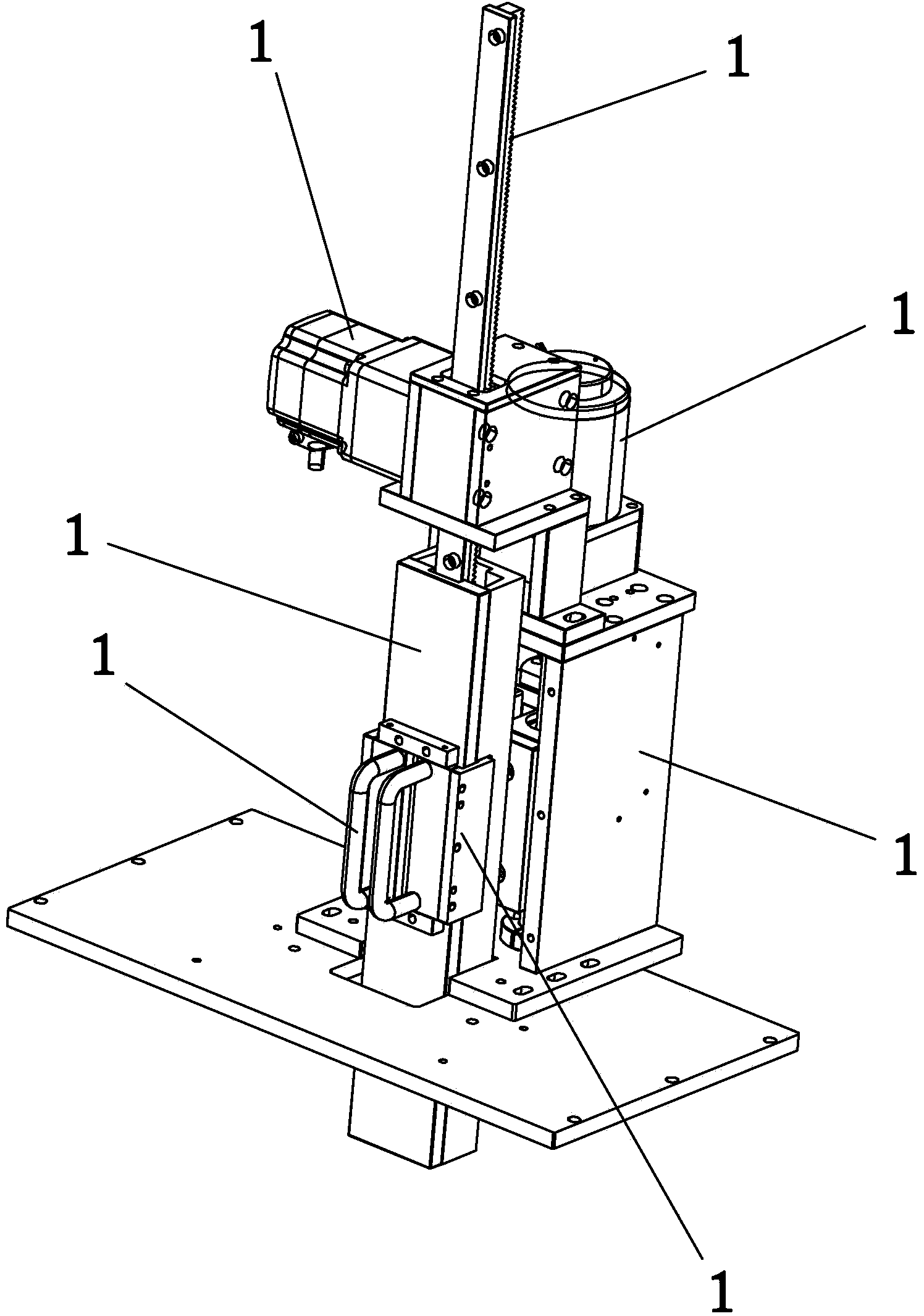

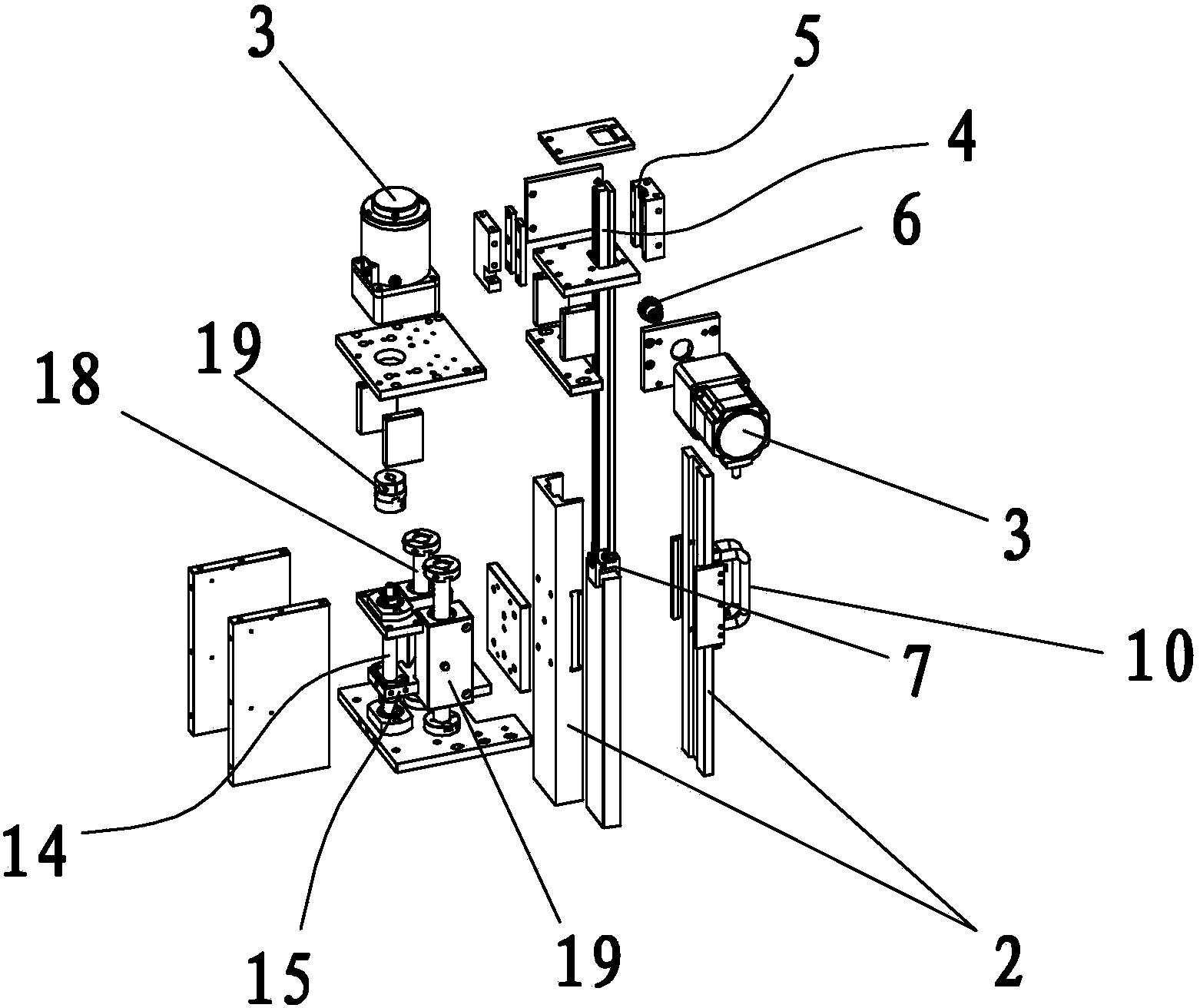

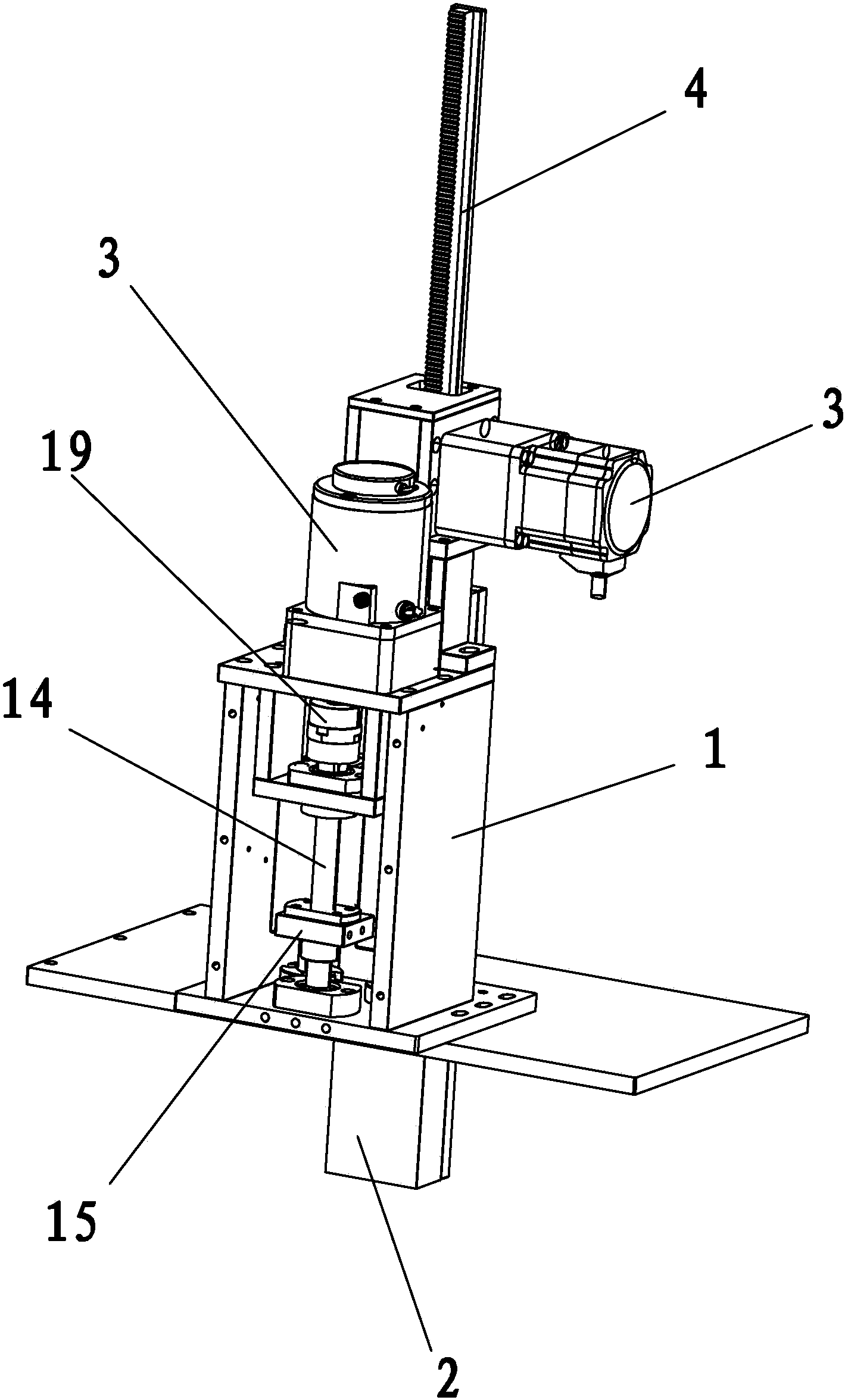

[0026] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 Shown, the wax changing device of polishing machine of the present invention, it comprises the support 1 that is used to support various parts, is used for pushing the pushing device that wax strip moves and rubs with cloth wheel, is used to maintain the stable stabilizer 2 of wax strip and uses To respectively drive the driving device and the power device that cooperates with the stabilizer 2, the above-mentioned components are all assembled and fixed by the bracket 1. Wherein, the stable frame 2 is composed of an upper cover plate and a lower cover plate, and a slide hole 2.3 for accommodating wax strips is provided between the two cover plates, and an opening and closing plate is provided between the two cover plates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com