Rectangular glass segmented polishing method

A glass and rectangular technology, which is applied in the field of segmented polishing of rectangular glass, can solve problems such as uneven edge removal and irregular glass corners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

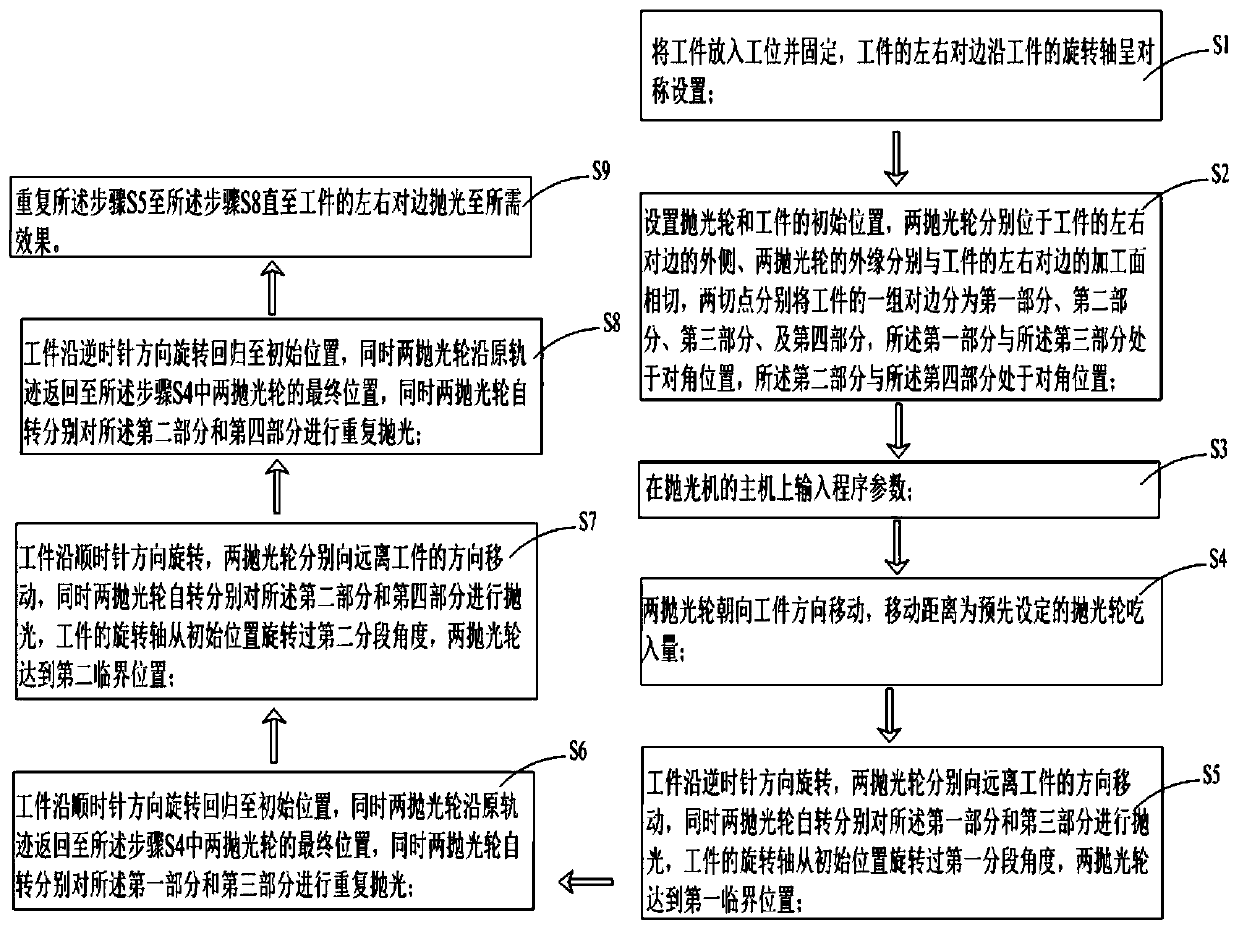

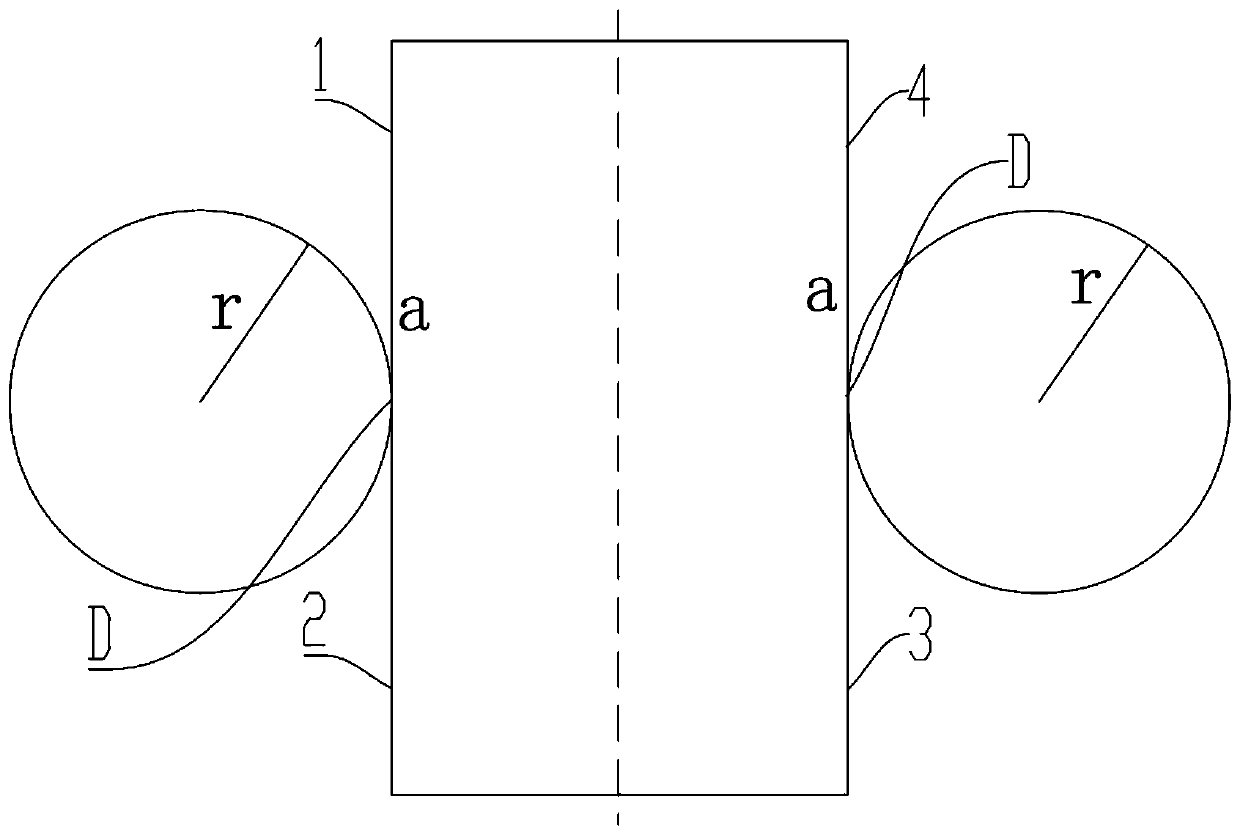

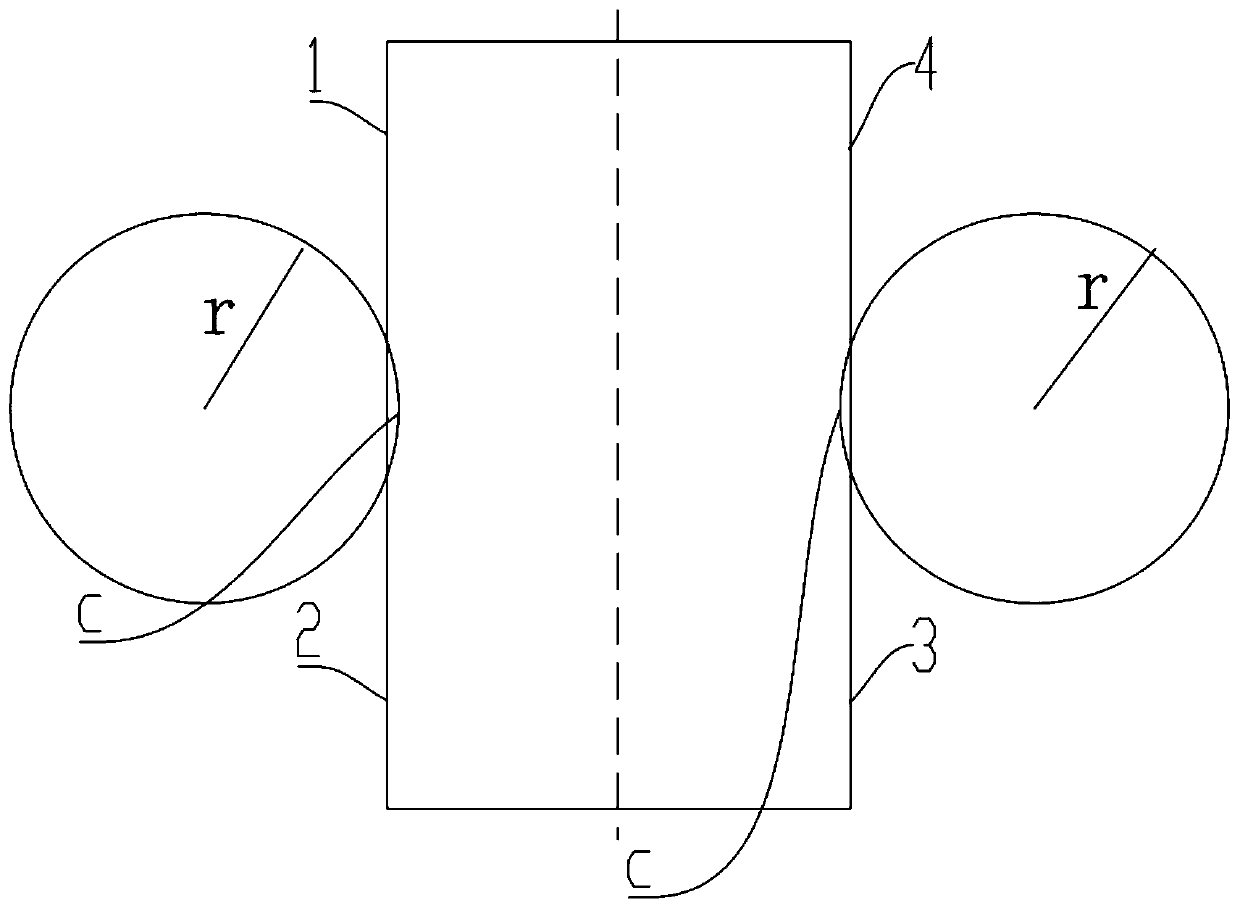

[0032] see Figure 1 to Figure 5 , The present invention provides a segmental polishing method for rectangular glass. The rectangular glass includes two sets of opposite sides, upper and lower, and left and right. When polishing, the upper, lower, and left and right pairs of sides are polished separately. The polishing principles of the two groups of sides are the same, and the polishing process of the left and right sides includes the following steps:

[0033] Step S1. Put the workpiece into the station and fix it. The left and right sides of the workpiece are arranged symmetrically along the rotation axis of the workpiece. Several workpieces are stacked in the same direction and put into the station, multiple workpieces can be polished at the same time, which improves the polishing efficiency. Specifically, in this embodiment, a cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com