Rapid gasket pressing device and application method thereof

A fast, shim technology, used in grinding machines, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of inability to meet processing needs, intensified competition, and inconvenience for users, achieving excellent polishing results and shortening work. The effect of time and long use cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with accompanying drawing description and specific embodiment:

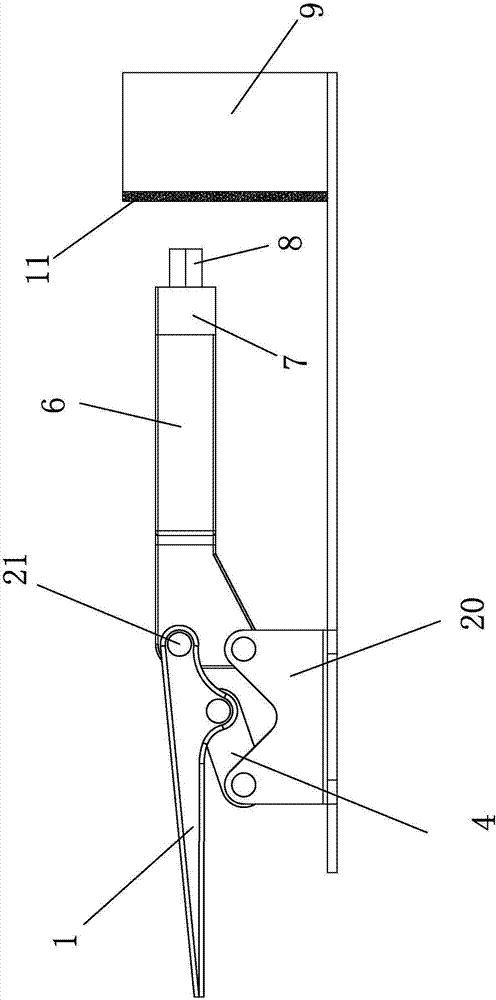

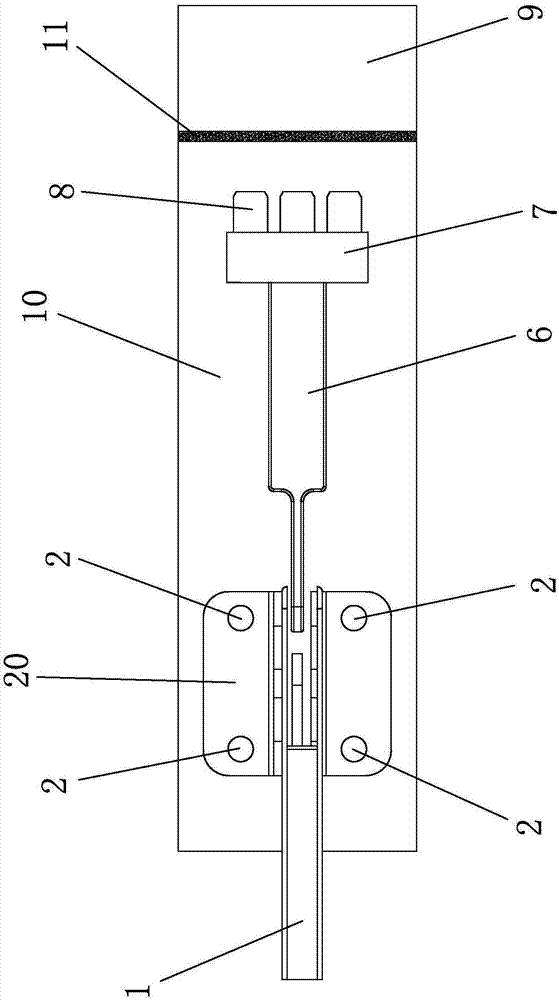

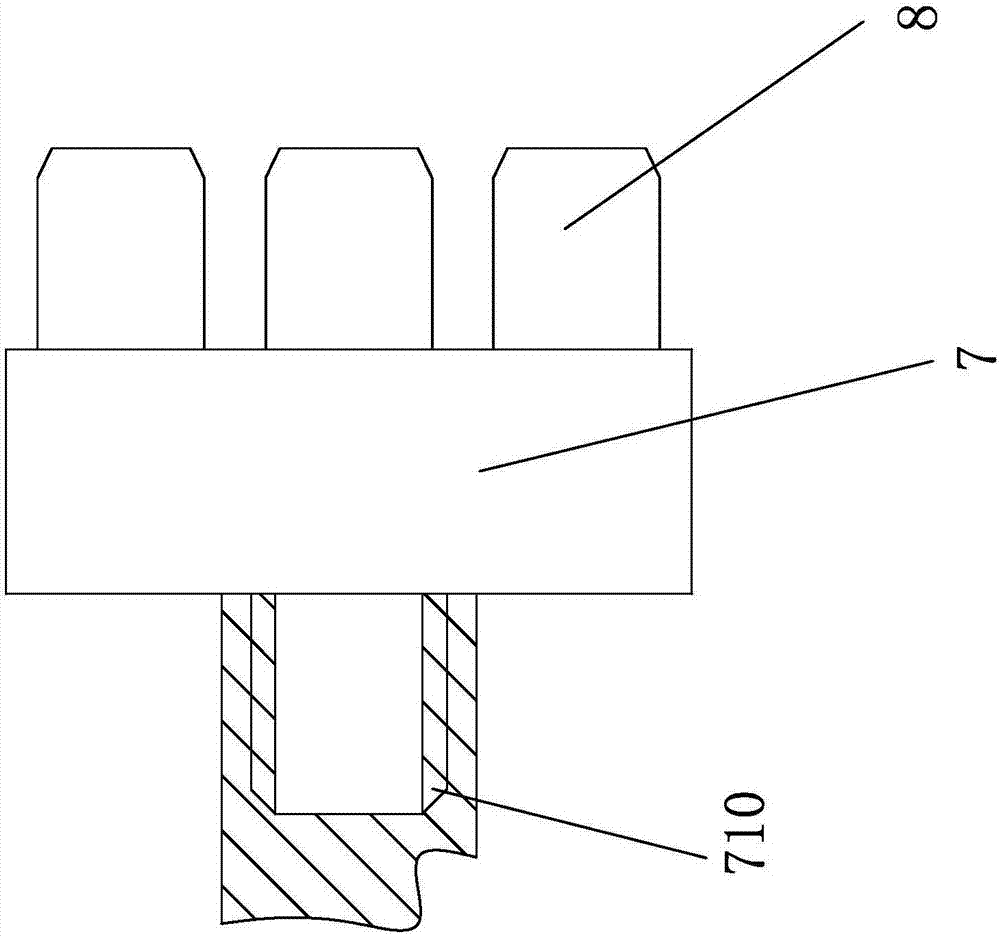

[0038] Such as Figures 1 to 2 As shown, a gasket rapid pressing device includes a fixed base plate 10, an elastic base 9 for placing the pressed gasket 11 is provided at one end of the fixed base plate 10, and a mounting plate 9 is provided at the other end of the fixed base plate 10. Seat 20, on the mounting seat 20 is hinged with quick positioning main rod 6, is provided with pressing head 8 at the front end of described quick positioning main rod 6, is hinged at described quick positioning main rod 6 rear end and can drive quick positioning main rod The pressing head 8 on the rod 6 moves toward the elastic base 9 to press the handle 1 horizontally, and the horizontal pressing handle 1 is hinged on the mounting base 20 .

[0039] The quick-pressing device for gaskets in the present invention is characterized in that a connecting block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com