Circulating myotonin polishing device and operating method

The technology of a polishing device and operation method, which is applied in grain finishing, grain processing, application, etc., can solve the problems of impracticality, high production cost, limited space and location, etc., and achieves a product with strong practicability, simple structure, and convenient transformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and specific embodiment the invention is further introduced:

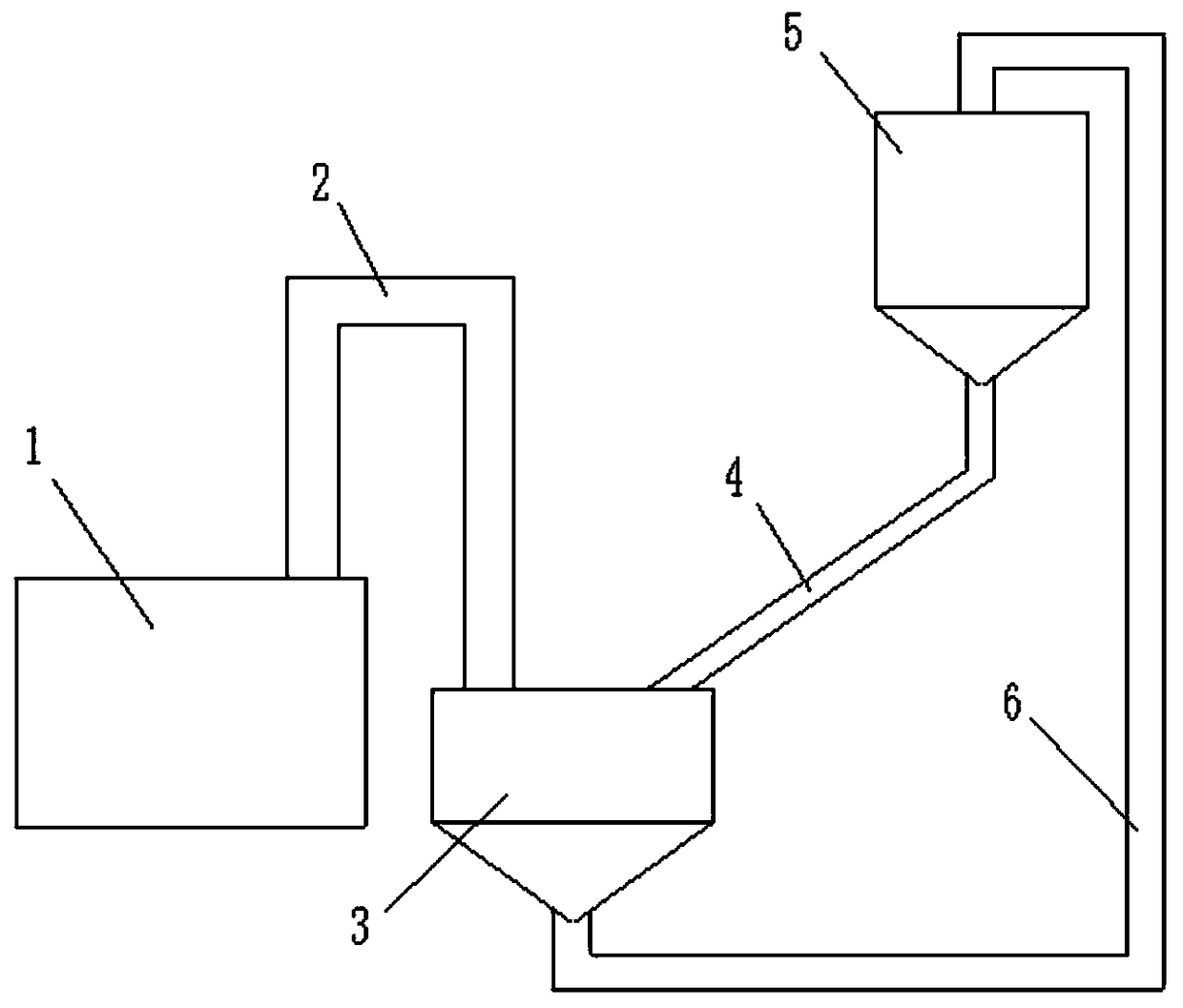

[0012] refer to figure 1 , a kind of coix seed circular polishing device of the present invention, comprises the storage warehouse 1 that is used for storing finished job's tears rice, and the polishing machine 5 that is used for polishing the job's tears rice, is provided with a transit bin between the polishing machine 5 and the storage bin 1 3, wherein the discharge port of the polishing machine 5 is connected to the transfer bin 3 through the discharge pipe 4, the transfer bin 3 is connected to the storage bin 1 through the first hoist 2, and the transfer bin 3 is also connected to the polishing machine 5 through the second hoist 6 The feed port is connected, the bottom of the transfer bin 3 is funnel-shaped, and the feed port of the second hoist 6 is set at the bottom of the transfer bin 3, so as to avoid the problem that part of the barley rice cannot be p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com