Intelligent polishing equipment for building and polishing method

An architectural and intelligent technology, applied in grinding/polishing equipment, metal processing equipment, machine tools for surface polishing, etc., can solve the problems of poor applicability of polishing equipment, and the polishing efficiency needs to be further improved, and achieve simple structure, easy operation, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

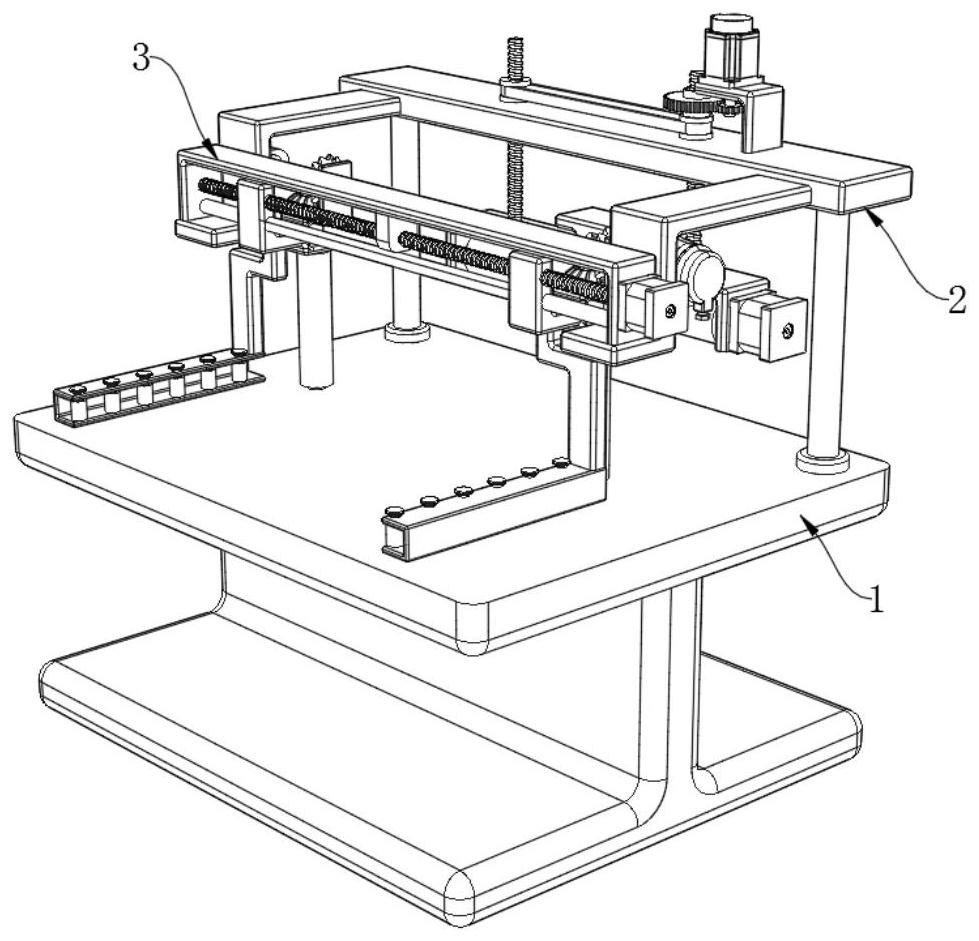

[0043] see figure 1 , figure 2 As shown, a kind of intelligent polishing equipment for construction in this embodiment includes a support platform 1, and an adjustable processing mechanism is arranged on the top of the support platform 1. The adjustable processing mechanism is used to adapt to the processing of materials of different sizes. The support platform 1 The bottom end of the bottom is fixedly connected with an auxiliary support plate, and the auxiliary support plate is used to improve the stability of the support platform 1. At the same time, in order to ensure the stability of the auxiliary support plate, the bottom end of the auxiliary support plate is provided with anti-skid lines.

[0044] The above-mentioned adjustable processing mechanism includes a top surface polishing mechanism 2 and a side surface polishing mechanism 3. One side of the top surface polishing mechanism 2 is provided with a side surface polishing mechanism 3. The top surface polishing mechan...

Embodiment 2

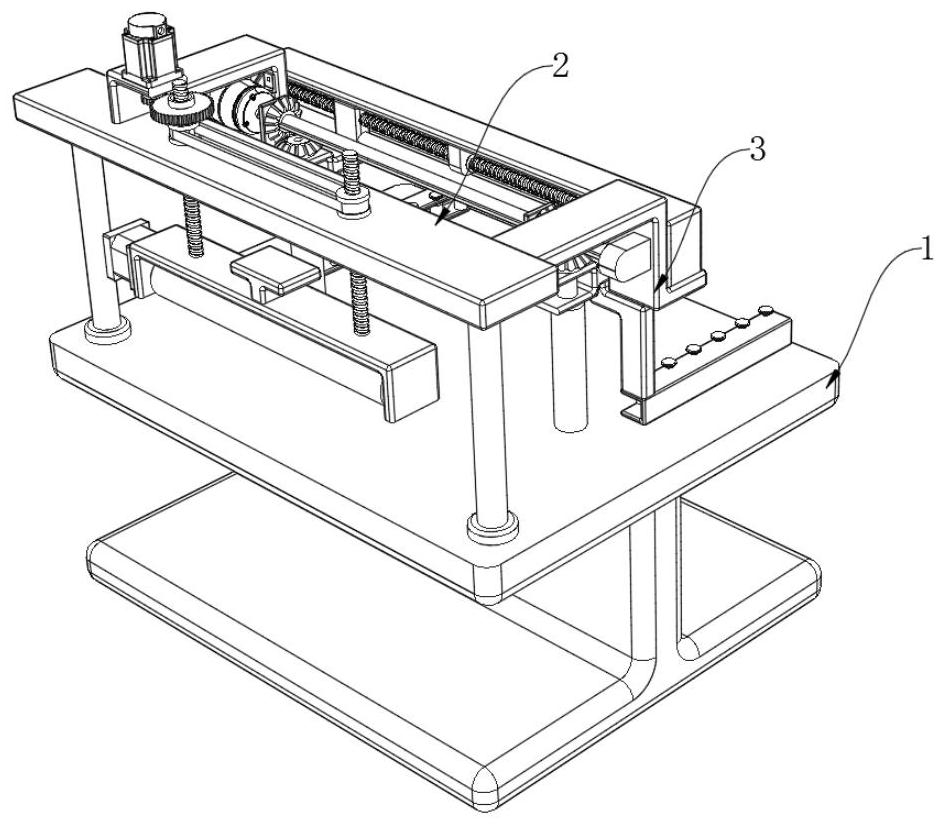

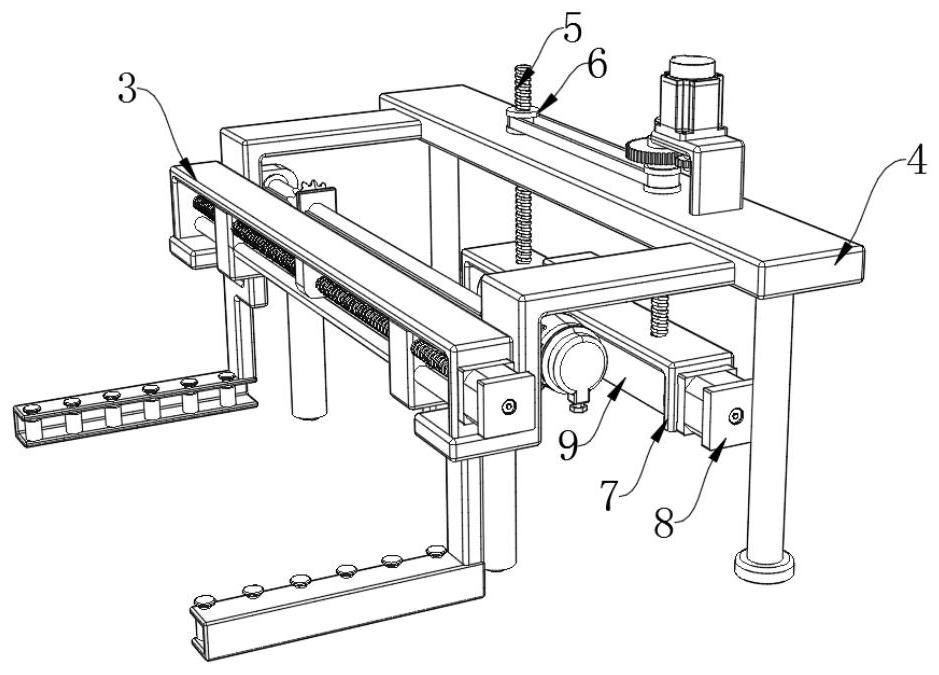

[0046] A kind of building intelligent polishing equipment of this embodiment, its structure is basically the same as embodiment 1, further, refer to Figure 3-Figure 6 As shown, the top surface polishing mechanism 2 of the present embodiment includes a carrying frame 4, a top surface polishing roller 9, a height adjustment unit and a top surface polishing drive unit 8, wherein the carrying frame 4 is fixedly installed on the support table 1, and the top surface polishing roller 9 is movably installed under the carrier frame 4 through the height adjustment unit, and the top surface polishing drive unit 8 is used to drive the top surface polishing roller 9 to rotate. Specifically, the height adjustment driving unit includes two adjusting screws 5 installed on the carrying frame 4, the bottom ends of the adjusting screws 5 pass through the carrying frame 4 and are rotatably connected with the assembly frame 7, and the top surface polishing roller 9 is rotatably installed Inside t...

Embodiment 3

[0049] An intelligent polishing device for construction in this embodiment, its structure is basically the same as that of Embodiment 1, further, the side polishing mechanism 3 includes two mounting frames 21, and a side polishing roller 23 rotatably mounted on the bottom of the mounting frame 21 And a side polishing driving unit and a distance adjusting unit 24, wherein the side polishing driving unit is used to drive the side polishing roller 23 to rotate, and the distance regulating unit 24 is used to adjust the distance between two side polishing rollers 23.

[0050] refer to Figure 7-Figure 9 , the side polishing driving unit of the present embodiment includes extension frame 16, side polishing driving motor 17, conduction rod 18, matching guide plate 19, driving bevel gear 20 and driven bevel gear 22, and the two ends on one side of carrying frame 4 are all fixed An extension frame 16 is connected, and one side of the extension frame 16 close to the carrying frame 4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com