Non-contact polishing device

A polishing device, non-contact technology, applied in grinding drive devices, surface polishing machine tools, grinding/polishing equipment, etc., can solve problems such as poor polishing quality, achieve high precision, reduce surface ripples, and satisfy processing requirements The effect of the condition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

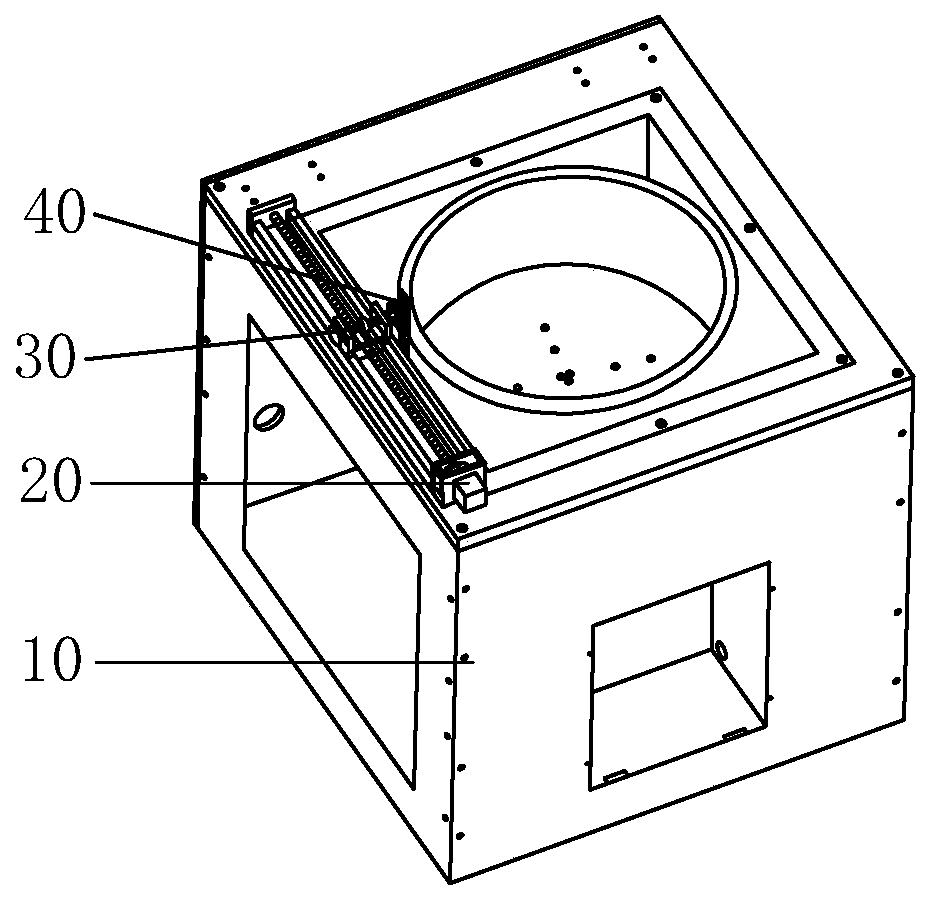

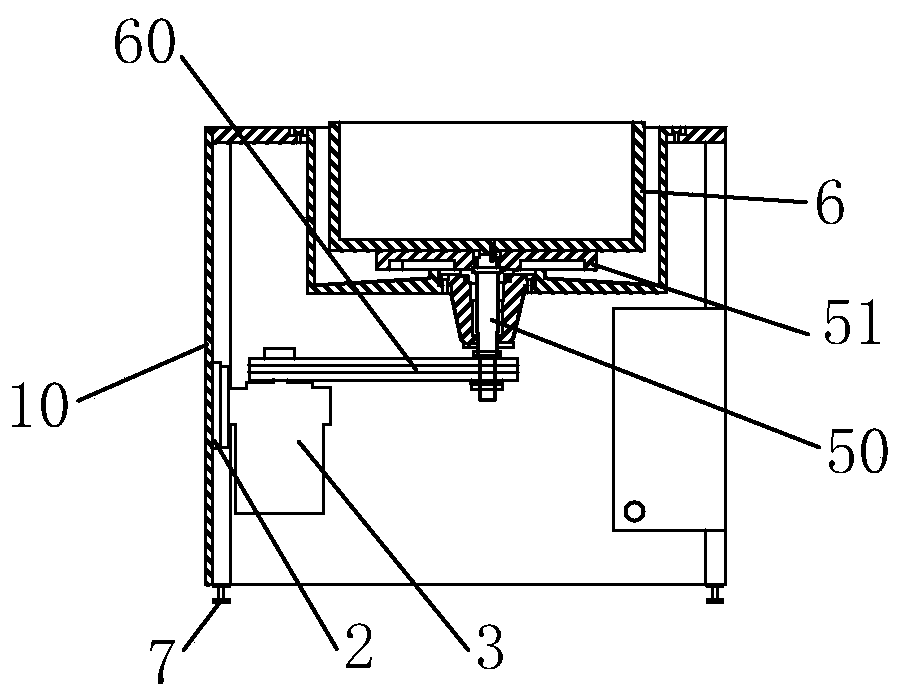

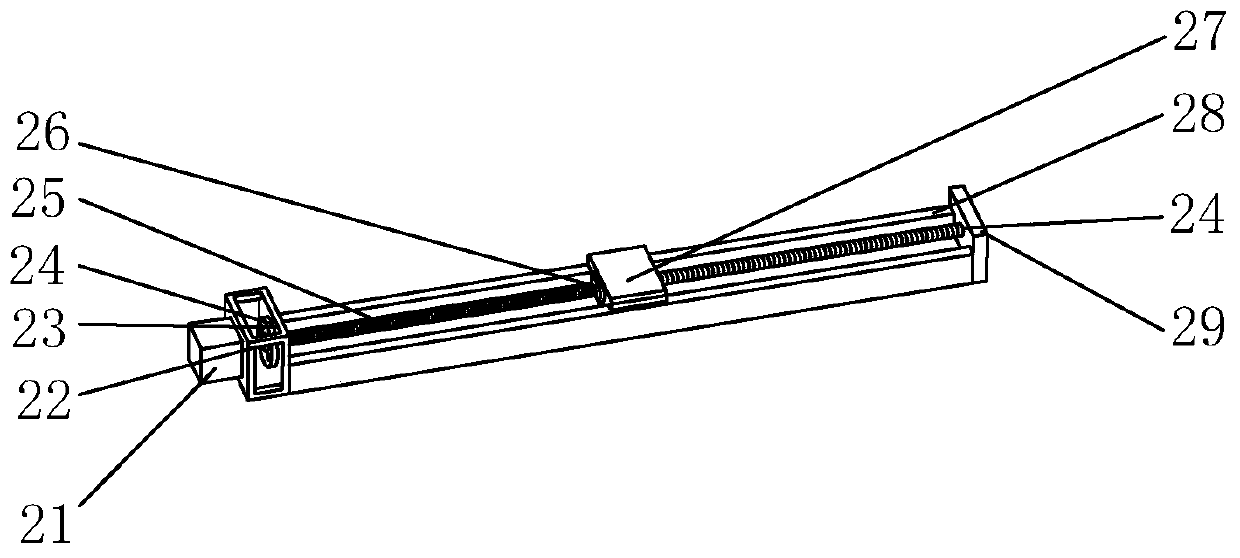

[0023] Example: such as Figure 1 to Figure 6 As shown, the non-contact polishing device mainly includes a machine base 10, and also includes a motor 3, a motor plate 2, a spindle system 50, a polishing roller 6, a linear reciprocating feeding mechanism 20, a longitudinal fine-tuning mechanism 30 and a vertical lifting mechanism 40, The motor plate 2 is fixedly installed on the machine base 10, the motor 3 is installed on the motor plate 2, the main shaft system 50 is installed on the machine base 10 and is driven by the motor 3 through a pulley drive, and the polishing roller 6 is installed on the rollers in the main shaft system 50 On the bracket 51, the rubber sleeve 4 with grooves of different structures on the surface can be placed on the polishing roller 6 as required, without the need to manufacture a large number of polishing rollers 6 with different structures, which reduces the cost and shortens the time required for replacing the polishing roller 6. time, greatly im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com