Patents

Literature

75results about How to "Meet the process conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Material and method for preparing insertion laminated material

InactiveCN1497007AEasy to produceEasy to control sizeCosmetic preparationsLayered productsEmulsion polymerizationSolvent

Provided is an image forming element having improved mechanical strength and other physical characteristics, and comprising a flexible thermoplastic base. A sprayed material comprises a sprayed layered material with particles having a diameter of <=3 [mu]m. A practicing embodiment includes an article comprising a matrix and the sprayed layered material with a polymer particle dispersed in a medium. A producing method of these materials comprises mixing and grinding particles, and emulsifying the polymer supported in a solvent with a surfactant. As an alternative method, a producing method of a nanocomposite material comprising forming spraying agent particles by incorporating a non-dispersible emulsion polymerization monomer in a medium with a dispersible surfactant in the medium, and then producing the nanocomposite material therefrom, is disclosed.

Owner:EASTMAN KODAK CO

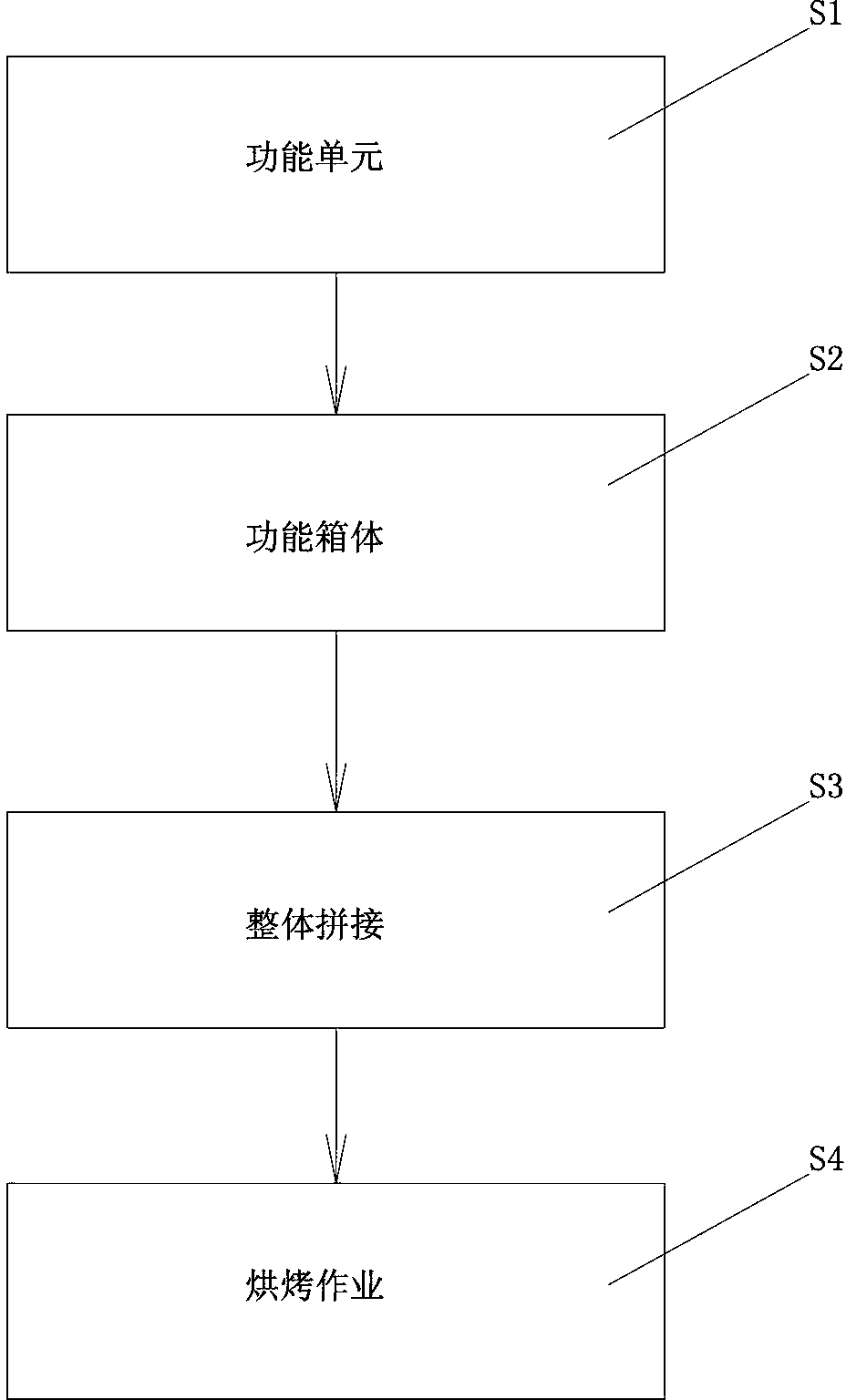

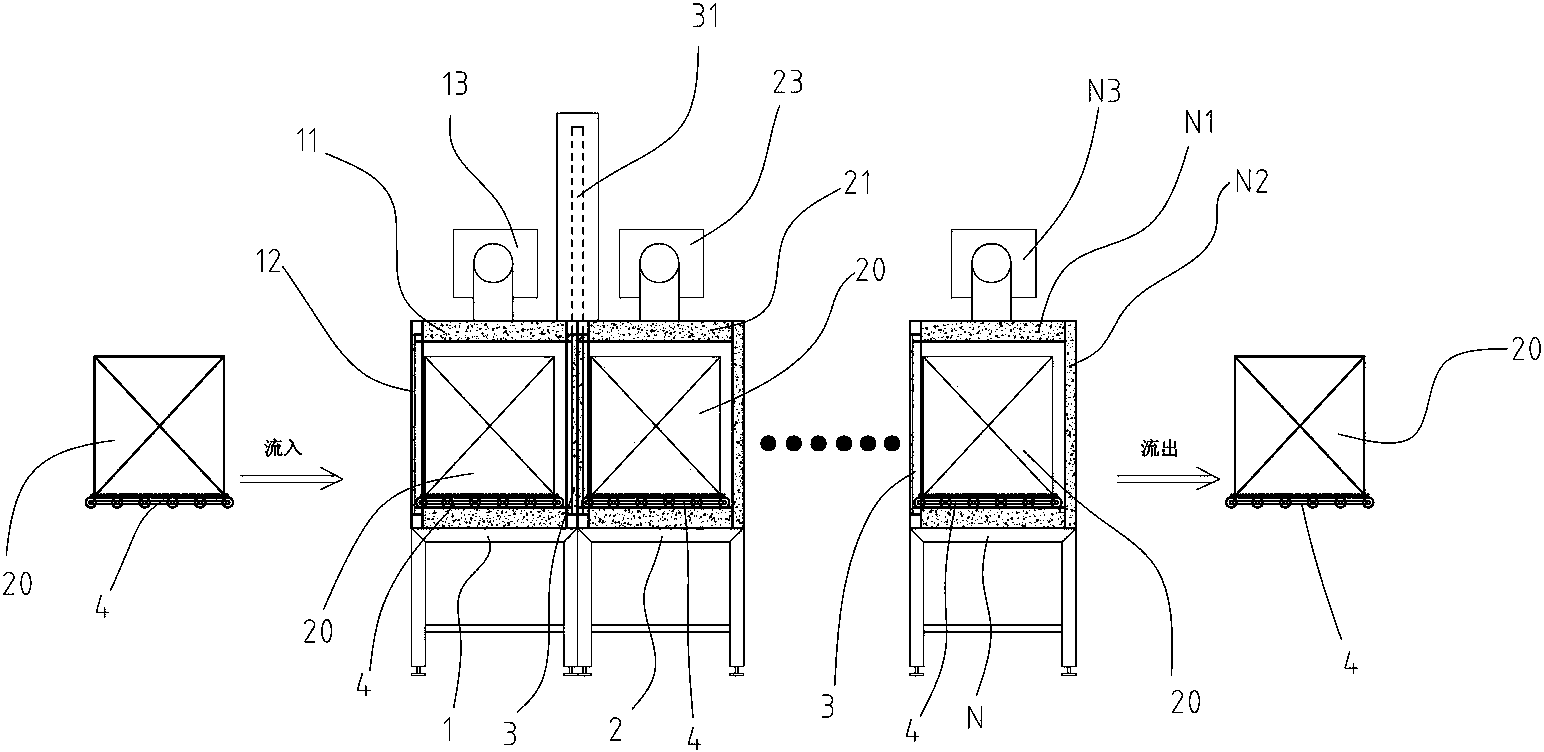

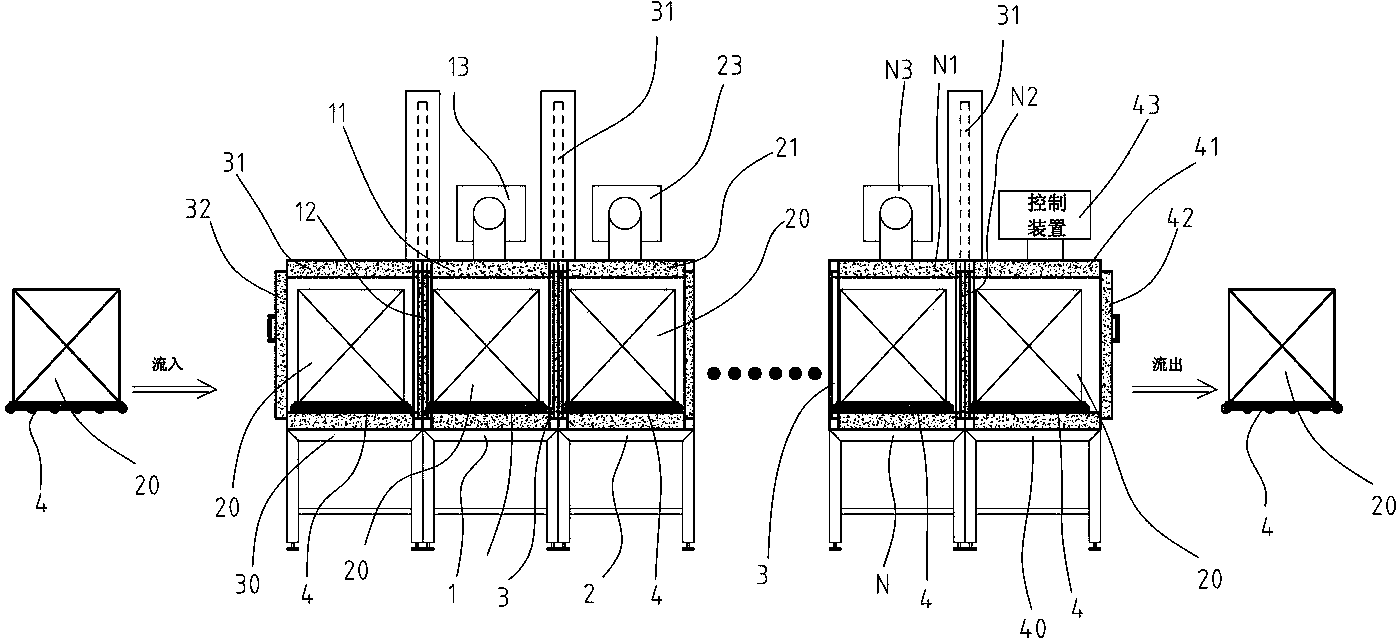

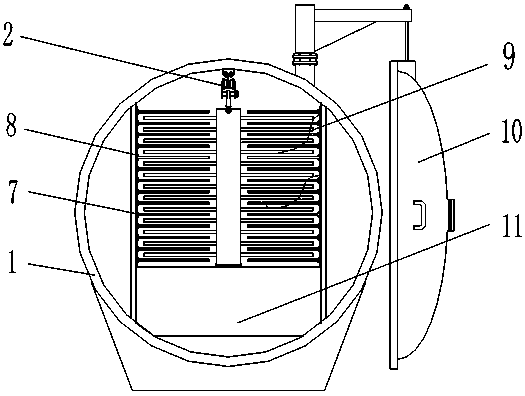

Full-automatic combining module new energy material vacuum baking method and vacuum baking line

ActiveCN103398558AReduce labor intensityShorten the timeCell electrodesDrying chambers/containersProduction lineThermodynamics

Owner:SHENZHEN XINYUREN TECH

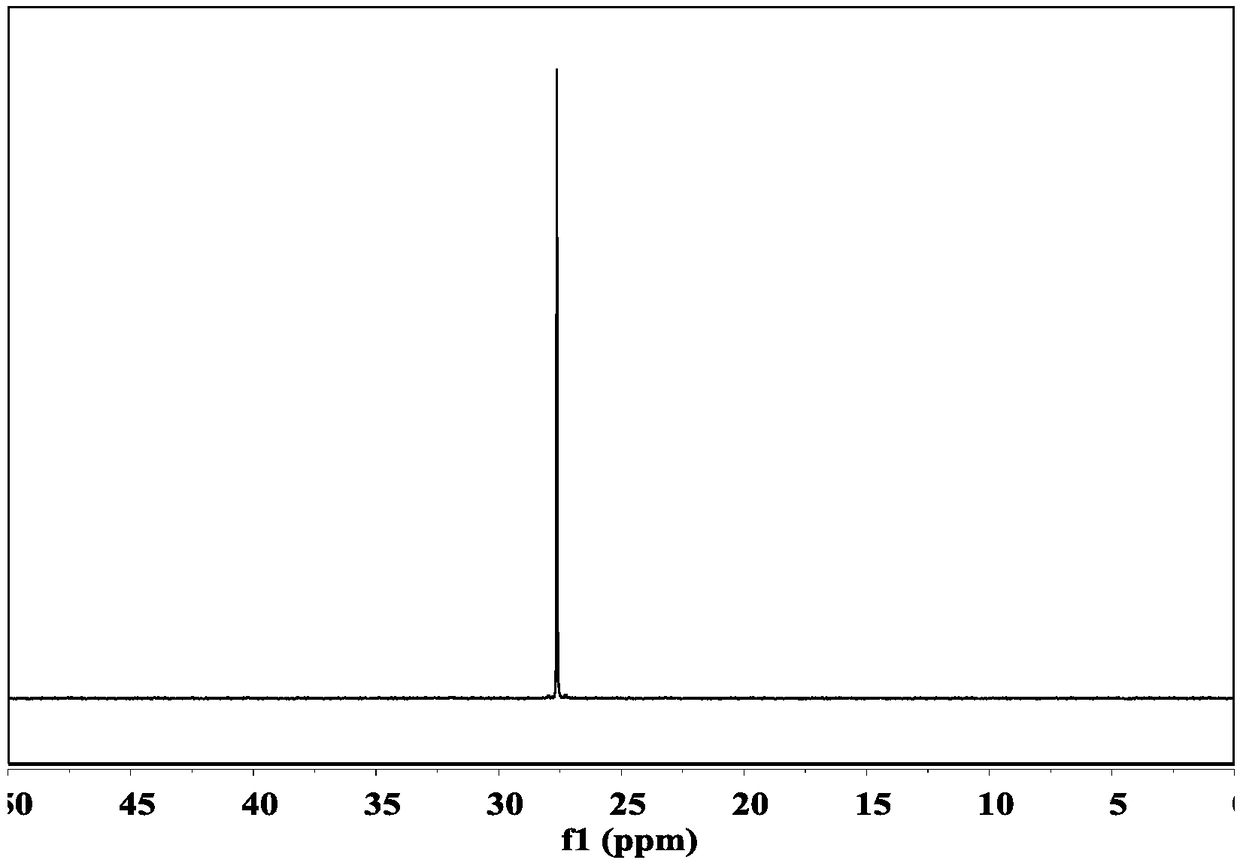

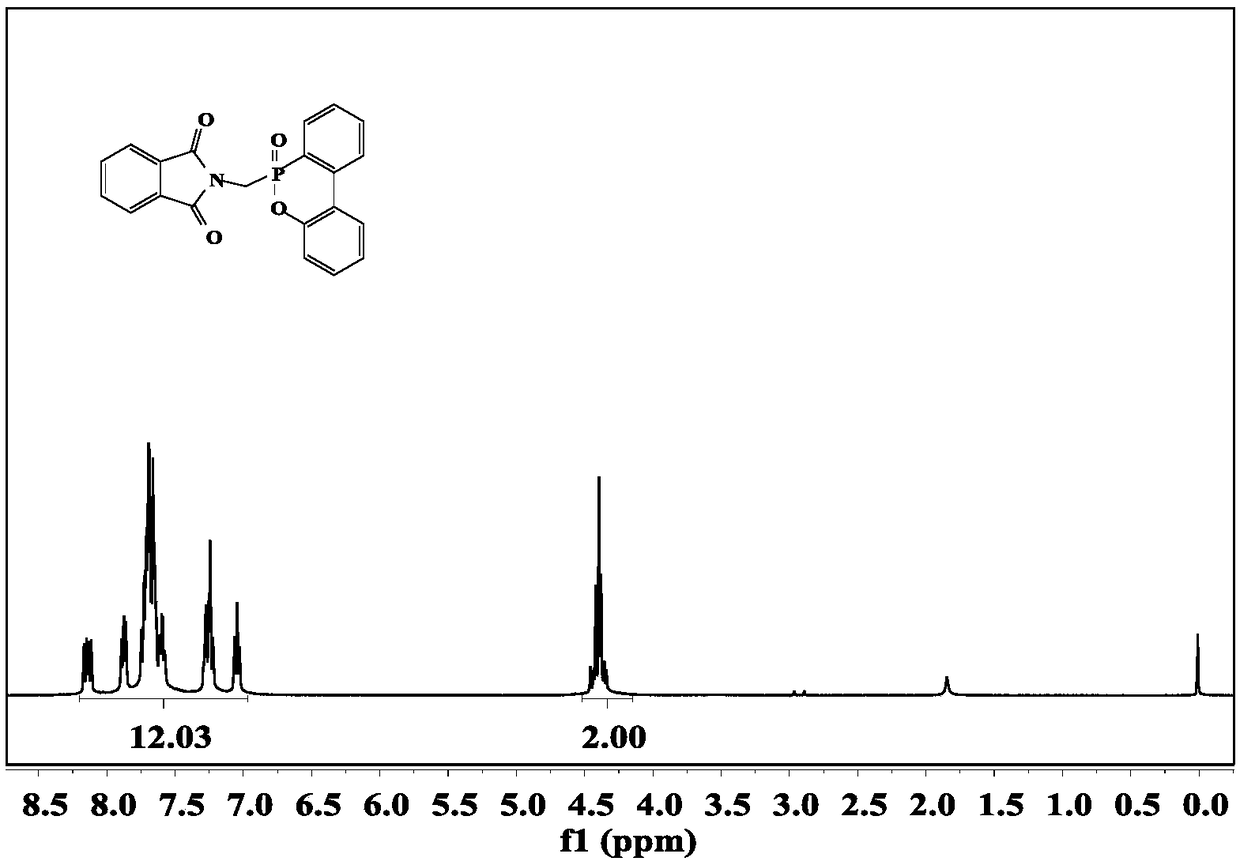

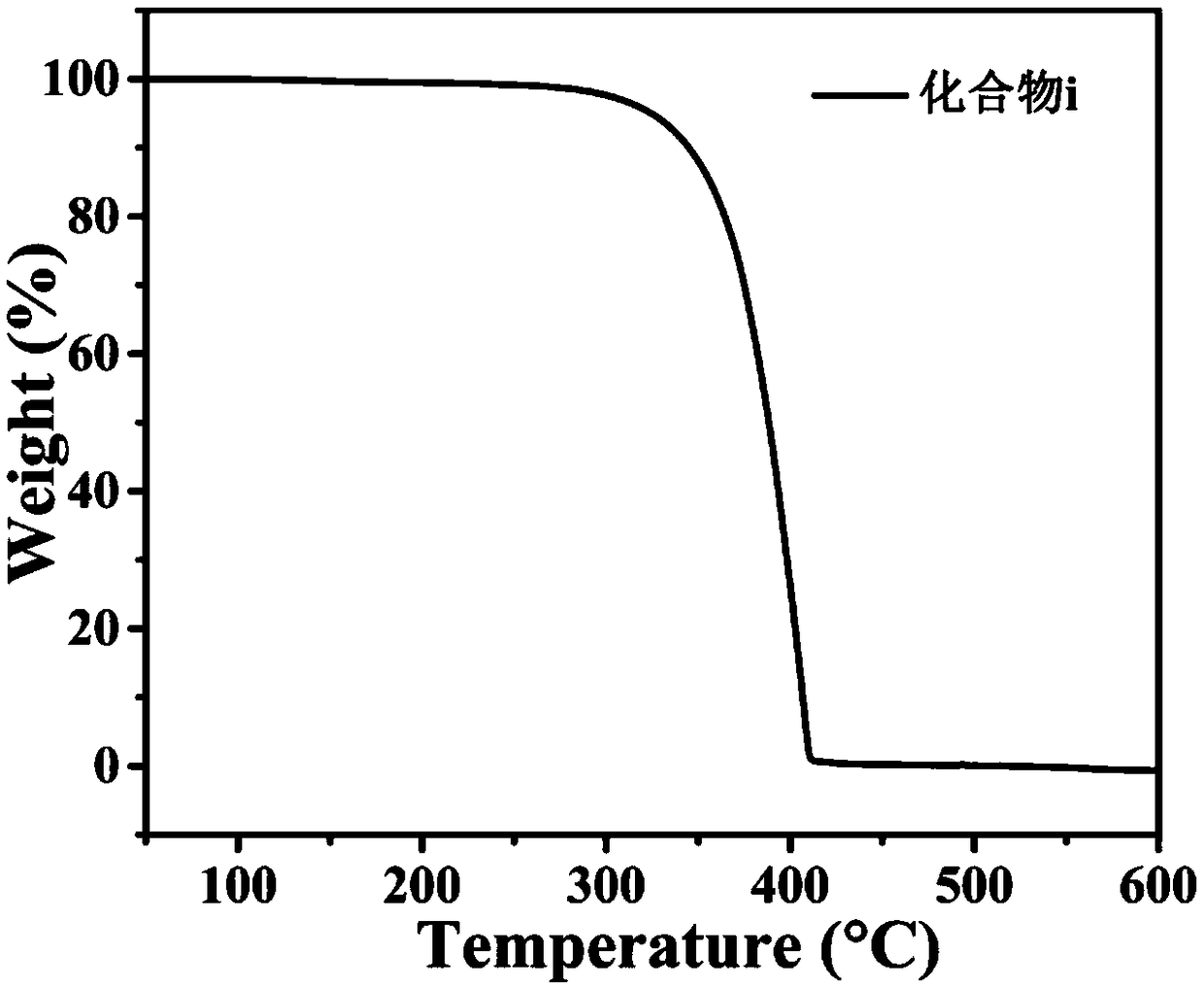

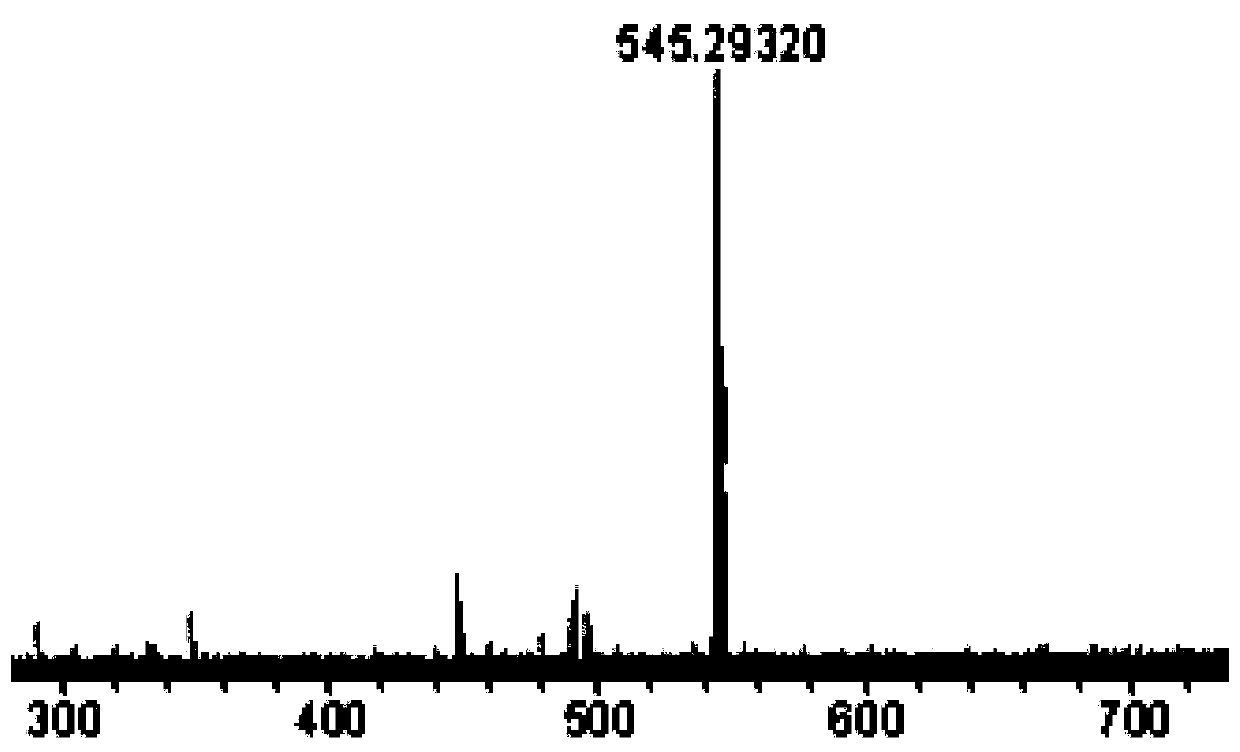

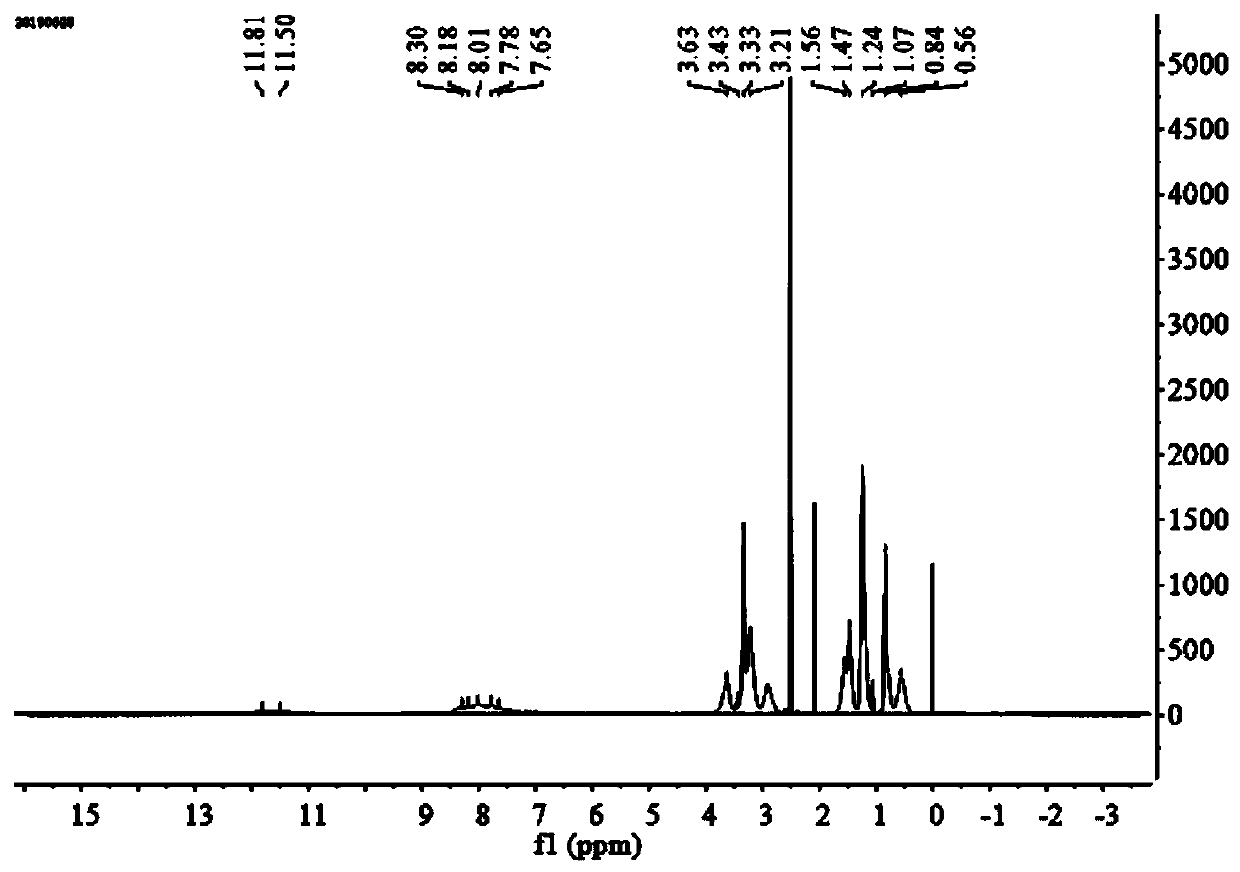

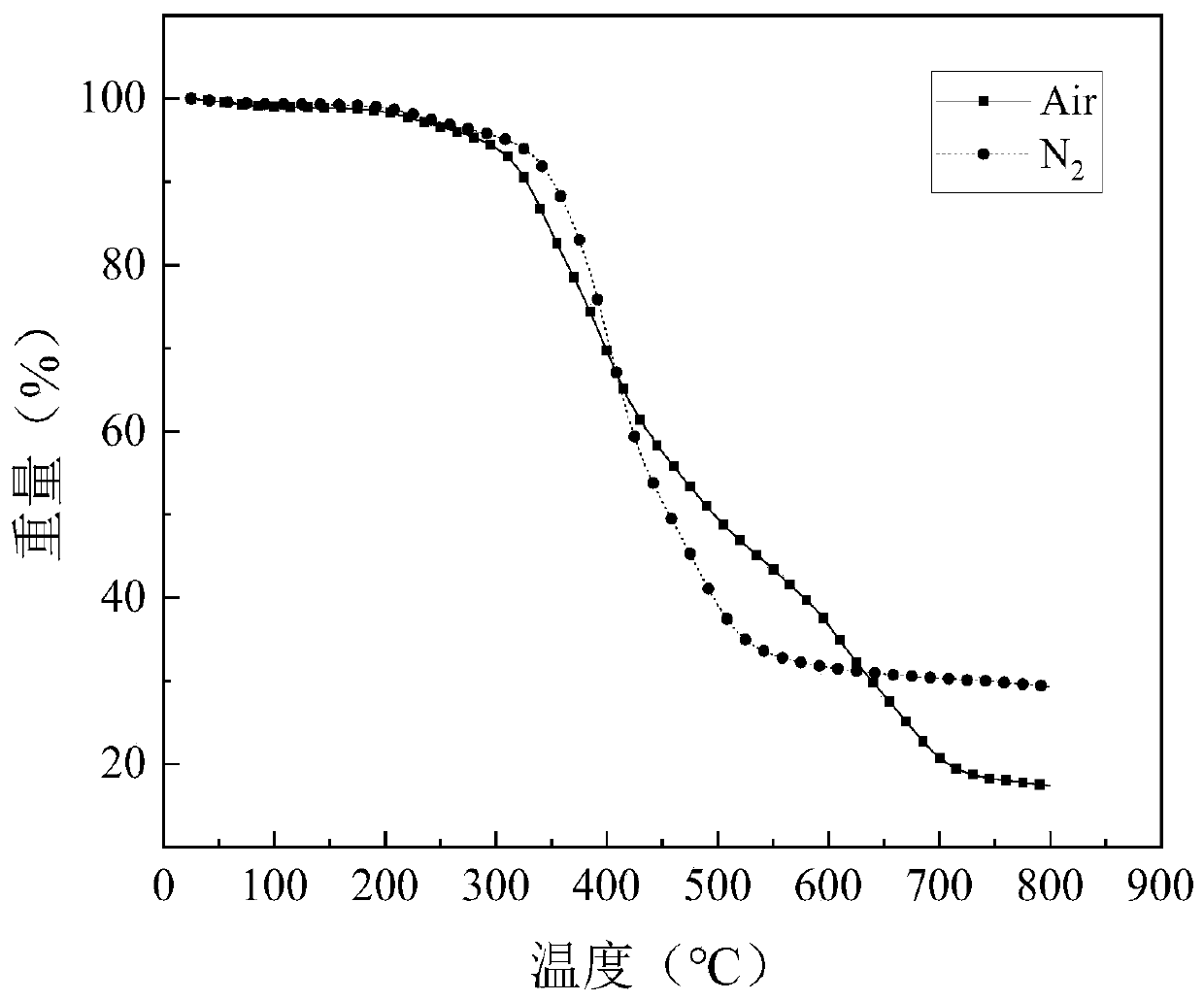

DOPO-phthalimide derivative, and preparation method and application thereof

ActiveCN108640949AImprove structural rigidityReduce tensionGroup 5/15 element organic compoundsSulfonyl chlorideSulfonate

The invention provides a DOPO-phthalimide derivative with a structure as shown in a formula I which is described in the specification. The invention also provides a preparation method for the DOPO-phthalimide derivative. The preparation method comprises the following steps: 1) subjecting a DOPO derivative and an aldehyde compound to a nucleophilic addition reaction to prepare a DOPO-alcohol compound; (2) reacting the DOPO-alcohol compound with sulfonyl chloride so as to prepare a DOPO-sulfonate compound; and (3) subjecting the DOPO-sulfonate compound and a phthalimide metal salt to a nucleophilic substitution reaction so as to obtain the DOPO-phthalimide derivative. The invention further provides the application of the above DOPO-o-phthalimide derivative as a flame retardant to modification of polymer resin. The polymer resin having undergone flame-retardant modification passes the V-0 level in a vertical burning test; at the same time, a flame-retardant product is allowed to maintaingood thermal properties, mechanical properties and physical appearance.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

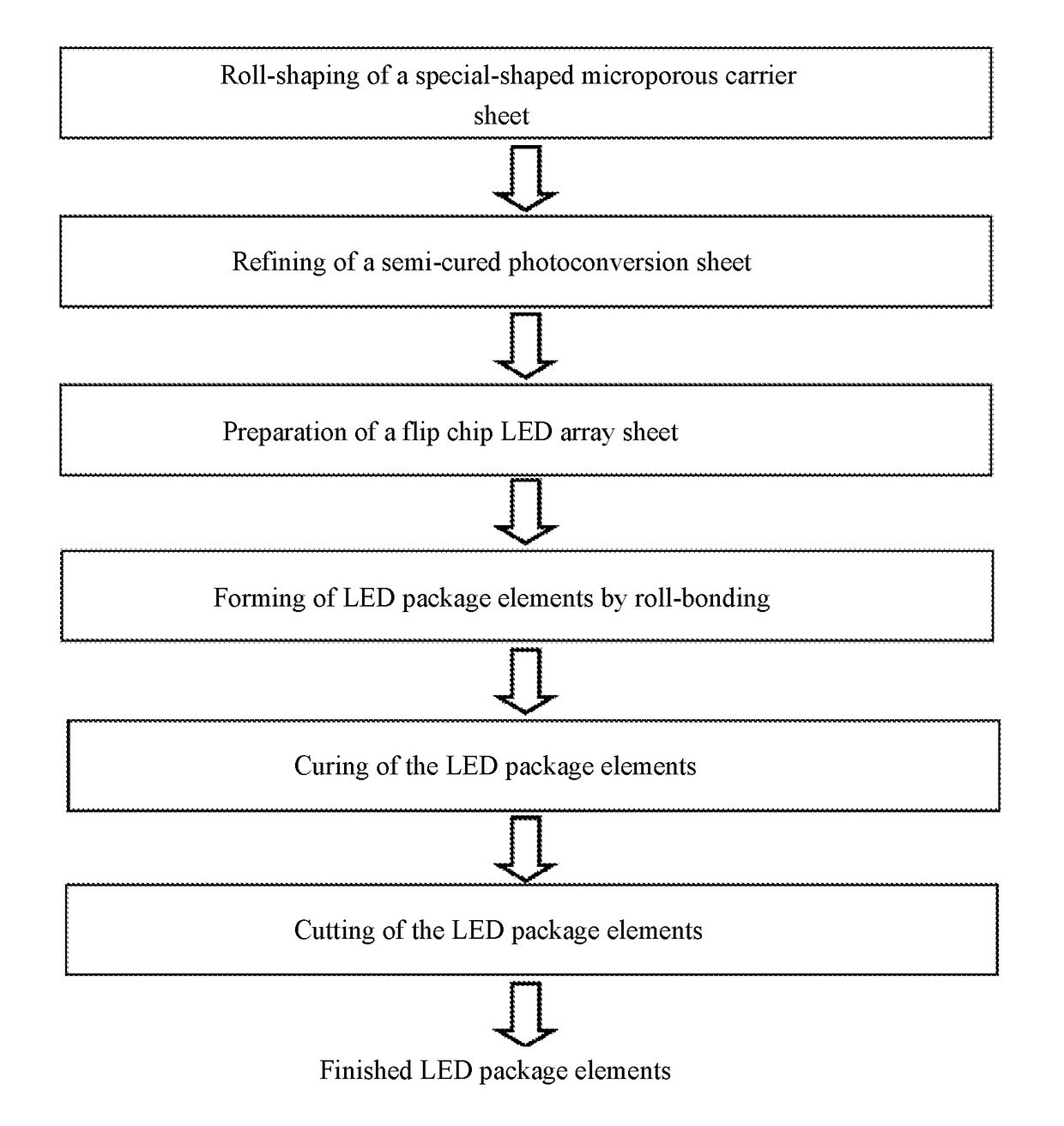

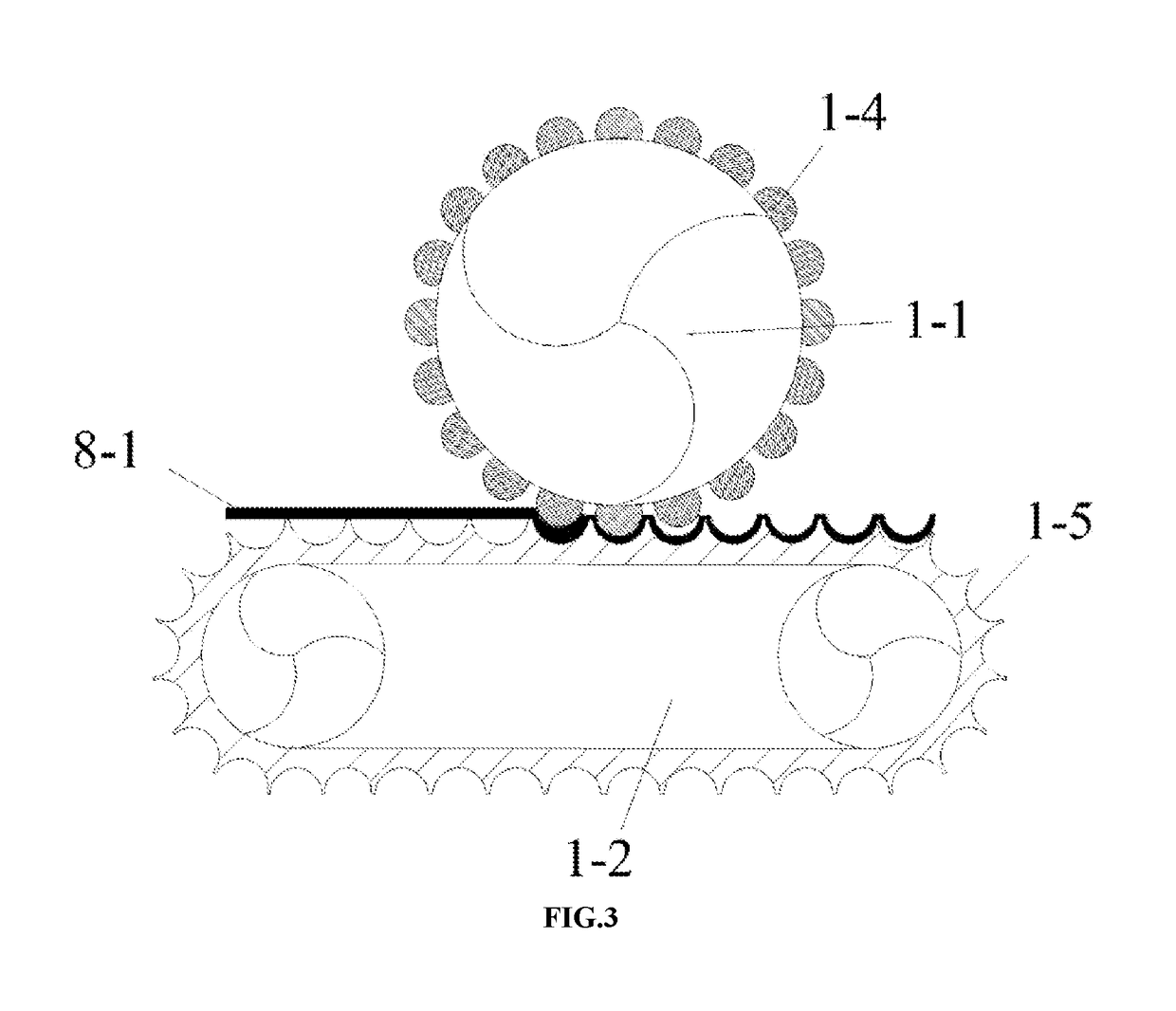

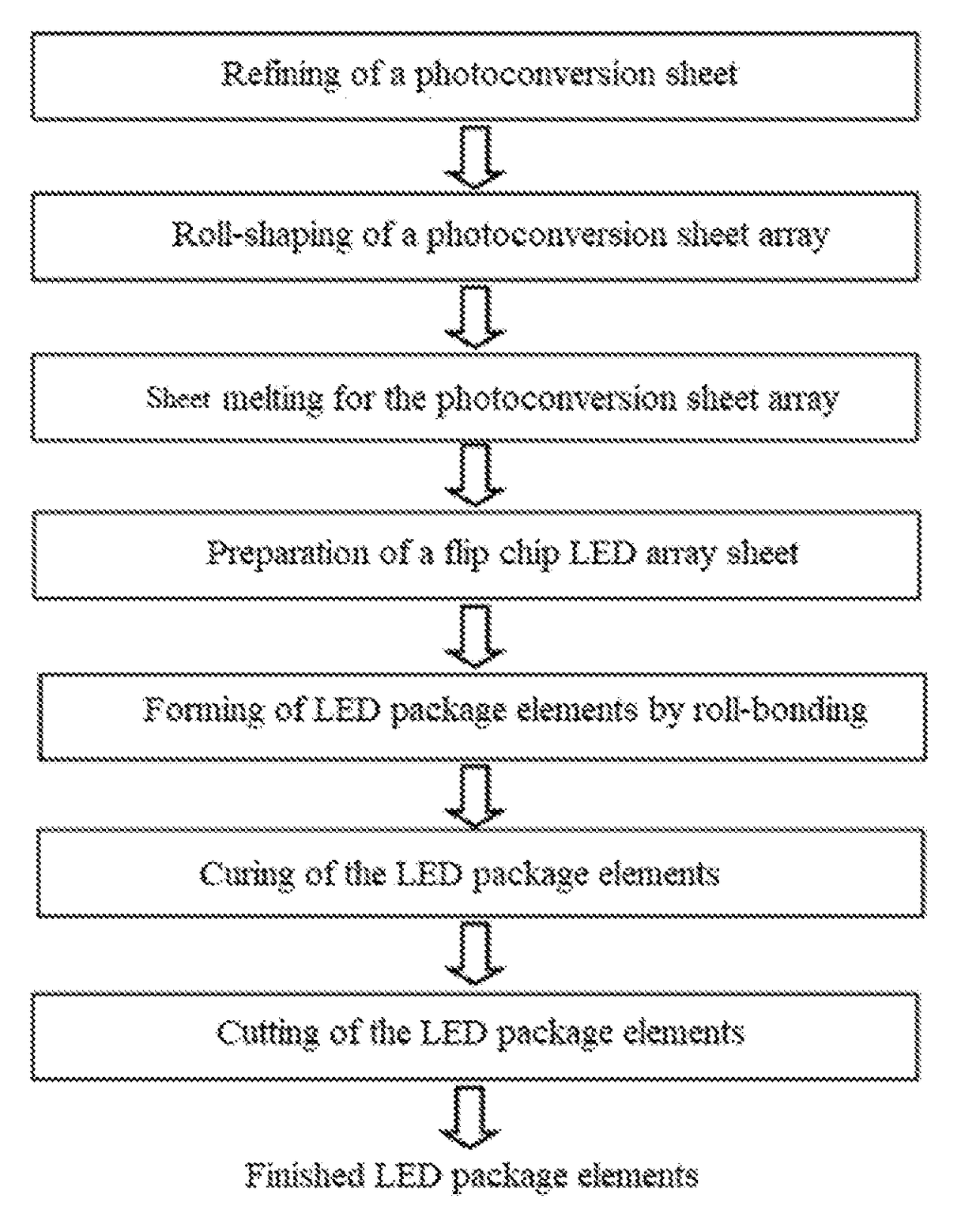

Process Method for Refining Photoconverter to Bond-Package LED and Refinement Equipment System

ActiveUS20180198032A1Improve production efficiencyHigh yieldSemiconductor devicesLed arrayEngineering

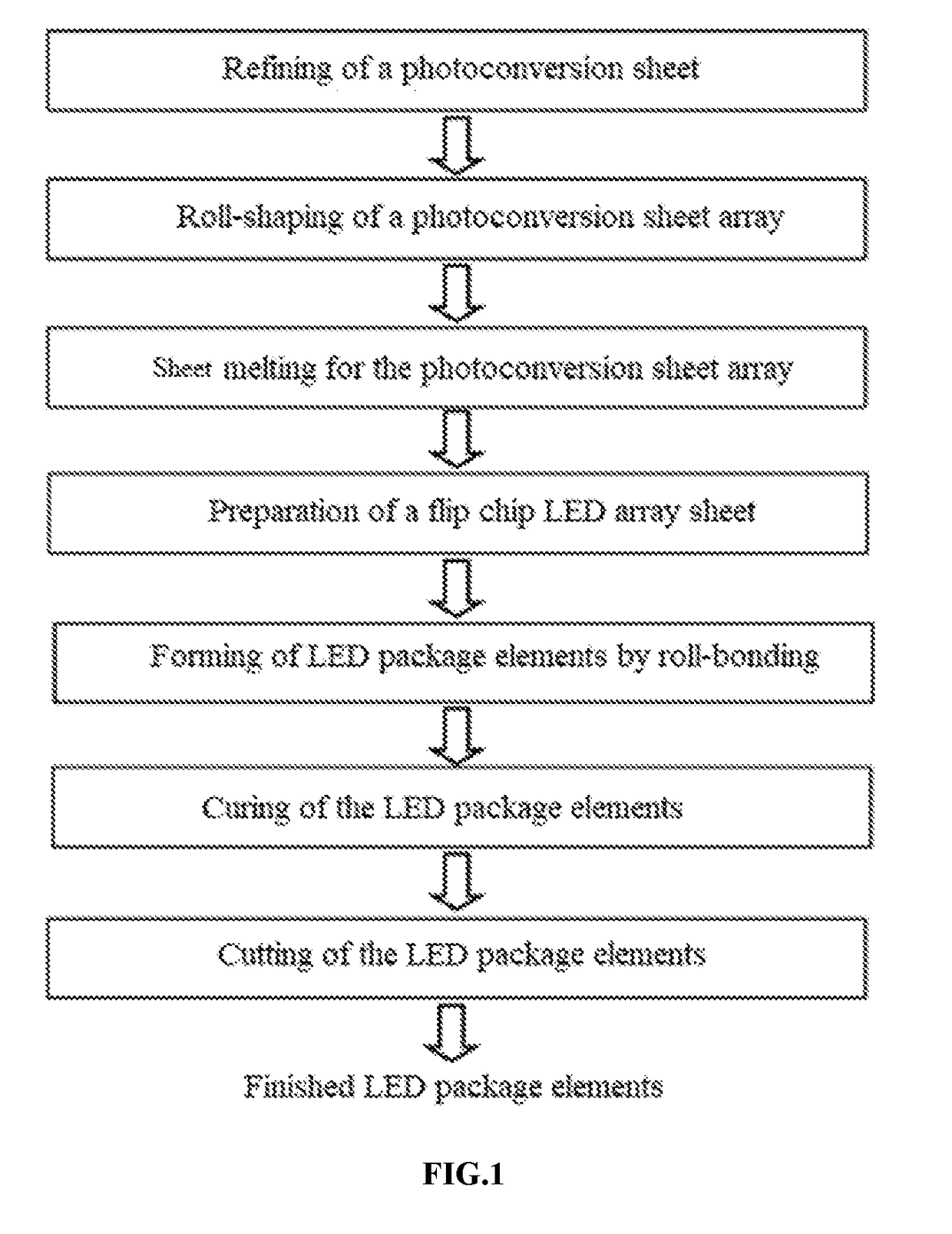

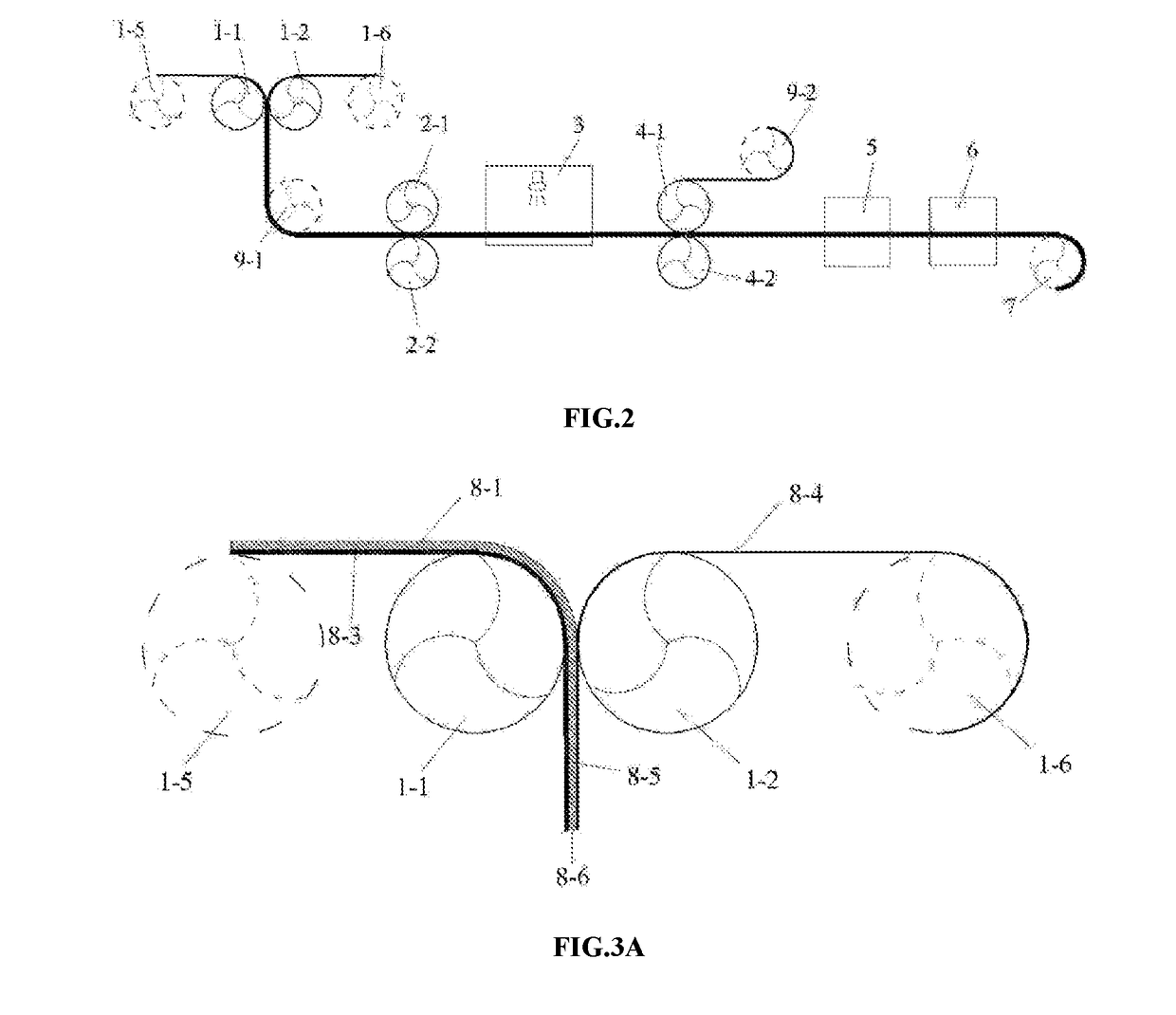

Provided are a process method for bond-packaging an LED using a refined photoconverter, and a refining equipment system. The process method includes the following continuous process flow: roll-shaping of a special-shaped microporous carrier sheet, refining of a semi-cured photoconversion sheet, preparation of a flip chip LED array sheet, forming of LED package elements by roll-bonding, curing of the LED package elements, and cutting of the LED package elements. The present invention has a significant advantage of a refined photoconverter, and especially can meet a requirement of a continuous process flow of bond-packaging an LED using an organic silicone resin photoconverter, so as to enhance the production efficiency and yield of LED packages in industrialized batch production.

Owner:JIANGSU CHERRITY OPTRONICS CO LTD

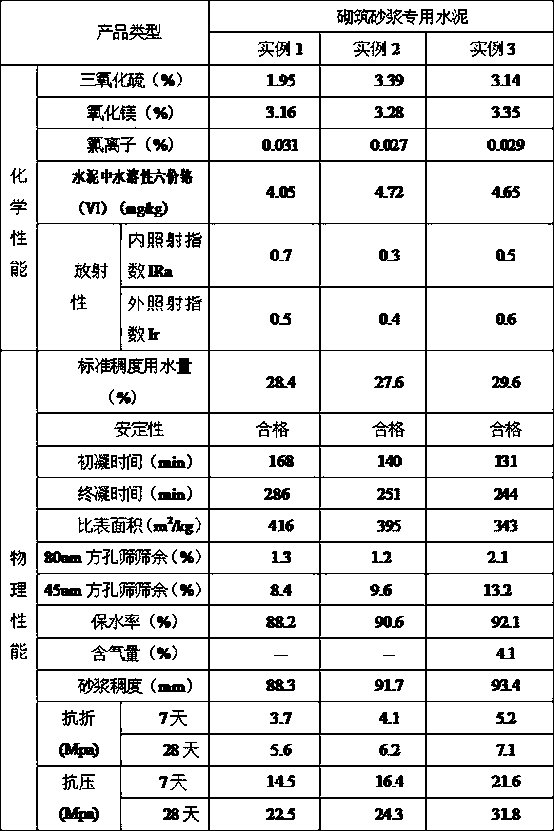

Special cement for masonry mortar and preparation method thereof

ActiveCN109851259APromoting energy saving, consumption reduction, emission reduction and waste utilizationSimple preparation processCement productionSlagCement mortar

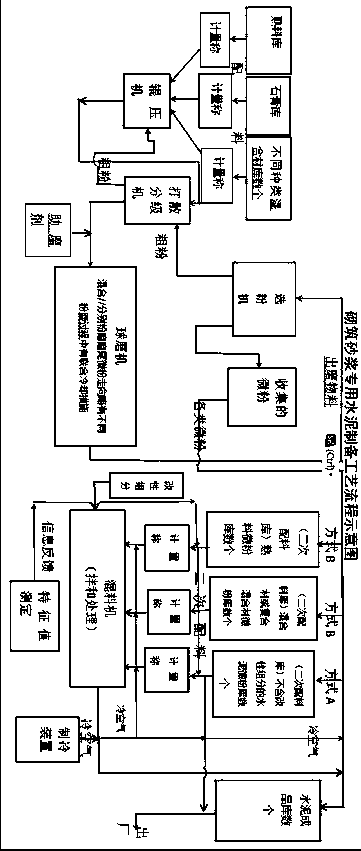

A special cement for masonry mortar comprises the following raw materials in proportion: clinker, gypsum, limestone, grinding aid and modifying component, and also comprises one or more of active or inactive mixtures including granulated blast furnace slag, granulated blast furnace slag powder, pozzolanic mixture and fly ash and other waste slag is allowed to replace the active mixture. The invention also discloses a preparation method of a special cement for masonry mortar, and a secondary batching mixing and homogenizing system is adopted in the design. The method has a wide source of raw materials and relates to the field of cement mortar. The homogeneity of cementitious material system in mortar is improved and the properties and construction efficiency of mortar are improved without adding admixtures and additives when the special cement for masonry mortar is used to prepare masonry mortar.

Owner:王紫娴 +1

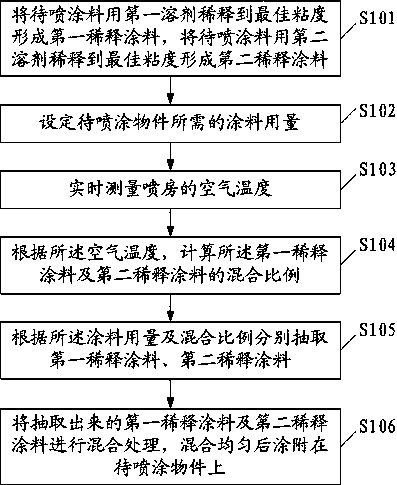

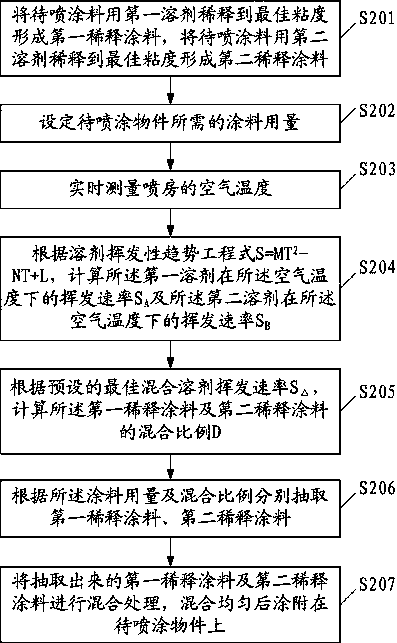

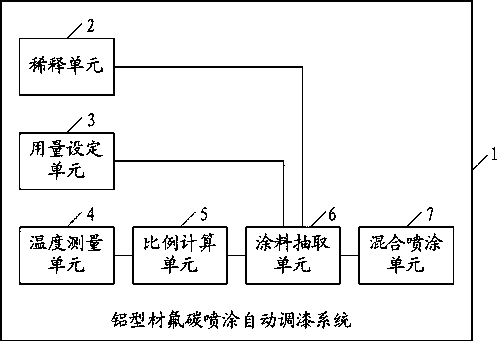

Automatic paint mixing method and system for coating aluminum profile with fluorocarbon

ActiveCN103657963AGuaranteed accuracyGuaranteed stabilityLiquid surface applicatorsMixing methodsEngineeringFluorocarbon

The invention discloses an automatic paint mixing method for coating an aluminum profile with fluorocarbon. The method comprises the following steps: a first solvent for a to-be-sprayed paint is diluted to optimum viscosity so as to form a first diluted paint; a second solvent for the to-be-sprayed paint is diluted to optimum viscosity so as to form a second diluted paint; the using amount of the paint required by an object to be coated is set; the air temperature in a spraying room is measured in real time; according to the air temperature, the mixing ratio of the first diluted paint and the second diluted paint is calculated; according to the using amount of the paint and the mixing ratio, the first diluted paint and the second diluted paint are extracted respectively; mixing treatment is performed on the extracted first diluted paint and second diluted paint; after the extracted first diluted paint and the extracted second diluted paint are mixed uniformly, the object to be coated is coated with the mixture. The invention further discloses an automatic paint mixing system for coating the aluminum profile with the fluorocarbon. Through the adoption of the method and system, the air temperature and humidity in the spraying room are measured in real time, so that the regulation of the ratio of the diluted paints is achieved, the integration of paint mixing and spraying is achieved, the matching ratio of solvents is accurate, and the using amount of the diluted paints is accurate.

Owner:GUANGDONG JMA ALUMINUM PROFILE FACTORY GRP

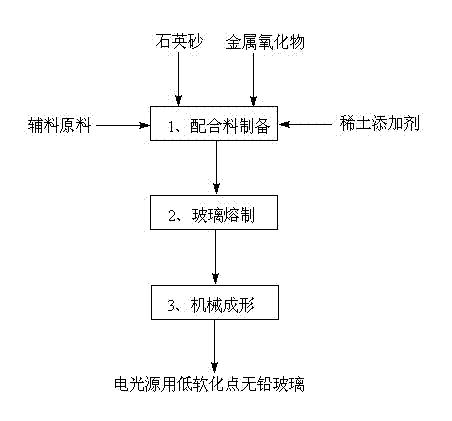

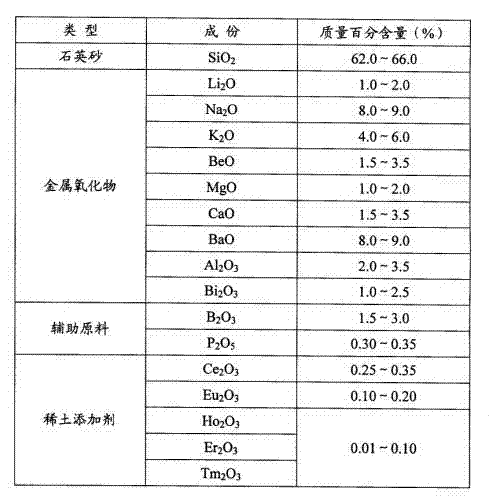

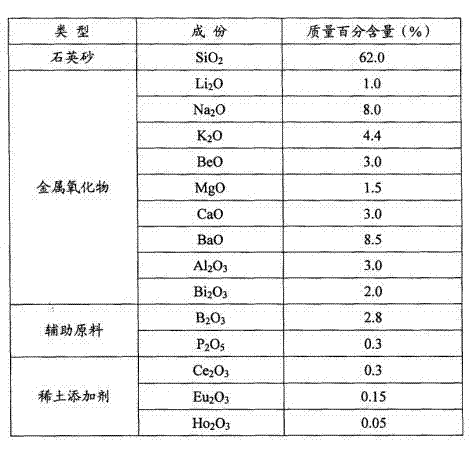

Preparation method of low-softening-point lead-free glass products for electric light sources

ActiveCN102951842AGood processing characteristicsGood chemical stabilityRare-earth elementUltraviolet lights

The invention relates to an electric light source glass method, and especially relates to a preparation method of environmental-protection and low-softening-point lead-free glass products for electric light sources. The low-softening-point lead-free glass products for electric light sources are prepared through the steps of batch preparation, glass melting and mechanical shaping. A rare earth element additive is added to the formula of present lead-free glass to form the components of the batch. An up-conversion luminescence principle is applied to carry out conversion luminescence of infrared lights and ultraviolet lights to realize visible light luminescence; the rare earth additive is simultaneously used as a clarifying agent, a color complementation agent and a conversion luminescence couplant, so the visible light transmittance of the glass is improved; and beryllium oxide and bismuth oxide are added, so the softening point of the glass is further reduced, and the melting and shaping processes and the performances of the products are improved. The glass products have the advantages of high visible light transmittance, ultraviolet and insolation resistances, and no harmful elements.

Owner:YANGZHOU TONGHE GLASS

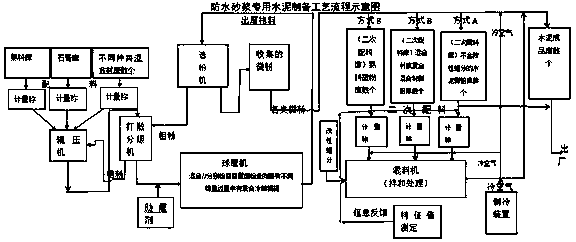

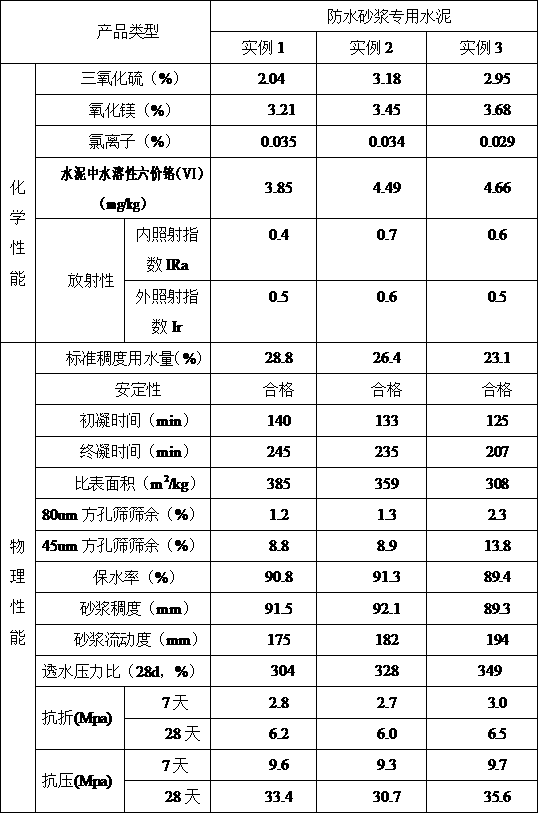

Cement special for waterproof mortar and preparation method thereof

ActiveCN109809720ATake advantage ofPromoting energy saving, consumption reduction, emission reduction and waste utilizationCement productionSlagMixed materials

The invention discloses cement special for waterproof mortar. The cement is prepared from the following raw materials: clinker, gypsum, limestone, a grinding aid and a modifying component, and furtherfrom one or more active or nonactive mixed materials comprising granulated blast furnace slag, slag powder, cinerite and flyash. And other residues are allowed to be mixed in to replace active mixedmaterials. The invention also discloses a preparation method of the cement special for waterproof mortar, and the raw materials have a lot of sources; in terms of the problem that temperature of cement is high and thus difficult for being mixed with the modifying component in an existing cement production technology, a cement cooling method and a cement cooling device are combined; in the design,a secondary batching, stirring and homogenizing system is adopted, so that technological conditions for adding the modifying component and preparing various mortar are achieved; when mortar is stirred, no admixture is added, so that the homogeneous problem of a gelatinizing material system in the mortar is alleviated and various performance and construction efficiency of the mortar are improved.

Owner:王紫娴 +1

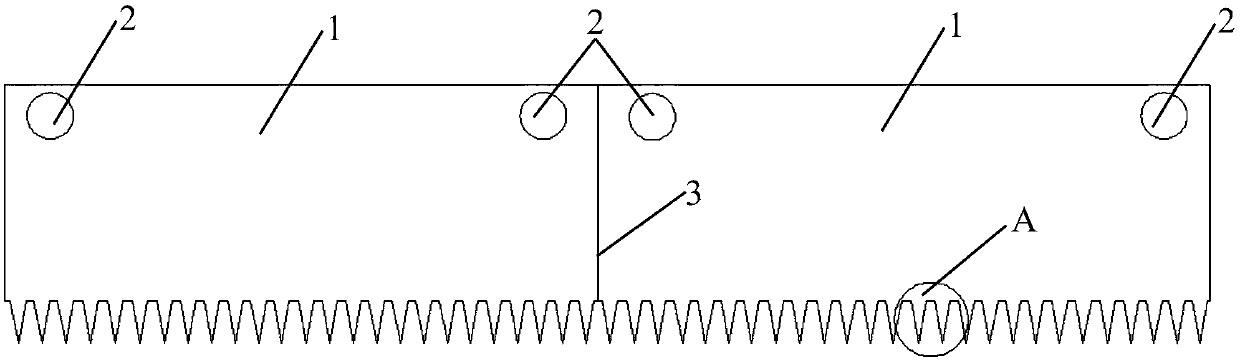

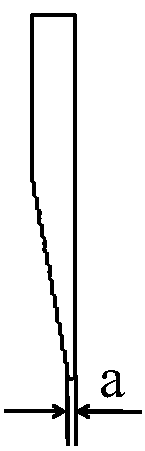

Serrated knife for high-speed carpet textile machine and machining method thereof

The invention discloses a serrated knife for a high-speed carpet textile machine. The serrated knife comprises a knife rest and a blade component, wherein the blade component comprises a plurality ofblade bodies; a plurality of sawteeth are arranged on one side of each blade body; the plurality of sawteeth are arranged at equal intervals; a plurality of mounting holes are formed in one side, farfrom the sawteeth, of each blade body; the plurality of blade bodies are detachably connected with the knife rest through the plurality of mounting holes; the end parts of the plurality of blade bodies are correspondingly spliced with one another; splicing lines are formed in spliced positions; the splicing lines are positioned at the roots of the sawteeth, so that the phenomena that the splicinglines have cracks at cutting edges of the splicing lines and the shearing quality of carpet fabric is reduced are avoided; meanwhile, the invention further discloses a machining method of the serratedknife. The serrated knife machined through the method is high in quality, sharp in cutting edges and long in service life, and improves the shearing efficiency of the carpet fabric.

Owner:昆山立达纺织实业有限公司

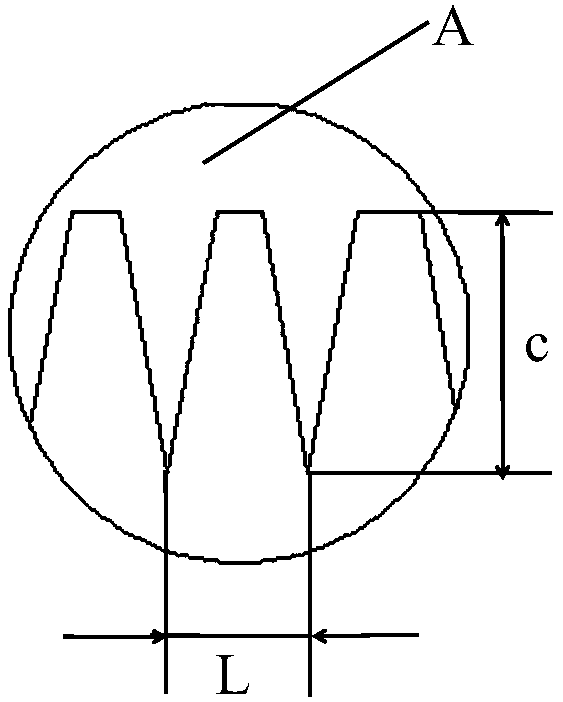

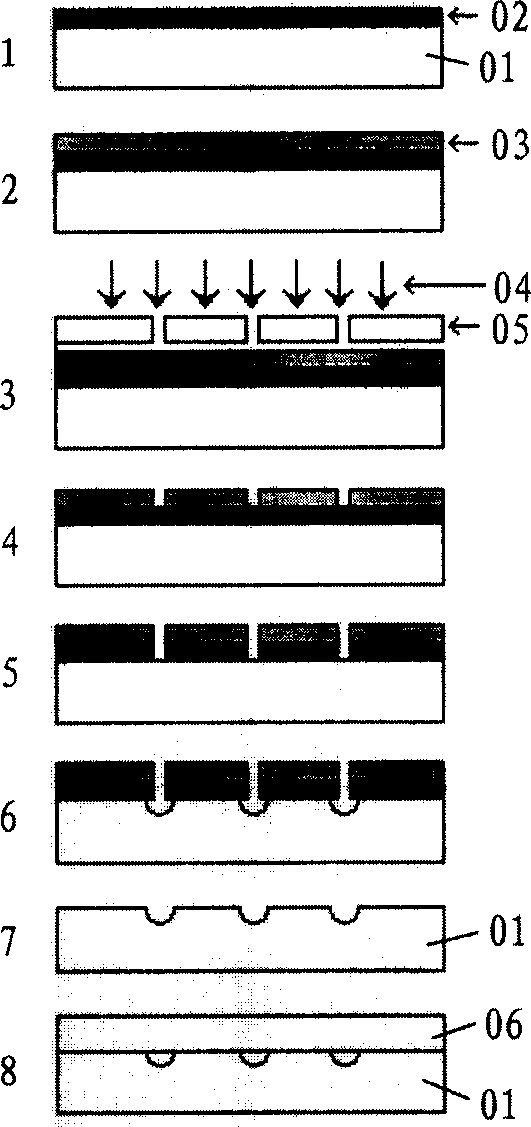

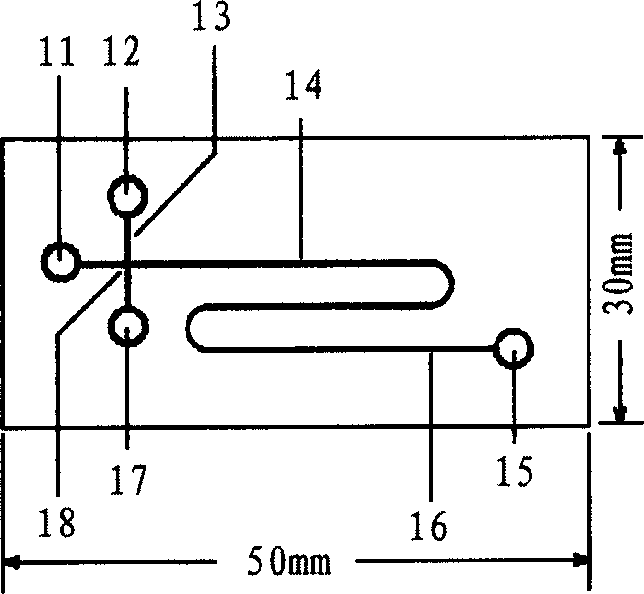

Method for producing electrophoretic microchip

InactiveCN1365003AImprove protectionProcess conditions are easy to meetMaterial analysis by electric/magnetic meansEtchingElectrophoresis

The production process of electrophoretic microchip incldues the steps of: designing electrophoretic microchip based on functional requirement and corresponding technological conditions while considering the parameters of sample inlet electrophoretic channel and separating electrophoretic channel width and length, pipe shape and interval, and making mask based on the designed microchip figure; and the making electrophoretic microchip through selecting high quality quartz as substrate, wet photoetching to form notches and other patterns in the substrate and linkage to form microtube network to constituted electrophoretic microchip. The present invention has the advantages of reliable protection in wet etching process, simple linkage process combining pre-linkage and sintering, etc.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

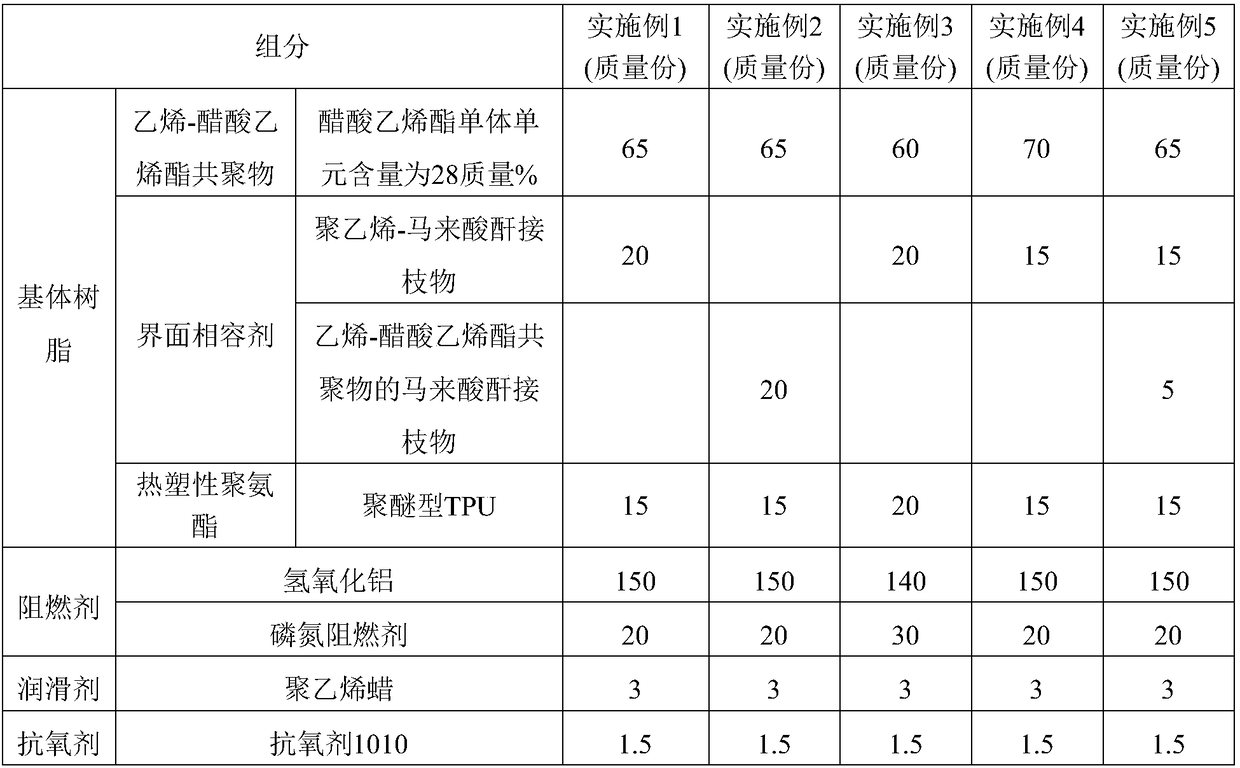

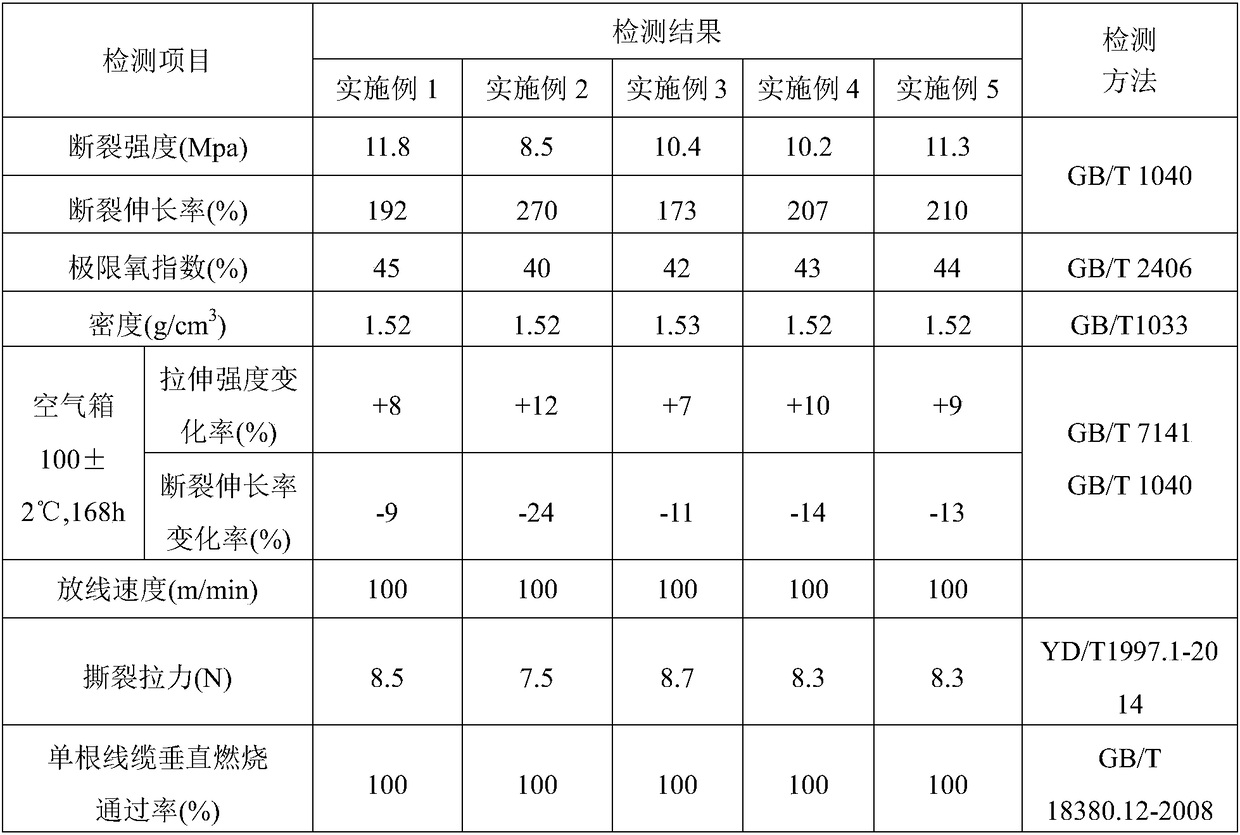

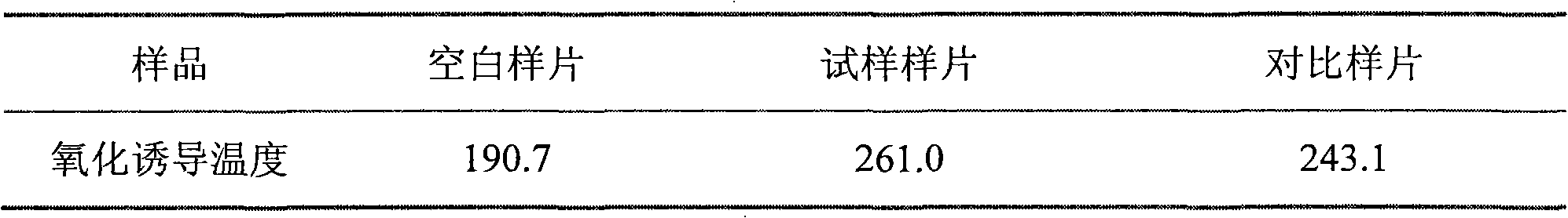

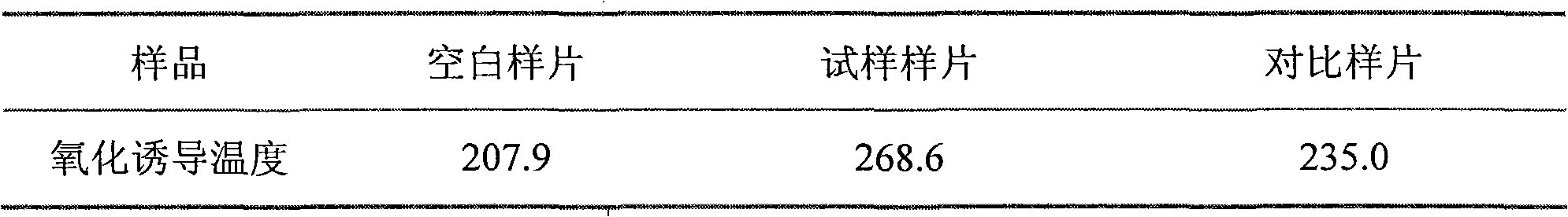

Polyolefin cable material as well as preparation method and application thereof

ActiveCN108314829AGuaranteed requirements for vertical burningMeet the requirements of tearing forcePlastic/resin/waxes insulatorsPolyolefinPolymer science

The invention provides a polyolefin cable material as well as a preparation method and application thereof. The polyolefin cable material comprises: (a) 100 parts by mass of matrix resin, wherein thematrix resin comprises 40 to 80 (preferably, 60 to 80) parts by mass of ethylene-vinyl acetate copolymer, 10 to 30 (preferably, 15 to 25) parts by mass of thermoplastic polyurethane and 10 to 30 (preferably, 15 to 25) parts by mass of interfacial compatibilizer; (b) 80 to 200 (preferably, 130 to 180) parts by mass of a flame retardant, wherein the flame retardant comprises 50 to 150 (preferably, 130 to 150) parts by mass of aluminum hydroxide and 15 to 40 (preferably, 20 to 30) parts by mass of phosphorus nitrogen flame retardant; (c) 0 to 4 (preferably, 2 to 4) parts by mass of lubricating agent; (d) 0.5 to 2.5 parts by mass of antioxidant. The polyolefin cable material provided by the invention can meet various performance requirements in YD / T1113-2001 and has excellent flame resistance.Furthermore, in a cable prepared from the cable material, the cable body can meet the single cable vertical combustion test requirement and also can meet the tear tension requirement.

Owner:ZHEJIANG WANMA MACROMOLECULE MATERIAL

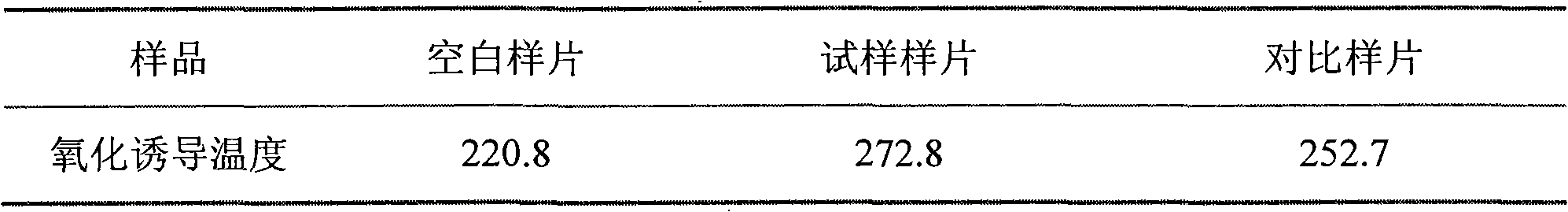

Heat oxygen aging resistance high polymer material and preparation method and application thereof

InactiveCN101633789AHigh antioxidant efficiencyImprove thermal stabilityGallic acid esterPolymer science

The invention discloses a heat oxygen aging resistance high polymer material and a preparation method and an application thereof; the high polymer material adopts gallic acid and / or gallic acid ester as antioxidant and the dosages are 0.005%-10.00% of high polymer material. Gallic acid and gallic acid ester belong to polyhydrophenol compound and have high antioxidation rate in polymer, non-toxic and environmentally friend; the gallic acid and gallic acid ester have good thermal stability, can satisfy the processing conditions of various high polymer materials and have obvious antioxidant effect on high polymer.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

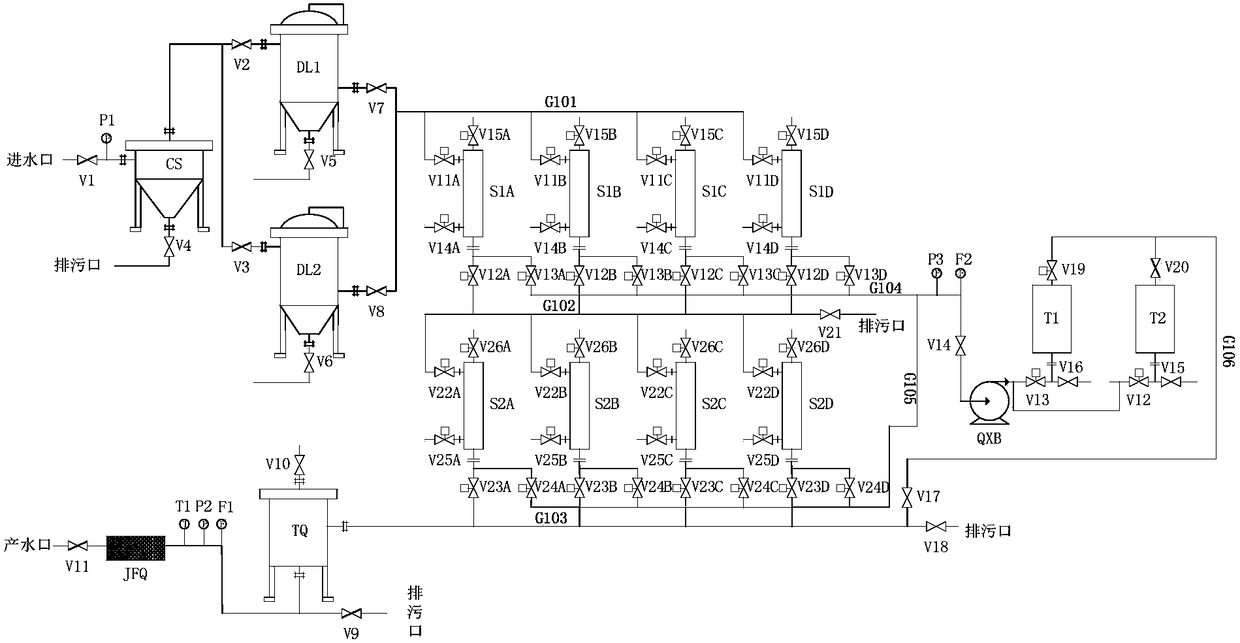

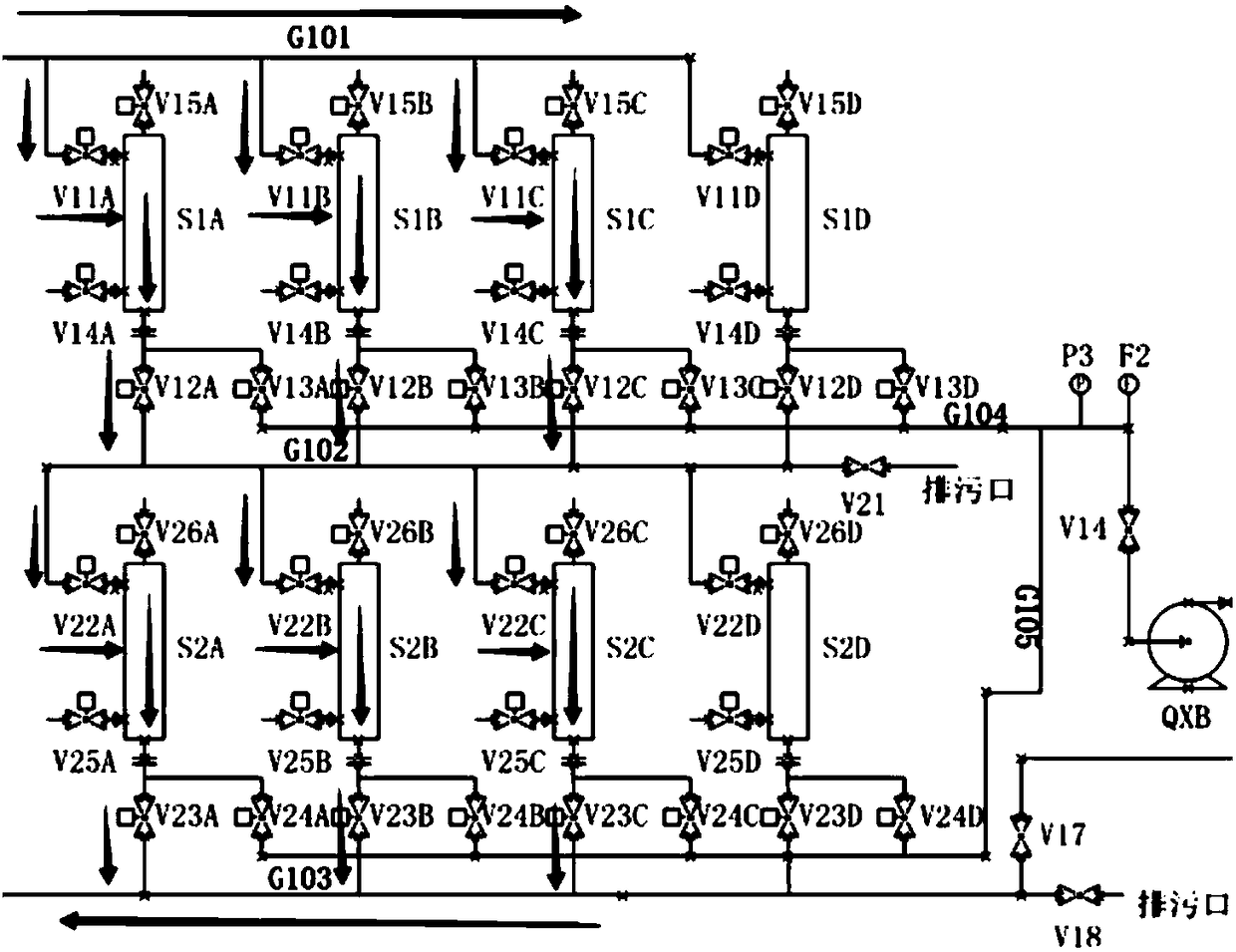

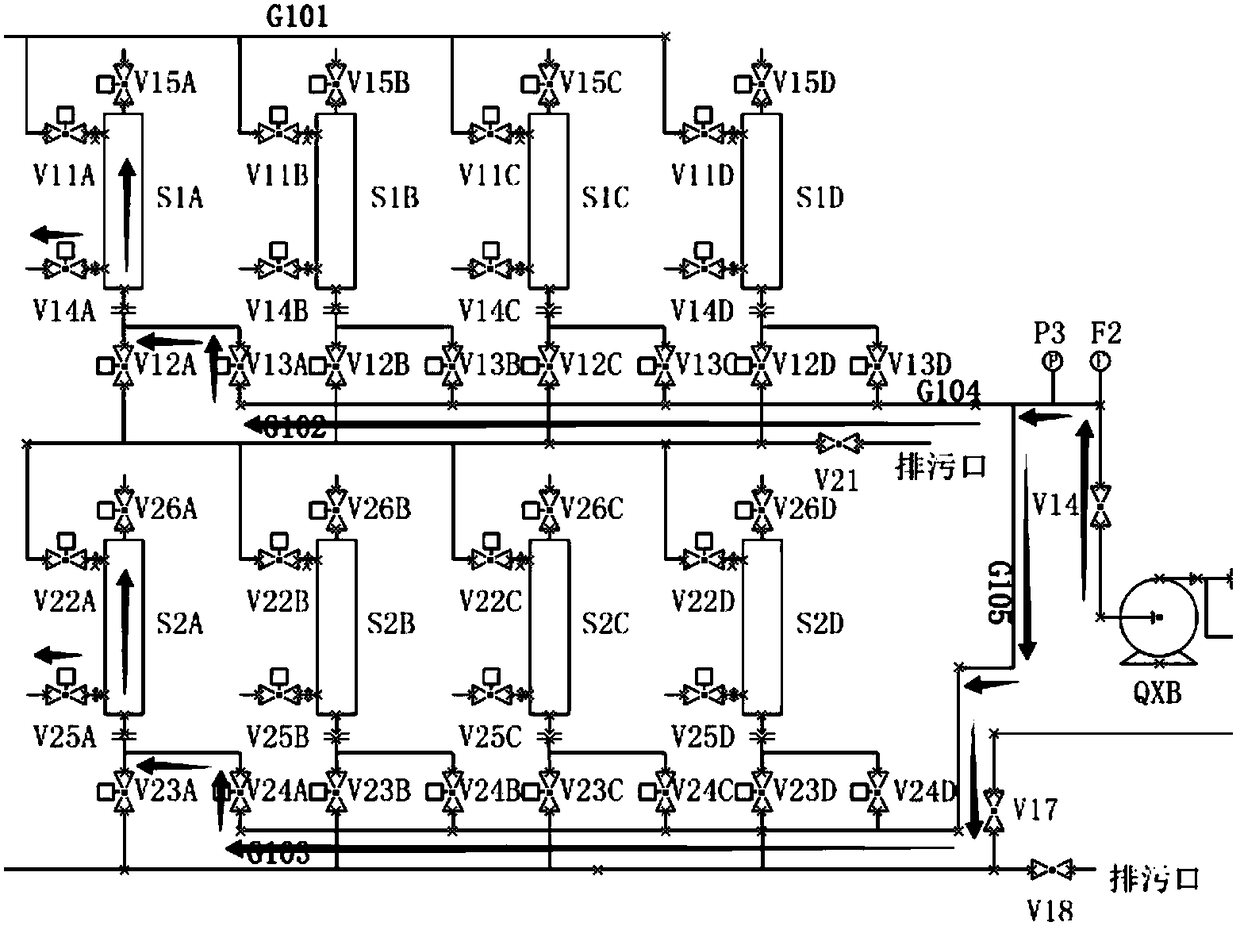

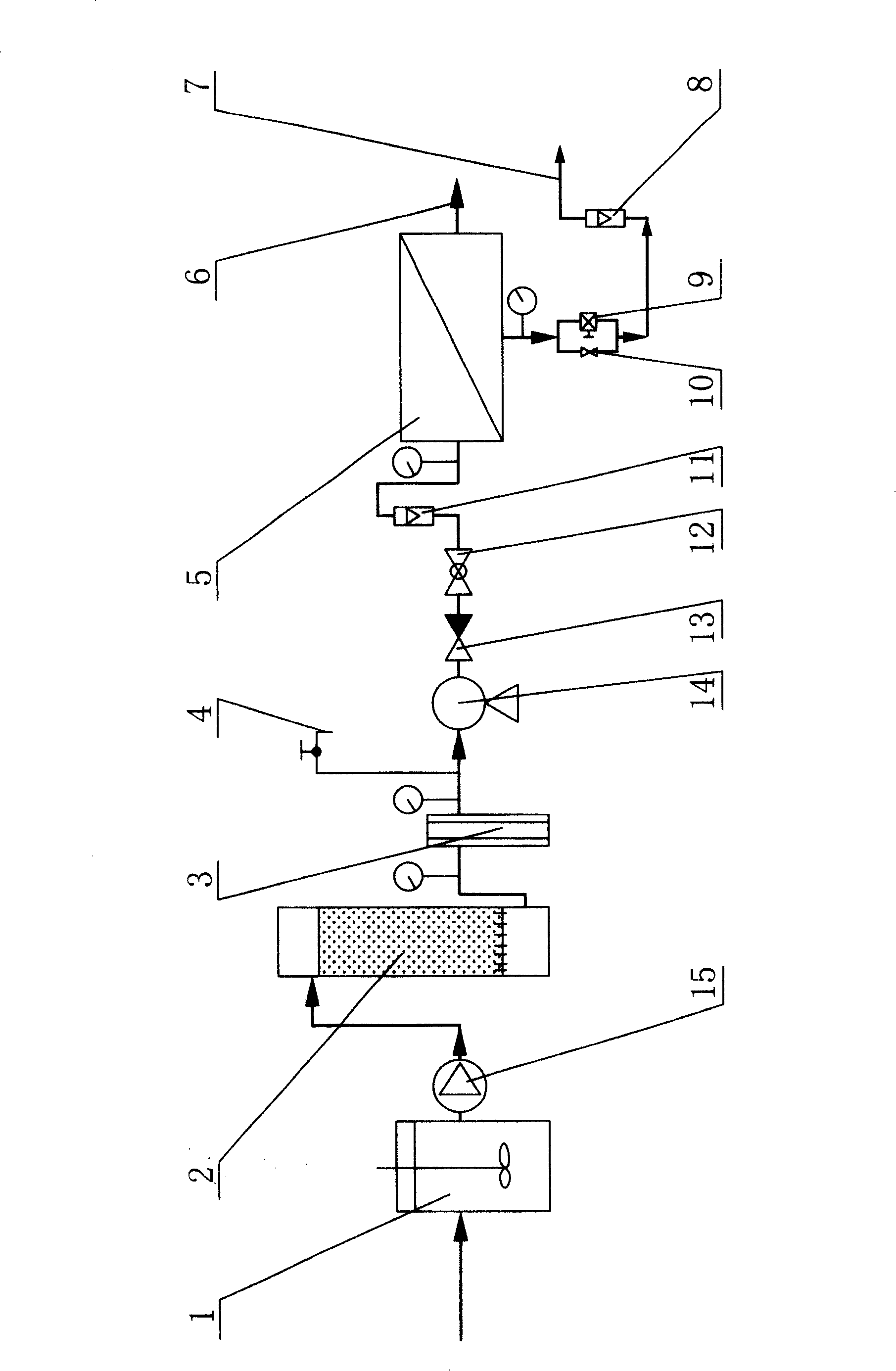

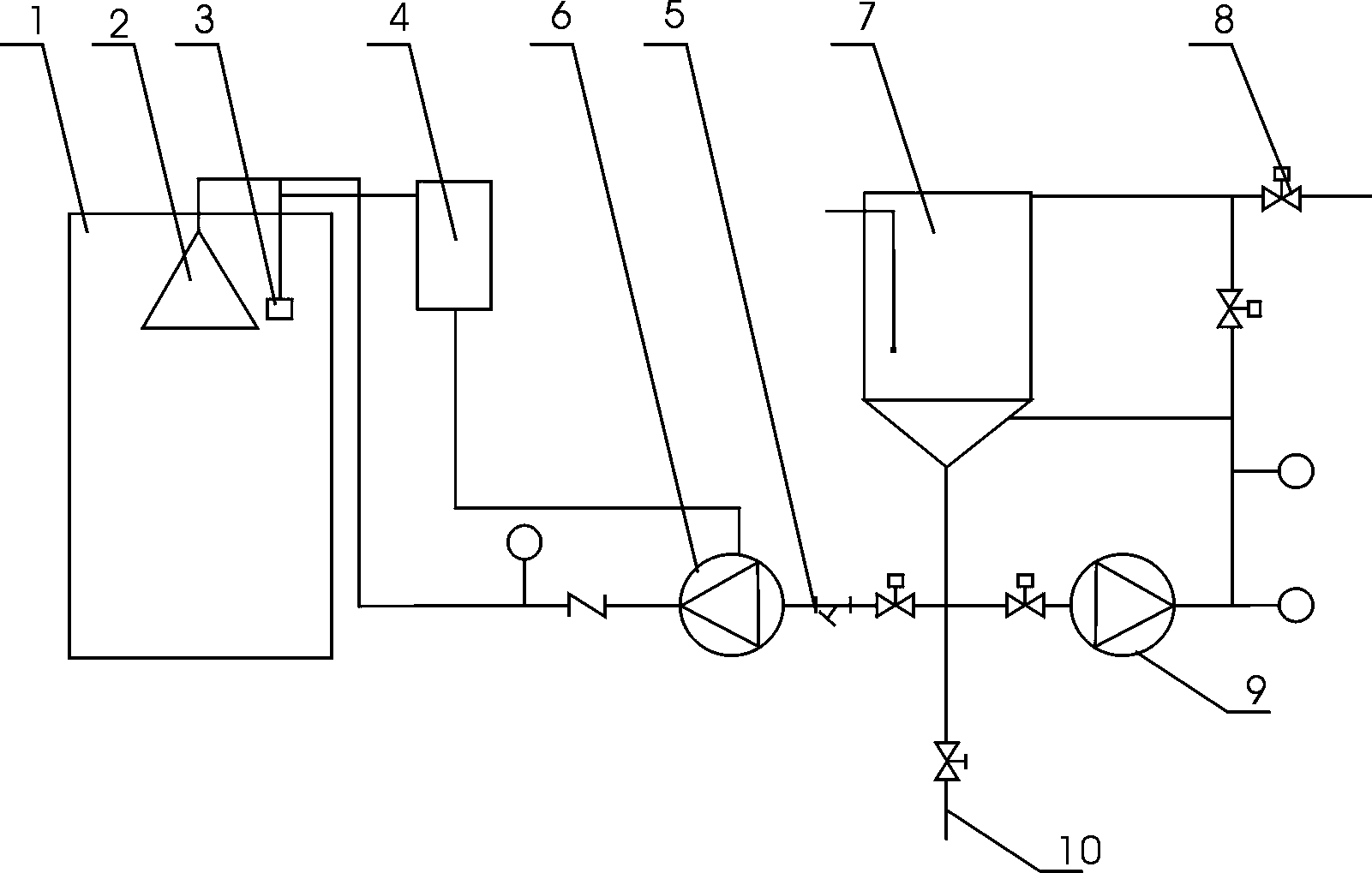

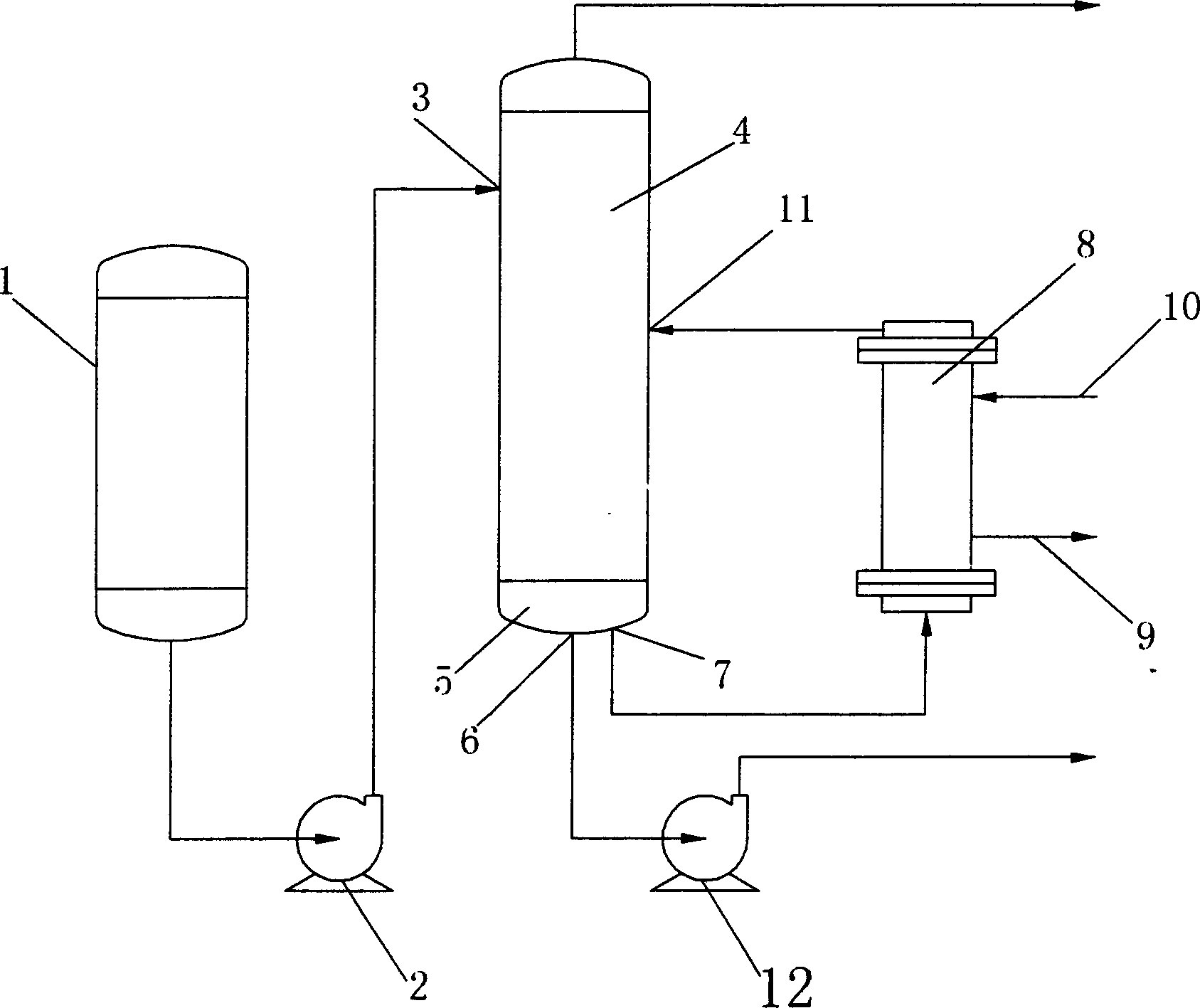

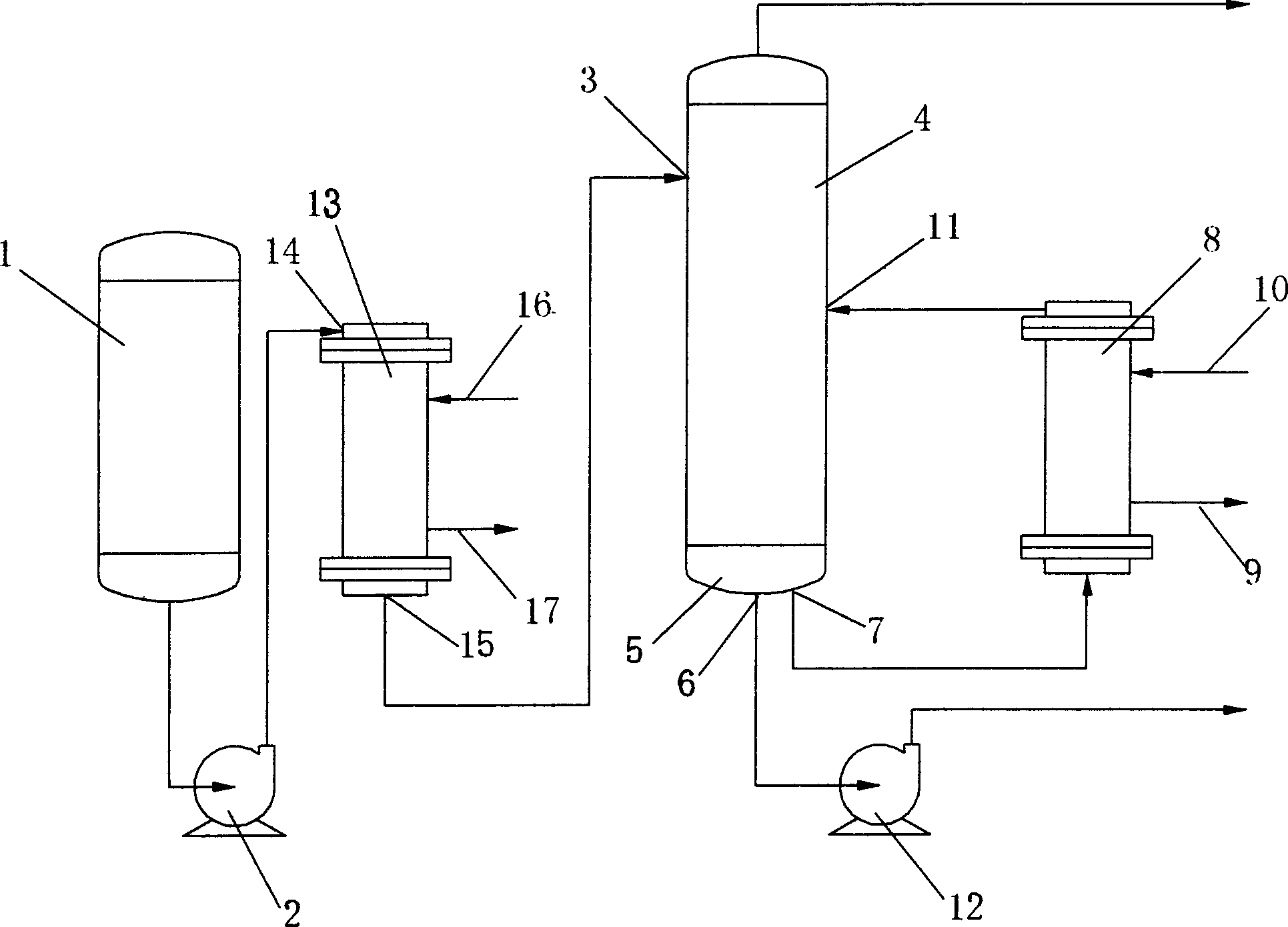

Technological system for treating terrestrial heat tail water by utilizing tubular membrane

PendingCN108314204AReduce processing costsImprove processing efficiencyWater/sewage treatment by centrifugal separationScale removal and water softeningWater treatment systemTechnological system

The invention creatively provides a technological system for treating terrestrial heat tail water by utilizing a tubular membrane. The technological system comprises a cyclone sand remover, bag type filters, a tubular membrane filtering device, a washing tank, a washing ump, a degassing tank and an electric control device; two sets of the bag type filters are arranged; one bag type filter is usedand one bag type filter is standby, and the two bag type filters are alternatively used; the tubular membrane filtering device is divided into two grades; each grade comprises four tubular membrane filters which are arranged in parallel, three tubular membrane filters are used and one tubular membrane filter is standby; the system is provided with a thermometer, a pressure meter and a flow meter;the electric control device comprises a PLC (Programmable Logic Controller) and can realize online automatic backwashing of equipment and prevent fouling and blocking, so that stable operation of equipment is ensured. The technological system takes a tubular membrane as a core and integrates equipment including the cyclone sand remover, the bag type filters and the like to form a technology of treating the terrestrial heat tail water by utilizing a set of water treatment system; the technological system has the advantages of high integration degree, high automation degree, high treatment efficiency and long service life; water treatment can reach reinjection water quality requirements and the treatment cost of reinjection water is greatly reduced.

Owner:TIANJIN HIPURE MEMBRANE TECH CO LTD

Preparation method and application of high-loss-resistance wood fire retardant

PendingCN111205315AImproves loss resistanceRaw materials are cheap and easy to getGroup 4/14 element organic compoundsWood treatment detailsPulp and paper industryFire retardant

The invention discloses a preparation method and application of a high-loss-resistance wood flame retardant, and relates to the technical field of wood modification. The high-loss-resistance wood flame retardant provided by the invention can realize synergistic flame retardance of nitrogen, sulfur and silicon, and the fireproof performance of wood is remarkably improved; hydrophobic alkyl chains and claw-shaped silane in the structure can effectively reduce hydrophilicity of wood. The claw-shaped silane structure can react with hydroxyl in wood so as to play a role in curing modification, anddifferent from a traditional physical curing technology, the loss resistance of the wood flame retardant can be further improved. The structure of the compound I is novel, the defect that a traditional flame retardant is prone to loss is overcome, the loss resistance of the flame retardant is improved, and the service life of wood products is prolonged. The high-loss-resistance wood fire retardantis added into the wood, the original color and use performance of the wood are not influenced, the fireproof performance and the waterproof performance of the wood are obviously improved, and the wood fire retardant is simple in synthesis process and easy to popularize.

Owner:RUBBER RES INST CHINESE ACADEMY OF TROPICAL AGRI SCI +1

Dyestuff pesticide waste water treatment device

InactiveCN101239744ASolve concentrationSolve the problem of high salt contentGeneral water supply conservationWater/sewage treatment bu osmosis/dialysisWater storage tankActivated carbon filtration

The present invention provides a processing unit of dyestuff, pesticide and waste. The invention relates to an equipment of treating, separating and recovery pesticide and dyestuff by nanofiltration combined process. The unit is composed of linked water inlet, a water storage tank, a supercharge pump, a carbon filter, a microstrainer or millipore filter, a water outlet in orders, a linked high pressure pump, a check valve, a filter are set between water outlets in orders, a recovery outlet is set on the filter. Waste after being treated is processed with normal biological treatment, suitable for engineering application, the technology is not only a new clean producing technology of the dyestuff, pesticide production, but also a creation of the dyestuff, pesticide waste treating process, the technology has a high intensification, lower occupation, high automation degree, convenient control management, wide engineering application.

Owner:扬州市江都区华伦化机环保设备厂

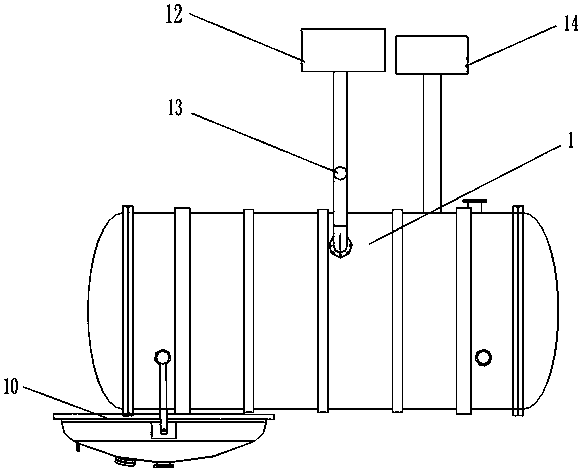

Desulfuration equipment for tank top device, and desulphurization production technology

InactiveCN103566721AEnsure environmental safetyHigh degree of intelligenceDispersed particle separationSpray nozzleCirculating pump

The invention relates to a hydrogen sulfide removing technological scheme, and specifically relates to desulfuration equipment for a tank top device, and a desulphurization production technology. According to the desulfuration equipment, the top of an oil storage tank is provided with a spray nozzle; the spray nozzle is connected to a medicine feeding outlet via a pipeline; the medicine feeding outlet is connected to an outlet end of a medicine feeding pump; an inlet end of the medicine feeding pump is connected to the bottom of a medicine storage tank via a digital control valve; the bottom of the medicine storage tank is connected to a blowoff valve and an inlet end of a circulating pump; an outlet end of the circulating pump is respectively connected to the middle part of the medicine storage tank and an outlet end of a water inflowing medicine valve; the outlet end of the water inflowing medicine valve is connected to the top of the medicine storage tank; a hydrogen sulfide sensor is arranged on the top of the oil storage tank, and is connected to a host controller via a signal cable; and the controller is connected to switching circuits of the medicine feeding pump respectively. The desulfuration equipment and the desulphurization production technology are capable of avoiding conflicts of desulfuration safe production and cost control.

Owner:陈俊丞

Shaping die for automobile exhaust system shell product

The invention provides a shaping die for an automobile exhaust system shell product. The shaping die for the automobile exhaust system shell product comprises an upper die base and a lower die base. Astripper plate is arranged under the upper die base, side shaping slotting tools are arranged on two sides of the upper die base, and a side shaping puncher chip is arranged under the stripper plate.The lower die base is provided with a side shaping block, the side shaping block is located under the side shaping puncher chip and matched with the side shaping puncher chip, side shaping sliding blocks are arranged on two sides of the side shaping block, and the side shaping sliding blocks and the side shaping slotting tools can move relatively. Compared with common shaping dies, the shaping die for the automobile exhaust system shell product is provided with movable sliding blocks, is convenient to maintain, achieves convenient and safe operation due to adjustability, and meets various machining conditions. The shaping sliding blocks are installed on the movable sliding blocks, and thus R-angle springback and material stacking occurring due to the fact that parts are in arc shapes andare provided with no reinforcing ribs can be avoided. Otherwise, three dies need to be produced, and manpower and material resources are wasted.

Owner:WUXI MEIYER MACHINERY MFG

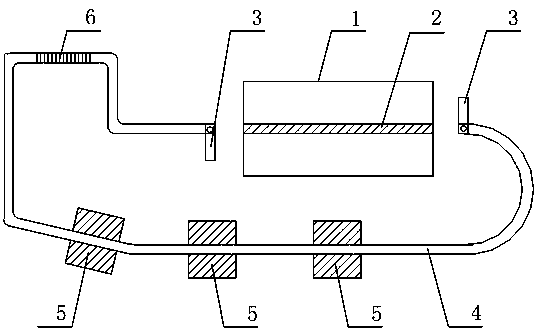

Wet spinning vacuum freeze-drying method and drying equipment

ActiveCN109440202ARealize continuous drying productionSimple processArtificial filament washing/dryingWet spinning methodsYarnFiber

The invention provides a wet spinning vacuum freeze-drying method and drying equipment. The method includes the steps that (1), fibers of wet spinning are directly put in a vacuum drying bin to be freeze-dried, the fibers are completely frozen, and a next step is carried out; (2), plate layers start to be heated, meanwhile, vacuumizing is carried out, the vacuum degree in the vacuum drying bin iswithin the range of 10 pa-800 pa, meanwhile, the temperatures of plates are controlled to be 30-120 DEG C and reach 0 DEG C or above, and the fibers are dried. A feed port and a discharge port of thevacuum drying bin are formed in the two ends respectively, a guide rail in the bin is arranged on the top in a bin body, the two ends of the guide rail in the bin are connected with a guide rail outside the bin through pneumatic connecting devices respectively to form an annular guide rail, and a lifting yarn arranging table is arranged below the portion, close to feed port of the vacuum freeze-drying bin, of the guide rail outside the bin. In the wet spinning process, industrialized fiber dewatering and drying can be carried out without pre-freezing or any organic solvent, and continuous drying production of long fibers can be achieved.

Owner:QINGDAO JIFA GROUP +1

Method and device for dehydration of glycol by extending coking period of tower-drier reboiler

InactiveCN1557795AExtend the coking cycleIncrease heat loadHydroxy compound separation/purificationPreparation by hydrolysisReboilerPulp and paper industry

The glycol dewatering method for delaying the scaling period of reboiler in drying tower includes the control on the material temperature of drying tower, and features that the glycol solution temperature is 95-130 deg.c. The present invention also provides a glycol dewatering apparatus related to the method for delaying the scaling period of reboiler in drying tower. The method of the present invention can decrease the scaling speed of the reboiler obviously to reduce stop loss, lower cost in descaling, reduce drained sewage and protect environment.

Owner:北京东方石油化工有限公司

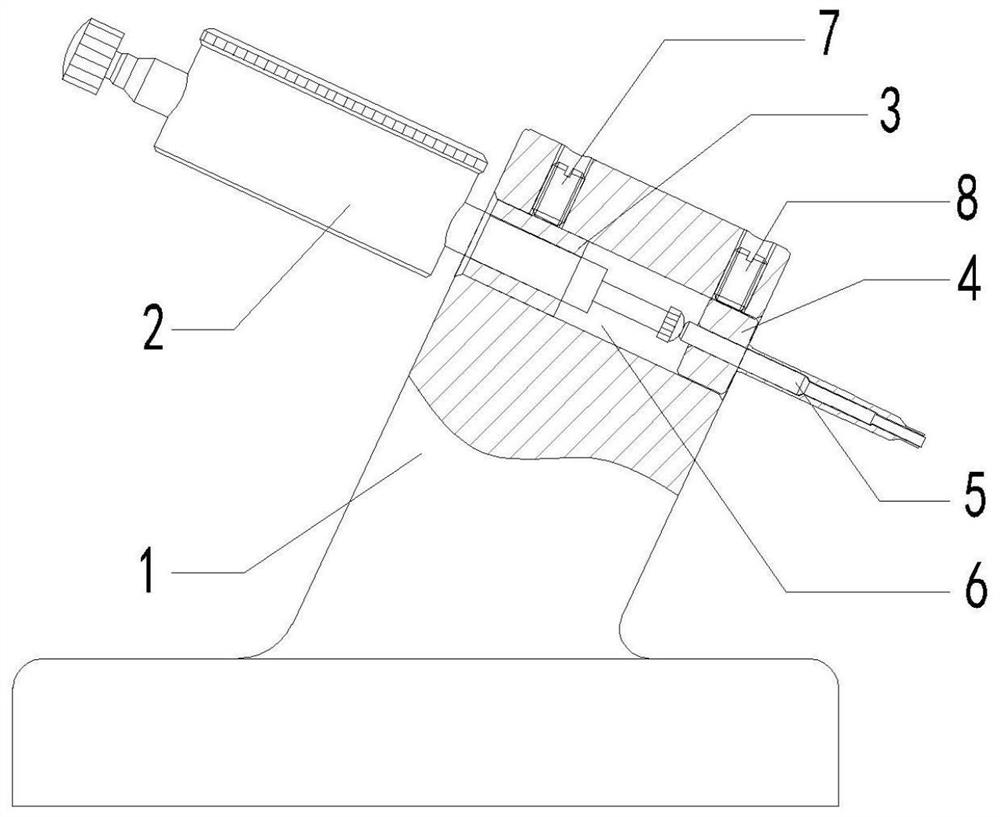

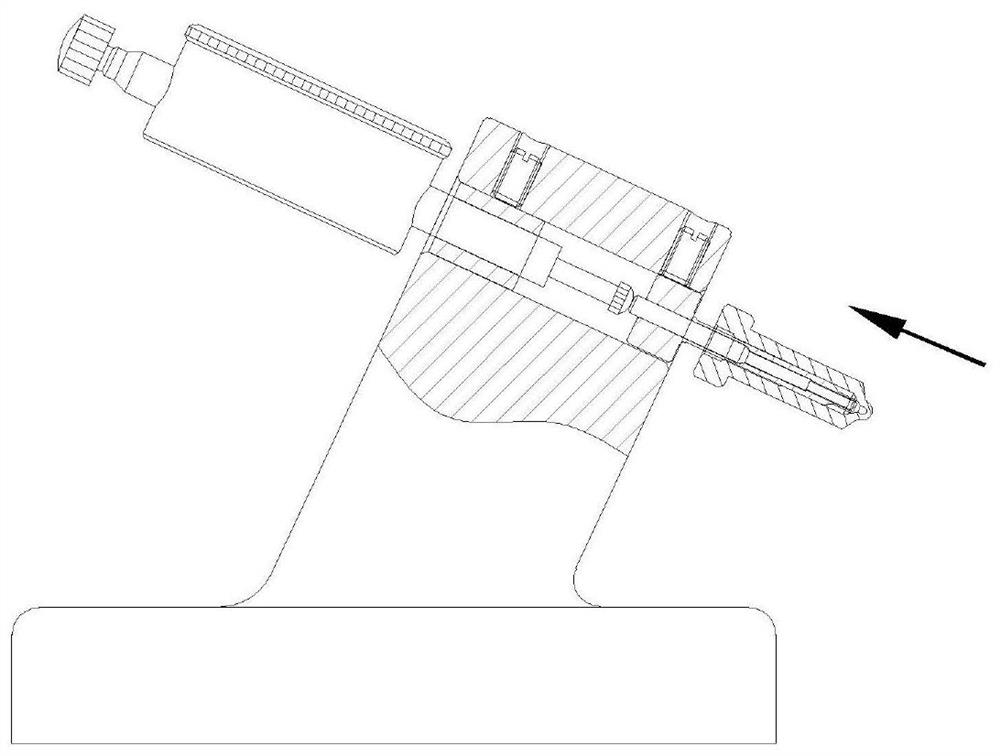

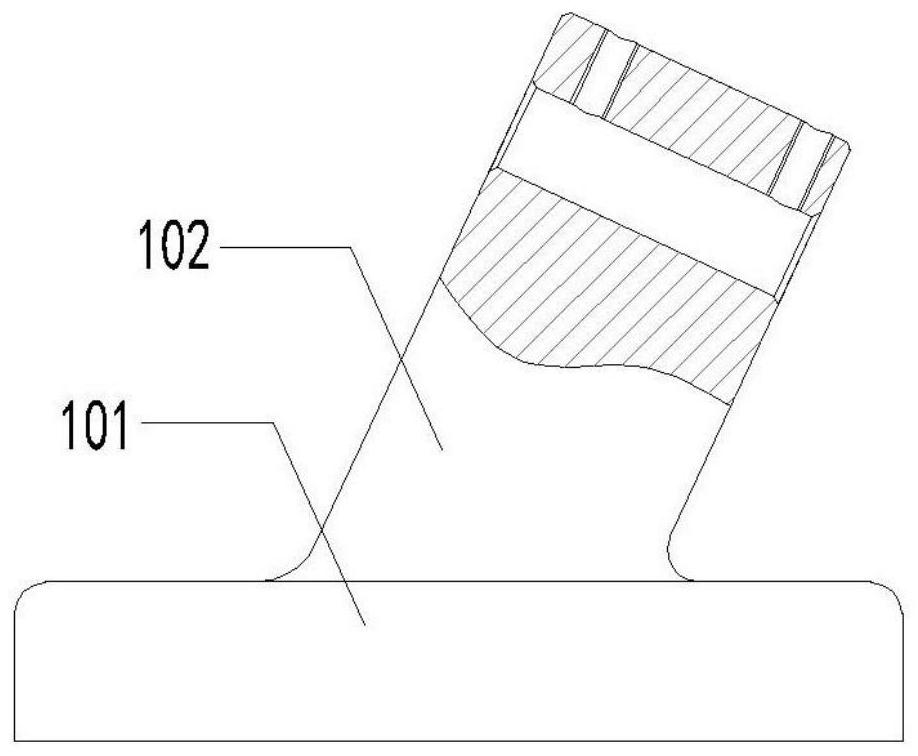

Device for detecting sealing seat surface angle of needle valve body

PendingCN112197737AShorten detection timeLow costMeasurement devicesStructural engineeringMechanical engineering

The invention provides a device for detecting the sealing seat surface angle of a needle valve body. The device comprises a base frame, a digital display indicating gauge, a bushing, a fixed measuringrod and a sliding measuring rod, a guide hole is formed in the base frame; the bushing is arranged on the periphery of the guide hole in a sleeving mode; the digital display indicating gauge penetrates through the bushing and is inserted into the guide hole; the fixed measuring rod is inserted into the guide hole, one end of the sliding measuring rod abuts against one end of the digital display indicating gauge, and the other end of the sliding measuring rod penetrates through the fixed measuring rod. The device provided by the embodiment of the invention can improve the detection speed and the detection rate and ensure the product processing precision.

Owner:山西柴油机工业有限责任公司

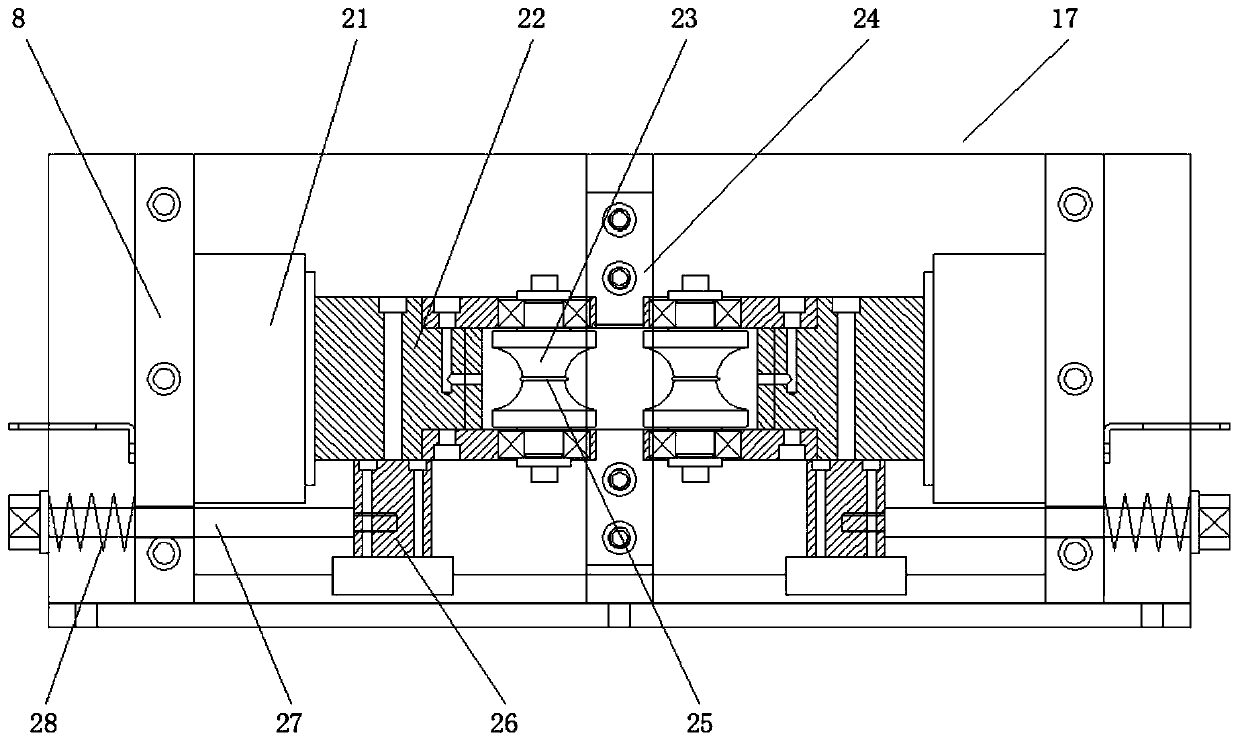

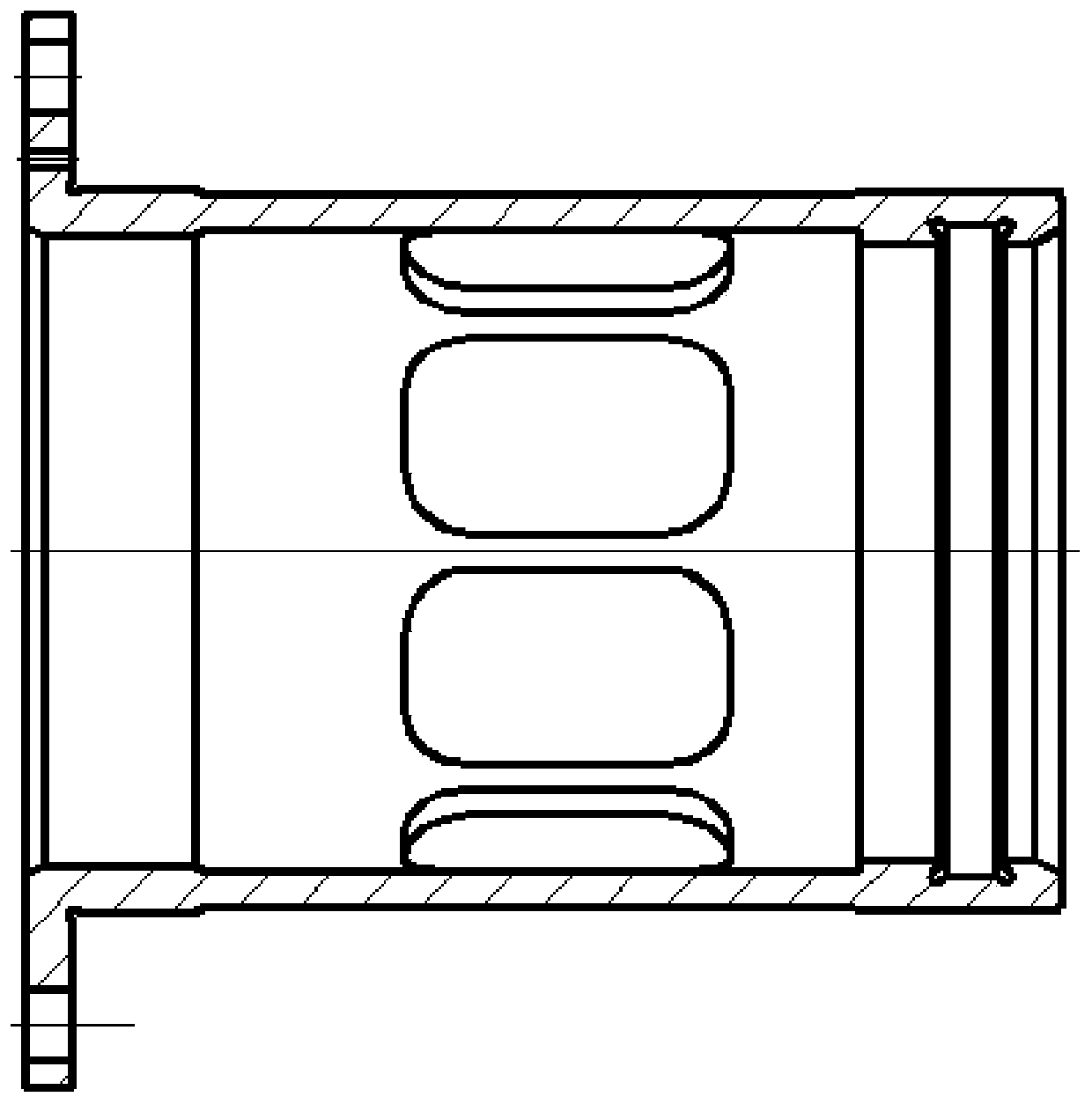

High-flux tube surface longitudinal groove machining device

The invention discloses a high-flux tube surface longitudinal groove machining device. The machining device comprises a support, a workpiece clamp and a rolling structure, wherein a partition plate isarranged inside the support, a screw rod is arranged on the partition plate in the support, and a guide rod is arranged on the partition plate below the screw rod; an oil tank is fixed on the left side of the upper end of a workbench, an oil cylinder seat is fixed on the workbench on the right side of the oil tank, a driving gear is arranged on an output shaft of the oil cylinder seat, and a rotating motor is fixed on the side face of the output shaft on the side face of the oil cylinder seat; and a supporting frame is arranged on a sliding seat, and the workpiece clamp is arranged on the workbench on the right side of the supporting frame in a sliding mode. According to the high-flux tube surface longitudinal groove machining device, the tooth shape and the groove shape of longitudinal groove pipes are determined through the tooth-shaped convex block structure in the middle part of a rolling mould, and through the semi-arc size of the rolling mould, the positioning of steel tubes aredetermined and the steel tubes cannot be deformed; and the longitudinal grooves are formed conveniently, the claw hand is pushed by an air cylinder to move forwards and backwards, the air cylinder ismatched with a limiting block to drive the claw hand to clamp the workpiece, so that the high-flux pipes with different pipe diameters are automatically adjusted.

Owner:WUXI CHEM EQUIP CO LTD

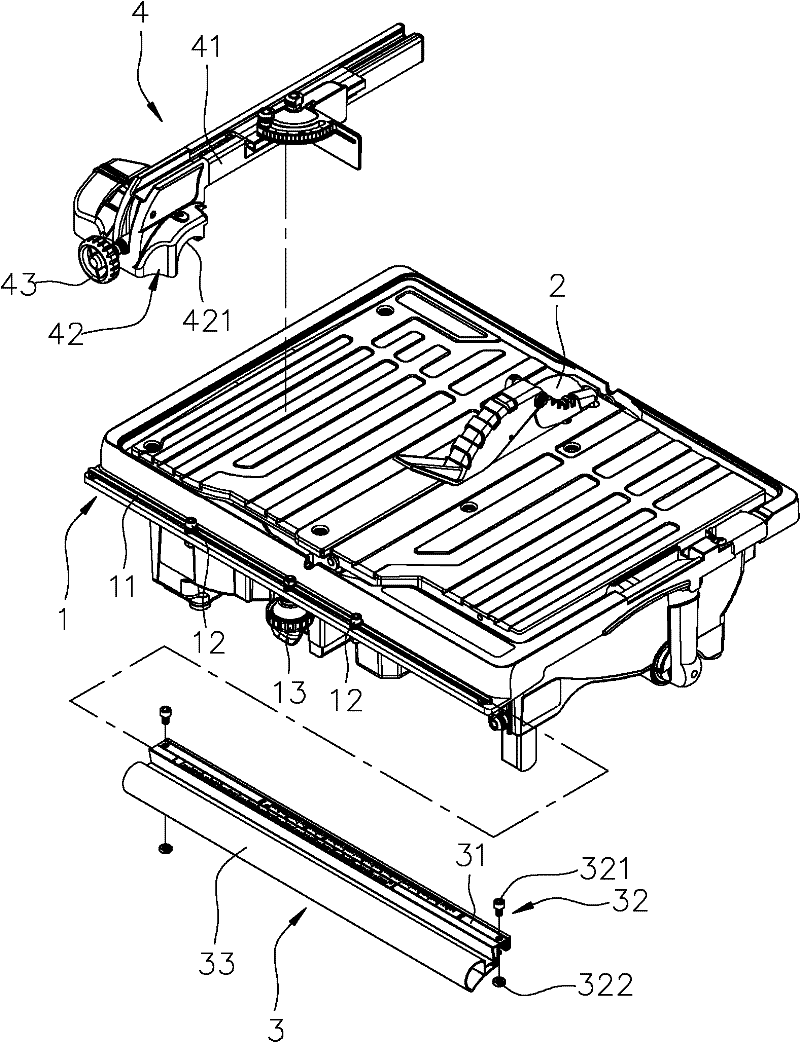

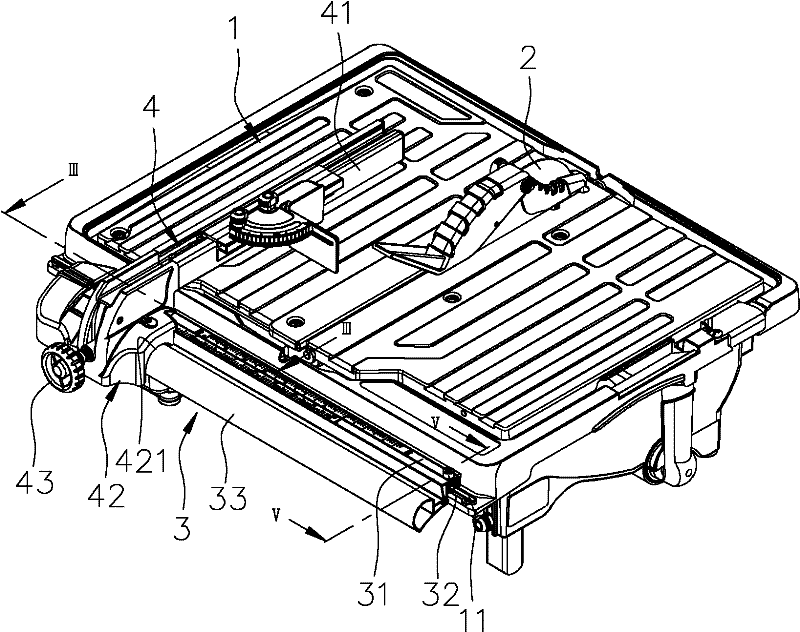

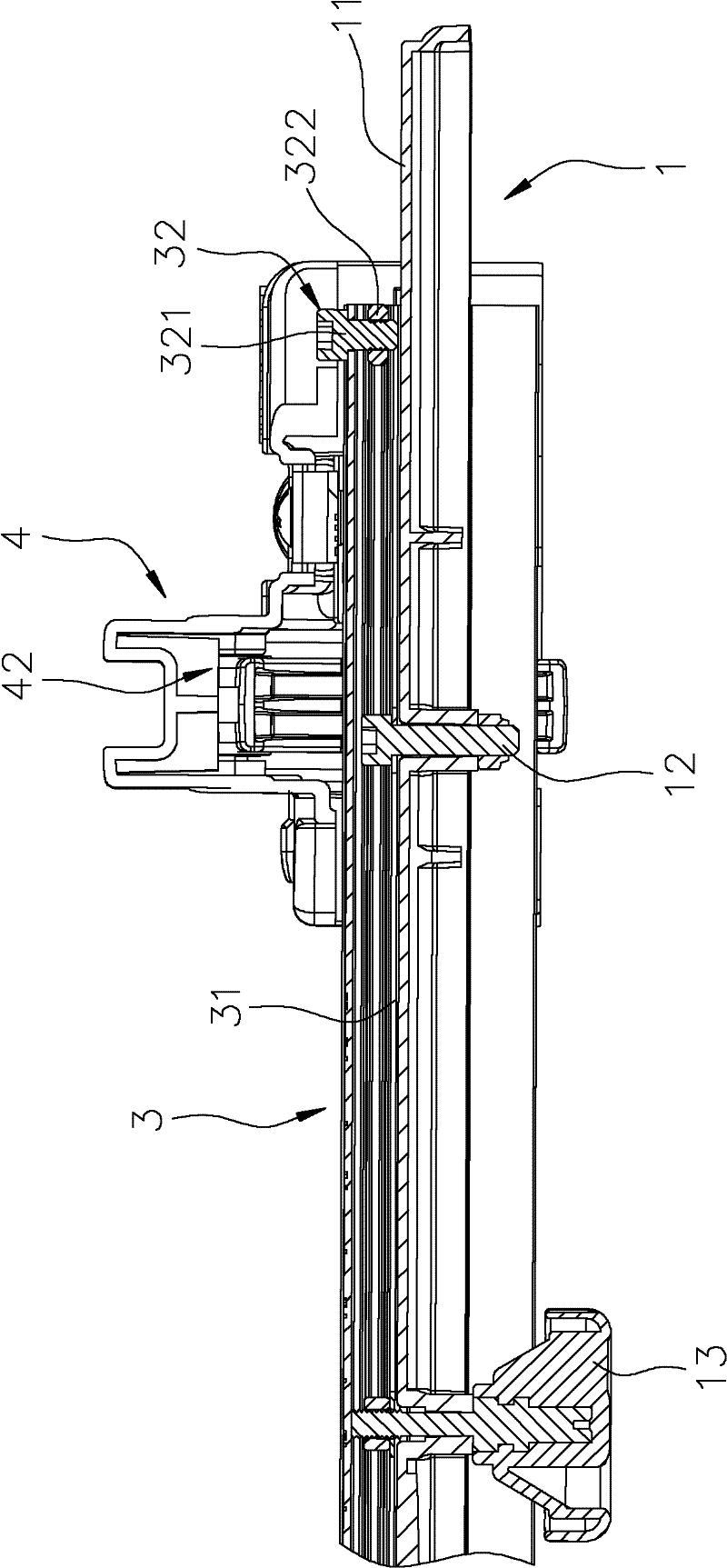

Cutter with extendable machining range

InactiveCN102632294AMeet the processing conditionsShorten the lengthMetal sawing devicesEngineeringLarge size

The invention provides a cutter with an extendable machining range. The cutter comprises an operating platform, a sawing unit, a movable type guide rail unit, a backup plate unit, and a fixing piece mounted on one of the operating platform and the movable type guide rail unit. The operating platform comprises a first guide rail; the movable type guide rail unit comprises a slot main body mounted on the first guide rail and a second guide rail; the fixing piece is abutted against the other one of the operating platform and the movable type guide rail unit, which is not provided with the fixing piece; and the backup plate unit comprises a backup plate arranged on the platform face of the operating platform, and a guide base arranged on the second guide rail. When the cutter moves relatively to the operating platform through the movable type guide rail unit, the cutter can extend outwards in a machining range, so that even if a size of the working piece is larger, a machining condition of the working piece with a larger size is met by changing a position of the movable type guide rail unit relative to the operating platform.

Owner:REXON IND CORP LTD

Elastic supporting structure type bearing outer ring finish lapping machining method

ActiveCN111015379AReduce thicknessReduced effective distanceRevolution surface grinding machinesEngineeringMachine

The invention discloses an elastic supporting structure type bearing outer ring finish lapping machining method, and relates to the elastic supporting structure type bearing outer ring finish lappingmachining method in order to solve the problem that in existing elastic supporting structure type bearing manual polishing, the product precision is low. The finish lapping machining method comprisesthe steps that firstly, specialized tools are designed, specifically, the specialized tools comprise a finish lapping machine tyre cushion, a specialized C-shaped fulcrum and a fulcrum gasket, the finish lapping machine tyre cushion is composed of a machine tool installing portion and a bearing contact portion, and the fulcrum gasket is composed of a bearing outer ring clamping portion and a C-shaped fulcrum connecting portion; secondly, pre-machining is conducted, and a bearing outer ring to be subjected to finish lapping is obtained; thirdly, assembling is conducted; and fourthly, finish lapping is conducted on the bearing outer ring, and an elastic supporting structure type bearing outer ring is obtained. The elastic supporting structure type bearing outer ring finish lapping machiningmethod has the advantages that the purpose that finish lapping is conducted on the elastic supporting structure type bearing outer ring by adopting the BS122 finish lapping machine is achieved; and the technical requirements such as the straightness and the roundness of the machined product meet the requirements of a finished product, and the qualification rate reaches 95% or above. The elastic supporting structure type bearing outer ring finish lapping machining method is mainly applied to elastic supporting structure type bearing finish lapping.

Owner:AVIC HARBIN BEARING

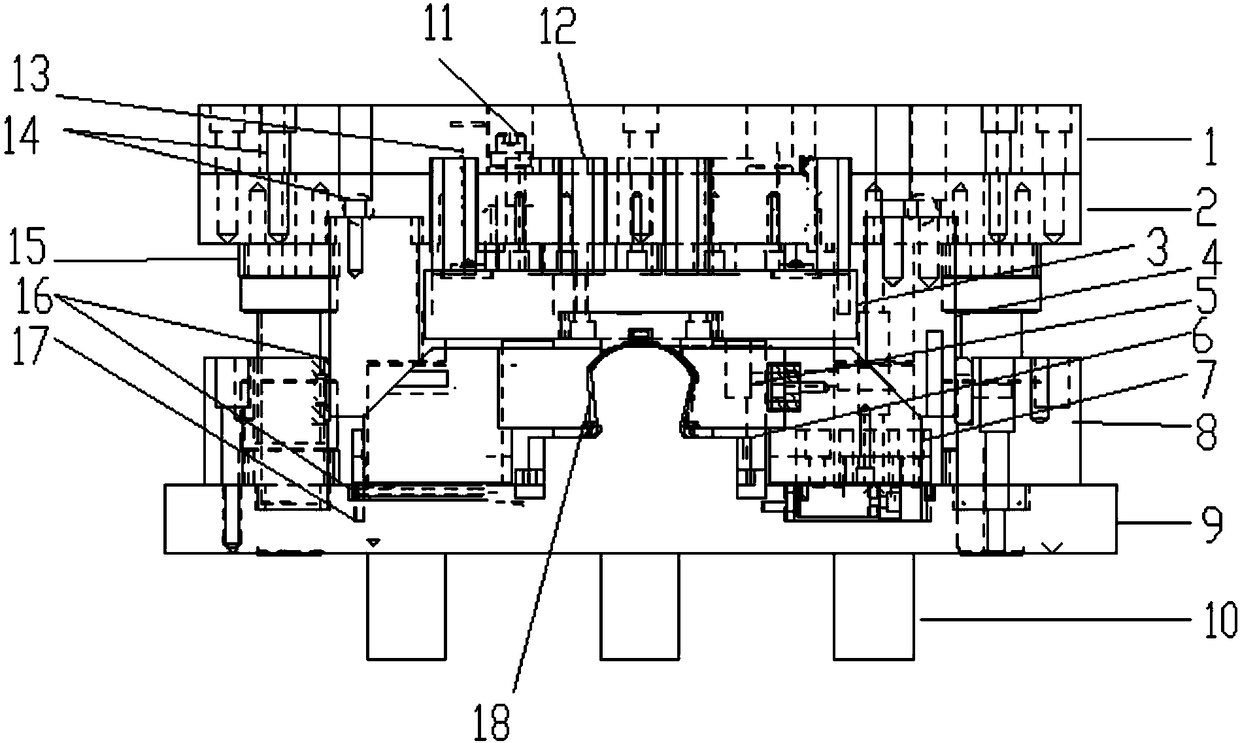

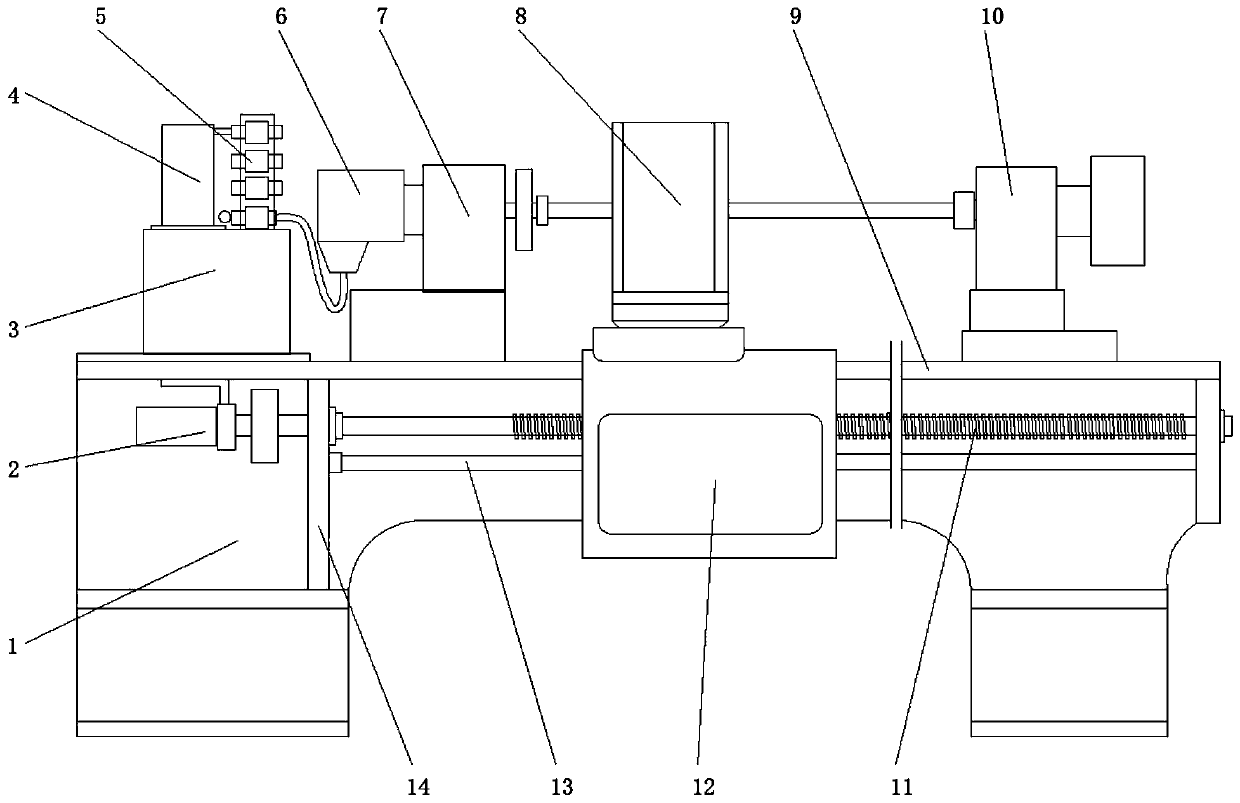

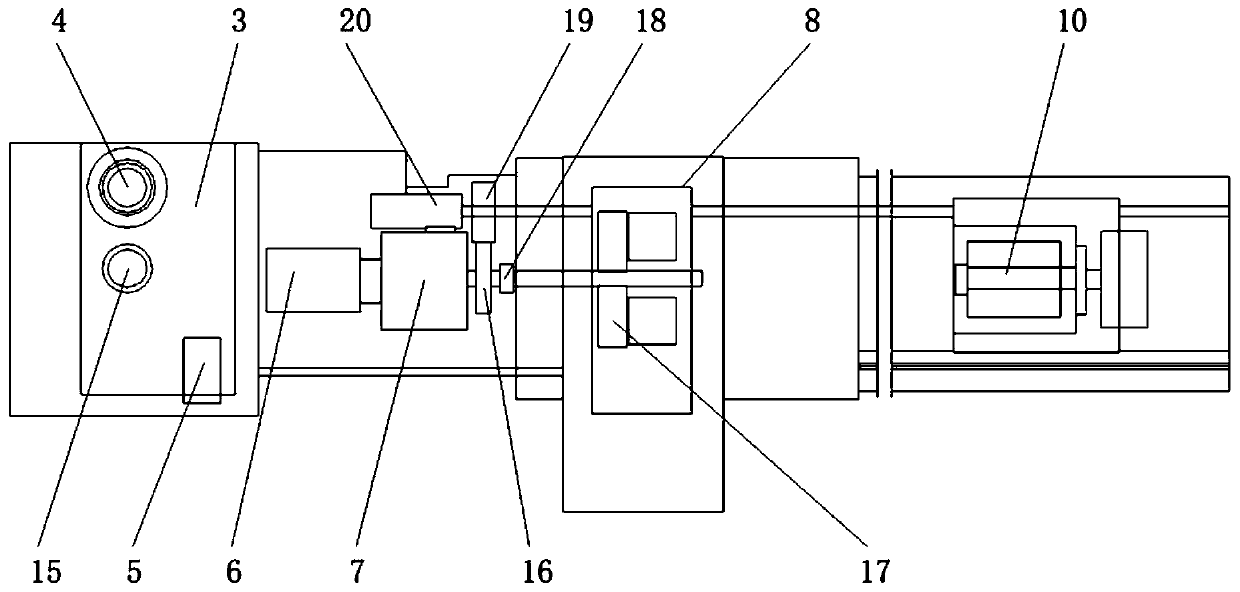

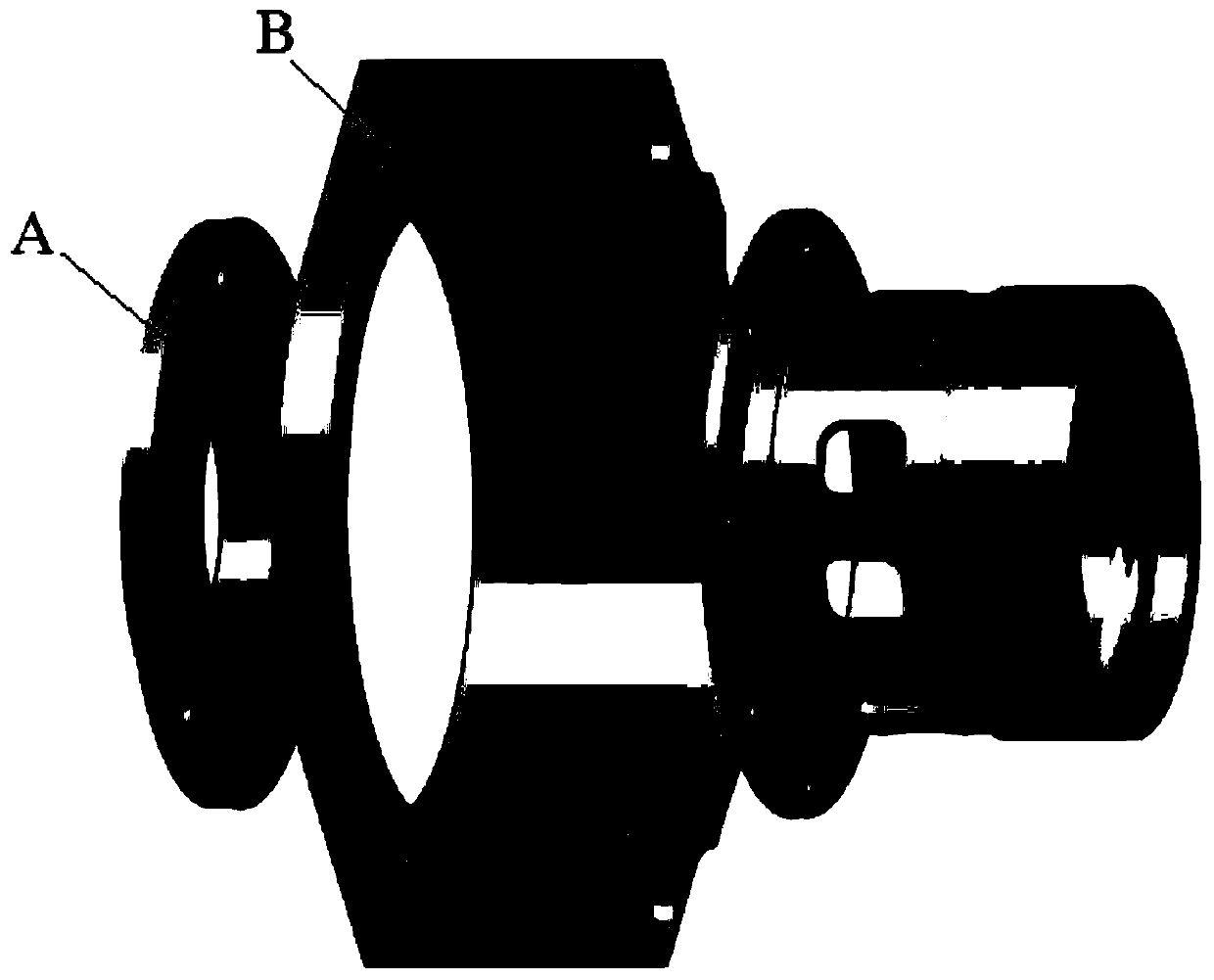

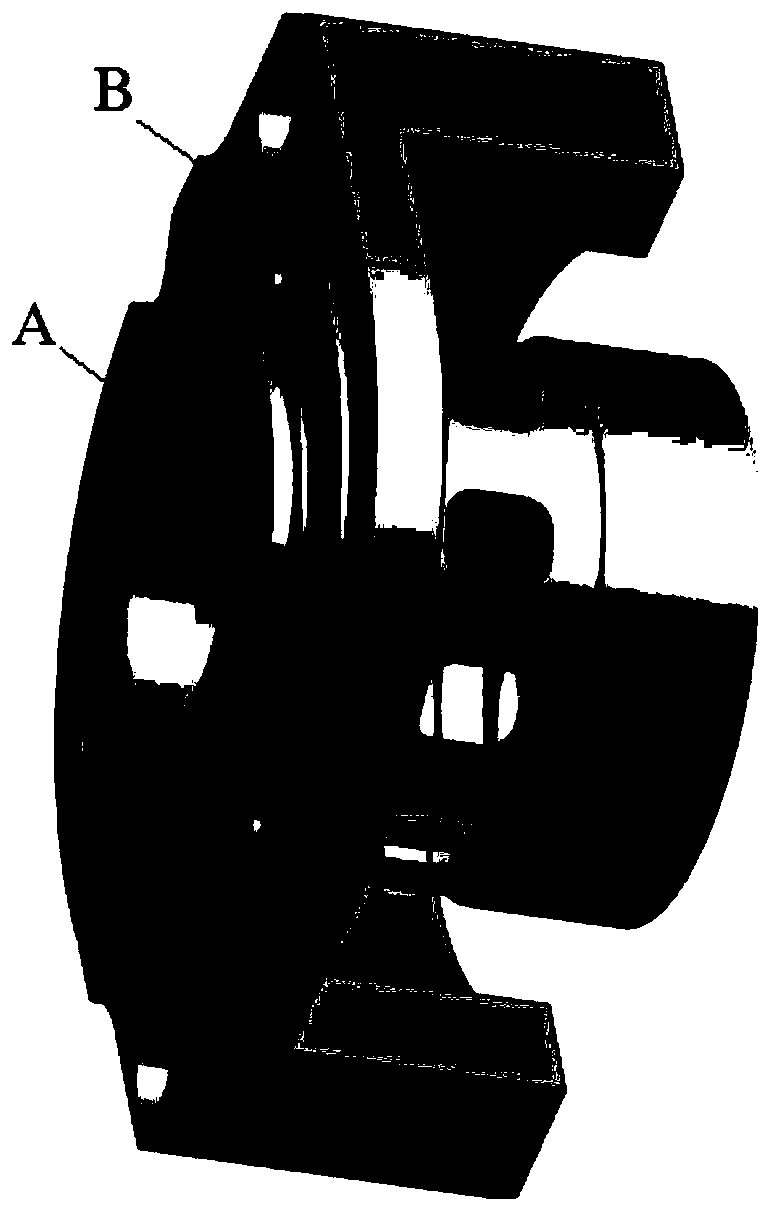

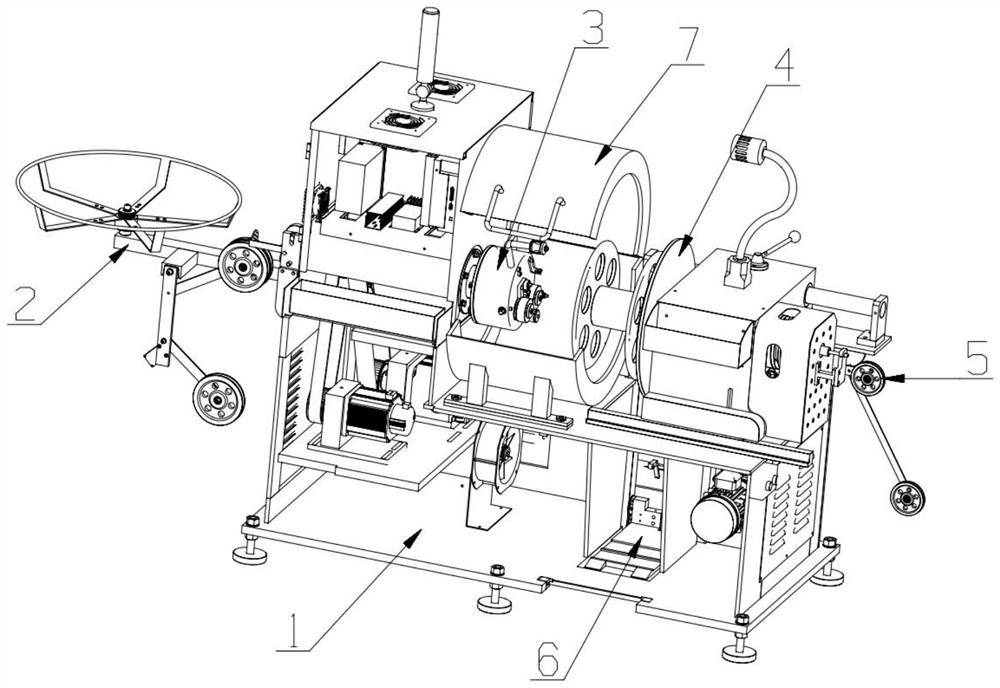

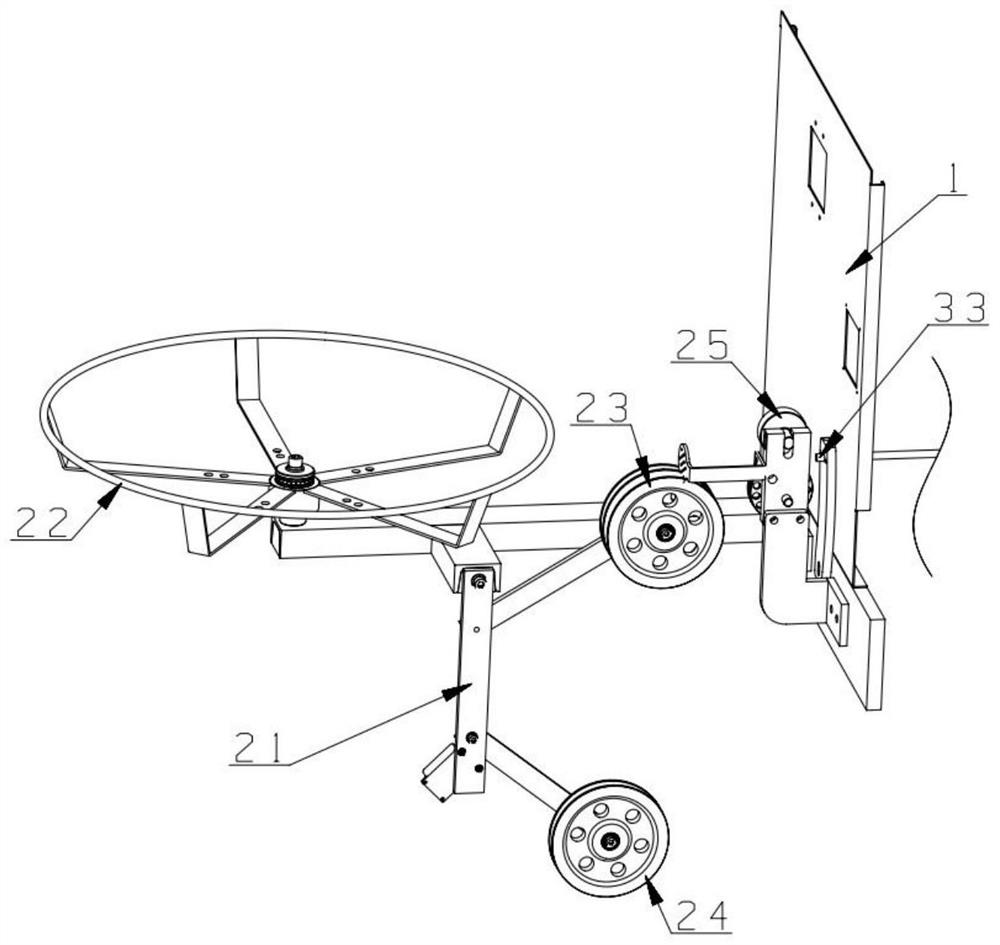

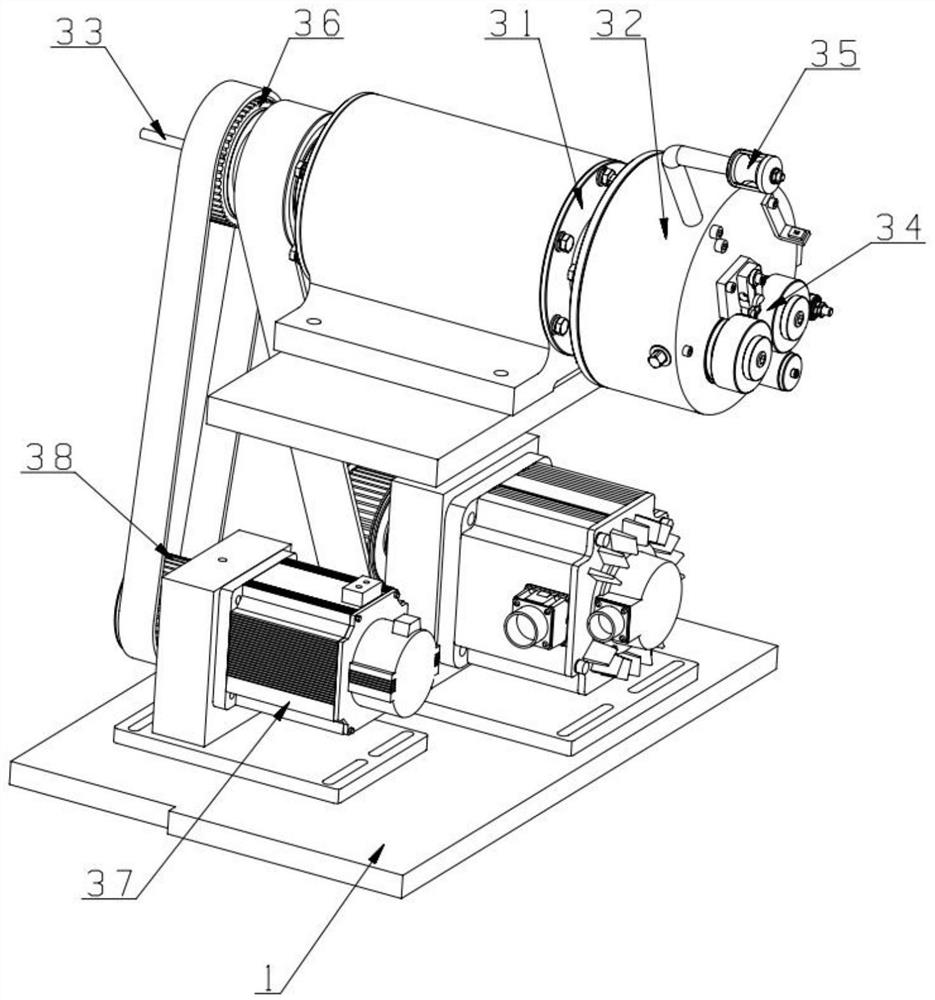

Numerical control optical fiber spiral armoring machine

ActiveCN113219608AMeet the process conditionsFibre mechanical structuresElectric machineryEngineering

The invention discloses a numerical control optical fiber spiral armoring machine which comprises a machine frame, a feeding device, an armoring main machine, a wire coil device, a discharging device and a wire coil feeding device, wherein the feeding device, the armoring main machine, the wire coil device, the discharging device and the wire coil feeding device are connected with the machine frame, the feeding device, the armoring main machine, the wire coil device and the discharging device are sequentially arranged from left to right, and the wire coil feeding device is arranged below the wire coil device. Two motors are adopted to run at different speeds in a matching mode, the rotating speed difference is formed, the effect of eliminating torsion on a product is achieved, the purpose of stepless speed regulation is achieved, the needed speed ratio is adjusted at will, the automation degree of the device is high, the yield is greatly improved, meanwhile, the wire coil feeding device is arranged inside, and the attractiveness and safety are improved.

Owner:盐城君朋机械有限公司

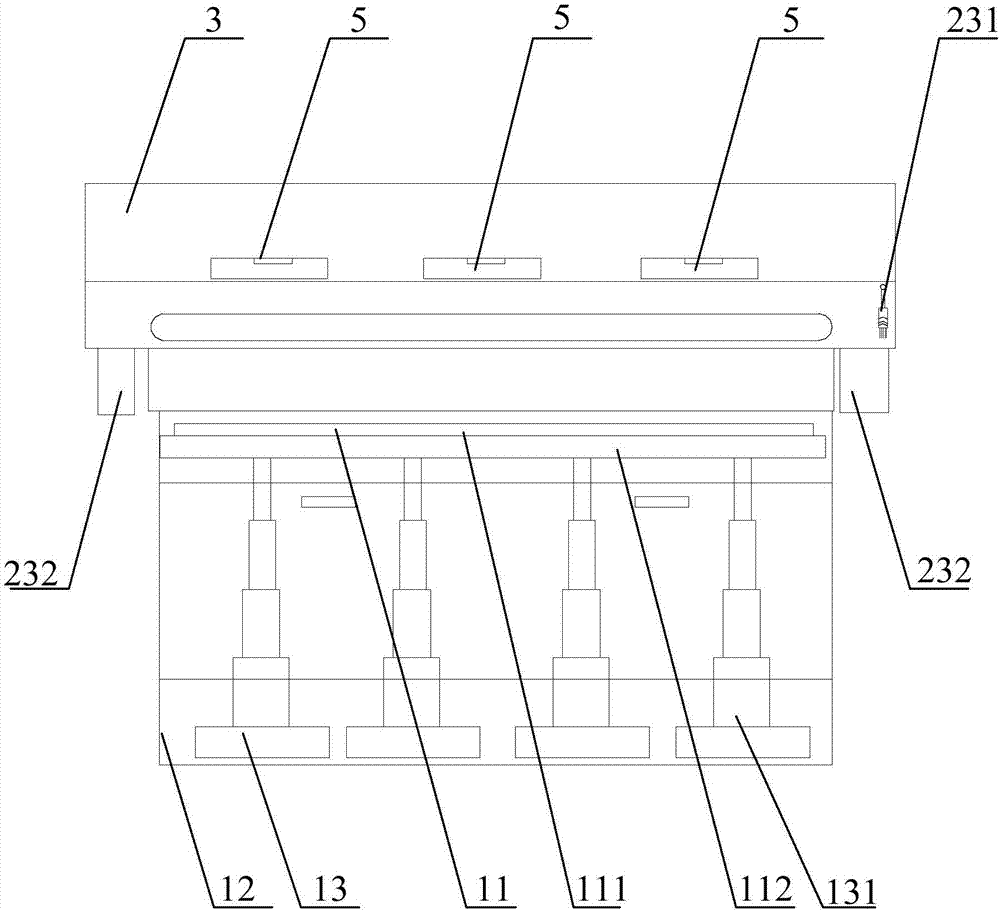

Cuboid-shaped 3D printing equipment and 3D printer

ActiveCN107008903AImprove levelnessImprove compactnessAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingControl system

The invention relates to the technical field of selective laser melting metal 3D printing, in particular to cuboid-shaped 3D printing equipment and a 3D printer. The cuboid-shaped 3D printing equipment comprises construction-forming device and a powder supplying system. A powder laying device is used for laying metal powder in a powder feeding device on an operation platform in a rolling-type powder laying mode. A powder flattening piece driving mechanism is connected with a powder flattening piece and used for driving the powder flattening piece to move on the operation platform in a reciprocating mode so as to flatten the metal powder on the operation platform. The powder flattening piece driving mechanism is electrically connected with a control system of the 3D printer. The power laying device lays the metal powder on the operation platform in a rolling-type mode, the powder flattening device flattens the metal powder on the operation platform, and accordingly the flatness of a metal powder layer on the operation platform is improved, the density and surface smooth finish of a component can be improved effectively, and the machining condition of a large-size cuboid-shaped component with the forming length being larger than or equal to 3 m is met.

Owner:窦鹤鸿

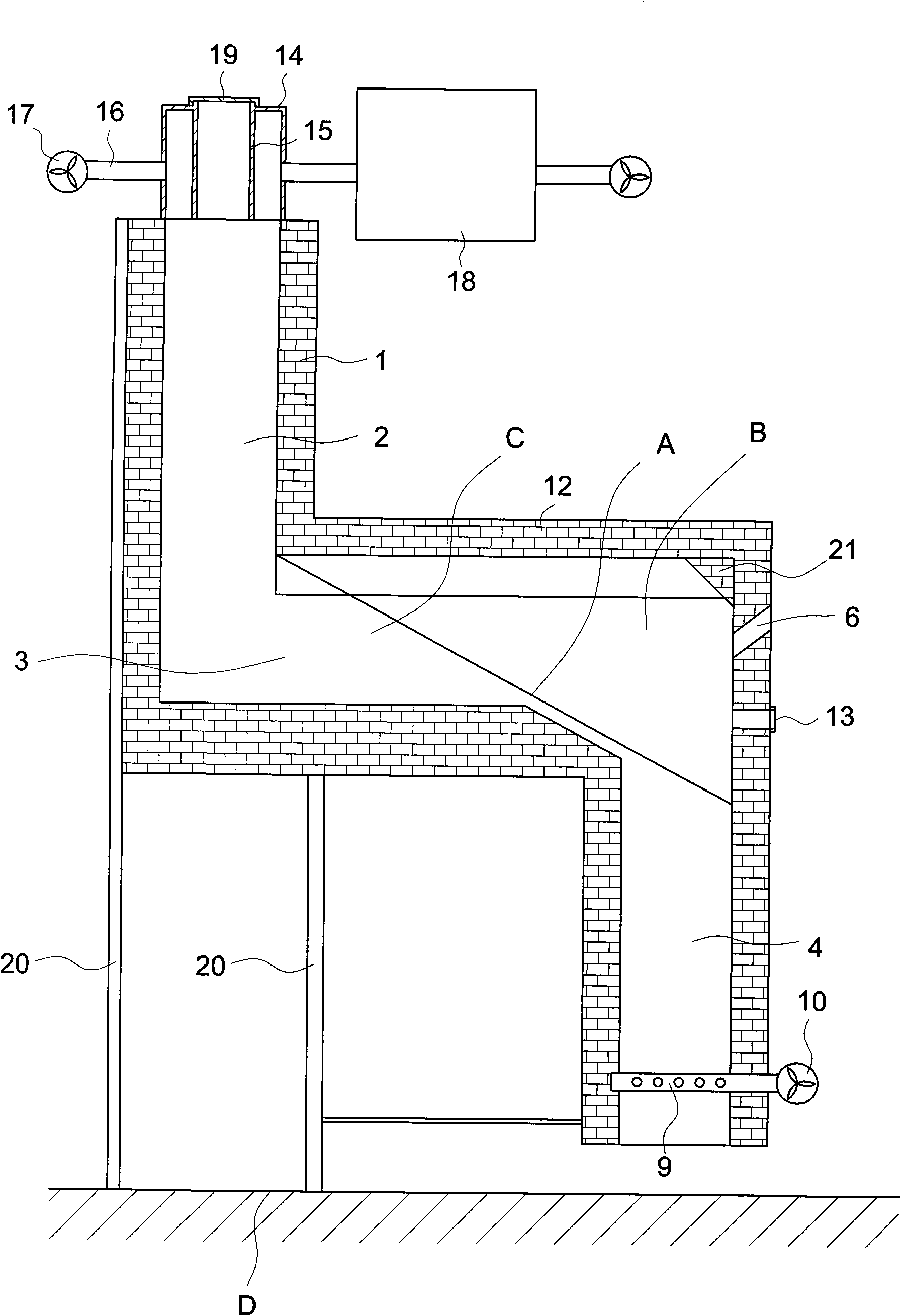

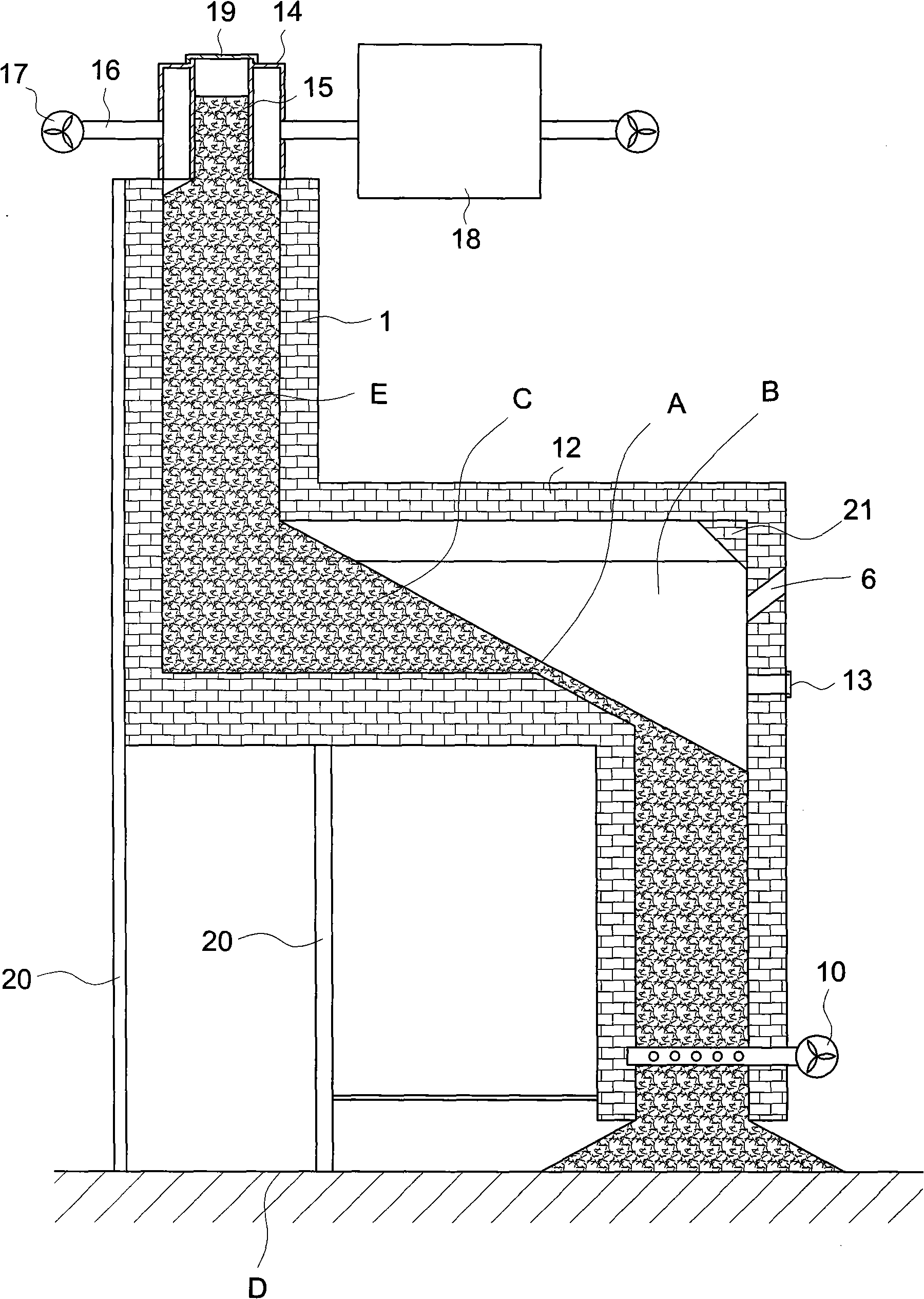

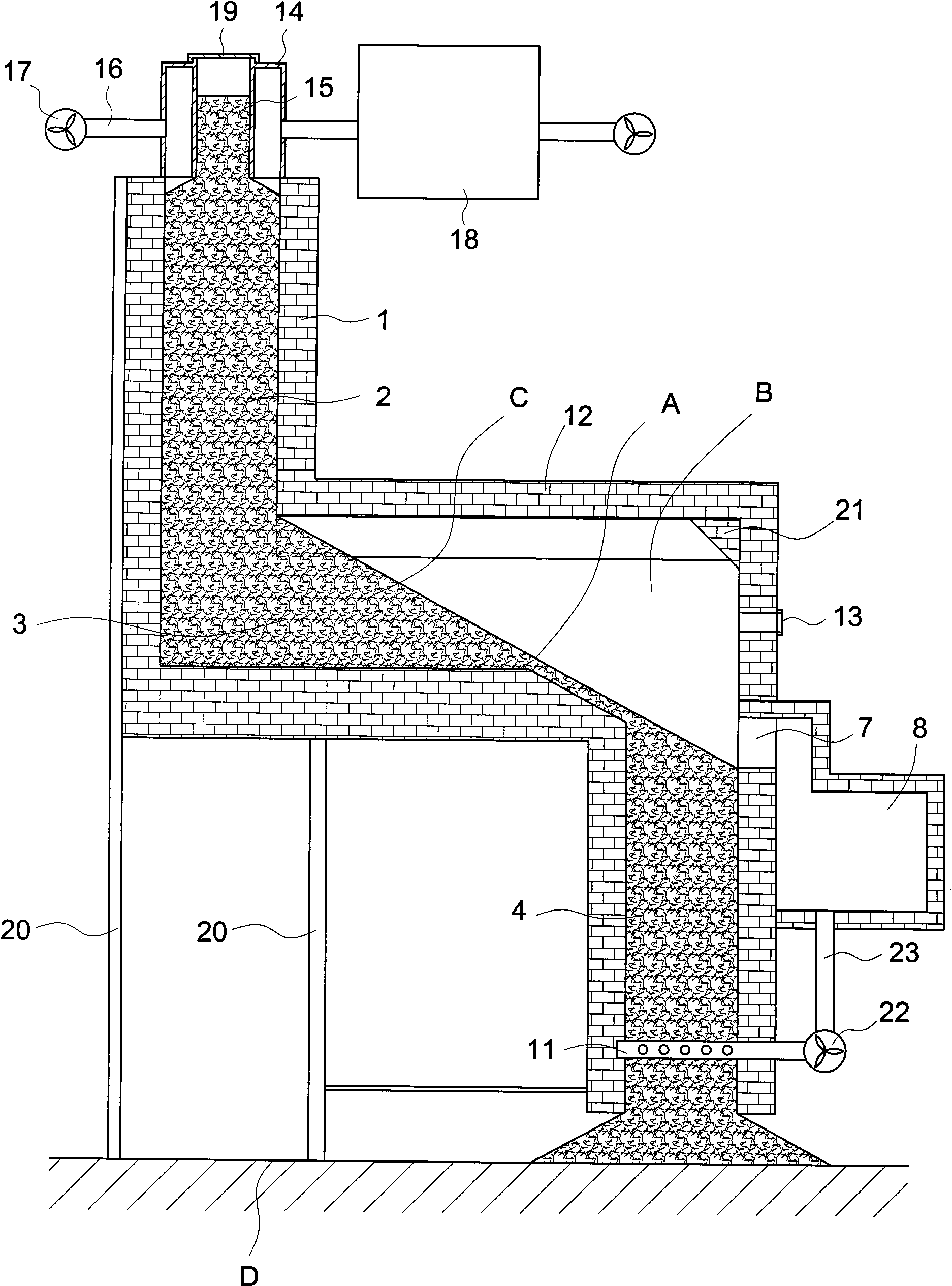

Dislocation type centre section naked flame vertical kiln

The invention relates to a structural improvement for a brick and concrete structured vertical kiln of calcined lime, gangue, chainotte, plaster and other block materials, in particular to a middle part open fire vertical kiln in which a pre-heating chamber and a cooling chamber are in malposition. The invention comprises a kiln body arranged on the base, the kiln body comprises an upper pre-heating chamber, a middle calcining chamber and a lower cooling chamber, the pre-heating chamber, the calcining chamber and the cooling chamber are mutually communicated, inner cavity of the calcining chamber is divided by the natural stacking slant of the block materials to form a material stacking space and a heating room, the projection positions of the pre-heating chamber and the cooling chamber on a horizontal plane are totally staggered, the lower end of the pre-heating chamber is connected with the top end of the natural stacking slant of the block materials, and the upper end of the cooling room is connected with the bottom end of the natural stacking slant of the block materials. The invention has the advantages of fast and complete combustion of fuel, greatly increased kiln yield per unit, easy operation, improved stability of quality, little impurities and high quality of the produced lime, slight pollution and environmental protection.

Owner:黄远辉

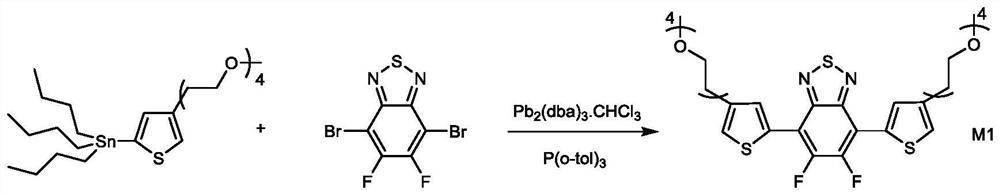

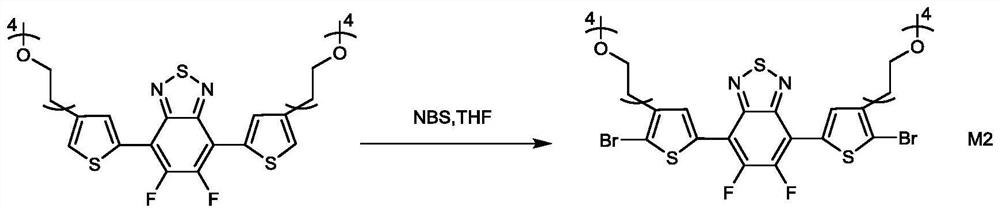

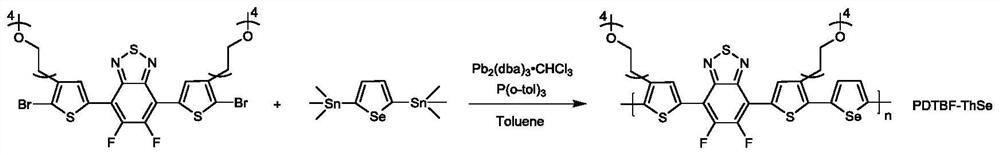

Conjugated polymer material capable of being processed by green solvent and preparation method of conjugated polymer material

PendingCN113980250AGood thermal stabilityBroad absorption spectrumSolid-state devicesSemiconductor/solid-state device manufacturingSide chainPower storage

The invention belongs to the field of organic photoelectric materials. In recent years, as wide application of donor (D)-acceptor (A) type conjugated polymers gradually attracts attention of people, in order to solve the problem that conjugated polymer materials capable of being processed by green solvents are deficient, the dissolving property of the materials in polar solvents is regulated and controlled through side chain modification, and necessary conditions are provided for green industrial production of solar cell devices and electrochromic devices in the future. In the field of solar cells, the material can be matched with numerous acceptor materials, and single-layer or laminated devices can be prepared through green solvent processing; and the material has high contrast in the field of electrochromism, can be prepared into an electrochromic device of a hydrogel electrolyte, can be compatible with a water electrolyte to prepare an environment-friendly electrochromic device, and reduces the influence of an organic electrolyte on the environment. The material has dual functions of photovoltaic and electrochromism, and can be prepared into a device integrating power generation, power storage and intelligent window in the future.

Owner:JILIN UNIV

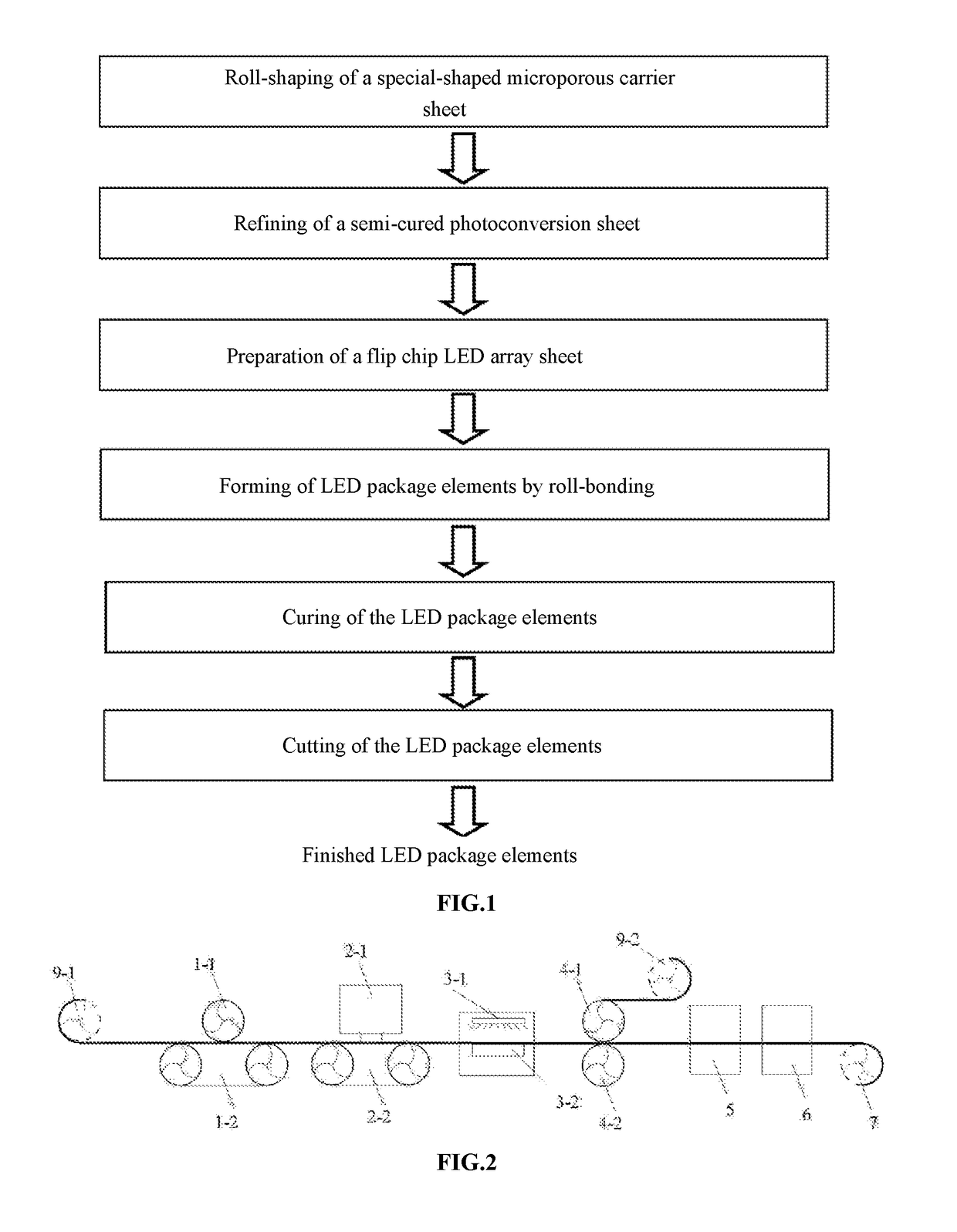

Process Method Using Deformable Organic Silicone Resin Photoconverter to Bond-Package Led

ActiveUS20180233639A1Improve production efficiencyHigh yieldSolid-state devicesSemiconductor devicesLed arrayEngineering

A process method for bond-packaging an LED using a special-shaped organic silicone resin photoconverter includes the following continuous process flow: roll-molding of a refined photoconversion sheet, roll-shaping of a photoconversion sheet array, sheet melting for the photoconversion sheet array, preparation of a flip chip LED array sheet, forming of LED package elements by roll-bonding, curing of the LED package elements, and cutting of the LED package elements. The present invention has a significant advantage of bond-packaging an LED by continuous rolling, and can meet a condition requirement of bond-packaging an LED using a special-shaped organic silicone resin photoconverter, thereby enhancing the production efficiency and yield of LED packages in industrialized batch production.

Owner:JIANGSU CHERRITY OPTRONICS CO LTD

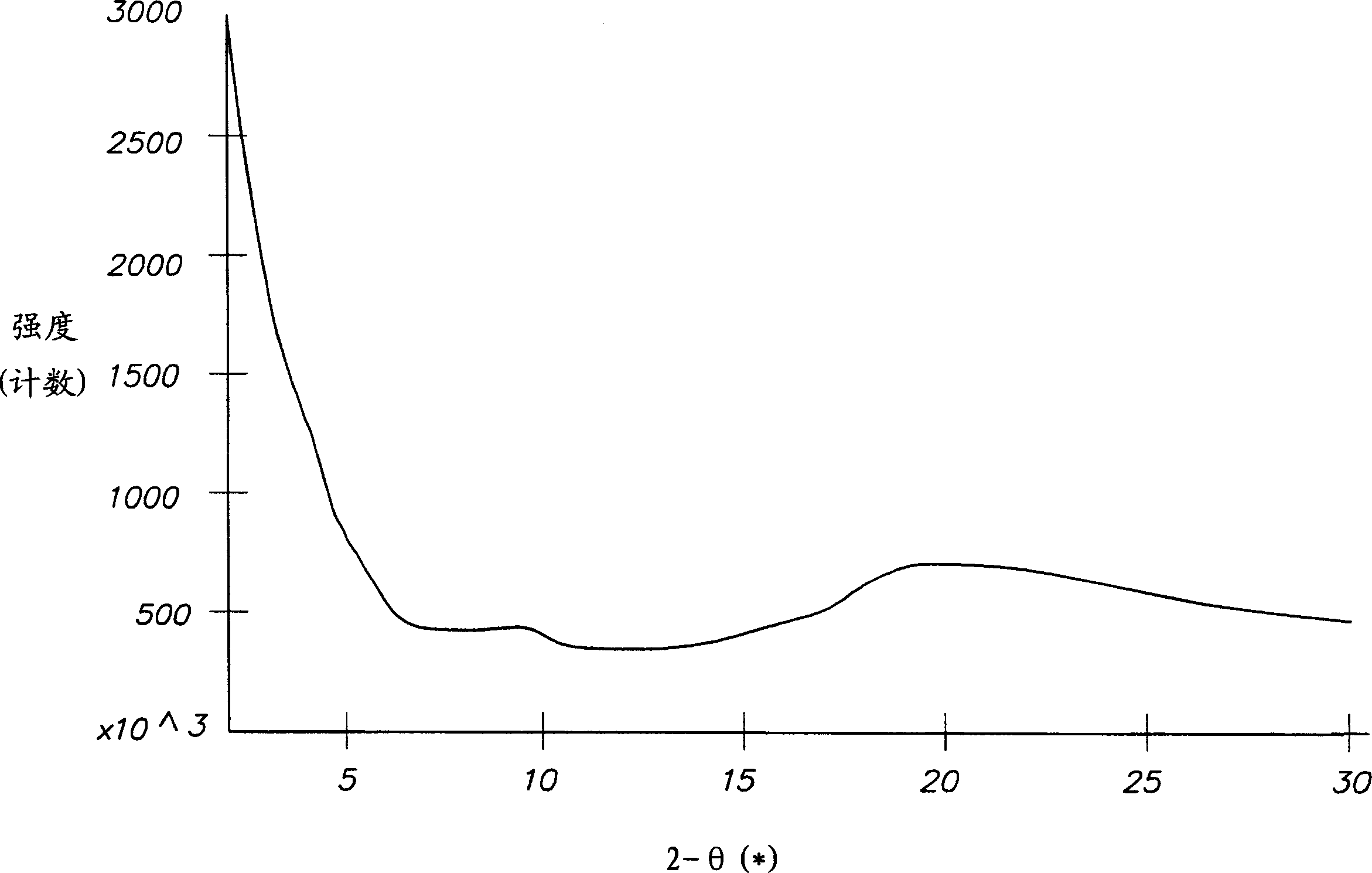

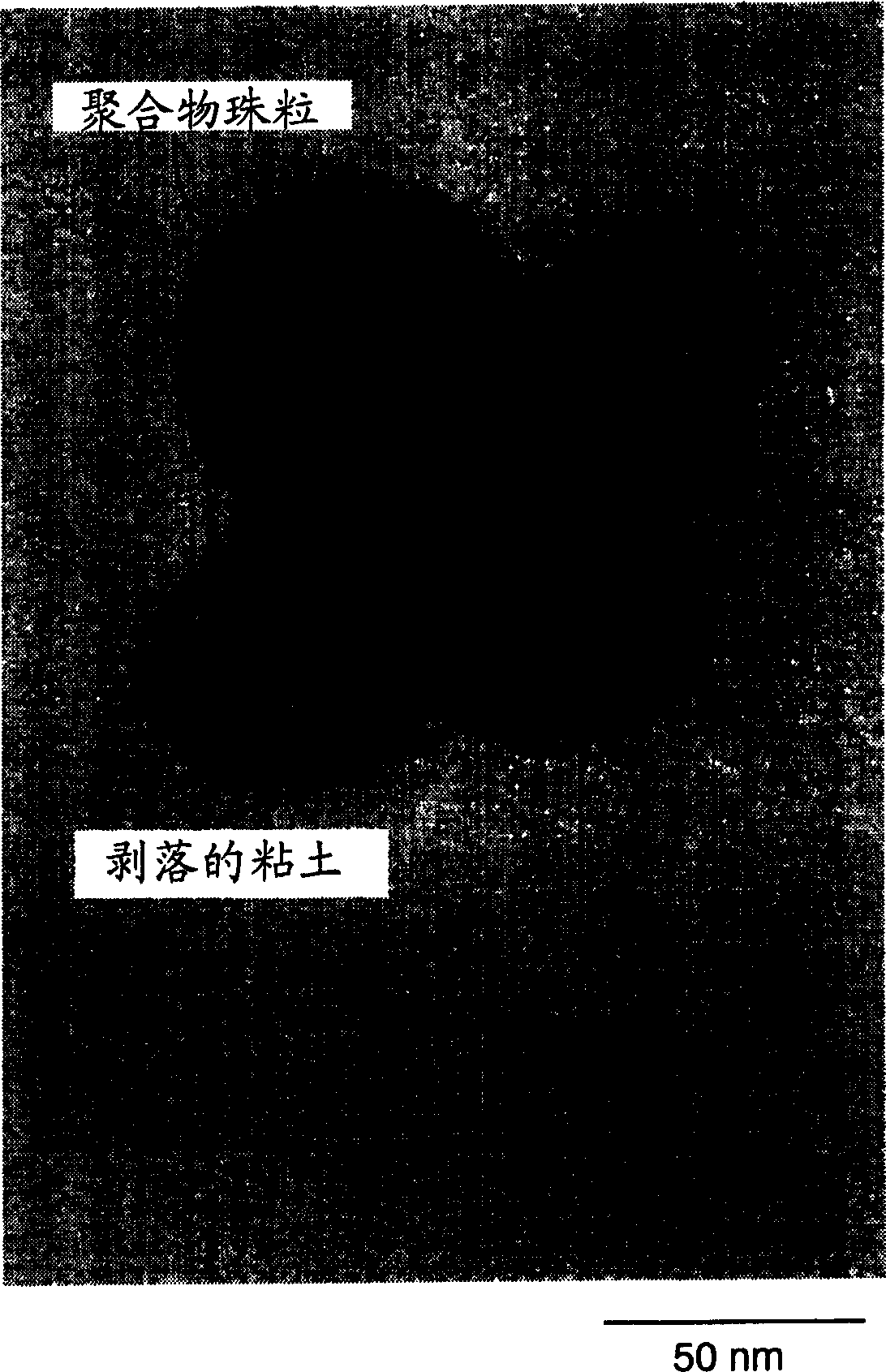

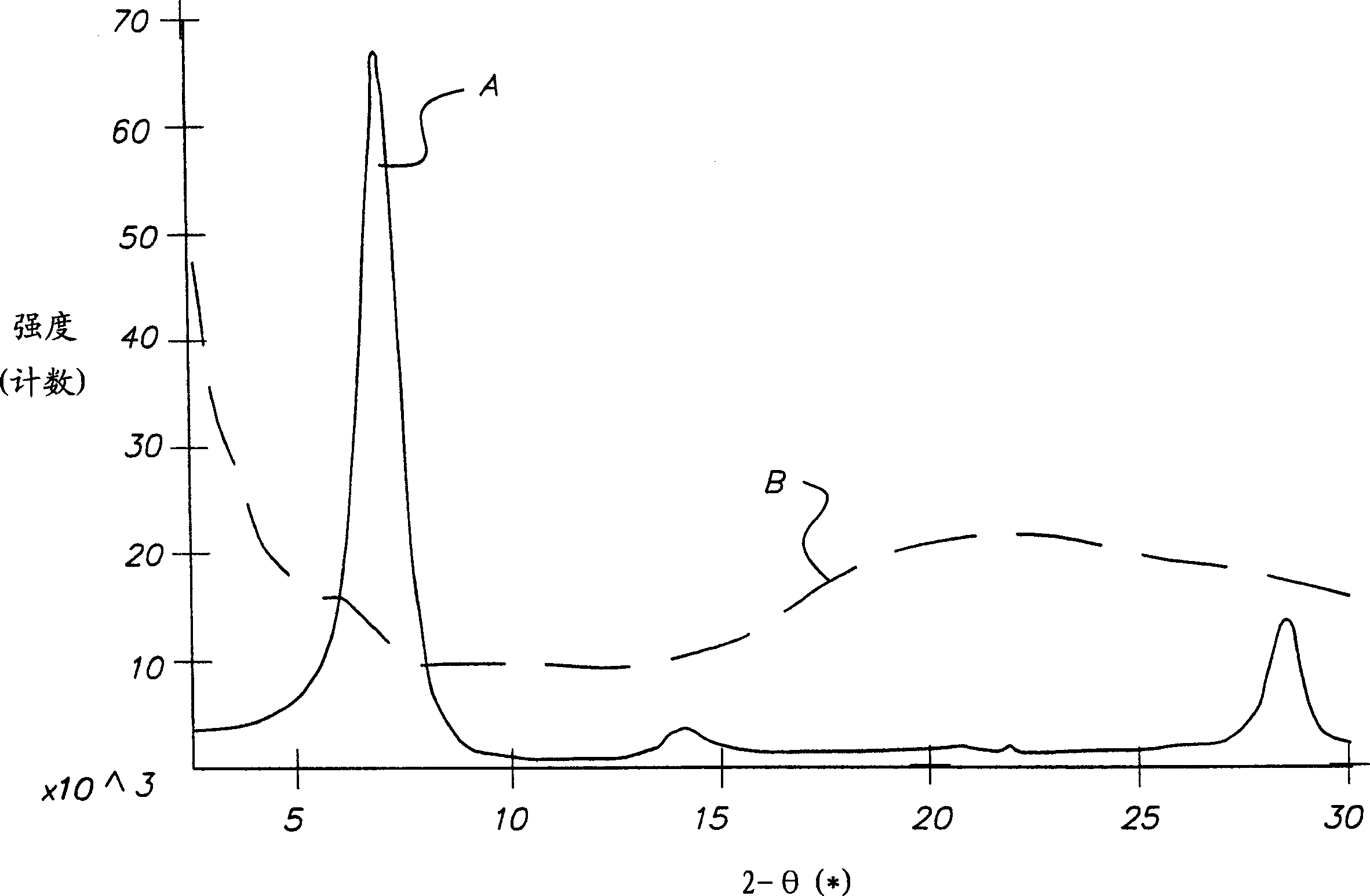

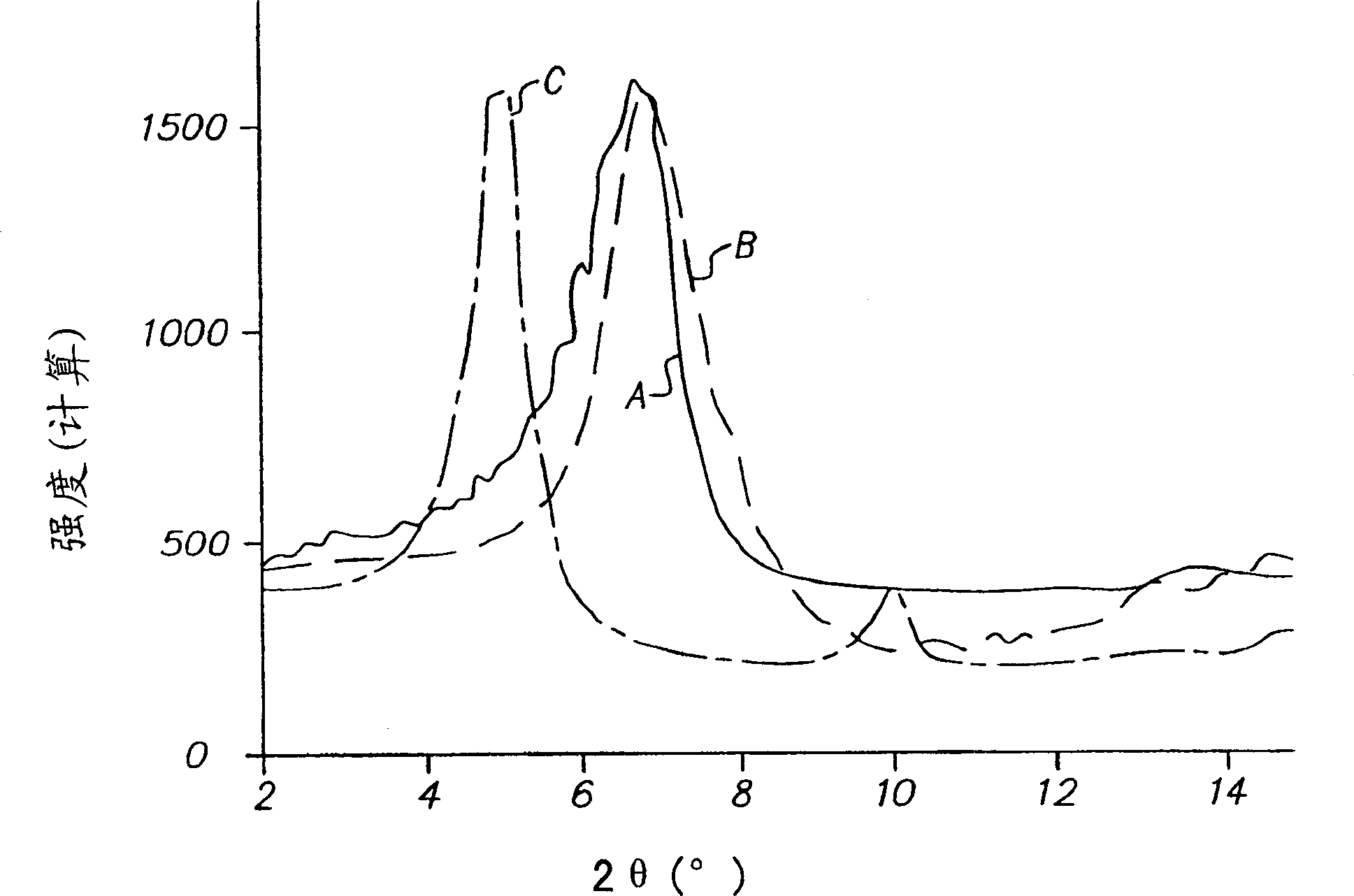

Product made of clay embedded with block copolymer

InactiveCN1418918AGood physical propertiesImprove heat deflection temperaturePhotosensitive materialsHydrotalcitePolymer scienceCopolymer

An intercalated clay comprising a clay intercalated with a block copolymer wherein said block copolymer comprises a hydrophilic block capable of intercalating said clay. An additional embodiment is an article comprising a matrix polymer and clay wherein said clay is intercalated with a block copolymer, wherein said block copolymer comprises a hydrophilic block capable of intercalating said clay and a matrix compatible block compatible with said matrix polymer.

Owner:EASTMAN KODAK CO

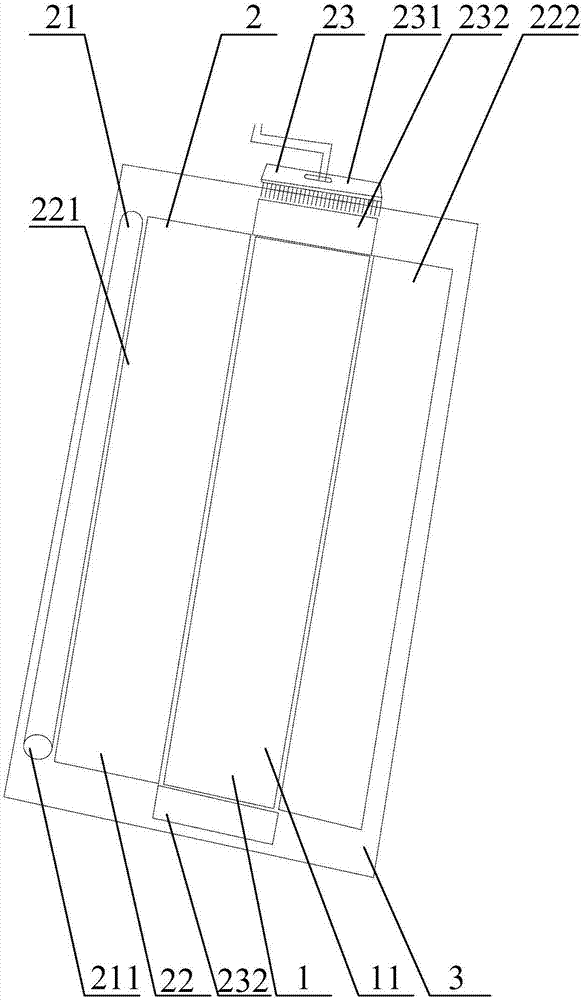

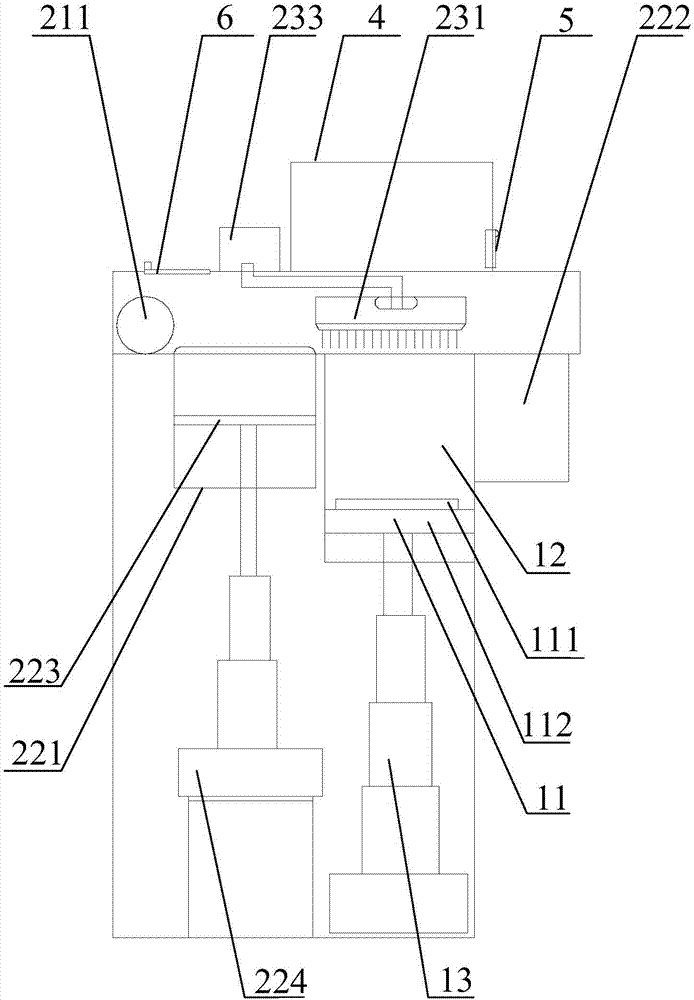

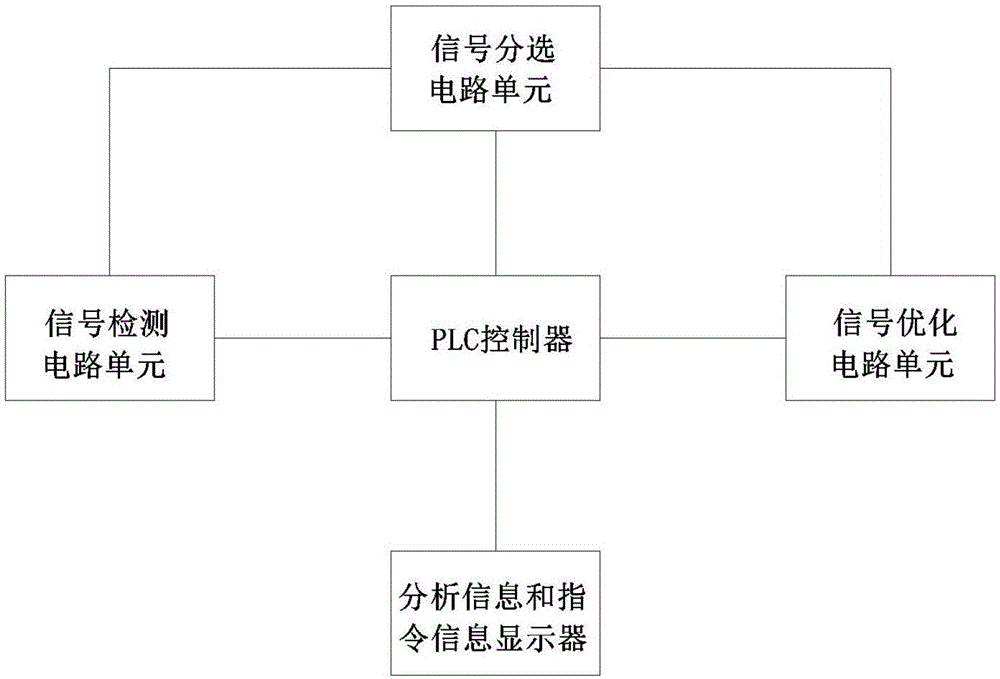

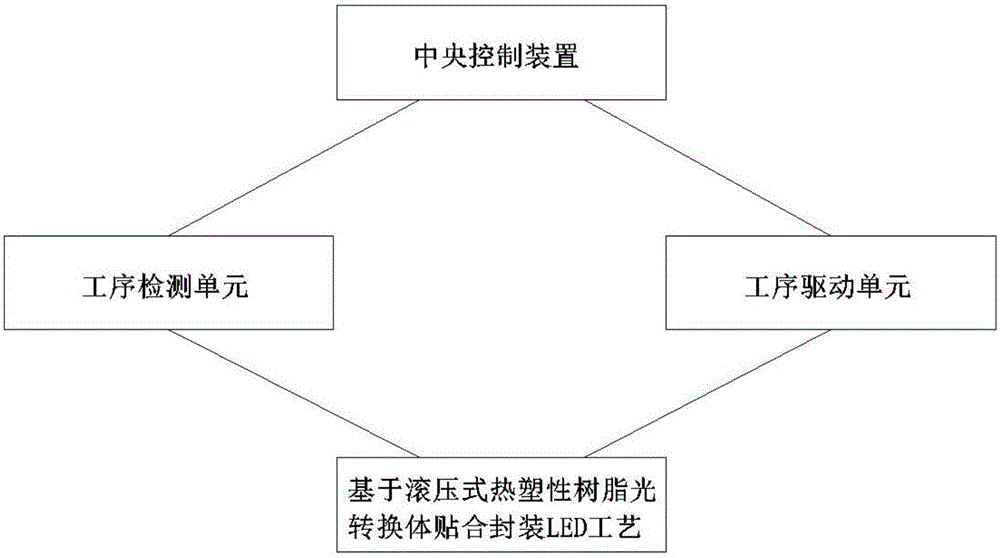

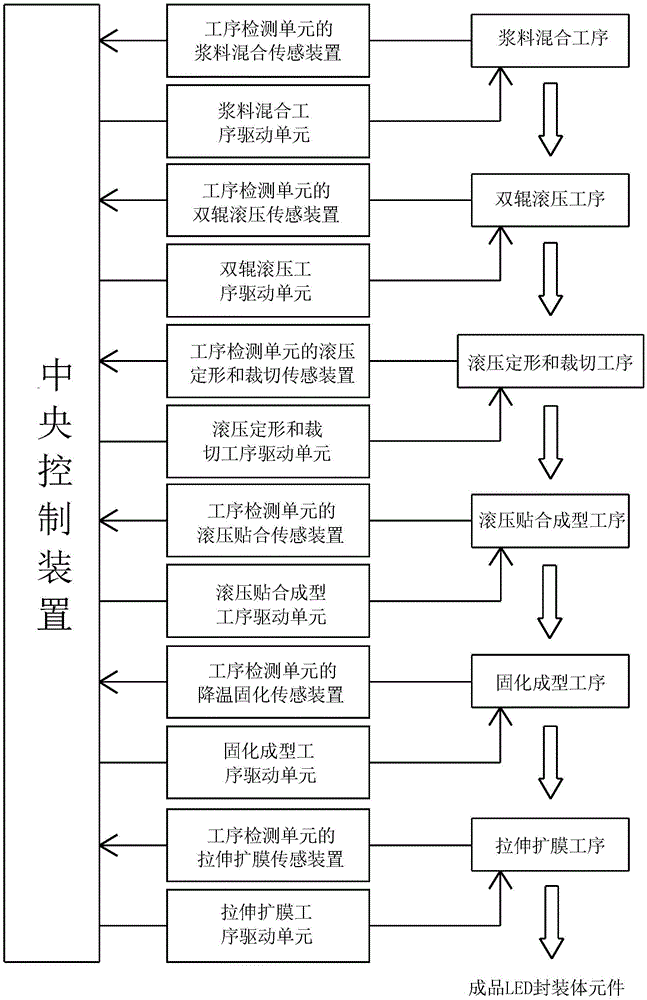

Rolling type smart control system for laminating packed LEDs based on thermoplastic resin photo-conversion body and control method thereof

The invention relates to a smart control system for rolling type laminating packed LEDs based on thermoplastic resin photo-conversion bodies and a control method thereof. The smart control system comprises at least process detection units for a rolling fixing and cutting fixing process, a rolling laminating forming process, a fixed forming process for rolling laminating packed LEDs with thermoplastic resin photo-conversion bodies, a central control device and a process driving unit, wherein the central control device is respectively in signal connection with each process detection unit and the process driving unit, receives the state information of each process detection unit and processes into operation information for real-time regulating and controlling the process detection units. The smart control system and the control method have the advantages of detecting and controlling rolling laminating packaging LED process and device systems, the requirements of process and equipment systems of rolling type thermoplastic resin photo-conversion body laminating packed LEDs, and the production efficiency of mass production of LED packaging and high-quality product rate are improved.

Owner:JIANGSU CHERRITY OPTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com