Automatic paint mixing method and system for coating aluminum profile with fluorocarbon

A technology for automatic adjustment of aluminum profiles, applied in the direction of mixing methods, chemical instruments and methods, coatings, etc., can solve the problems of cumbersome operation, low operation efficiency, waste of paint, etc., and achieve accurate solvent ratio, accurate solvent ratio, The effect of reducing job steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

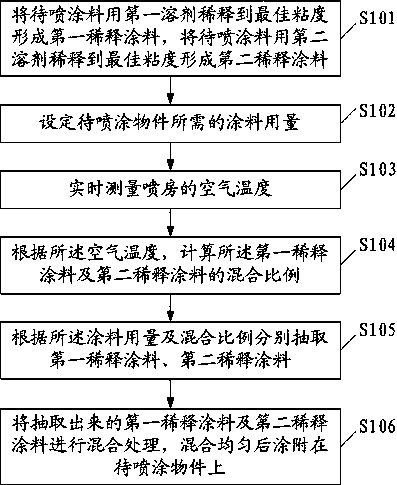

[0026] figure 1It is the flow chart of the first embodiment of the automatic paint adjustment method for fluorocarbon spraying of aluminum profiles of the present invention, including:

[0027] S101. Dilute the paint to be sprayed to an optimal viscosity with a first solvent to form a first diluted paint, and dilute the paint to be sprayed to an optimal viscosity with a second solvent to form a second diluted paint.

[0028] The volatilization rates of the first solvent and the second solvent are different.

[0029] It should be noted that due to different production lines, the optimum viscosity of the paint used for spraying is different.

[0030] More preferably, the method for determining the optimal viscosity of the coating to be sprayed comprises:

[0031] a. Dilute the paint to be sprayed into multiple viscosities with the same solvent;

[0032] b. Spray the coatings to be sprayed with different viscosities on the production line respectively;

[0033] c. Comparing t...

no. 2 example

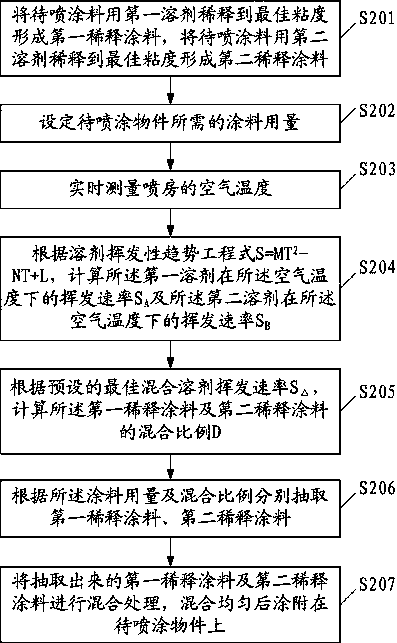

[0044] figure 2 It is the flow chart of the second embodiment of the automatic paint adjustment method for fluorocarbon spraying of aluminum profiles of the present invention, including:

[0045] S201. Dilute the paint to be sprayed to an optimal viscosity with a first solvent to form a first diluted paint, and dilute the paint to be sprayed to an optimal viscosity with a second solvent to form a second diluted paint.

[0046] The volatilization rates of the first solvent and the second solvent are different.

[0047] It should be noted that due to different production lines, the optimum viscosity of the paint used for spraying is different.

[0048] More preferably, the method for determining the optimal viscosity of the coating to be sprayed comprises:

[0049] a. Dilute the paint to be sprayed into multiple viscosities with the same solvent;

[0050] b. Spray the coatings to be sprayed with different viscosities on the production line respectively;

[0051] c. Comparin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com