Numerical control optical fiber spiral armoring machine

An armoring machine and helical technology, which is applied in the field of numerical control optical fiber helical armoring machine, can solve the problems of inaccurate transmission ratio, failure to achieve ideal speed difference, and inability to achieve precise speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0083] The present invention will be further described below in conjunction with the accompanying drawings.

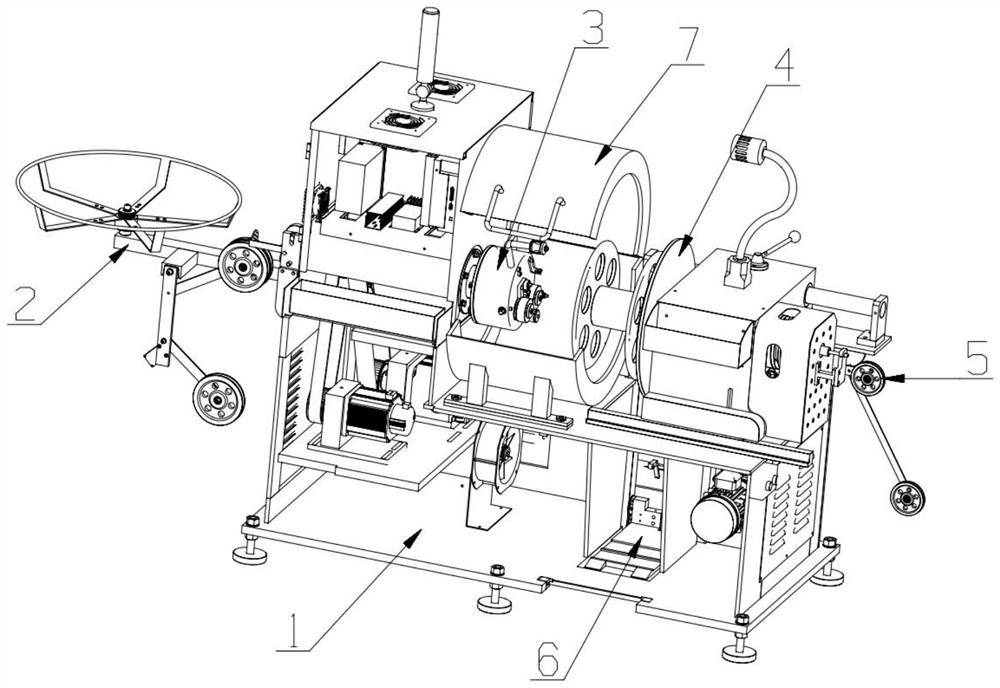

[0084] Such as Figure 1-7 As shown, the numerically controlled optical fiber helical armoring machine provided in this embodiment includes:

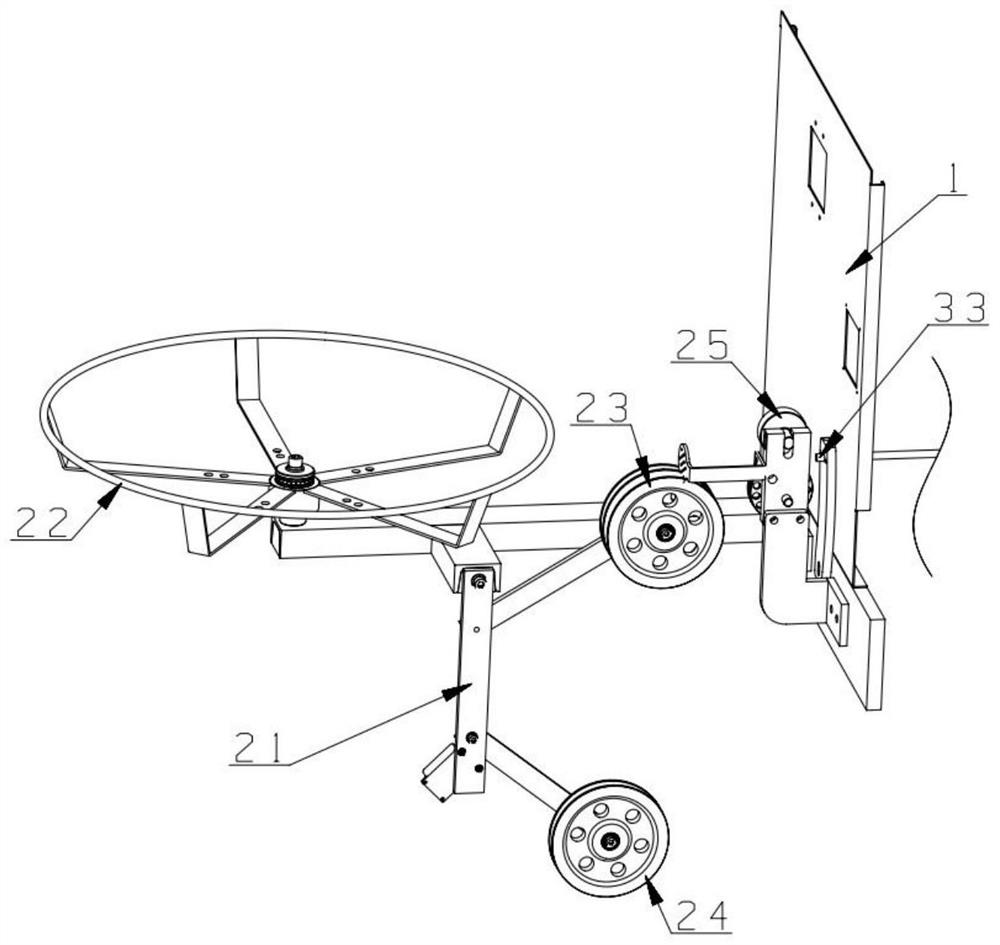

[0085] Frame 1 and the feeding device 2 connected with the frame 1, the armored main frame 3, the coil device 4, the discharging device 5 and the coil loading device 6, the feeding device 2, the armored host 3, the wire coil The reel device 4 and the discharge device 5 are arranged sequentially from left to right, and the wire reel feeding device 6 is arranged below the wire reel device 4 .

[0086] Working principle of the present invention is:

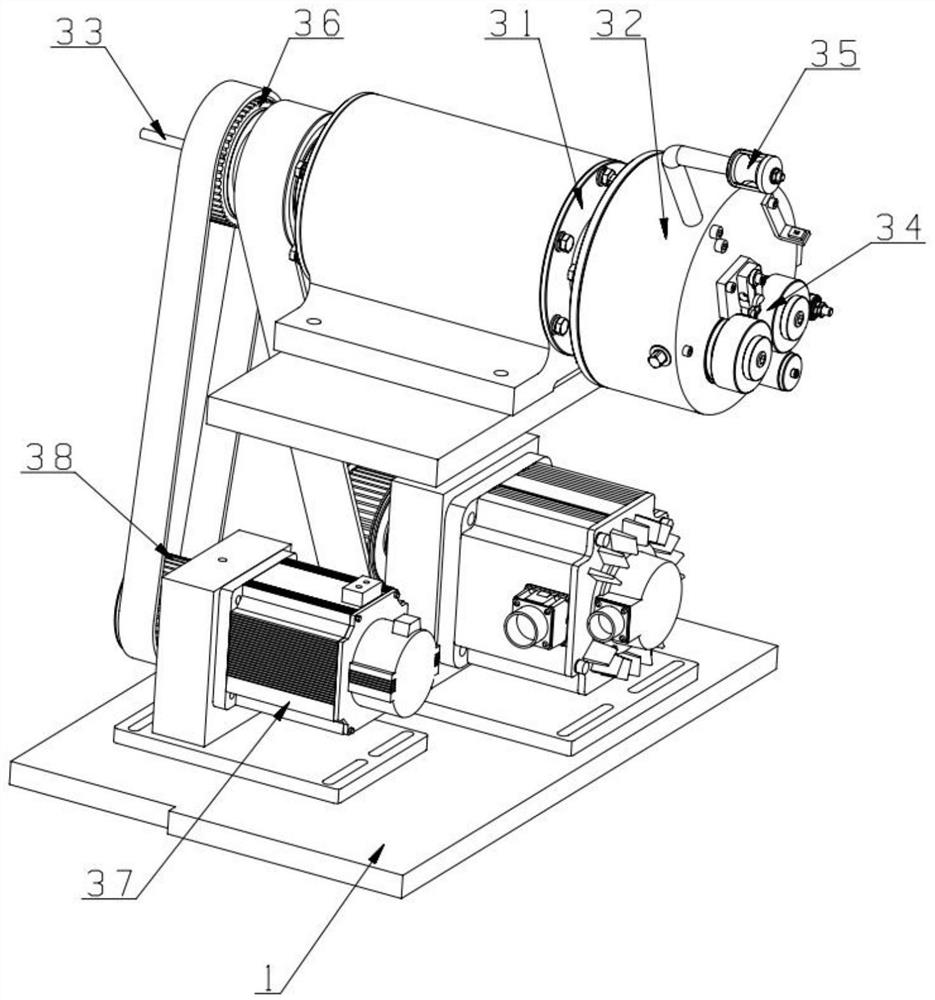

[0087] The present invention provides a numerically controlled optical fiber spiral armoring machine. When in use, the lining tube material is fed from the first core tube 33 of the armoring host 3 through the feeding device 2, and the lining tube material enters the main shaft 31 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com