Dislocation type centre section naked flame vertical kiln

An open flame and vertical kiln technology, which is applied in the central open flame vertical kiln and lime calcination field, can solve the problems of difficult adjustment and control of the calcination process, lime clogging in the kiln body, uneven lime calcination, etc. The effect of not easy to stick

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

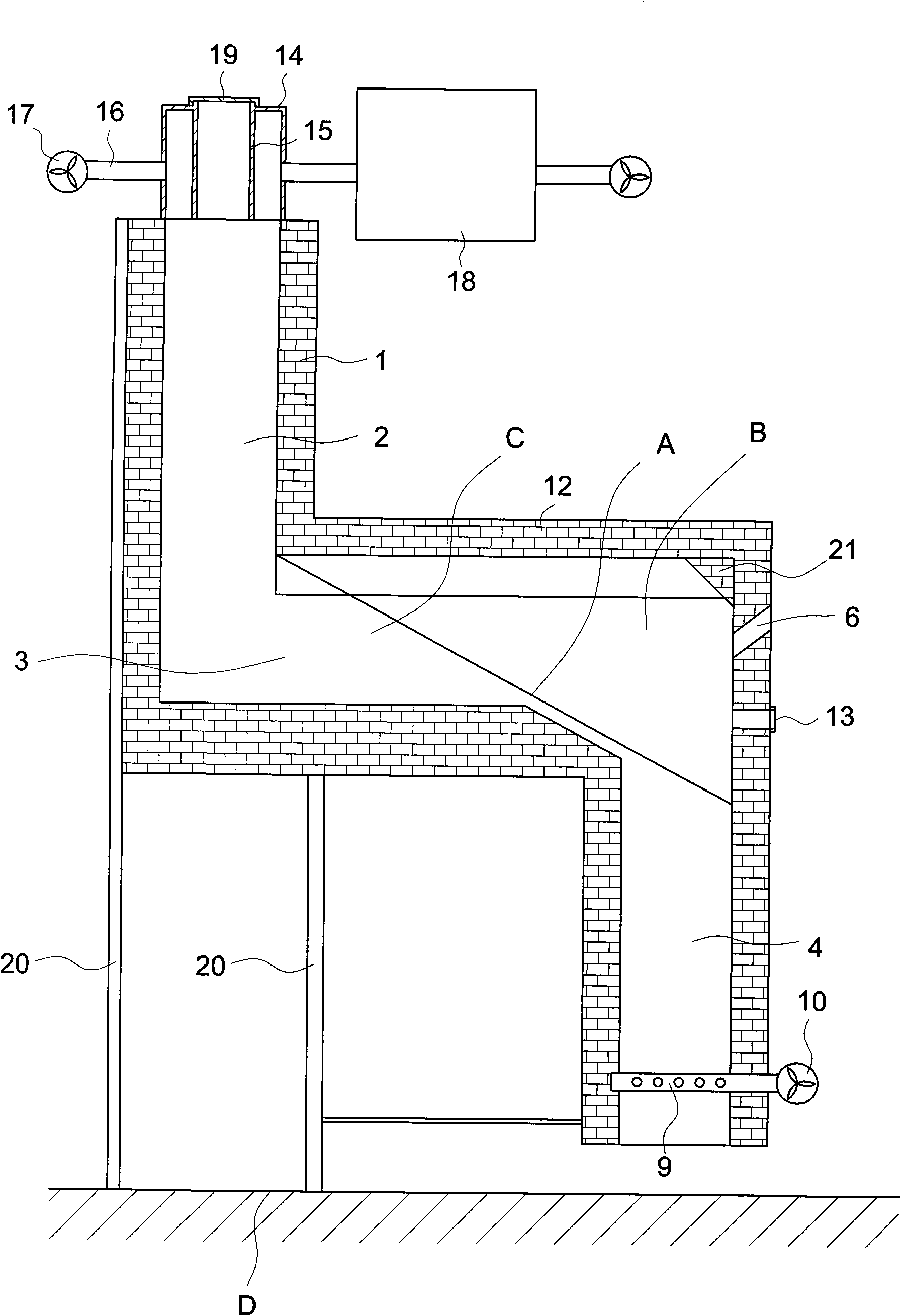

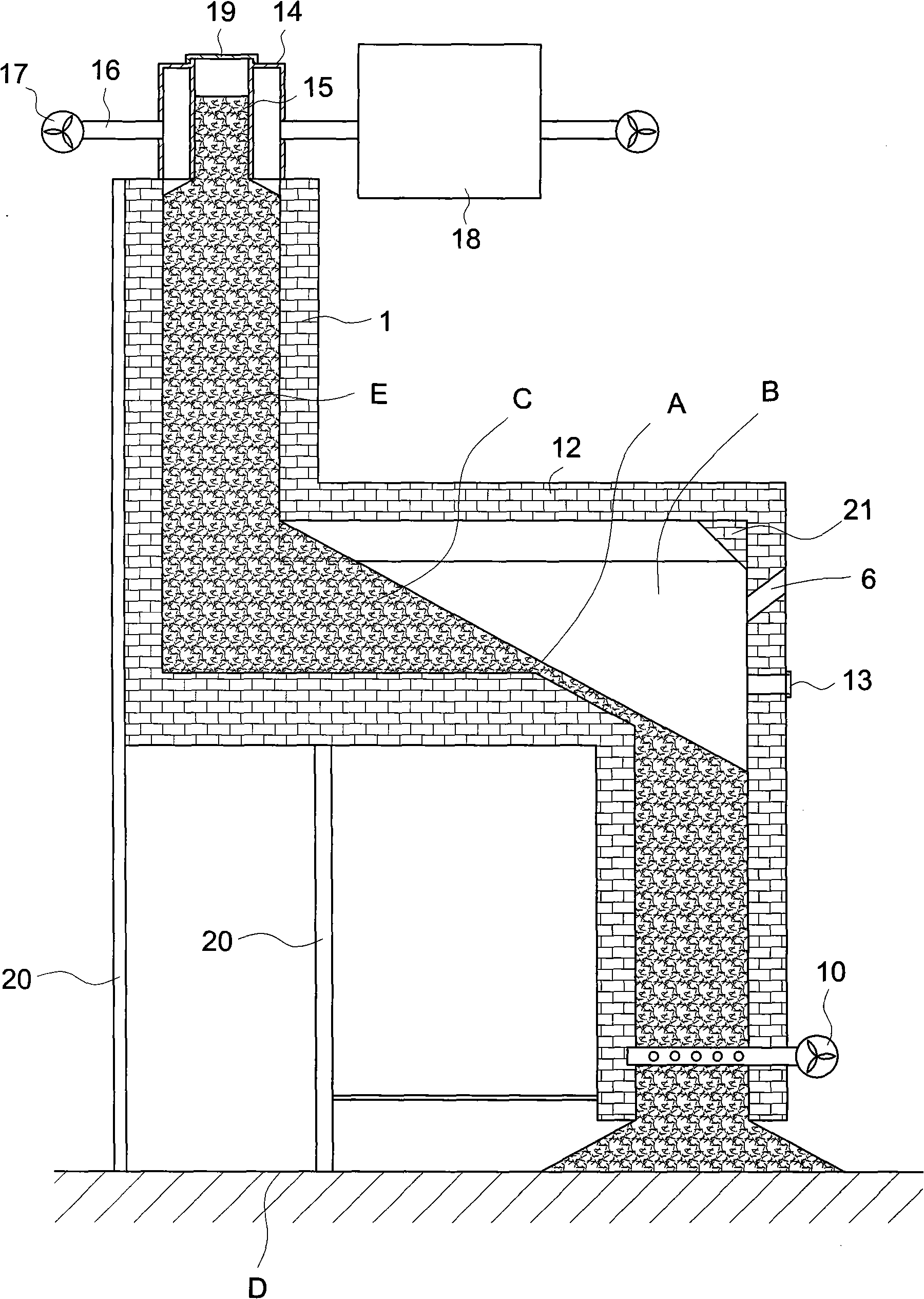

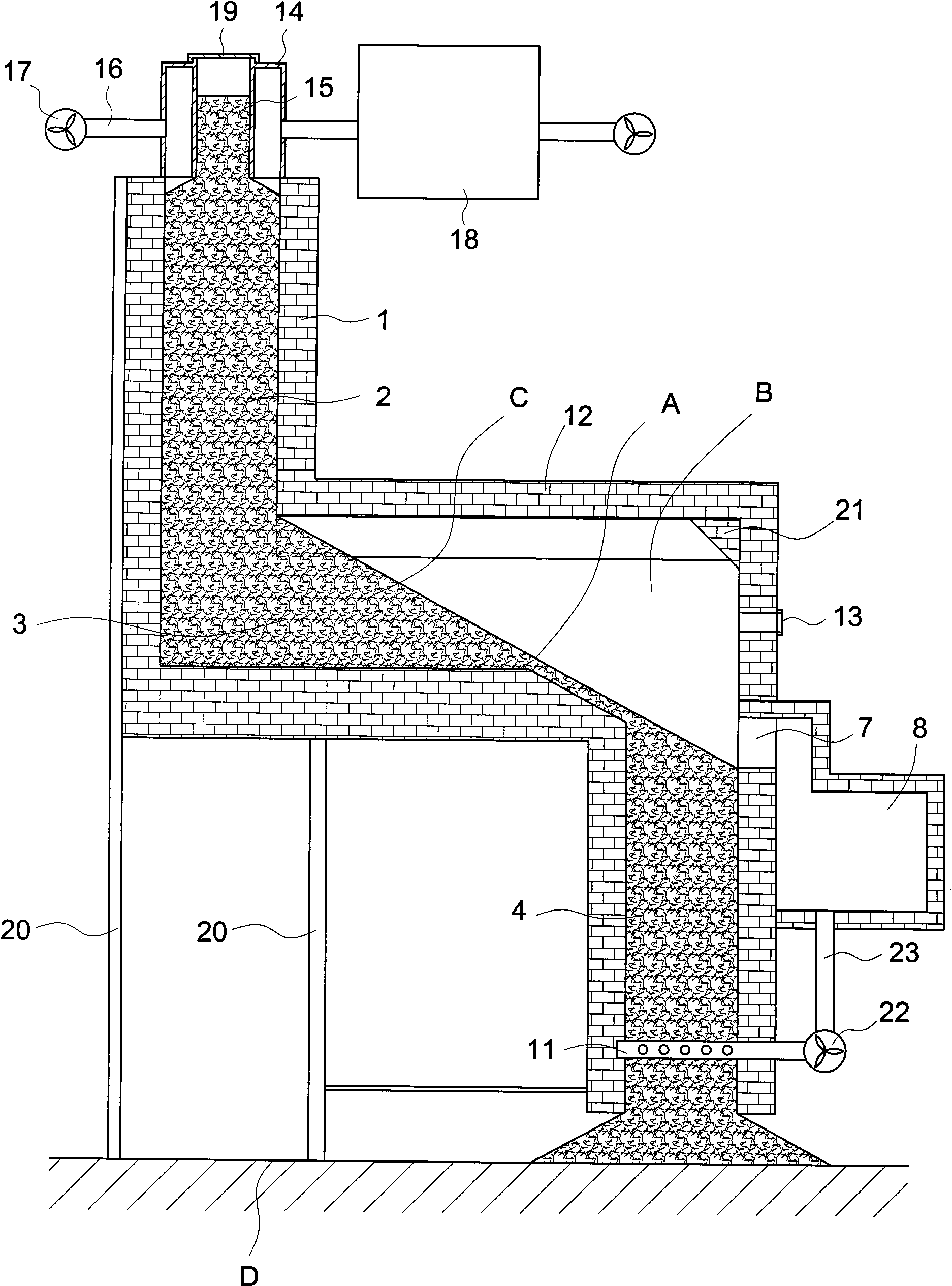

[0043] A staggered central open flame shaft kiln, used for calcination of bulk materials, includes a kiln body 1 on a foundation D, the kiln body 1 includes a preheating chamber 2 in the upper part, a calcining chamber 3 in the middle and a lower kiln body The cooling chamber 4, the preheating chamber 2, the calcining chamber 3 and the cooling chamber 4 are interconnected, and the inner cavity of the calcining chamber 3 is separated by a natural accumulation slope A of block materials to form a material accumulation space C and a heating space B, so The projection positions of the preheating chamber 2 and the cooling chamber 4 on the horizontal plane are completely staggered, the lower end of the preheating chamber 2 is connected to the top of the natural accumulation slope A of the bulk material, and the upper end of the cooling chamber 4 is naturally accumulated with the bulk material The bottom ends of the slopes A meet.

[0044] A chamfer may be provided at the connection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com