Cement special for waterproof mortar and preparation method thereof

A technology for preparing waterproof mortar and cement, applied in cement-based mortar production technology and comprehensive utilization of industrial solid waste and cement field, can solve the problems of high temperature of grinding cement and failure to dissipate cement heat in time, so as to improve the early strength , good application prospects, and the effect of improving construction work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

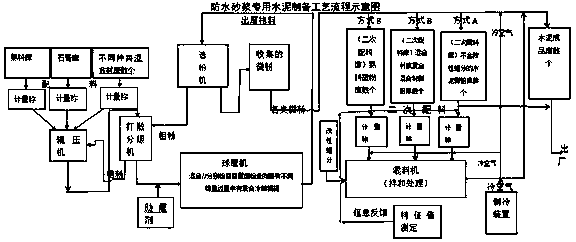

Method used

Image

Examples

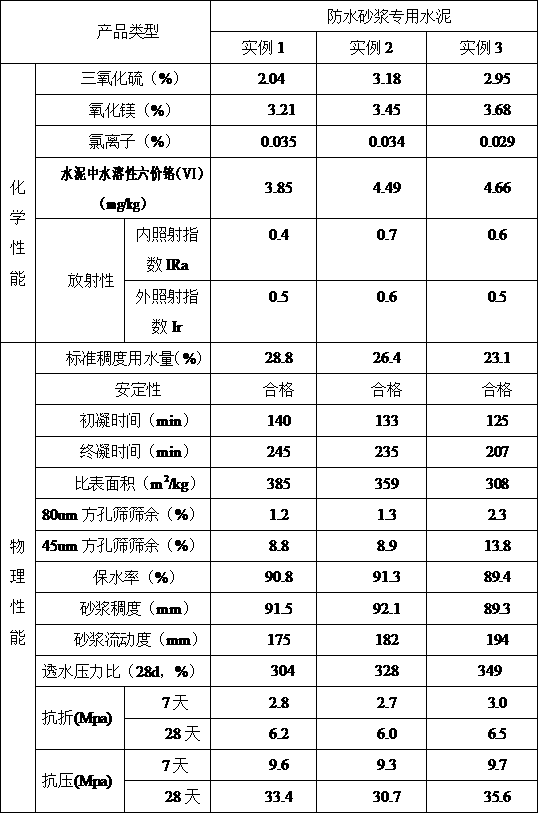

Embodiment 1

[0040] A special cement for waterproof mortar, which is composed of the following raw materials: 0.30 parts of clinker, 0.04 parts of industrial side gypsum, 0.0588 parts of limestone, 0.0002 parts of grinding aid (liquid), 0.001 parts of composite waterproofing agent, and 0.40 parts of granulated blast furnace slag parts, fly ash 0.12 parts, silico-manganese slag (inactive mixed material) 0.08 parts. Grinding aid (liquid) uses 1,4-dihydroxyethylpiperazine stock solution, composite waterproofing agent uses organic silicon waterproofing agent (liquid), and the components and raw materials used meet the relevant standards and the aforementioned requirements.

[0041] A preparation method of special cement for waterproof mortar, the specific steps are as follows:

[0042] Step 1: Select the above raw materials, take the measures of flat laying, vertical cutting and pre-homogenization, and put them into the clinker warehouse, gypsum warehouse, and multiple warehouses of different ...

Embodiment 2

[0048] A special cement for waterproof mortar, which is composed of the following raw materials: 0.36 parts of clinker, 0.07 parts of gypsum, 0.05 parts of limestone, 0.001 parts of grinding aid (liquid), 0.03 parts of composite waterproofing agent, 0.005 parts of early strength agent, 0.004 parts of water reducer, 0.30 parts of fly ash, 0.10 parts of slag (volcanic ash mixed material), 0.08 parts of kiln dust (other waste residue). The grinding aid (liquid) is compounded by 1,4 dihydroxyethylpiperazine and ethylene glycol, the composite waterproofing agent is made of hard fatty acid calcium water reducer, and the early strength agent is made of 1,4-dihydroxyisopropylpiperazine Oxyzine and triethanolamine are compounded, and the composite water reducer uses polycarboxylate water reducer, and the component materials used meet the relevant standards and the aforementioned requirements.

[0049] A preparation method of special cement for waterproof mortar, the specific steps are ...

Embodiment 3

[0056] A special cement for waterproof mortar, which is composed of the following raw materials: 0.50 parts of clinker, 0.055 parts of anhydrite, 0.30 parts of limestone, 0.005 parts of grinding aid (powder), 0.03 parts of composite waterproofing agent (powder), early strength agent 0.01 part, 0.02 part of composite water reducer (powder), 0.05 part of fly ash, 0.03 part of slag (volcanic ash mixed material). The grinding aid (powder) is compounded by 1,4-dihydroxyethylpiperazine and sodium thiocyanate, the composite waterproofing agent is made of hard calcium fatty acid, and the early strength agent is made of 1,4-dihydroxyisopropylpiperazine and acetic acid Calcium compound, composite superplasticizer uses polycarboxylate superplasticizer, and the component materials used meet the relevant standards and the aforementioned requirements.

[0057] A preparation method of special cement for waterproof mortar, the specific steps are as follows:

[0058] Step 1: Select the above ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com