Desulfuration equipment for tank top device, and desulphurization production technology

A technology of desulfurization equipment and top device, which is applied in the field of tank top device desulfurization equipment and desulfurization production process, can solve the problems of large amount of desulfurization agent, increased production cost, personnel poisoning, etc., and achieve automatic and stable operation of the system, saving chemicals, adapting to powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with specific embodiment this patent is described further.

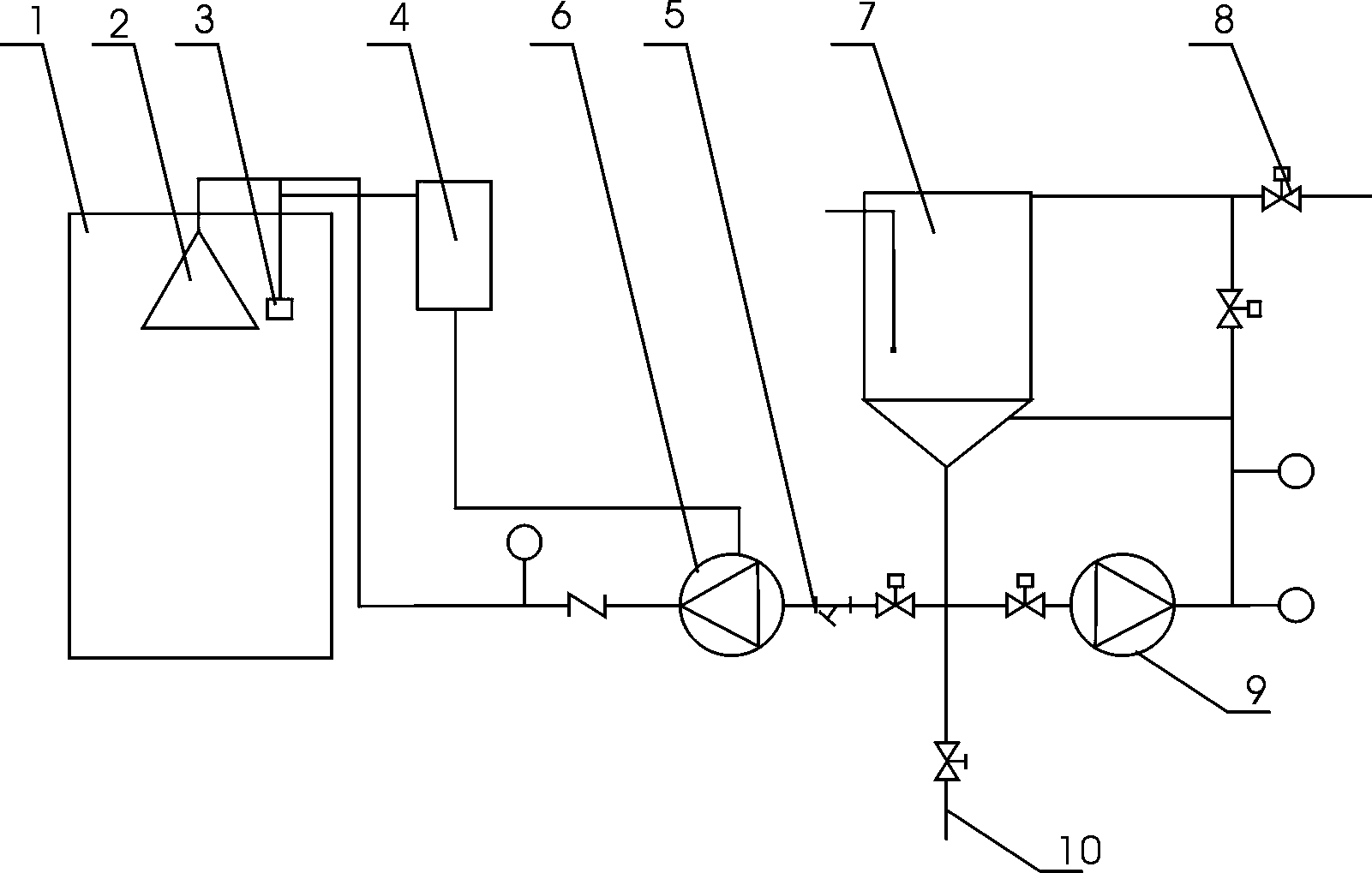

[0017] Tank top desulfurization equipment consists of oil storage tank, spray nozzle, hydrogen sulfide sensor, host controller, dosing outlet, dosing pump, medicine storage tank, water inlet medicine valve, circulation pump, sewage valve, oil storage tank A spray nozzle is set on the top, the spray nozzle is connected to the dosing outlet through a pipeline, the dosing outlet is connected to the outlet of the dosing pump, the inlet of the dosing pump is connected to the bottom of the medicine storage tank through a digital control valve, and the bottom of the medicine storage tank is connected to the drain valve and The inlet port of the circulating pump and the outlet port of the circulating pump are respectively connected to the middle of the medicine storage tank and the outlet port of the water inlet medicine valve. The outlet port of the water inlet medicine valve is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com