Cutter with extendable machining range

A processing range, cutting machine technology, applied in the direction of metal processing equipment, manufacturing tools, metal sawing equipment, etc., can solve the problems that do not meet the market demand, cannot meet the processing conditions of larger-sized workpieces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

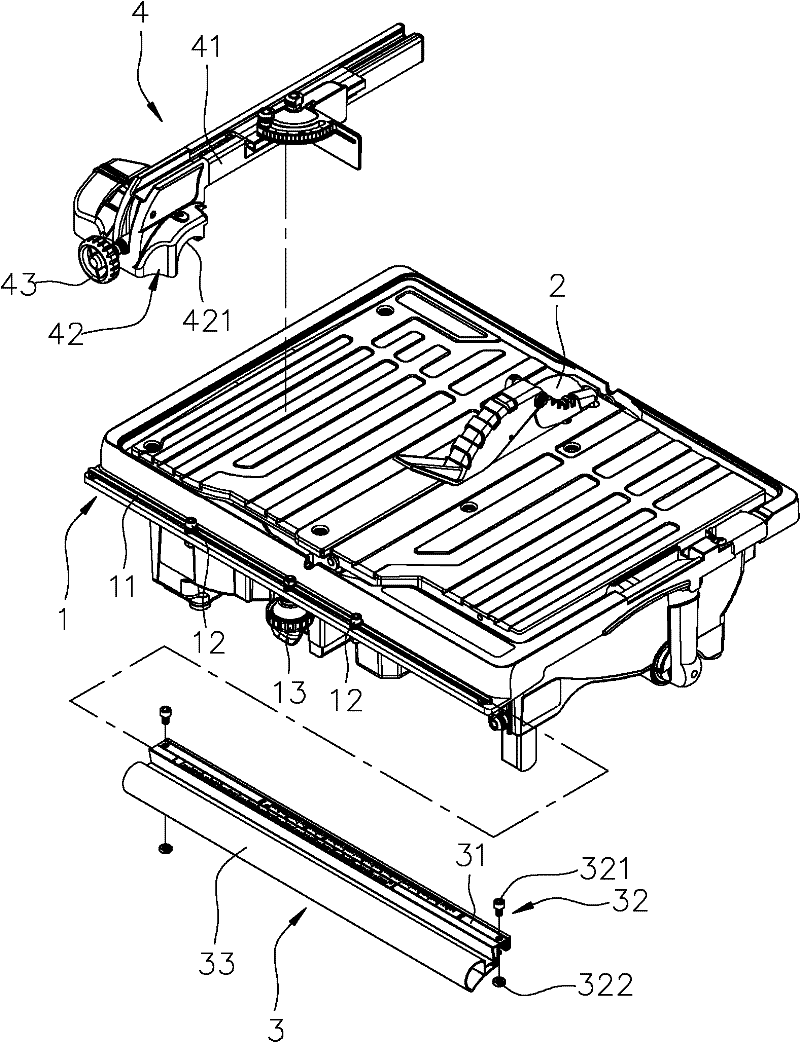

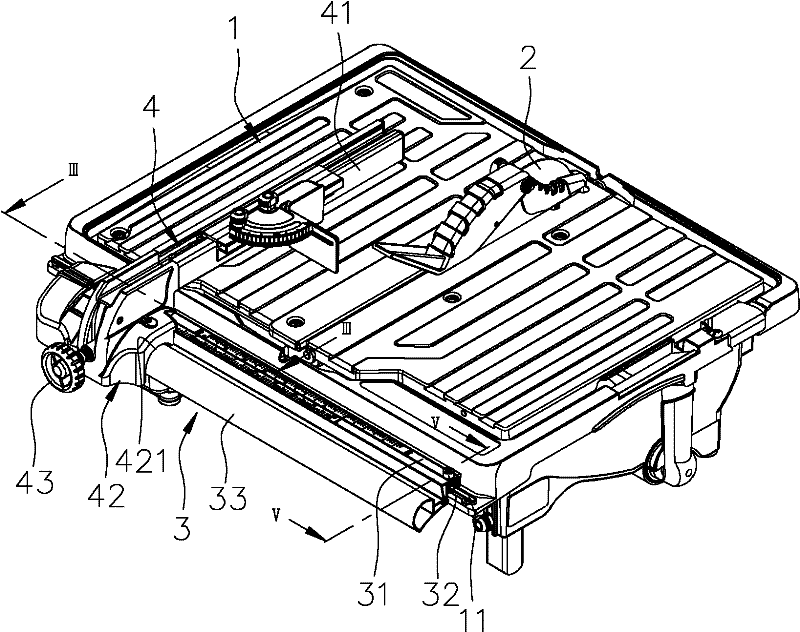

[0024] refer to figure 1 , figure 2 and image 3 , The first preferred embodiment of the cutting machine with extended processing range of the present invention includes a workbench 1 , a sawing unit 2 , a movable rail unit 3 , and a board unit 4 .

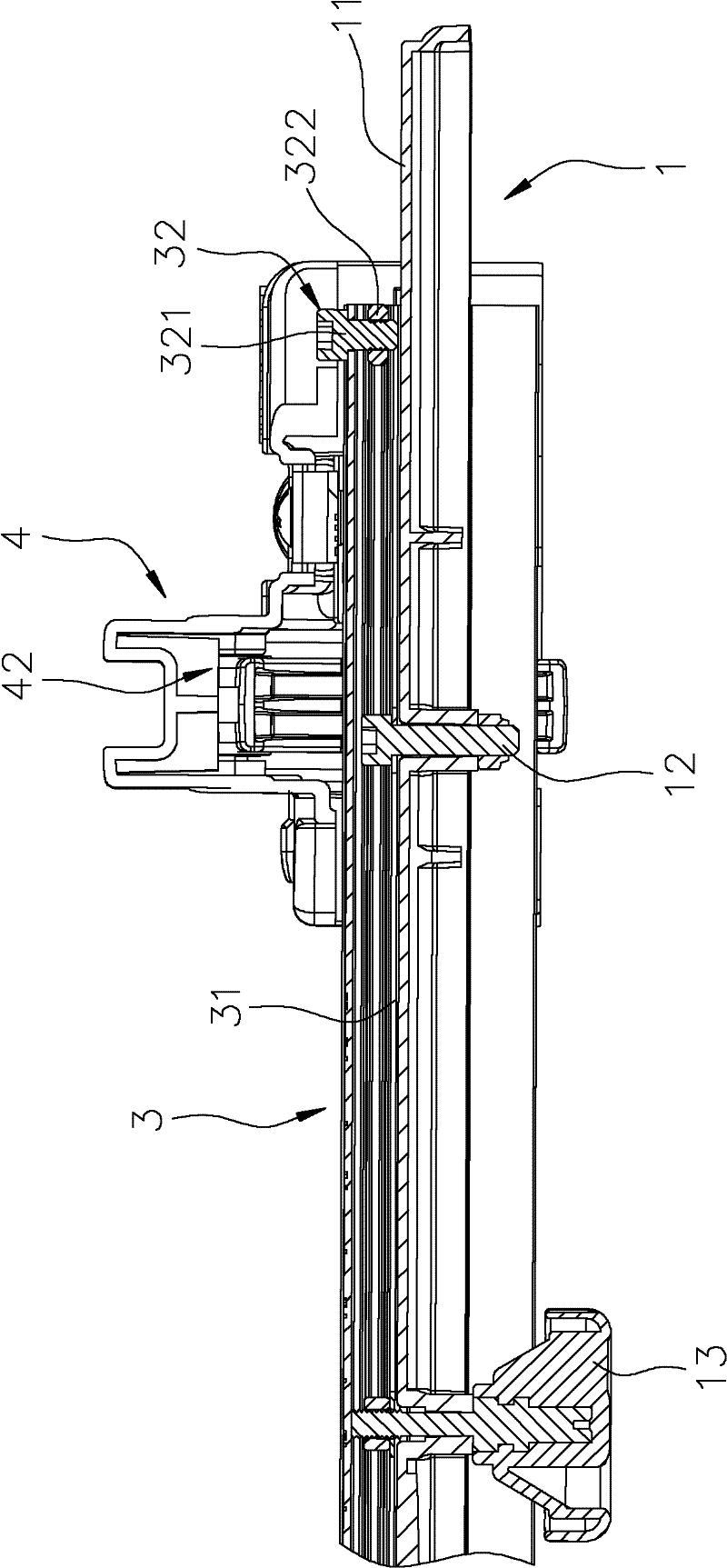

[0025] The workbench 1 includes a first guide rail 11 formed on a side edge, and the first guide rail 11 protrudes upward. The workbench 1 further includes two stop bolts 12 disposed on the first guide rail 11 and protruding upward from the channel body 31 , and a fixing member 13 disposed on the first guide rail 11 .

[0026] The sawing unit 2 is mounted on the workbench 1 .

[0027] Cooperate with reference Figure 5 , the mobile guide rail unit 3 is installed on the first guide rail 11 of the workbench 1, the mobile guide rail unit 3 includes a channel body 31 correspondingly arranged on the first guide rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com