Preparation method and application of high-loss-resistance wood fire retardant

A flame retardant and wood technology, applied in wood treatment, wood impregnation, wood impregnation, etc., can solve the problems of narrow application range, high price, easy loss of flame retardants, etc., and achieves good thermal stability, simple synthesis process, Simple effect of modification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

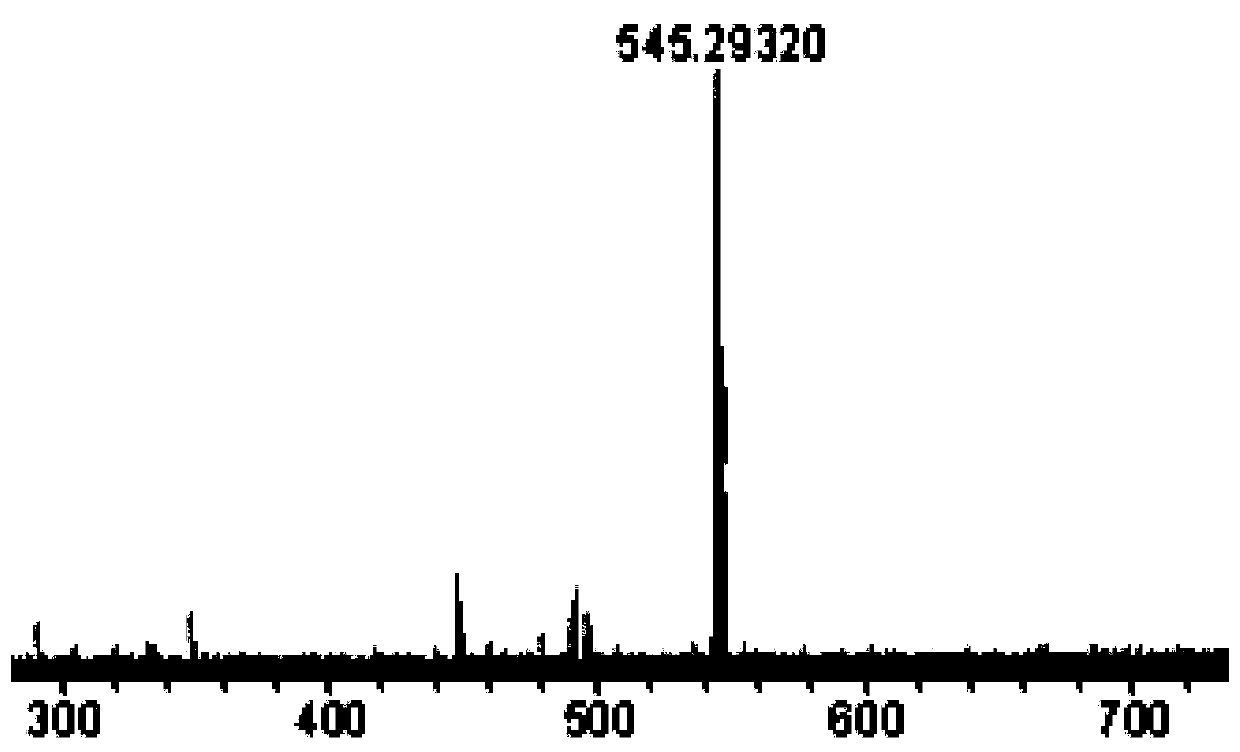

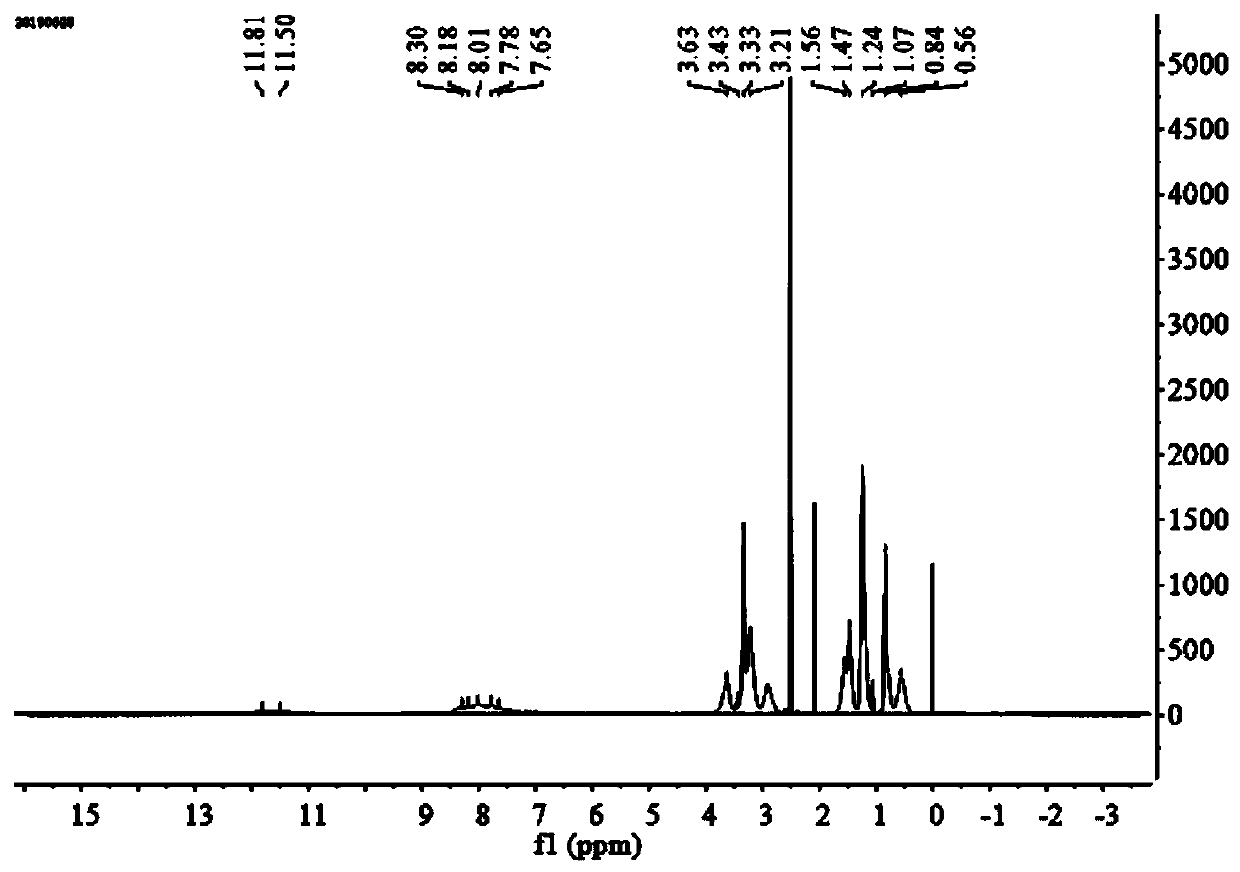

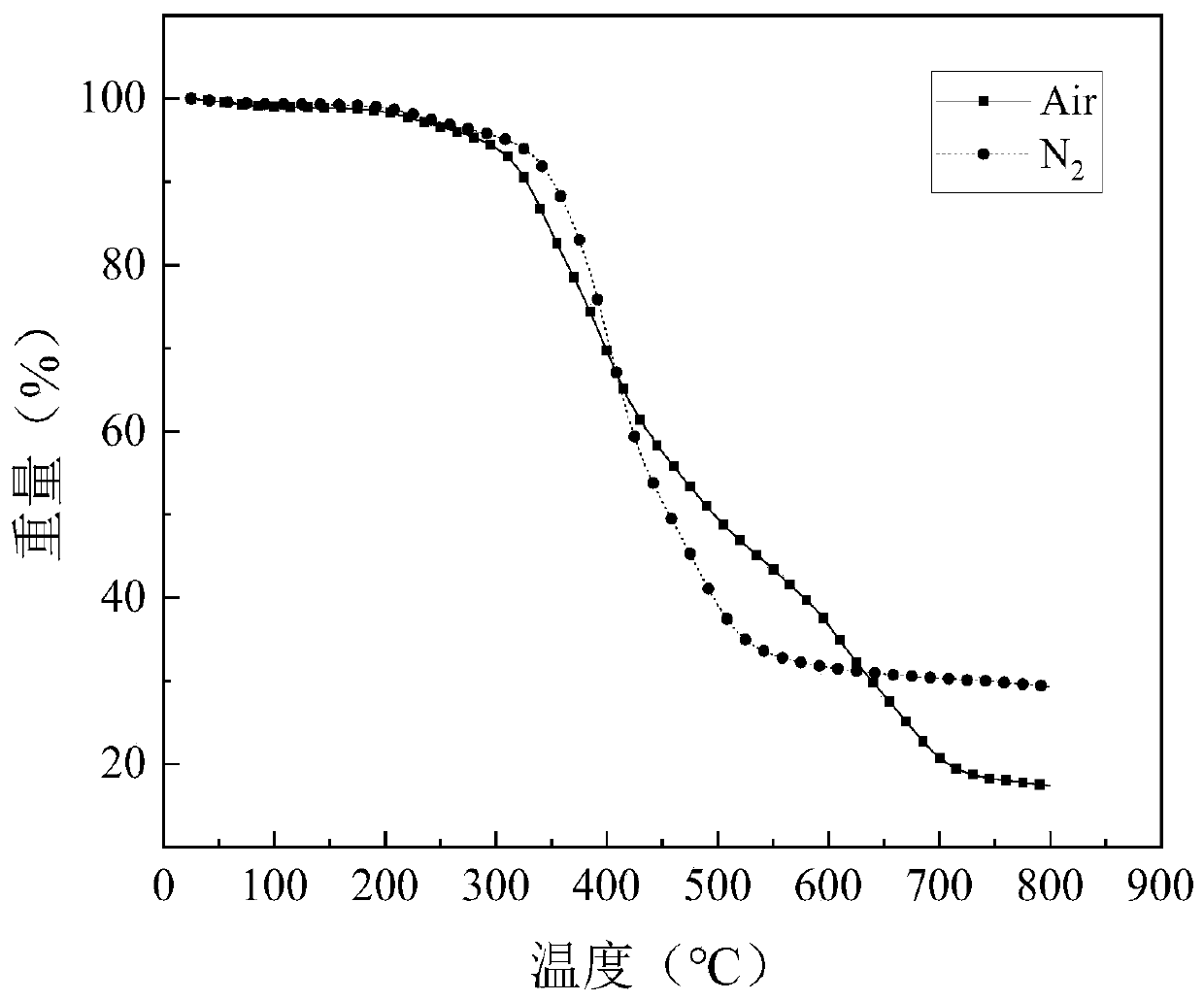

[0031] Example 1: See Figure 1-4 , in the embodiment of the present invention, a kind of preparation method of the wood flame retardant with high loss resistance, comprises the following steps:

[0032] A. Using toluene as solvent and cyanuric chloride as matrix, add n-hexylamine toluene solution at a reaction temperature of -5-0°C, use an acid-binding agent to adjust the pH to 8-9 and maintain it, and a nucleophilic substitution reaction occurs , obtain compound II, the reaction formula of this reaction is shown in following formula (1):

[0033]

[0034] B. With absolute ethanol as the solvent and compound II as the matrix, add the ethanol solution of 3-aminopropyltriethoxysilane at a reaction temperature of 45-50°C, and adjust the pH to 8-9 with an acid-binding agent And maintain, nucleophilic substitution reaction takes place, obtain compound III, the reaction formula of this reaction is as shown in formula (two):

[0035]

[0036]

[0037] C. Using the mixture...

Embodiment 2

[0066] Example 2: Dissolve 0.1 mol of cyanuric chloride in 200 ml of toluene, transfer to a four-necked flask, and place the four-necked flask in a low-temperature cooling circulation pump at 0°C. Take 0.15mol of n-hexylamine and dissolve it in 100ml of toluene, and transfer it to a constant pressure dropping funnel. Under the condition of stirring, the toluene solution of n-hexylamine was dropped into the four-necked flask filled with cyanuric chloride, and the reaction pH was adjusted to 9 with 0.3mol / L sodium carbonate aqueous solution, and maintained. After 8 hours, the reaction was terminated, the insoluble matter was removed by suction filtration, and the filtrate was transferred to a separatory funnel. And successively use 0.5mol / L hydrochloric acid to remove excess n-hexylamine in the filtrate. 0.5mol / L sodium hydroxide removes excess hydrochloric acid and adjusts the pH to 7. Finally, it was washed several times with deionized water, separated to retain the oil phas...

Embodiment 3

[0070] Example 3: Dissolve 0.1 mol of cyanuric chloride in 300 ml of toluene, transfer to a four-necked flask, and place the four-necked flask in a low-temperature cooling circulation pump at -5°C. Take 0.11mol of n-hexylamine and dissolve it in 100ml of toluene, and transfer it to a constant pressure dropping funnel. Under the condition of stirring, the toluene solution of n-hexylamine was dropped into the four-necked flask filled with cyanuric chloride, and the reaction pH was adjusted to 8 with 0.5mol / L sodium carbonate aqueous solution, and maintained. After 5 hours, the reaction was terminated, the insoluble matter was removed by suction filtration, and the filtrate was transferred to a separatory funnel. And successively use 0.5mol / L hydrochloric acid to remove excess n-hexylamine in the filtrate. 1mol / L sodium hydroxide to remove excess hydrochloric acid, and adjust the pH to 7. Finally, it was washed several times with deionized water, separated to retain the oil pha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com