Preparation method of low-softening-point lead-free glass products for electric light sources

A low softening point, lead-free glass technology, applied in the preparation of low softening point lead-free glass products for electric light source, electric light source, electric light source glass field, can solve the problem of low light transmittance and energy utilization efficiency, lead-free glass softening Point height and other problems, to achieve the effect of lowering the softening point of glass, enriching and changing fluorescent characteristics, and improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Main process equipment: batch material preparation equipment, electric melting furnace and mechanical forming equipment. Among them, the mechanical forming equipment is "Dana method" drawing tube forming equipment and so on.

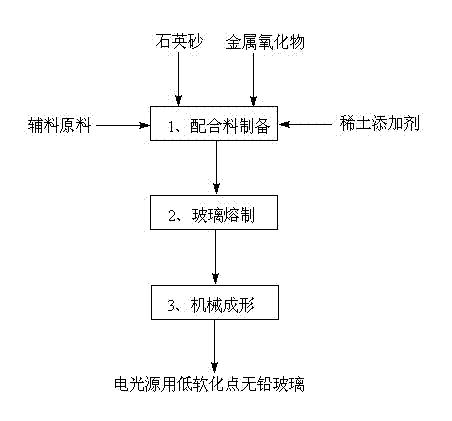

[0032] As shown in the figure, a method for preparing a lead-free glass product with a low softening point for an electric light source, the steps of the method are as follows:

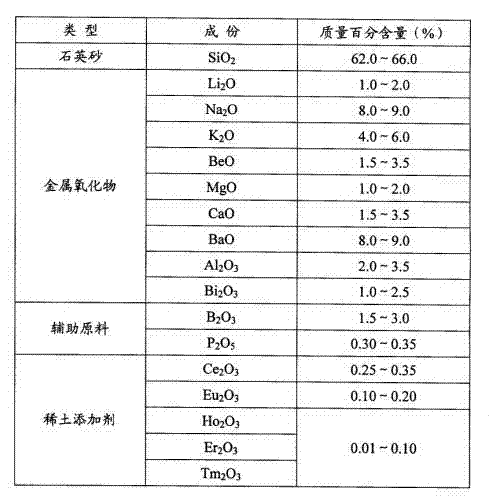

[0033] (1) Batch material preparation: In the batch material preparation equipment, the rare earth additive rare earth oxide RE 2 o 3 It is added in the form of rare earth carbonate, in which the heavy rare earth element erbium Er carbonate is added in the form of carbonate, calculated by mass percentage, and mixed uniformly in the preparation of the batch to obtain the batch. The batch consists of the following ingredients and proportions:

[0034]

[0035] (2) Glass melting: The glass batch prepared in the previous step is melted at a high temperature in an electr...

Embodiment 2

[0046] Main process equipment: batch material preparation equipment, electric melting furnace and mechanical forming equipment.

[0047] As shown in the figure, a method for preparing a lead-free glass product with a low softening point for an electric light source, the steps of the method are as follows:

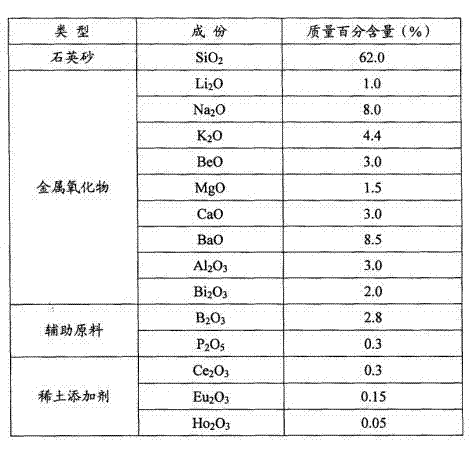

[0048] (1) Batch material preparation: In the batch material preparation equipment, the rare earth additive rare earth oxide RE 2 o 3 It is added in the form of carbonate of rare earth, among which the heavy rare earth element holmium Ho carbonate is added in the form of carbonate, calculated by mass percentage, and mixed uniformly in the preparation of the batch to obtain the batch. The batch consists of the following ingredients and proportions:

[0049]

[0050] (2) Glass melting: The glass batch prepared in the previous step is melted at a high temperature in an electric melting furnace using known glass melting technology to form a glass melt, which is formed thr...

Embodiment 3

[0053] Main process equipment: batch material preparation equipment, electric melting furnace and mechanical forming equipment.

[0054] As shown in the figure, a method for preparing a lead-free glass product with a low softening point for an electric light source, the steps of the method are as follows:

[0055] (1) Batch material preparation: In the batch material preparation equipment, the rare earth additive rare earth oxide RE 2 o 3 It is added in the form of rare earth carbonate, among which the heavy rare earth elements holmium Ho, erbium Er and thulium Tm rare earth oxides are added in the form of carbonate enrichment of any proportion of heavy rare earth elements, and the batch is obtained through uniform mixing. The batch consists of the following ingredients and proportions:

[0056]

[0057] (2) Glass melting: The glass batch prepared in the previous step is melted at a high temperature in an electric melting furnace using known glass melting technology to f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com