Polyolefin cable material as well as preparation method and application thereof

A polyolefin cable material, ethylene technology, used in plastic/resin/wax insulators, organic insulators, etc., can solve the problem of the tearing force not meeting the requirements, and achieve the effect of excellent flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] The present invention also provides a preparation method of the polyolefin cable material according to the present invention, comprising the step of mixing the components of the polyolefin cable pellets.

[0056] The preparation method of the polyolefin cable material according to the present invention comprises the following steps:

[0057] (1) Premix and disperse part (for example: 10-30% of the total mass of ethylene-vinyl acetate copolymer) ethylene-vinyl acetate copolymer, thermoplastic polyurethane and phosphorus nitrogen flame retardant to obtain a premixed mother material;

[0058] (2) Mix the premixed masterbatch with the remaining (for example: 70-90% of the total mass of ethylene-vinyl acetate copolymer) ethylene-vinyl acetate copolymer, interfacial compatibilizer, aluminum hydroxide, lubricant agent and antioxidant are blended and granulated to obtain polyolefin cable material.

[0059] Because the thermoplastic polyurethane of the present invention has po...

Embodiment 1-5

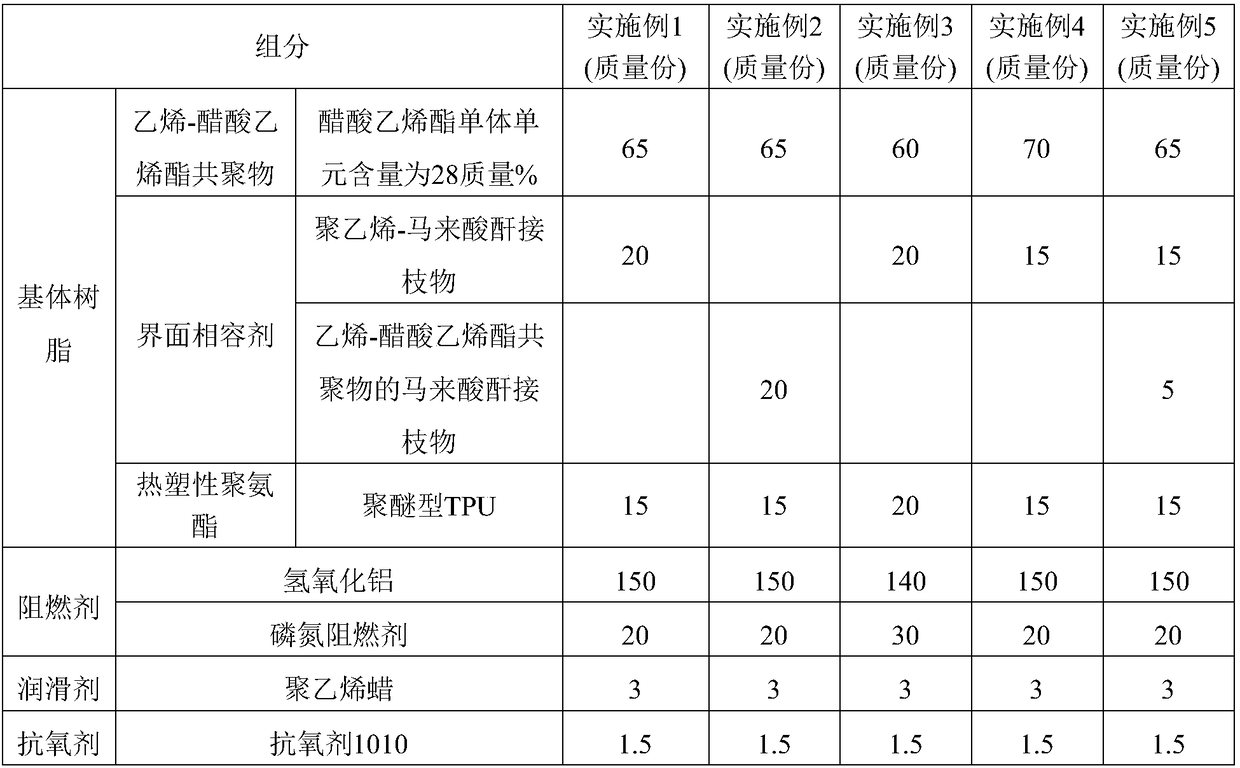

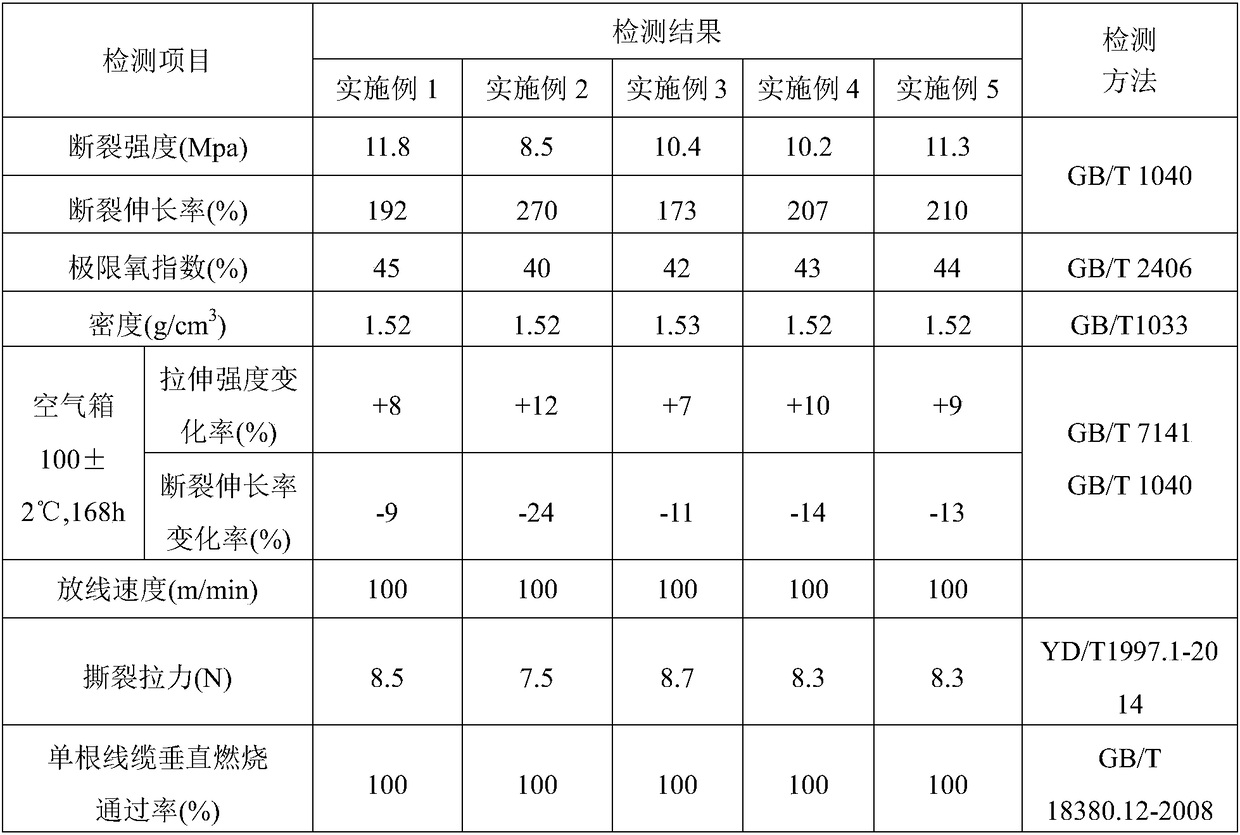

[0073] According to the mass fraction of each component in Table 1 below, the polyolefin cable material of Examples 1-5 was prepared according to the following preparation method.

[0074] (1) 20% ethylene-vinyl acetate copolymer (based on the total mass of ethylene-vinyl acetate copolymer), polyether TPU and phosphorus nitrogen flame retardant in the formula are produced in automatic metering two-stage equipment. The premixed masterbatch is obtained, wherein the extrusion temperature range is 125-155°C;

[0075] (2) Mix the premixed masterbatch with the remaining 80% of ethylene-vinyl acetate copolymer (based on the total mass of ethylene-vinyl acetate copolymer), interfacial compatibilizer, aluminum hydroxide, lubricant and antioxidant The agent is put into an internal mixer and blended to 150°C, and then granulated by a screw machine, and the processing temperature is in the range of 125-155°C to obtain a polyolefin cable material.

[0076] Table 1

[0077]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com