DOPO-phthalimide derivative, and preparation method and application thereof

A technology of phthalimide and derivatives is applied in the field of flame retardant modification of polymer materials to achieve the effects of high rigidity, low tension and satisfying processing conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

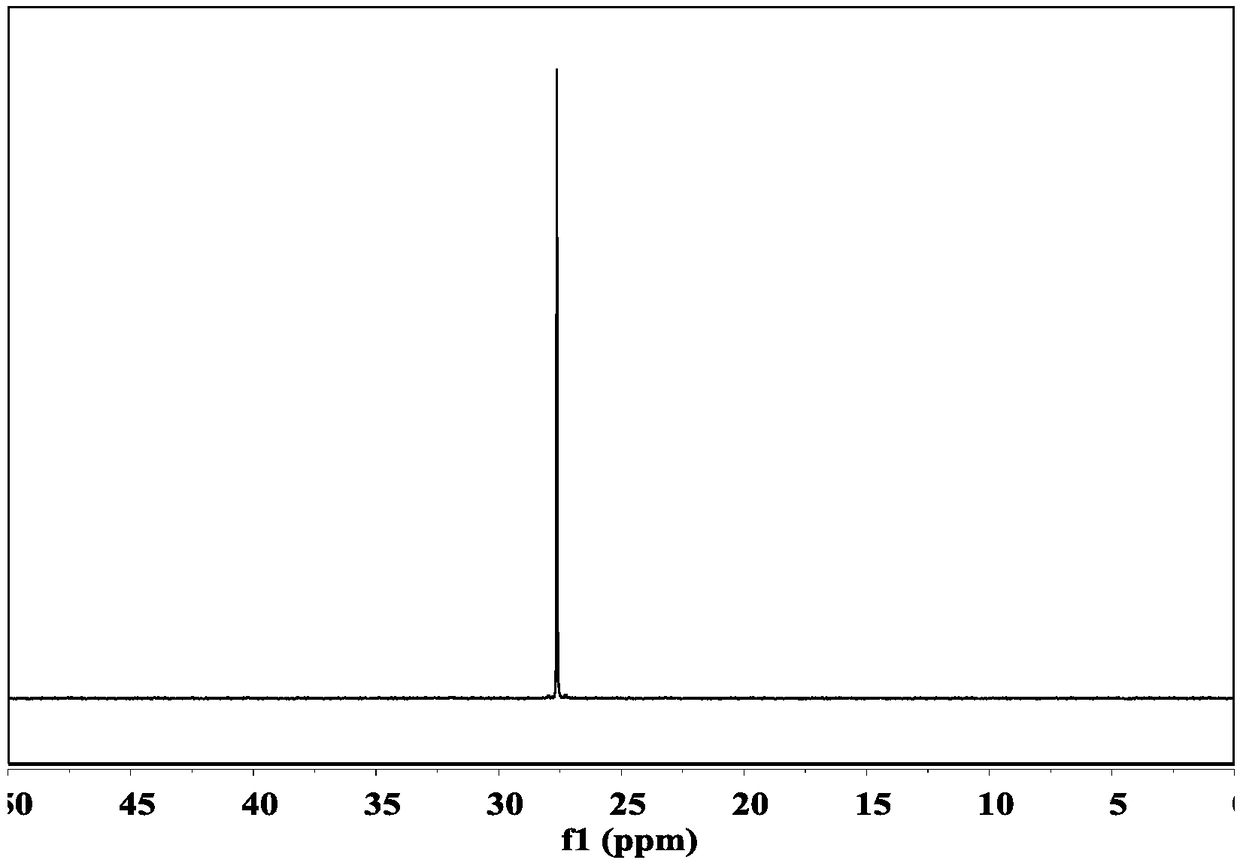

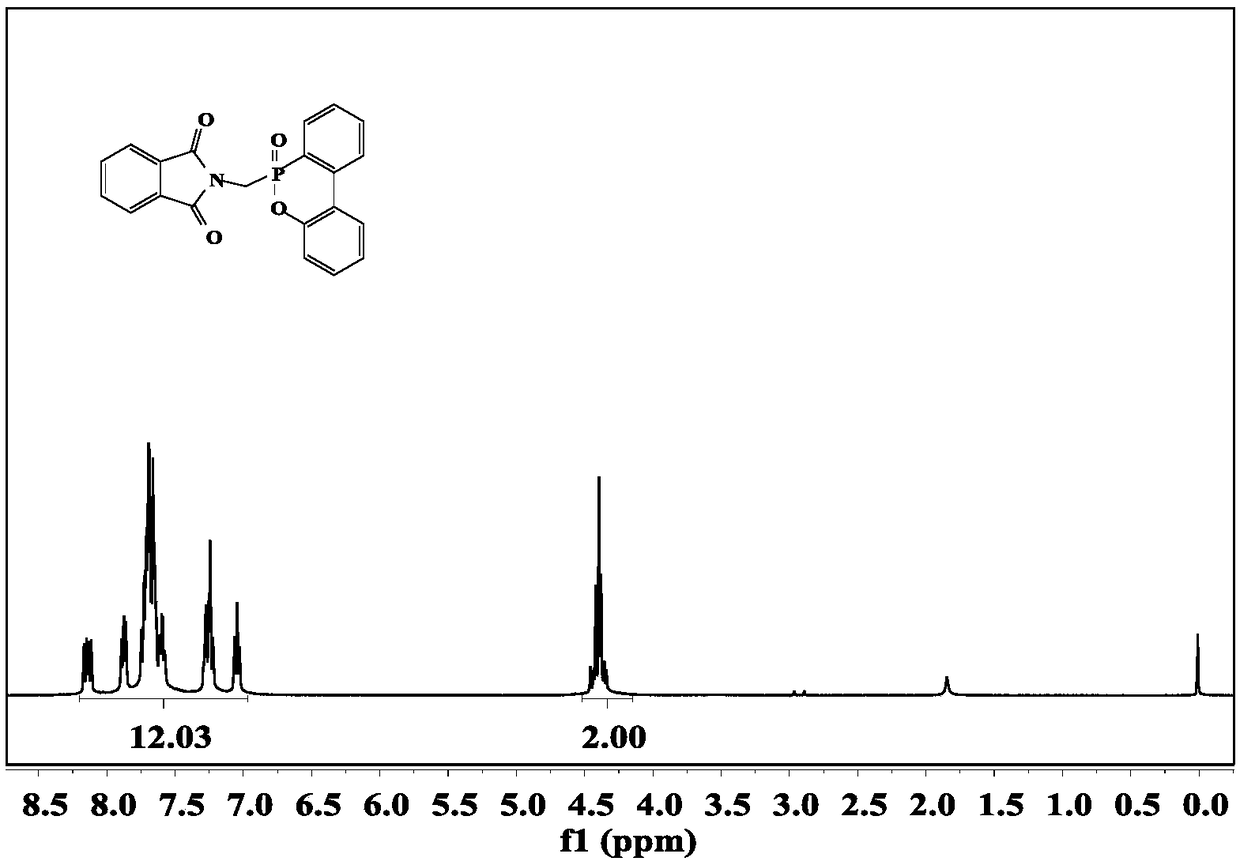

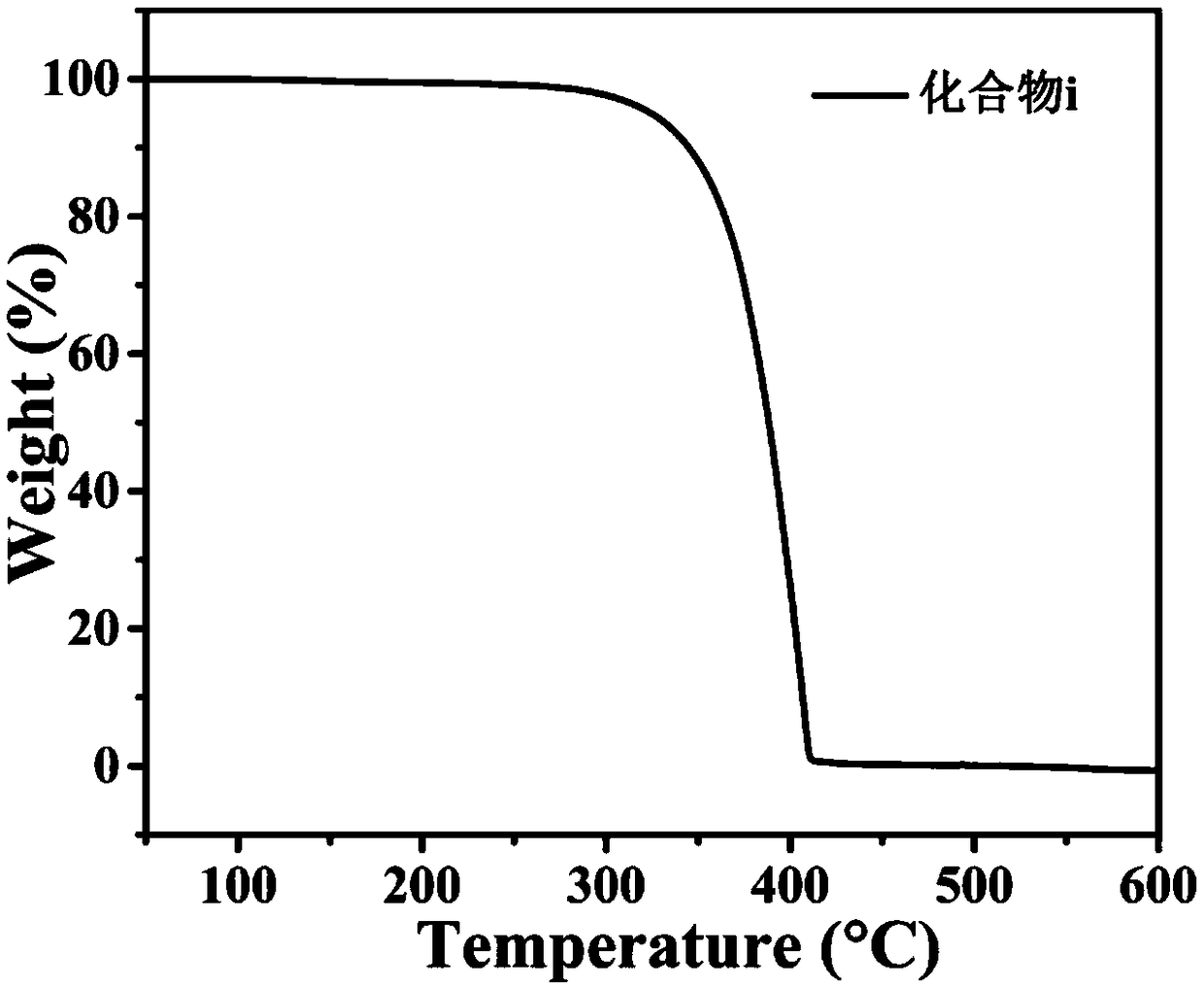

[0076] There is the preparation of formula (I-i) structure compound

[0077] (1) DOPO (162.00 g, 0.75 mol) and 200 ml of xylene were added to a three-necked flask equipped with a thermometer, a magnetic stir bar, and a spherical condenser. Under the protection of nitrogen, the temperature of the system was slowly raised to 95°C. After the system was completely transparent, 22.50 g of paraformaldehyde was added in batches within 3 hours. After feeding, the temperature was continued to stir and react for 6 hours. Suction filtration while hot, the obtained solid was dried under vacuum at 80° C. for 8 hours to obtain 179 g of product with a yield of 97.0%.

[0078] (2) Weigh 116.03 g (0.47 mol) of the adduct of DOPO and paraformaldehyde, and add 300 ml of pyridine into a three-neck flask equipped with a thermometer and a magnetic stir bar. Then 180.10 g (0.94 mol) of p-toluenesulfonyl chloride were added slowly over 1 hour. Stir overnight at 25°C. Suction filtration, washin...

Embodiment 2

[0083] There is the preparation of formula (I-i) structure compound

[0084] (1) DOPO (162.00 g, 0.75 mol) and 200 ml of benzene were added to a three-necked flask equipped with a thermometer, a magnetic stir bar, and a spherical condenser. Under the protection of nitrogen, the temperature of the system was slowly raised to 70°C. 27 g of paraformaldehyde were added in portions over 4 hours. After feeding was completed, the stirring reaction was continued for 8 hours at this temperature. Suction filtration while hot, the obtained solid was dried under vacuum at 80° C. for 8 hours to obtain 181 g of product with a yield of 98.0%.

[0085](2) Weigh 116.03 g (0.47 mol) of the above-mentioned DOPO-alcohol compound, and add 300 ml of picoline into a three-necked flask equipped with a thermometer and a magnetic stir bar. Under the condition of ice bath, 114.90 g (0.60 mol) p-toluenesulfonyl chloride was slowly added. After feeding, the temperature of the reaction system will ri...

Embodiment 3

[0088] There is the preparation of formula (I-i) structure compound

[0089] (1) DOPO (162.00 g, 0.75 mol) and 200 ml of cyclohexane were added to a three-necked flask equipped with a thermometer, a magnetic stir bar, and a spherical condenser. Under the protection of nitrogen, the temperature of the system was slowly raised to 70°C. 24.75 grams of paraformaldehyde were added in portions over 4 hours. After the feeding was completed, the stirring reaction was continued for 15 hours at this temperature. Suction filtration while hot, the obtained solid was dried under vacuum at 80° C. for 8 hours to obtain 175 g of product with a yield of 95.0%.

[0090] (2) Weigh 116.03 g (0.47 mol) of the adduct of DOPO and paraformaldehyde, add 200 ml of pyridine and 100 ml of triethylamine into a three-necked flask equipped with a thermometer and a magnetic stir bar. Then 180.10 g (0.94 mol) of p-toluenesulfonyl chloride were added slowly over 1 hour. Stir overnight at 25°C. Suction f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com