Full-automatic combining module new energy material vacuum baking method and vacuum baking line

A technology of new energy materials and baking methods, applied in the field of vacuum baking lines, to shorten the time of baking and cooling, improve equipment utilization, and achieve good drying effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

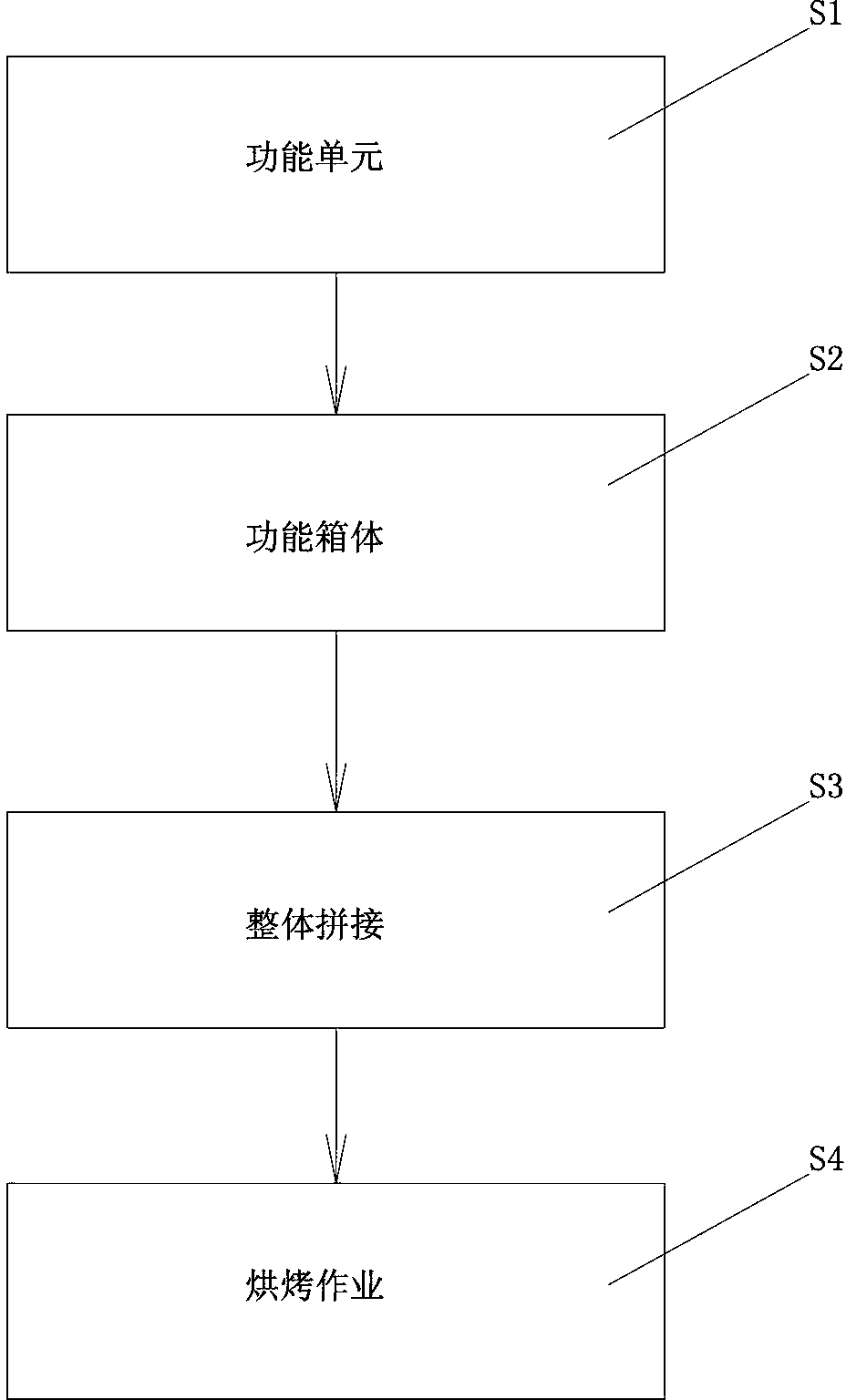

[0037] See figure 1 , figure 1 What is disclosed is a fully automatic composite module new energy material vacuum baking method,

[0038] (S1) According to different baking objects, the whole baking process is divided into at least two functional units with different functions; taking the vacuum baking of lithium batteries as an example to illustrate the method of the present invention (the same below), the whole process can be divided into There are six units of feeding, heating, vacuum drying, cooling, moisture detection and output. Of course, for a certain baking process, the moisture detection unit may not be set;

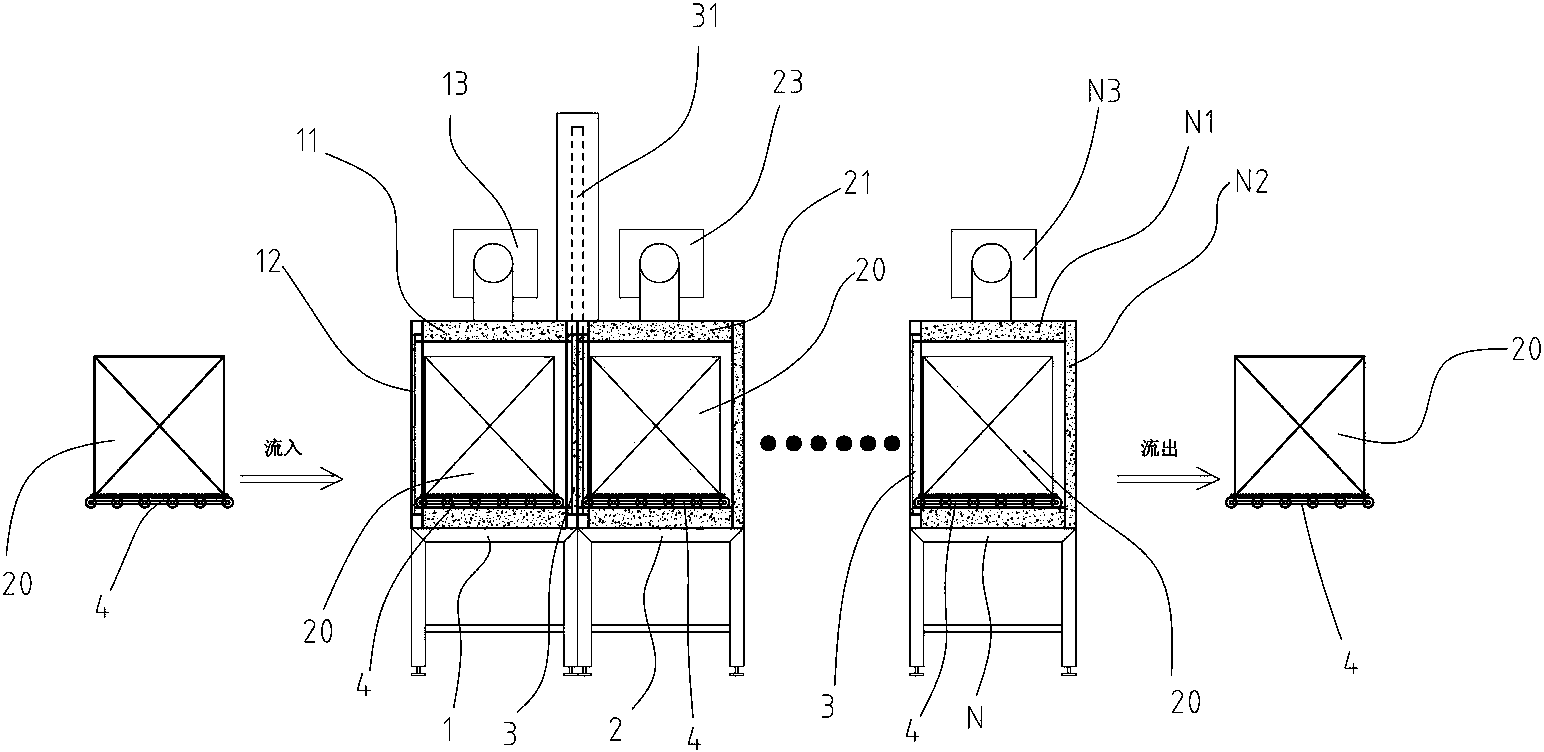

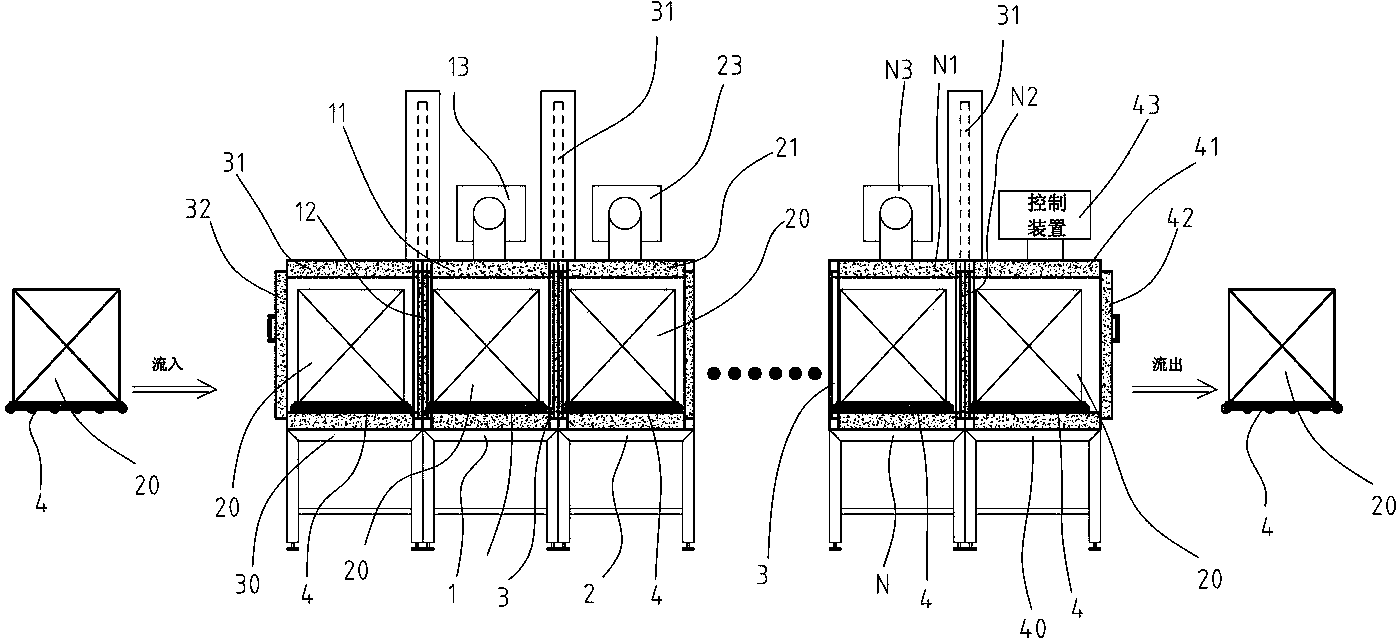

[0039] (S2) According to different functional units, select an independent sealable functional box with corresponding functions; based on the above six units, you can choose the corresponding six functional boxes for feeding, heating, vacuum drying, cooling, moisture detection and discharging According to different functions, corresponding functional source...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com