Wet spinning vacuum freeze-drying method and drying equipment

A technology of vacuum freeze-drying and wet spinning, applied in the field of spinning, can solve the problems of slow sublimation process, increased risk, and high production cost, achieve great economic and social benefits, facilitate mass production, and be easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0034] An embodiment of the drying method of the above wet spinning vacuum freeze-drying equipment of the present invention includes the following process steps:

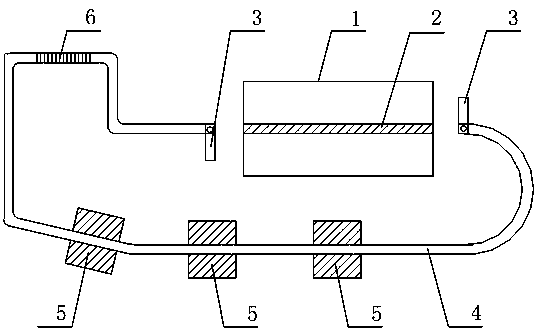

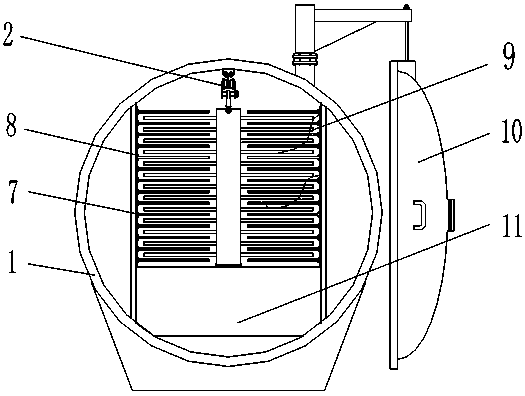

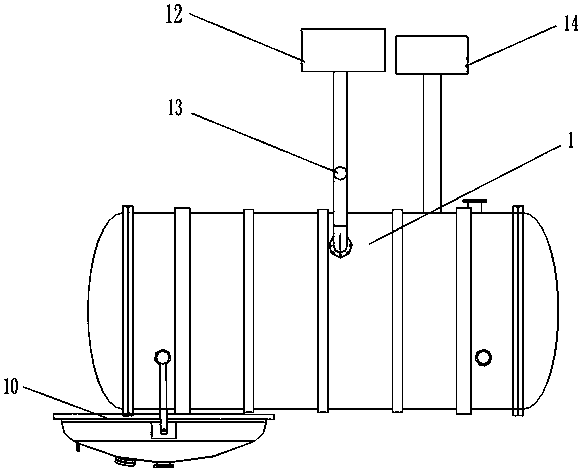

[0035] (1) After wet spinning, the fibers are washed or soaked in oil and placed on the pallet, and then the pallet is placed on the pallet rack of the material truck, and the material truck is hung on the rail 4 outside the warehouse through pulleys. The material truck 5 is sent to the vacuum freeze-drying warehouse 1 along the outer guide rail 4 and the inner guide rail 2 successively through the feed port and set on the heating plate. After the warehouse door 10 is closed, the freeze-drying starts;

[0036] (2) The vacuuming system directly starts to vacuum, and continuously vacuums, observe the temperature probe of the fiber, make the fiber reach all icing, until the temperature drops below 0℃, then proceed to the next step;

[0037] (3) Then, start heating the heating plate, and at the same time, continuously vacuumiz...

Embodiment 1

[0041] Example 1: After squeezing and dehydrating a rack of chitosan wet fibers that have been washed and oiled, the wet fibers weigh about 75 kg, placed on the material truck 5, and then passed through the outer rail 4 of the warehouse and pushed into the vacuum freeze-drying warehouse 1. Make the material truck 5 stay on the track 2 in the warehouse (the water catching capacity of the vacuum drying equipment is 300kg / 24h), after closing the warehouse door 10, start vacuuming, and observe that the temperature of the temperature probe The heating plate is heated, and the temperature of the heating plate is set to 60°C. The vacuum degree in the vacuum freeze-drying chamber 1 is set in the range of 50pa to 80pa. When the temperature of the material reaches 5°C, stop heating and open the venting of the vacuum freeze-drying chamber 1. The valve pushes the fiber out of the chamber body of the vacuum freeze-drying chamber 1. After cooling the fiber, a sample is taken to detect the mo...

Embodiment 2

[0042] Example 2: After squeezing and dewatering the three racks of wet alginate fibers washed and oiled, the wet alginate fibers weigh about 230 kg and are placed on the material truck 5, and then pass through the rail 4 outside the warehouse and push into the vacuum Freeze drying warehouse 1, make the material truck 5 stay on the track 2 in the warehouse (the water catching capacity of the vacuum drying equipment is 2000kg / 24h), after closing the warehouse door, start vacuuming, and observe that the temperature of the temperature probe 9 is -10℃ , Start heating the heating plate, set the temperature of the heating plate to 100℃, set the vacuum degree in the vacuum freeze-drying chamber 1 within the range of 100pa to 180pa, observe that the temperature of the material reaches 15°C, stop heating, and open the vacuum freeze-drying chamber 1. The vent valve of, push the fiber out of the chamber body of the vacuum freeze-drying chamber 1. After the fiber is cooled, a sample is tak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com