Novel tension adjustment mechanism of multi-wire diamond wire saw

A technology for a diamond wire saw and a tension adjusting mechanism, which is applied to stone processing tools, stone processing equipment, work accessories, etc., can solve problems such as poor adjustable performance, practical limitations, deflection or skew, and achieve a simple overall structure. Reasonable, reasonable arrangement rules, the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

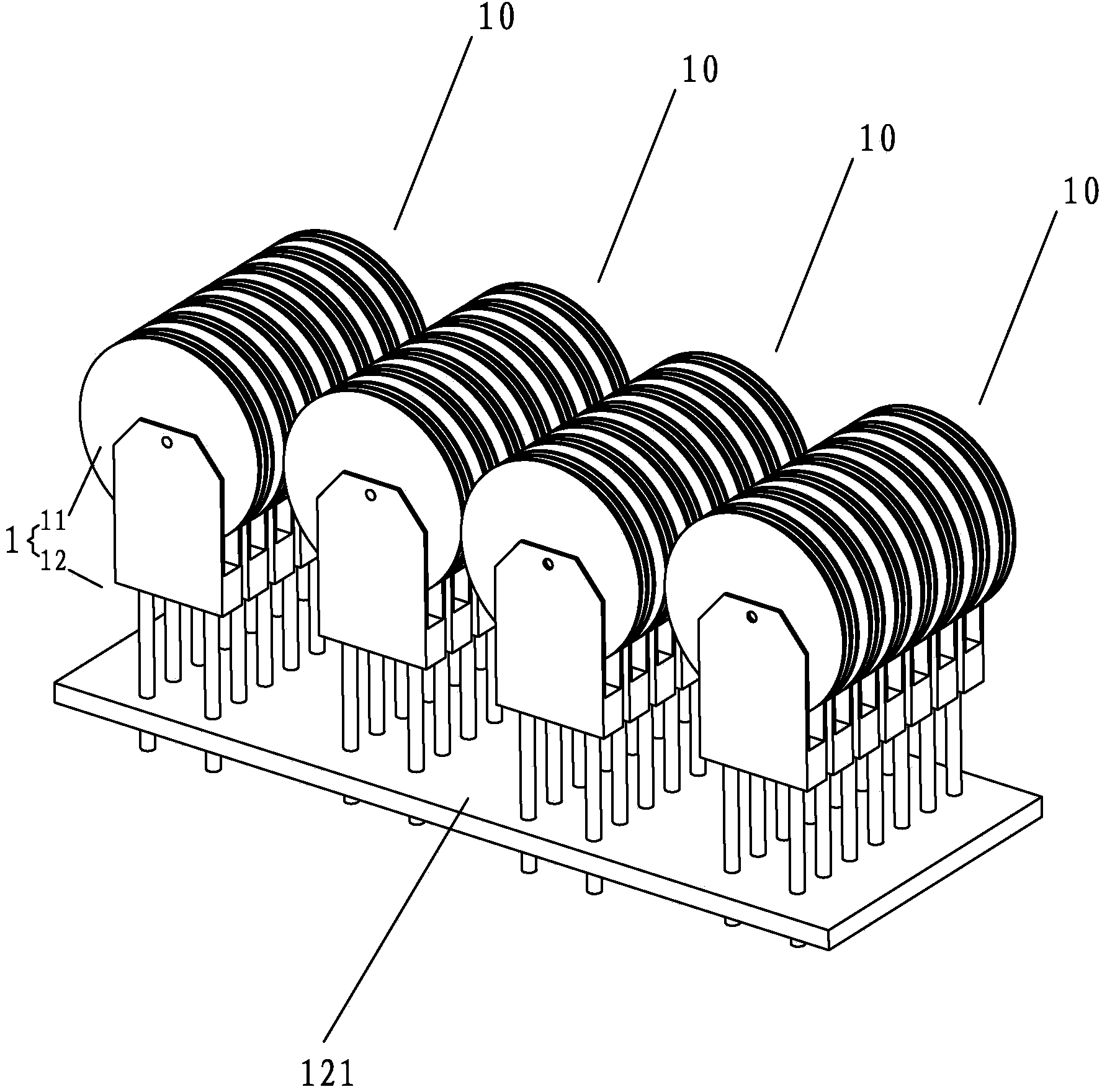

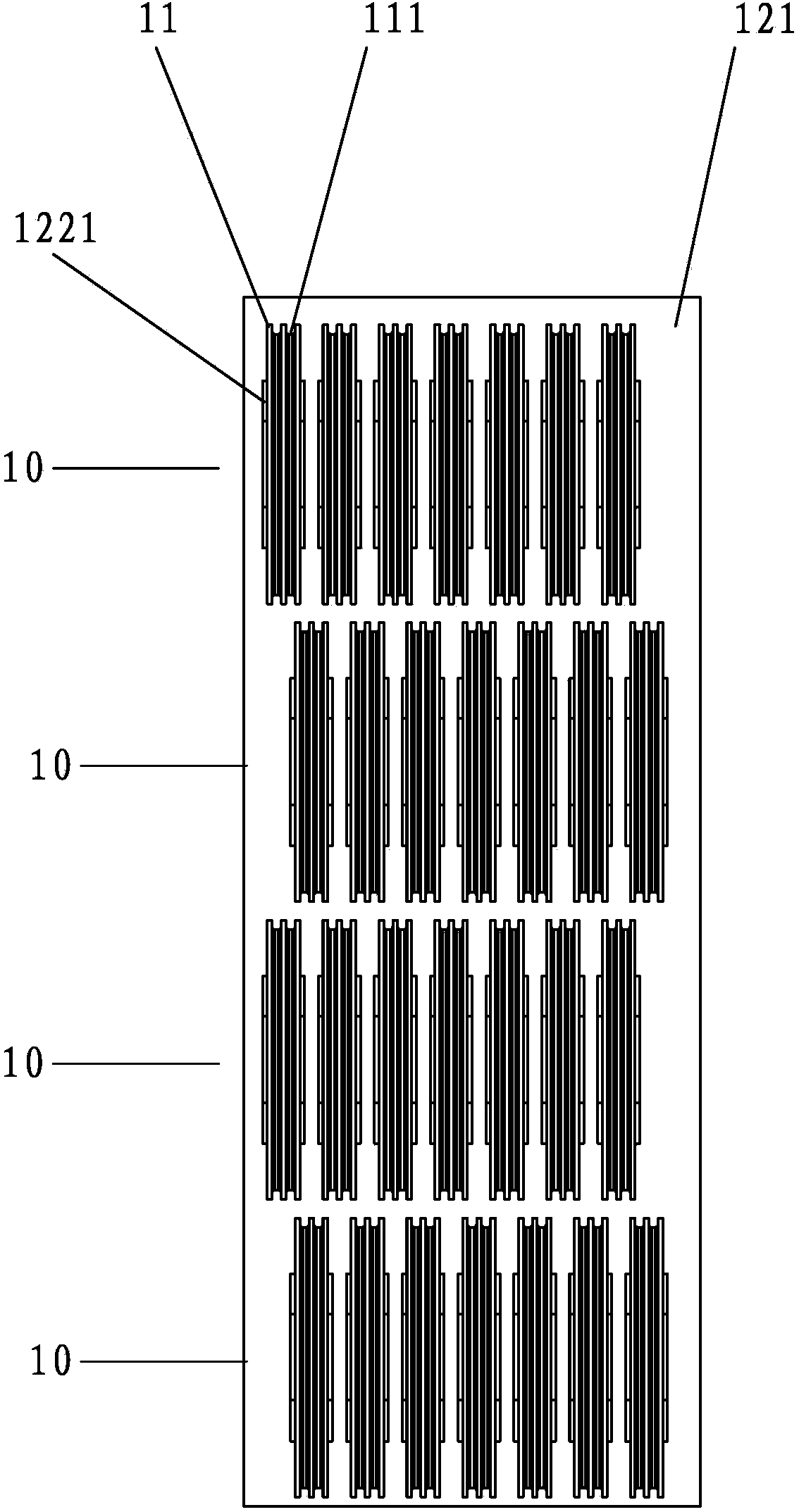

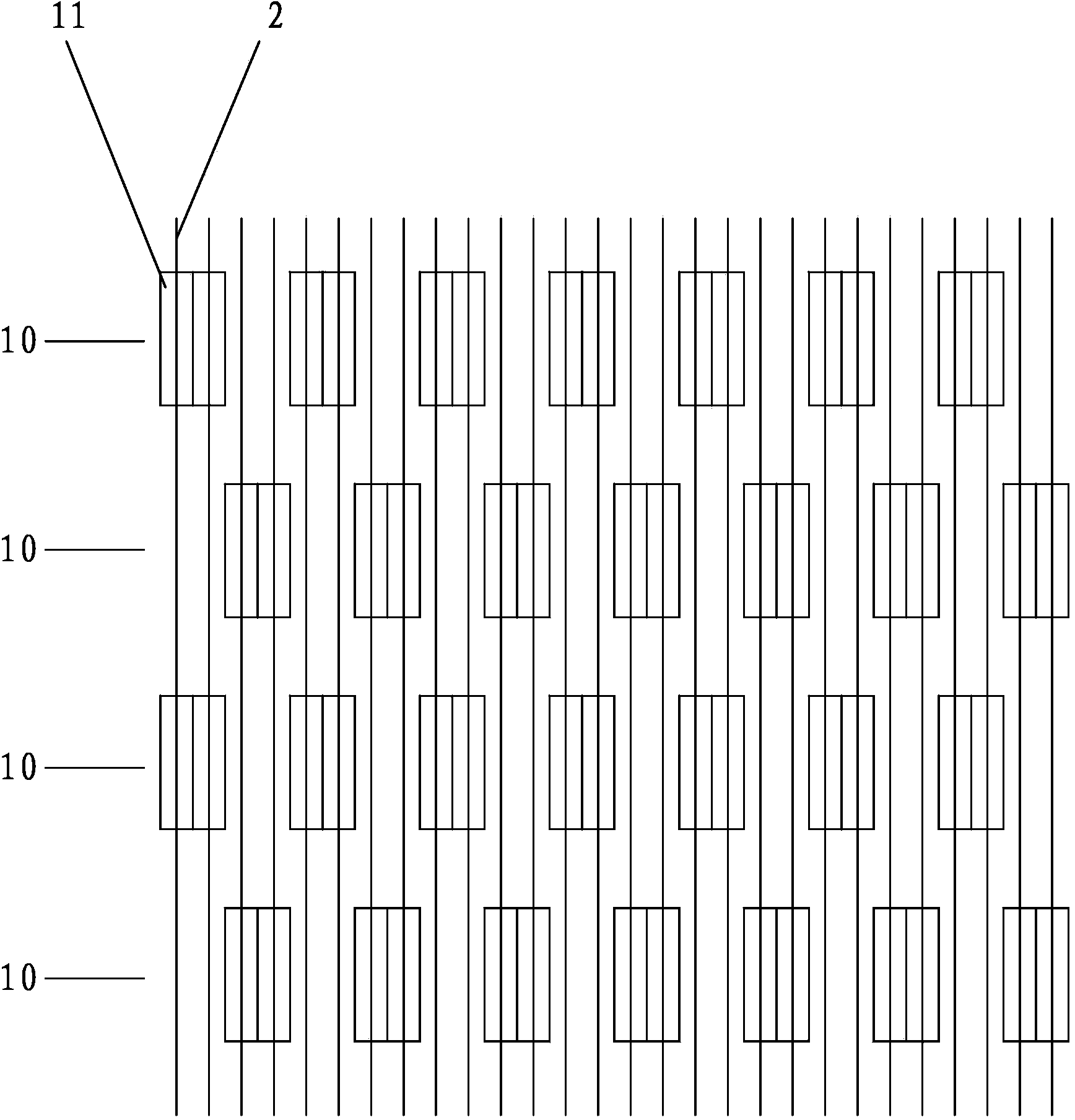

[0036] The novel tension adjustment mechanism of a kind of multi-rope diamond wire saw machine of the present invention, as Figure 1-6 As shown, a plurality of tension adjustment units 1 are included, and the tension adjustment unit 1 includes a tension wheel 11 and a tension driving device 12 for tension driving the tension wheel 11 .

[0037] Each tensioning pulley 11 is evenly formed with two rope grooves 111; each tension adjustment unit 1 is flat in the same plane as the respective tensioning pulley 11; multiple tension adjustment units 1 are arranged in parallel to form a tension adjustment unit row 10, and multiple rows The rows of tension adjustment units 10 are arranged in dislocation, the tension adjustment units 1 of the odd rows correspond one to one, the tension adjustment units 1 of the even rows correspond one to one,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com