Machining method for semicircular batten

A processing method and technology of beading, applied in the field of mechanical processing, can solve the problems of low qualification rate, easy deformation, unstable product performance, etc., and achieve the effect of meeting technical requirements and accurate drilling position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

[0030] A processing method for semicircular beading, comprising the following steps:

[0031] a. Fix and install the prefabricated fixture A on the faceplate of the floor lathe, and then debug it for use. The fixture A is as follows: Figure 7 and Figure 8 shown;

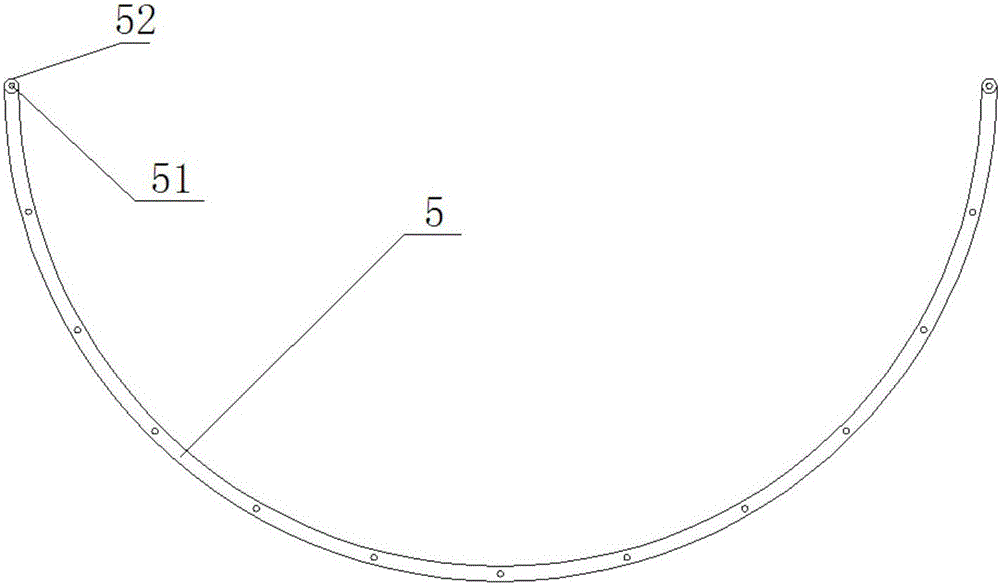

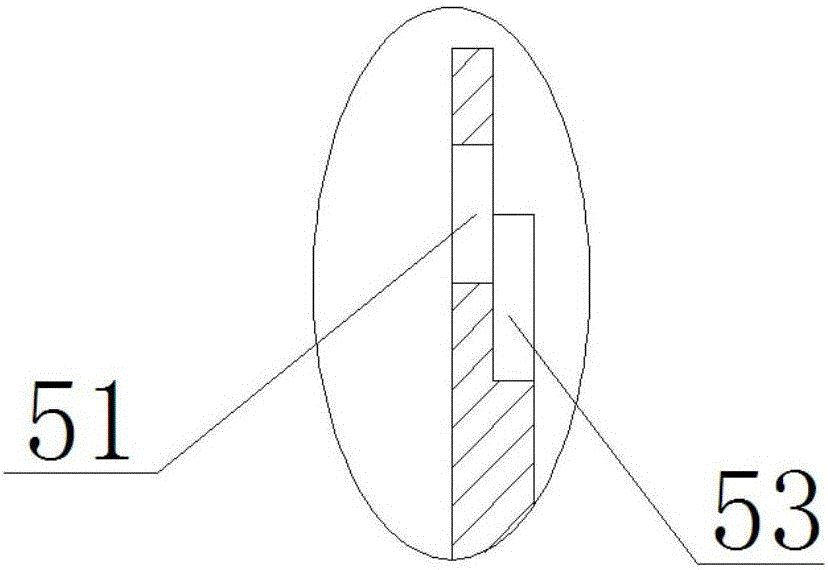

[0032] b. Select the corresponding blank size according to the size of the semicircle bead, reserve the semicircle bead position, and drill a plurality of through holes on the circumference of both sides of the reserved position, and the position of the through hole is consistent with the thread on the fixture A Corresponding to the hole; Figure 1 ~ Figure 3 As shown, its mosaic diagram is as follows Figure 4 ~ Figure 6 shown;

[0033] c. Fix the blank with the through hole on the fixture A by screws; light the surface of the material on the corresponding part of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com