Combined driller for machining container bottom plate

A container bottom plate and combined drilling rig technology, which is applied in the direction of boring/drilling, drilling/drilling equipment, boring machine/drilling machine components, etc. It can solve the problems of low work efficiency, small volume in the box, and poor working environment. Achieve the effects of simple structure, precise drilling position and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

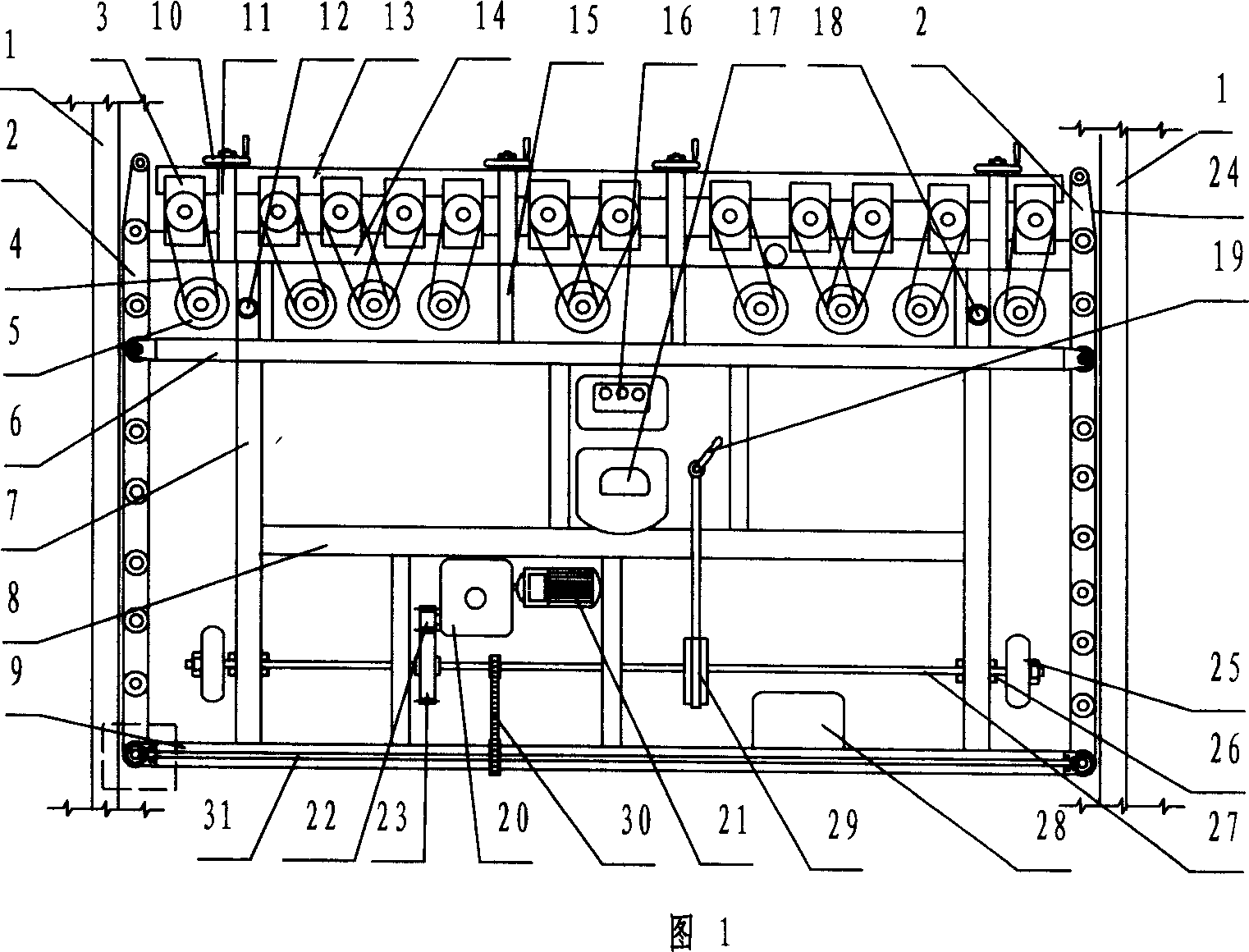

[0022] As shown in Figure 1: the support of the combination drilling rig is welded by two vertical beams 7 and crossbeams 14, 6, 8, 9 and 4 connecting plates 15, the combination drilling rig recommended by the present invention, the front crossbeam 14 and 12 drilling tool assemblies 3 are clamped between the crossbeams 13, and 9 motors 5 installed on the base are respectively arranged to drive the drill bit to rotate and drill through the belt 4 and the belt pulley, wherein three motors each drive two drilling tools to work. The drilling tool is installed by four locking wheels 10 to clamp the drilling tool between the crossbeam 13 and the crossbeam 14, and the position between the drilling tools can be adjusted arbitrarily as required. A belt tensioner is installed on each belt to adjust the tightness of the belt.

[0023] As shown in Figure 1, the walking mechanism of combined drilling rig is realized like this: left front wheel 12 and right front wheel 18 are respectively i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com