Hole-drilling and screw-locking device for container floor boards

A container and locking nail technology, which is applied to fixed drilling machines and other directions, can solve the problems of low production efficiency and installation dependence on container wooden floors, and achieve the effects of improving production efficiency, reducing labor intensity and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

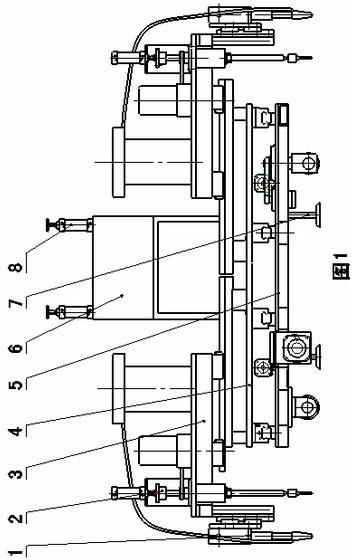

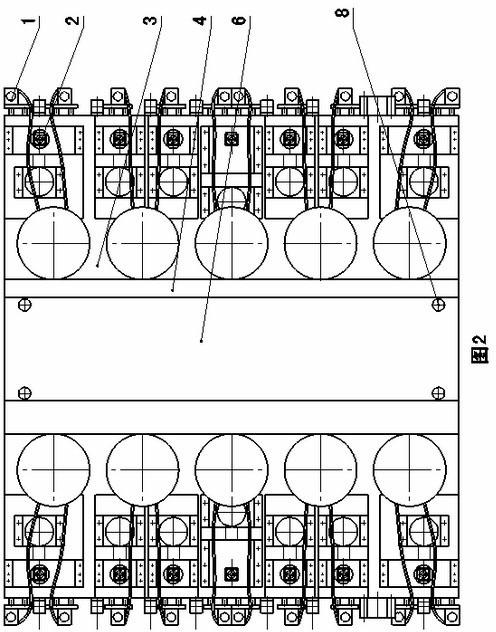

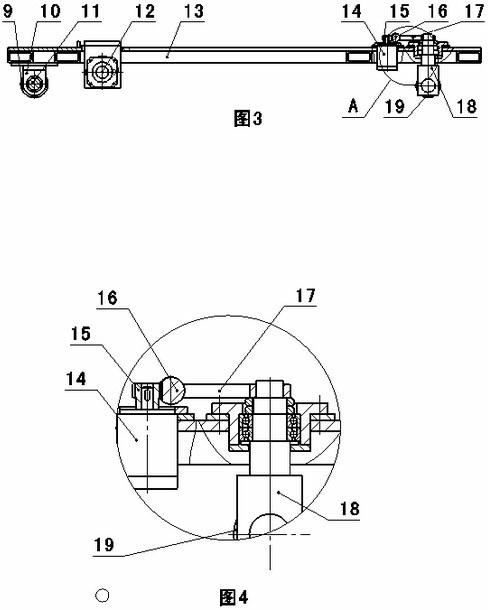

[0034]As shown in the drawings, the present invention has a traveling device 5, the traveling device comprises a car body 13, a driving part and a steering part, a traverse device 4 is installed on the top of the car body 13, and a transposition device is installed on the top of the traverse device 4 3. The drilling device 2 and the nail locking device 1 are installed on the transposition device 3, and the traverse device 4, the transposition device 3, the drilling device 2 and the nail locking device 1 move intermittently together with the car body 13 to complete the drilling, Nail locking function; the driving part of the walking device includes a driving wheel 9, a wheel shaft 11, a transmission belt 21 and a servo motor 12, and there are two driving wheels 9, which are installed on the wheel shaft 11 respectively, and the wheel shaft 11 is installed by two supporting seats 10 On the car body 13, the servo motor 12 is installed on the car body 13, and is connected with the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com