Tunnel inspection robot walking track supporting hanging frame and mounting method thereof

A technology for inspection robots and walking tracks, applied in manipulators, manufacturing tools, etc., can solve the problems of increasing the risk of manual inspection, easy accumulation of water in underground tunnels, and difficulty in air circulation, and achieves high installation accuracy and stability. Simple, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

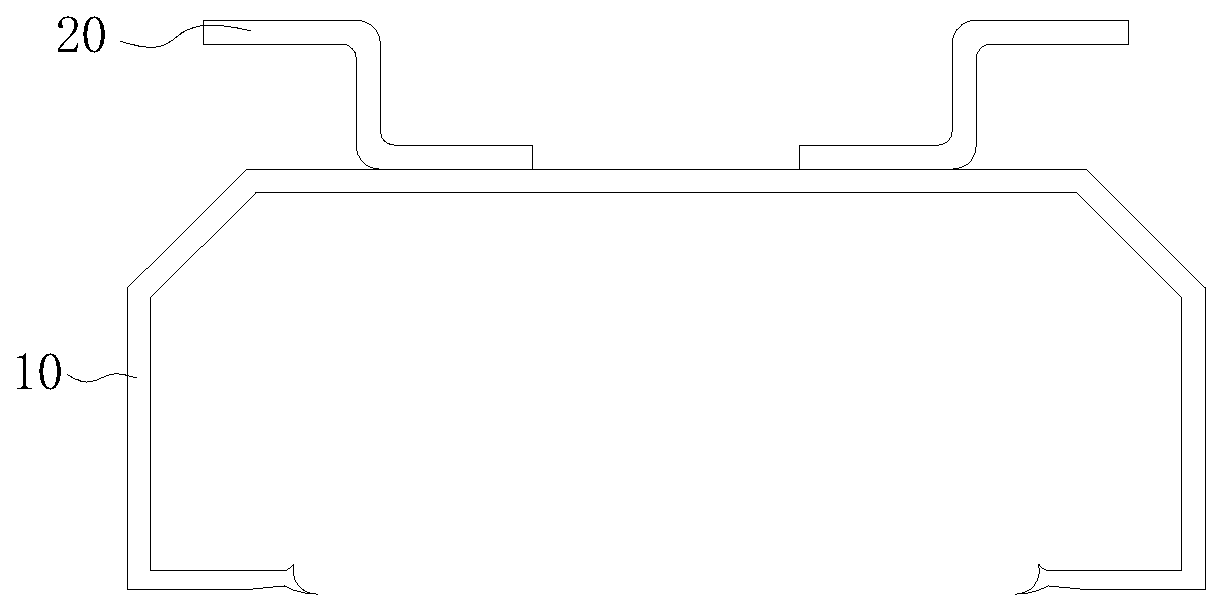

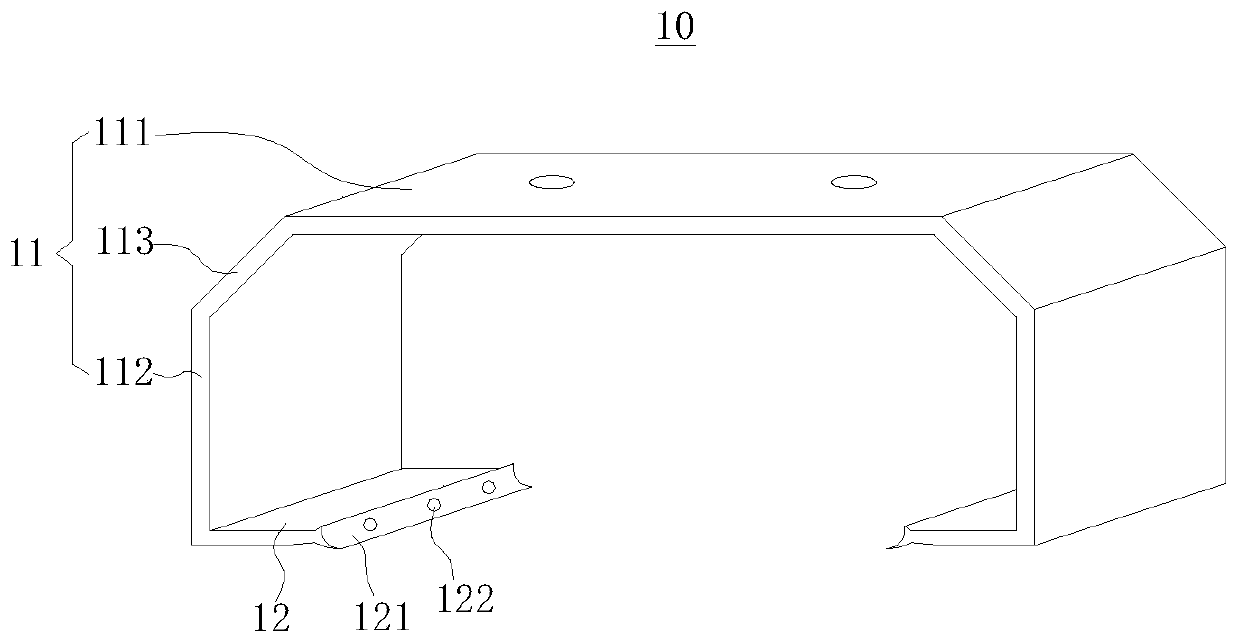

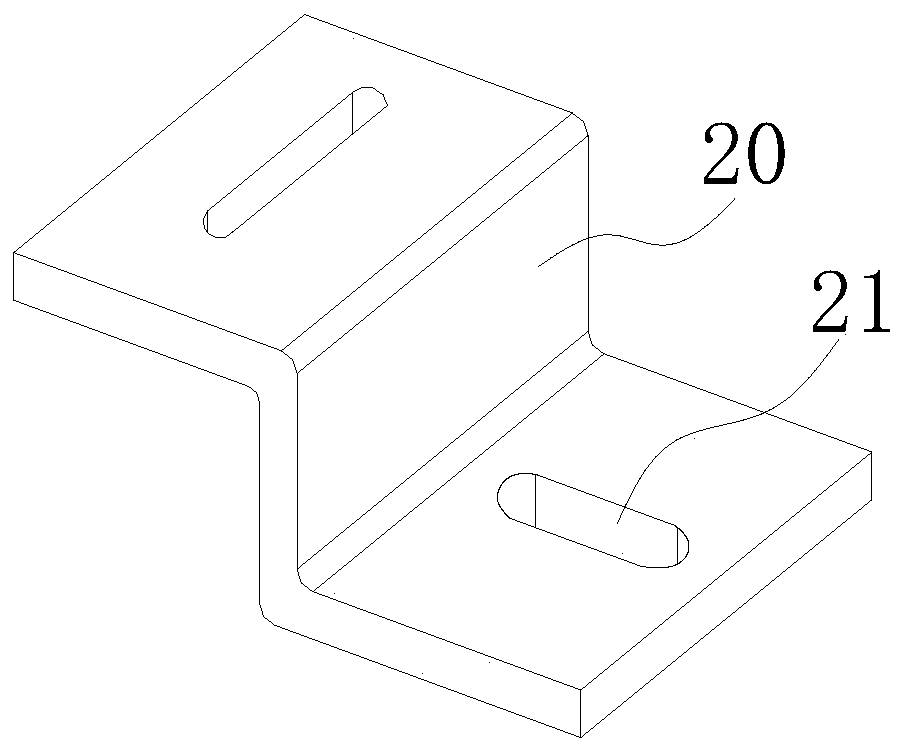

[0042] refer to figure 1 As shown, Embodiment 1 of the present invention provides a walking track support hanger for a tunnel inspection robot, including a main frame body 10 .

[0043] The main frame body 10 includes a U-shaped frame 11 and a fixing portion 12 .

[0044]The U-shaped frame 11 includes a first connecting plate 111 , a second connecting plate 112 and a third connecting plate 113 , all of which are plate-shaped structures. The quantity of the third connecting plate 113 is two, and the two third connecting plates 113 are arranged symmetrically at both ends of the first connecting plate 111, and the angle between the third connecting plate 113 and the first connecting plate 111 is 90°- 180°. In this embodiment, the angle between the third connecting plate 113 and the first connecting plate 111 is preferably about 135°. The quantity of the second connecting plate 112 is two and is respectively connected with two third connecting plates 113, and one end of the seco...

Embodiment 2

[0051] refer to figure 2 As shown, Embodiment 2 of the present invention provides a walking rail support hanger for a tunnel inspection robot, including a main frame body 10 .

[0052] The main frame body 10 includes a U-shaped frame 11 and a fixing portion 12 .

[0053] The U-shaped frame 11 includes a first connecting plate 111 and a second connecting plate 112, both of which are plate-like structures. The quantity of the second connecting plate 112 is two and symmetrically arranged at the two ends of the first connecting plate 111, one end of the second connecting plate 112 is connected with the first connecting plate 111, and the other end of the second connecting plate 112 is a free end, In this embodiment, the two second connecting plates 112 are parallel to each other, and the connection between the second connecting plate 112 and the first connecting plate 111 has a circular arc transition, which can avoid stress concentration and improve the structural strength of t...

Embodiment 3

[0060] Embodiment 3 of the present invention provides a method for installing a support hanger. The support hanger adopts the support hanger in Embodiment 1 or Embodiment 2. For its structure, refer to the corresponding content in Embodiment 1 or Embodiment 2. , which will not be described here.

[0061] This installation method includes the following steps:

[0062] S1: Determine the longitudinal position of the installation hole according to the track placed on the ground in the tunnel, draw a line on the ground with a marker pen, and then use a laser line projector to project the track trend line on the top of the tunnel, and mark it with a marker pen. Take several marked points, use the construction line to connect these marked points, and finally determine the drilling position of the installation hole according to the track line and the marked position on the ground.

[0063] It should be noted that in this step, it is necessary to ensure that the line connecting the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com