A quick-release slip drilling template

A technology for unloading slips and drilling molds, which is applied to the drilling molds used for workpieces, etc., and can solve the problems of not being suitable for quick production changes, labor and time-consuming, and high manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

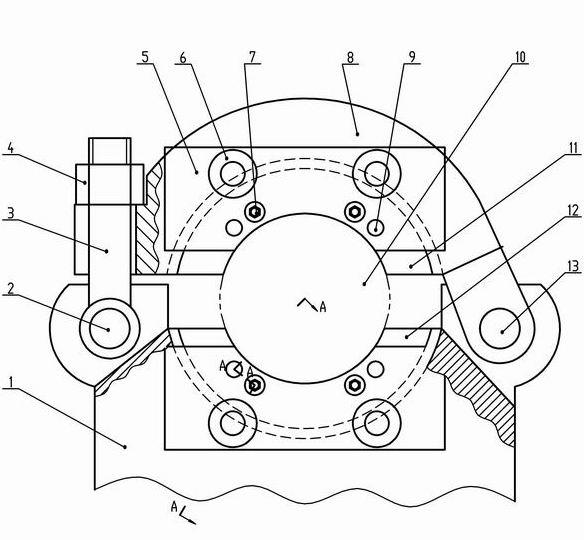

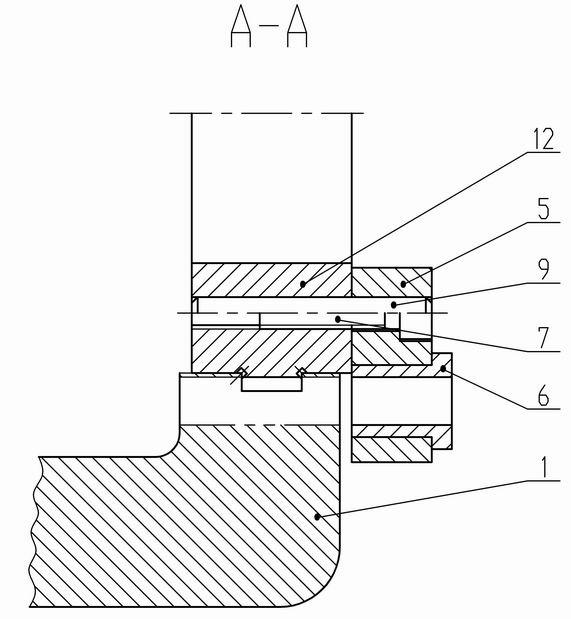

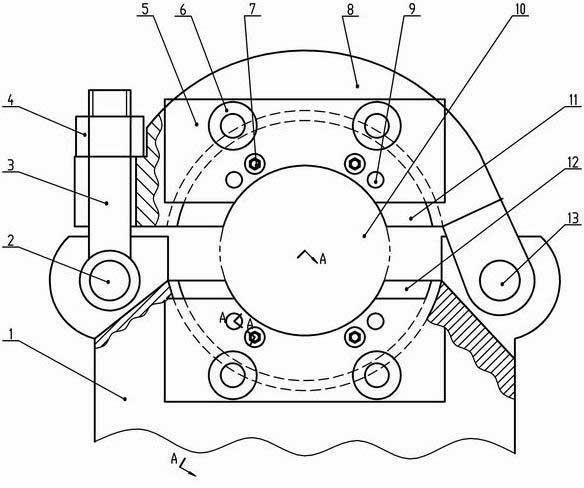

[0010] From figure 1 , figure 2 It can be seen from the figure that a quick-release slip drilling template includes a clamp body 1, a lower lining tile 12, a gland 8, an upper lining tile 11, a lining column 10, a drilling template 5, a drill sleeve 6, etc. Concrete 1 and the gland 8 are provided with grooves, and the lower lining tile 12 and the upper lining tile 11 are respectively provided with bosses in the circumferential direction, and the lower lining tile 12 and the upper lining tile 11 are tightly fitted in the clamp body 1 and the gland respectively. 8, one end of the gland 8 is connected to one side of the clamp body 1 through a hinge pin 13, the other side of the clamp body 1 is connected to a flat head bolt 3 through a pin shaft 2, and the other end of the gland 8 is provided with a U-shaped Mouth, the U-shaped mouth penetrates the flat head bolt 3, connects with the compression nut 4, and clamps the lining column 10 between the lower lining tile 12 and the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com