Upsetting forging press and operating method

A working method and technology of an upsetting machine, which are applied to the upsetting machine and the work field, can solve the problems of inflexibility, inconvenient stroke adjustment, and small space for upsetting of a high-speed forging machine, so as to reduce the technical quality requirements, easy to operate and Faster, lower productivity costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

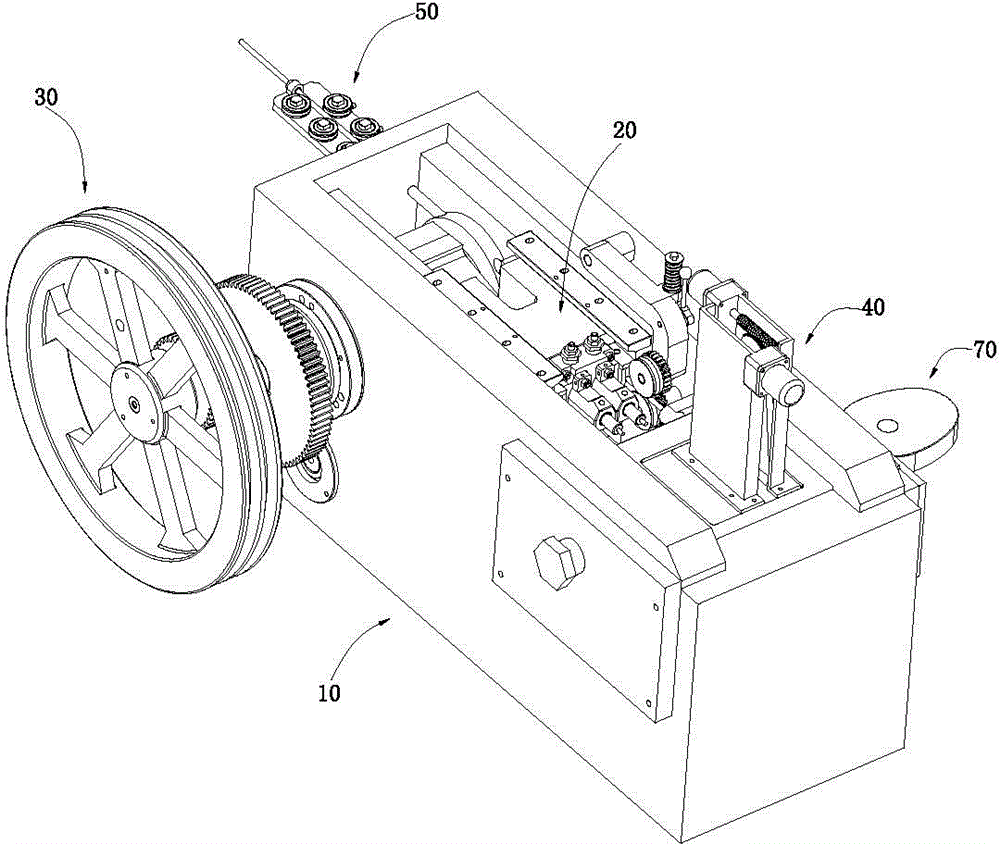

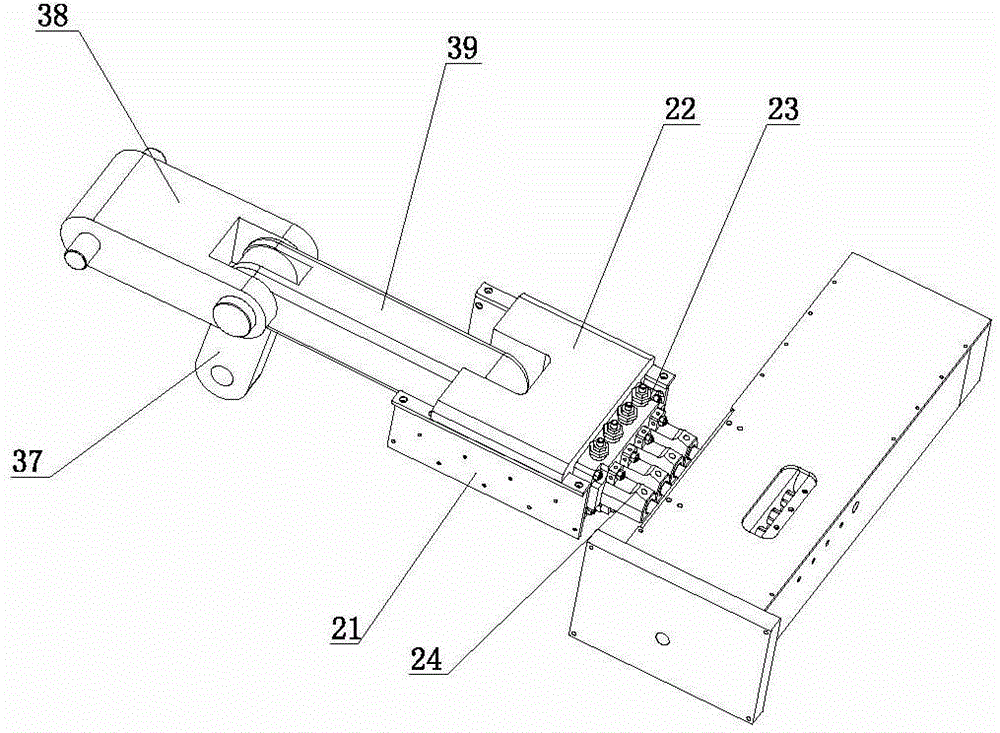

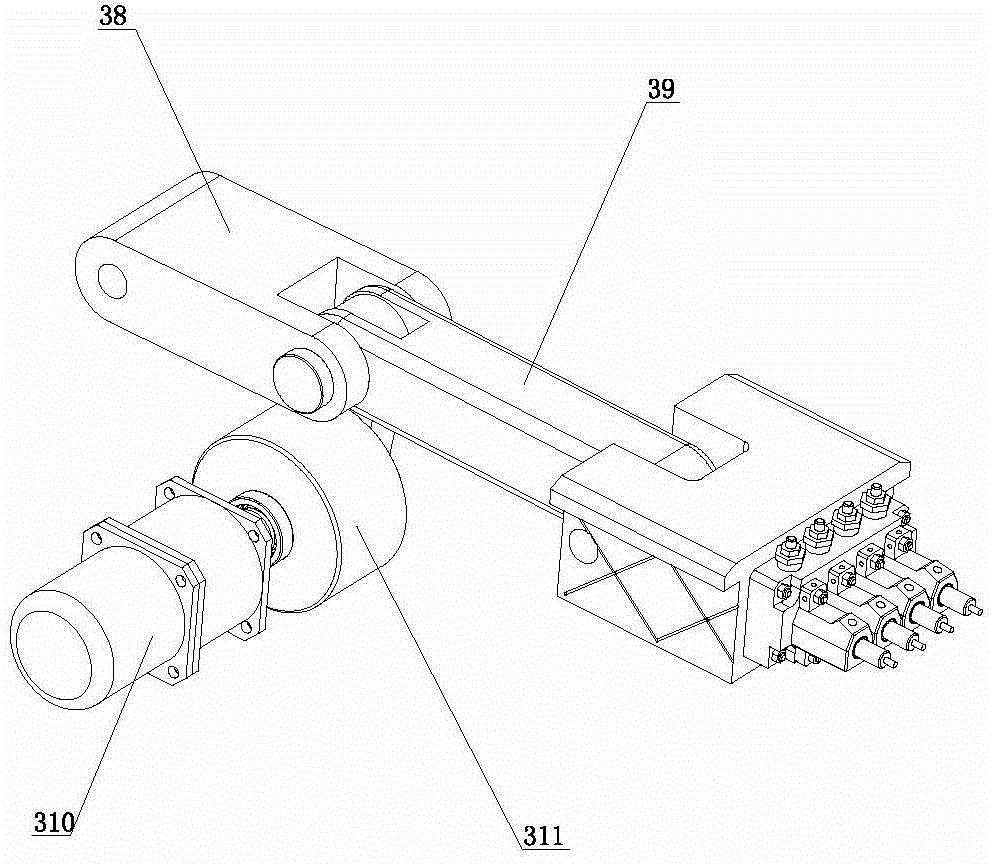

[0079] Such as figure 1 and figure 2 As shown, the upset forging machine includes a body 10, a punch assembly 20 installed on the body 10, a punch assembly driving mechanism 30 for driving the punch assembly 20, an ejector mechanism 40, a feeding mechanism 50 arranged on the body 10, The main mold assembly 60 and the main mold driving mechanism 70 driving the translation of the main mold assembly 60 .

[0080] Such as image 3 and Figure 4 As shown, the described body 10 includes a frame 11, a seat body 12 and a cover plate 13; the frame 11 includes a frame body 111 and a frame seat 112 corresponding to the main mold assembly 60, as Figure 4 As shown, the frame seat 112 includes a frame body 1122 and an end plate 1123, the frame body 1122 has a housing cavity 1121, one end of the housing cavity 1121 has an opening 11211, and the end plate 1123 is fixed on the On the base body 1122 . In this embodiment, the two ends of the frame seat 112 and the seat body 12 protrude fr...

Embodiment 2

[0120] Such as Figure 33 and Figure 34 As shown, the upset forging machine includes a body 10, a punch assembly 20 installed on the body 10, a punch assembly driving mechanism 30 for driving the punch assembly 20, an ejector mechanism 40, a feeding mechanism 50 arranged on the body 10, The main mold assembly 60 and the main mold driving mechanism 70 driving the translation of the main mold assembly 60 .

[0121] Such as image 3 and Figure 4 As shown, the described body 10 includes a frame 11, a seat body 12 and a cover plate 13; the frame 11 includes a frame body 111 and a frame seat 112 corresponding to the main mold assembly 60, as Figure 4 As shown, the frame seat 112 includes a frame body 1122 and an end plate 1123, the frame body 1122 has a housing cavity 1121, one end of the housing cavity 1121 has an opening 11211, and the end plate 1123 is fixed on the On the base body 1122 . In this embodiment, the two ends of the frame seat 112 and the seat body 12 protrude...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com