Preparation device and preparation method of nano photocatalytic self-foaming resin cement-based material

A technology for a cement-based material and a preparation device, which is applied in the field of cement-based material preparation, can solve problems such as low preparation efficiency and artificial damage, and achieve the effects of low cost, simple preparation and light weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] In the existing preparation device of porous light photocatalytic material, in the process of use, manual demolding operation is required after foaming molding, which is prone to manual damage, resulting in low preparation efficiency.

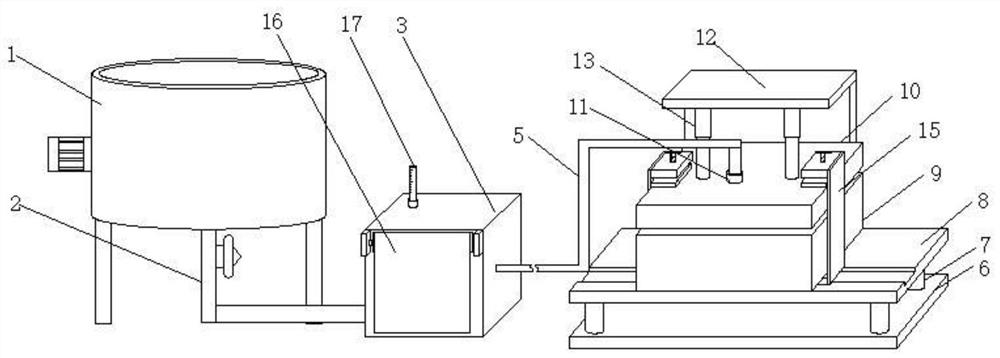

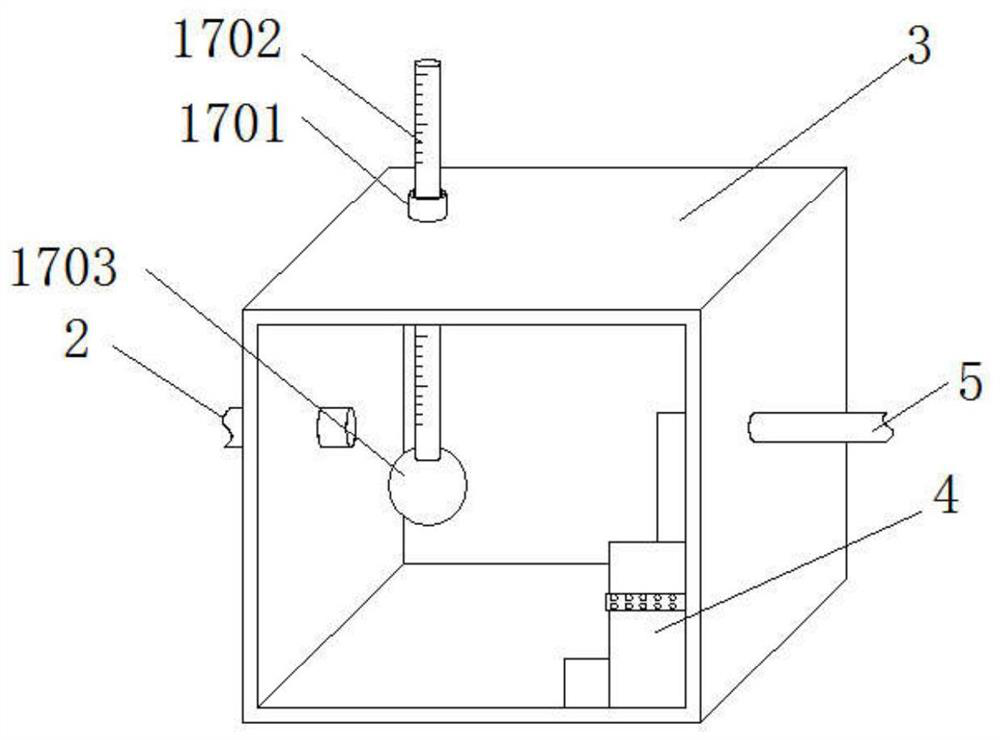

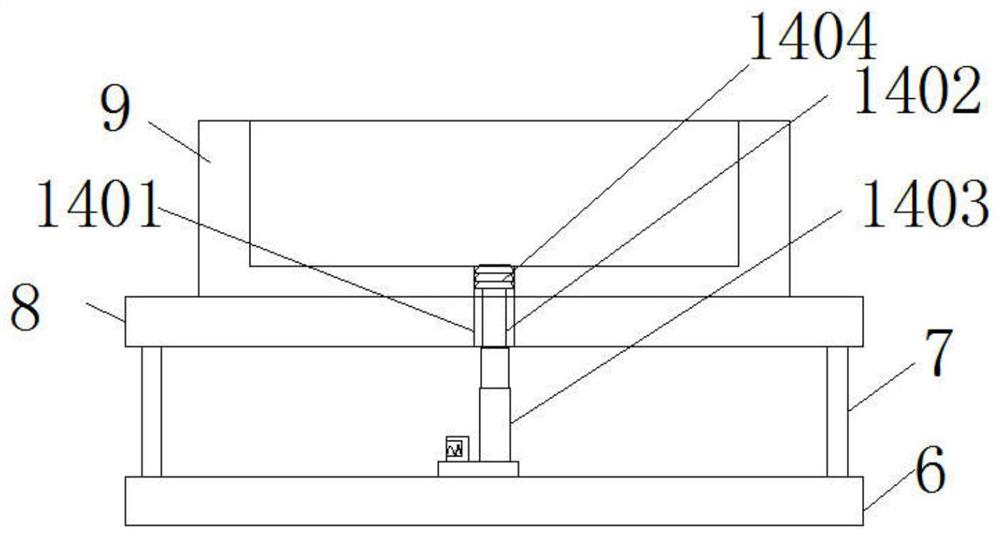

[0057] In order to solve this technical problem, the present invention proposes a preparation device for nano-photocatalytic self-foaming resin cement-based material, please refer to Figure 1 to Figure 5 , the preparation device of the nano-photocatalytic self-foaming resin cement-based material proposed by the present invention includes a stirring kettle 1, the bottom end of the stirring kettle 1 is fixedly installed with a material guide pipe 2, and one side of the material guide pipe 2 is fitted and connected with a storage material A submersible pump 4 is installed on the inner side of the tank 3 and the storage tank 3 .

[0058] A hose 5 is fixedly connected to the top of the submersible pump 4 , and the hose 5 is connected to the ...

Embodiment 2

[0071] The second embodiment of the present invention proposes a method for preparing a multi-nano photocatalytic self-foaming resin cement-based material, using the above-mentioned preparation device, and the preparation method includes a material mixing and storage step, a guide molding step, and a molding decompression step. Die steps:

[0072] Wherein the mixing storage step of the material includes:

[0073] Step 1, take 1L of PU foamed resin material A, 1L of PU foamed resin material B, and 0.5-1g of nano-photocatalytic material;

[0074] Step 2, put the nano-photocatalytic material and PU foam resin material A into the stirring tank (1) and mix, obtain the first mixture by fully stirring and dispersing, then the first mixture and PU foam resin material B are 1: 1: The volume ratio of 1 is rapidly mixed to obtain the second mixture;

[0075] Step 3, introducing the mixed second mixture into the storage tank 3 through the material guide pipe 2;

[0076] The steps of gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com