Patents

Literature

164results about How to "Easy demoulding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminum product high-pressure casting device and method

The invention discloses a novel aluminum product high-pressure casting machine and relates to the field of metal product casting. A traditional structure is improved, operation is more convenient and accurate, casting efficiency is improved, the density of products is improved by applying high pressure in a sequential increasing mode, the surface quality and the mechanical performance of the products are improved, the weight of the products is reduced under the premise that quality of the products is improved, and energy is saved.

Owner:TAIAN XINCHUANG ALUMINUM PROD CO LTD

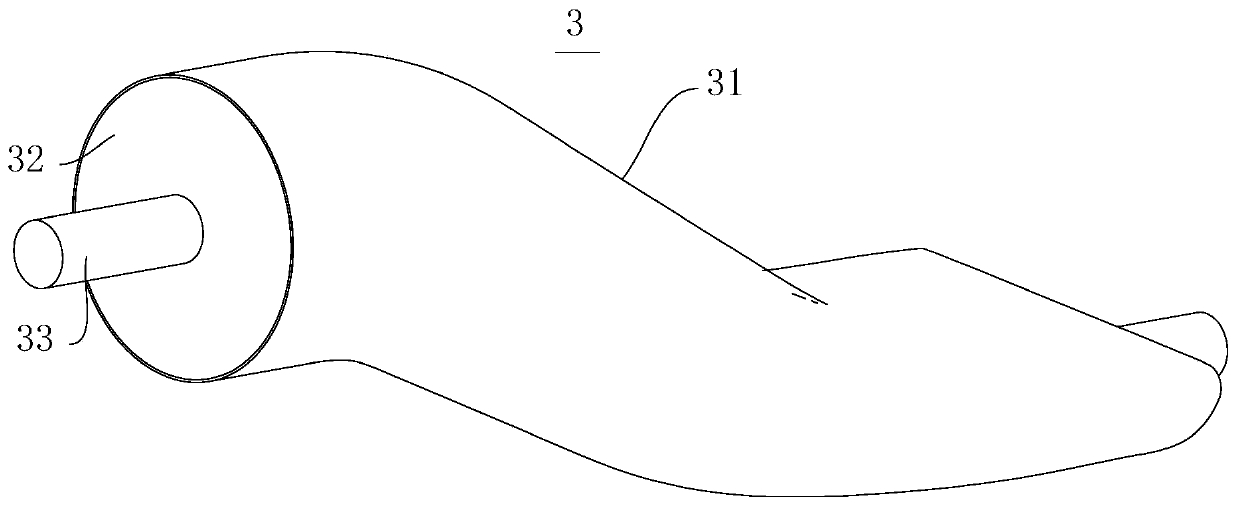

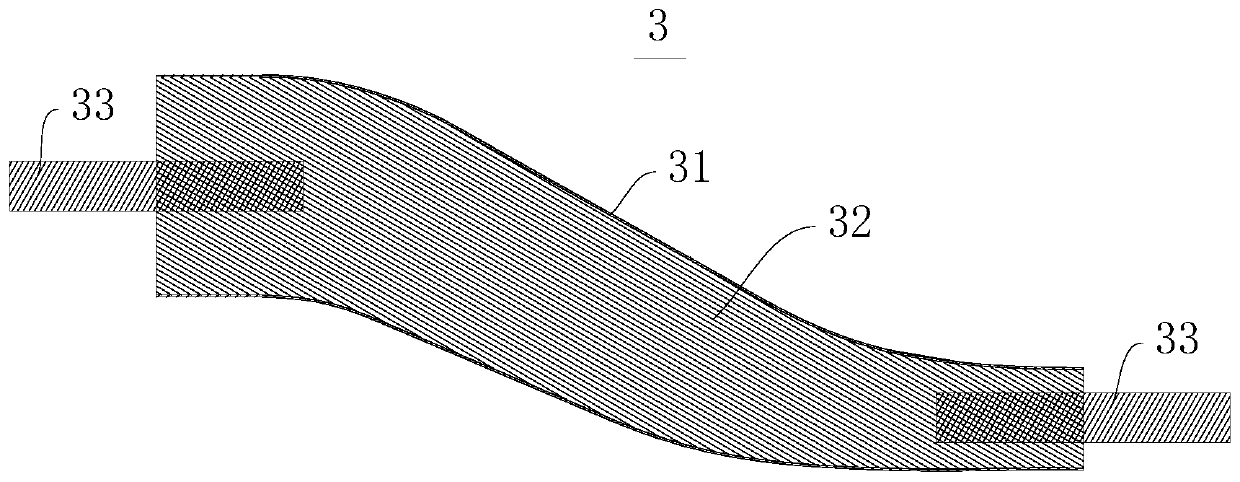

Forming method for variable cross-section hollow-structure composite part with high-precision inner surface

The invention relates to the technical field of forming of resin-based fiber reinforced composite prepreg through an autoclave, in particular to a forming method for a variable cross-section hollow-structure composite part with a high-precision inner surface. A forming mandrel is adopted and comprises a sold mold and a water-soluble core, and the water-soluble core is located in the spaced formedby the soft mold. The forming method includes the following steps that composite prepreg is paved on the surface of the soft mold; the composite prepreg is cured; and the water-soluble core is removed, and the soft mold and the cured composite are separated. The forming method provided by the invention adopts the forming mandrel combining the soft mold and the water-soluble core, the soft mold isused for being attached to the composite, and therefore high surface quality can be provided. The water-soluble core is used for supporting the soft mold, so that the soft mold has a preset shape, andthe cost of the forming mandrel is low. In the machining process of the composite part, during demolding, the water-soluble core is removed firstly, the soft mold is deformed and removed, and therefore demolding is achieved, and demolding operation is simple.

Owner:成都联科航空技术有限公司

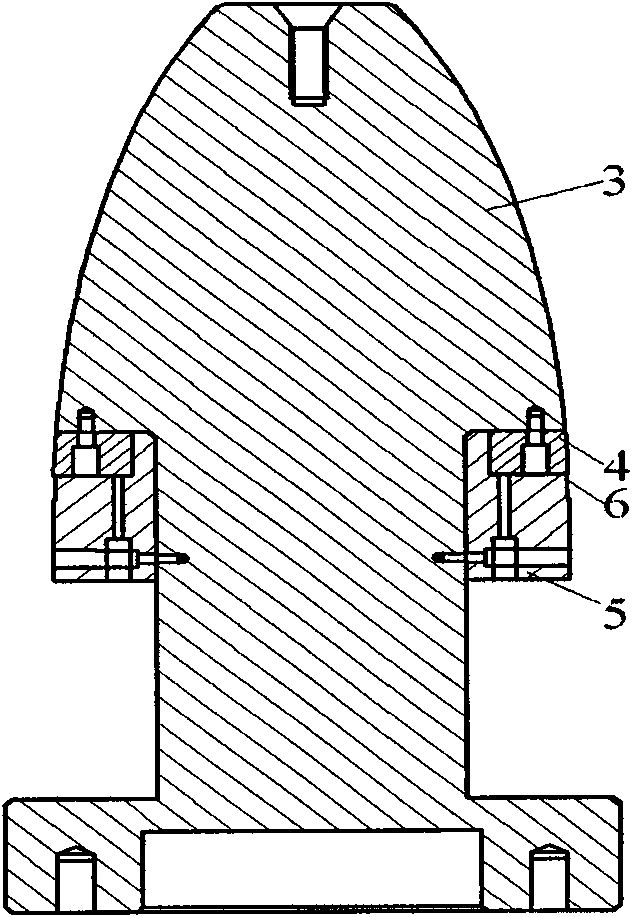

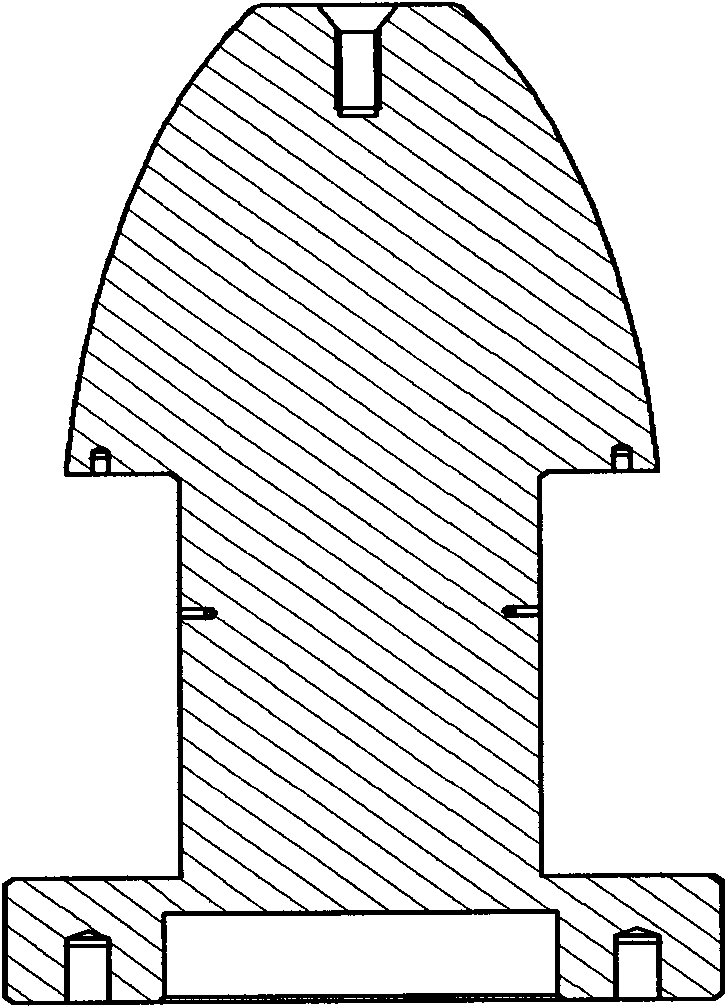

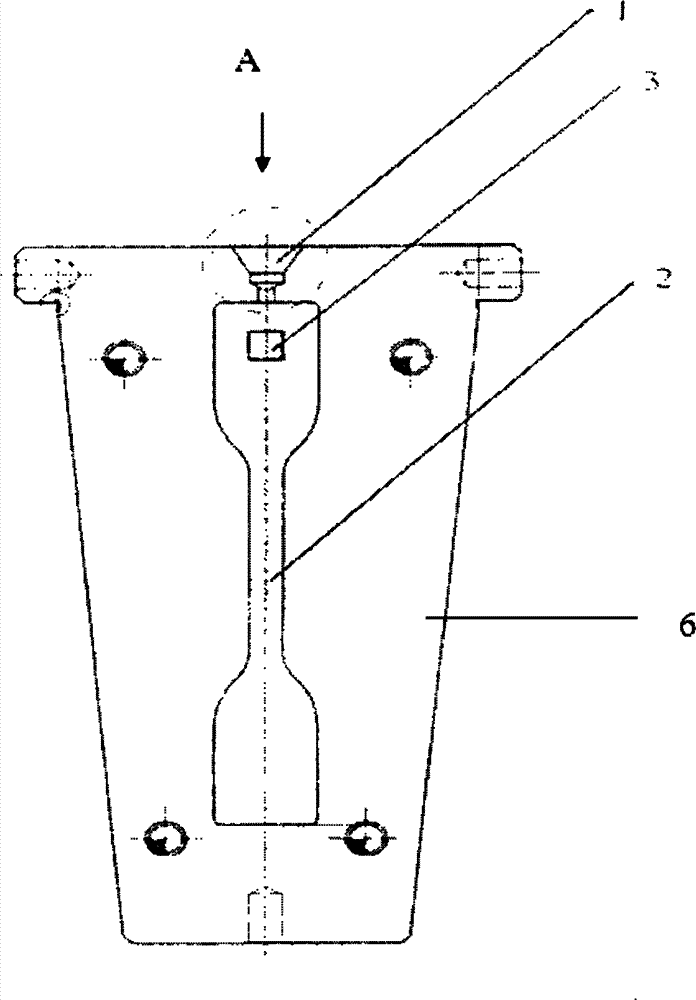

A core mold for spinning parts with transverse internal ribs and a method of moving back and demoulding

ActiveCN102284613AHigh quality and precisionHigh forming precisionShaping toolsEngineeringUltimate tensile strength

The invention relates to a mandrel for spinning a piece with a transverse inner rib and a backward moving demolding method of the mandrel. The outer shapes of a curved generatrix end of a mandrel main body and a clamping plate are curved generatrix shapes matched with the inner shape of a formed workpiece; the clamping plate is arranged on the outer side of a mounting surface formed by the large end face of the curved generatrix end of the mandrel main body; a ferrule is sleeved on a mandrel shaft; the small-diameter end of the ferrule is embedded between the clamping plate and the mandrel shaft of the mandrel main body and is attached to the mounting surface between the curved generatrix shaped end of the mandrel main body and the mandrel shaft; the small end face of the clamping plate is attached to the outer side of the mounting surface of the curved generatrix end of the mandrel main body; the arc surface of the excircle of the clamping plate is connected with the surface of the curved generatrix shaped end of the mandrel main body in a smooth mode; the large end face of the clamping plate is attached to the end face formed by a step on the surface of the outer circumference of the ferrule. A large complex curved generatrix thin-wall member spun workpiece with the transverse inner rib is demolded easily and conveniently, the forming quality and forming accuracy of the workpiece are improved, and the mandrel has the characteristics of short production period, high production efficiency, low production cost and low worker labor intensity.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

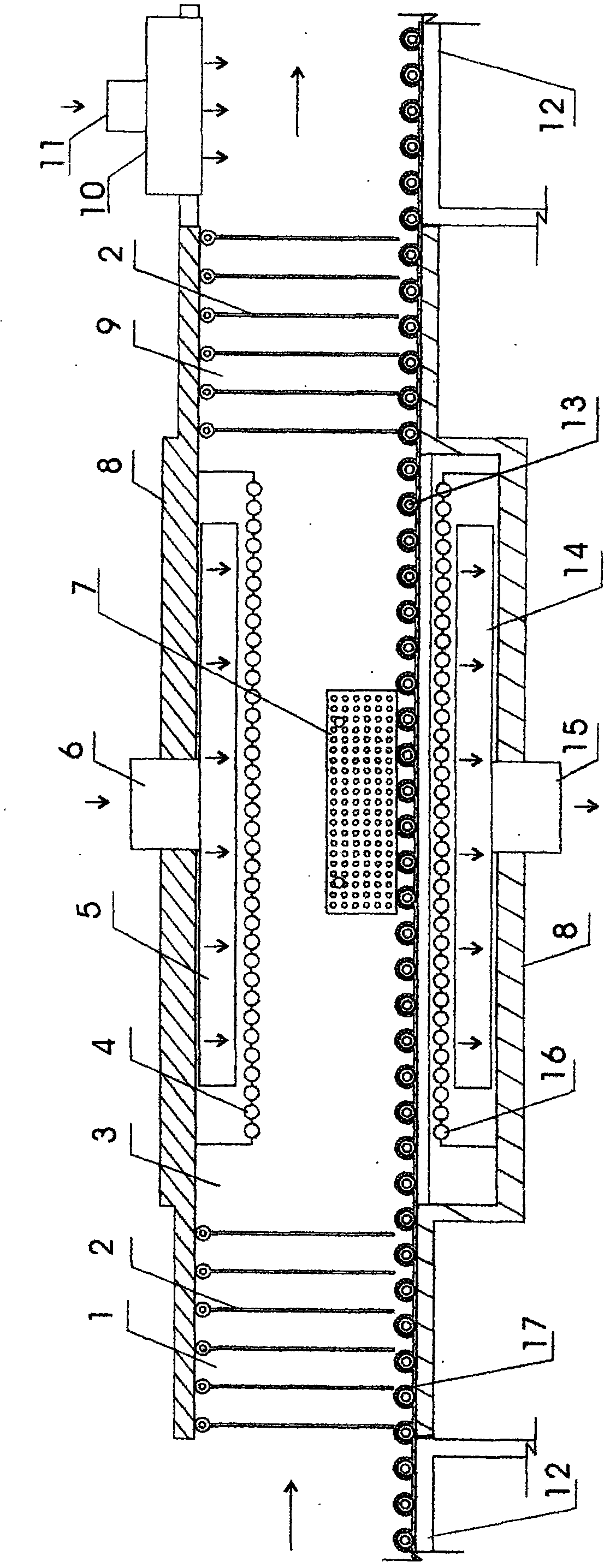

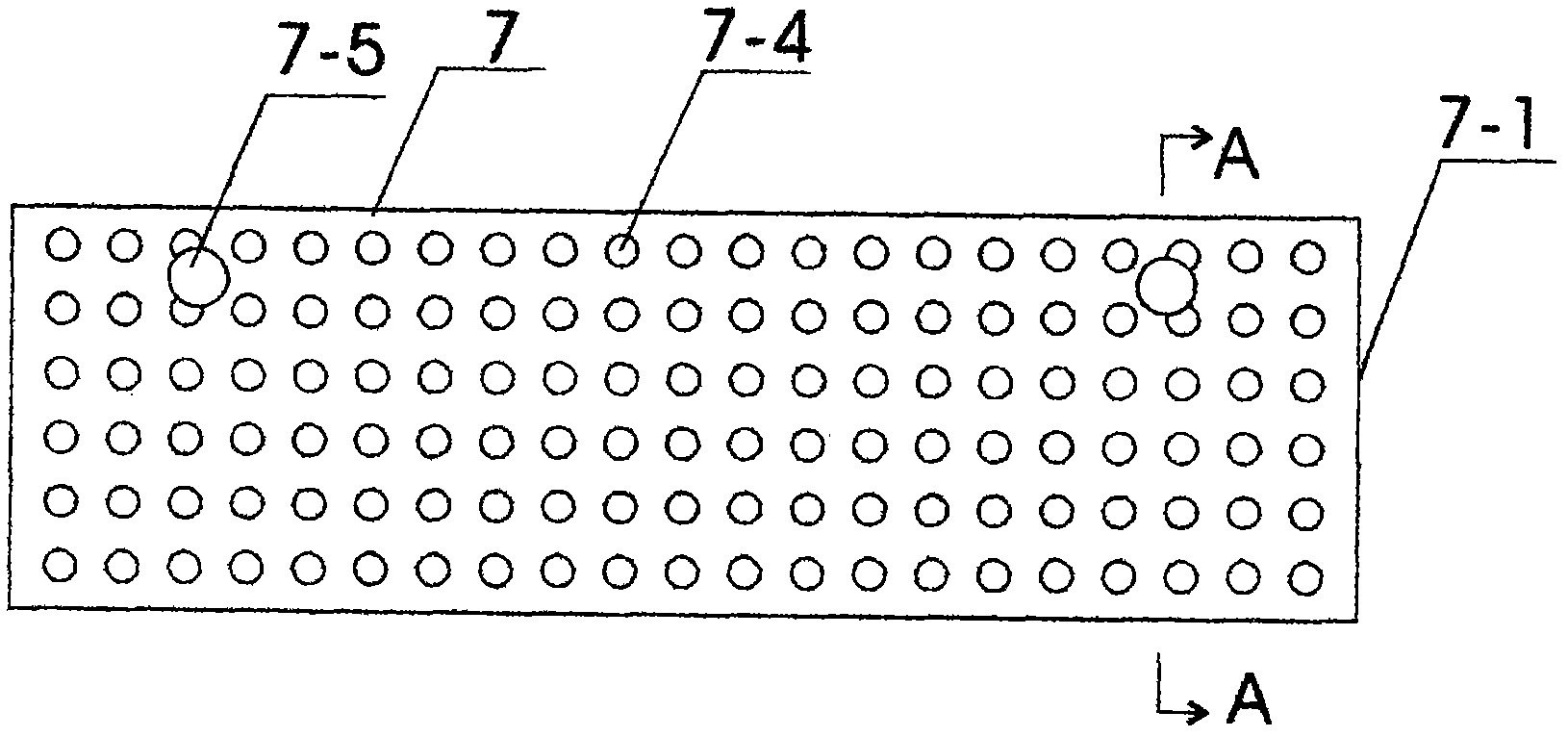

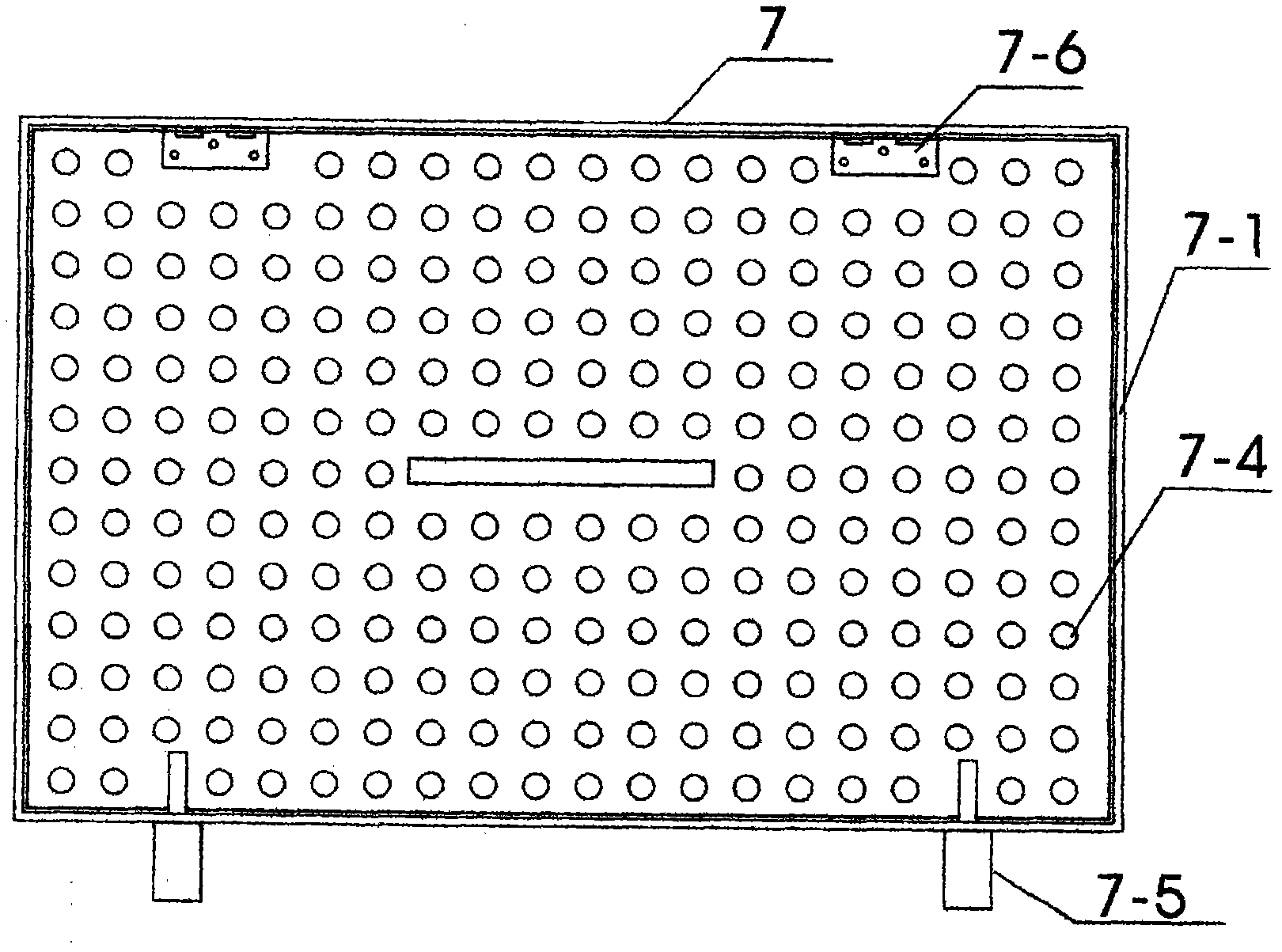

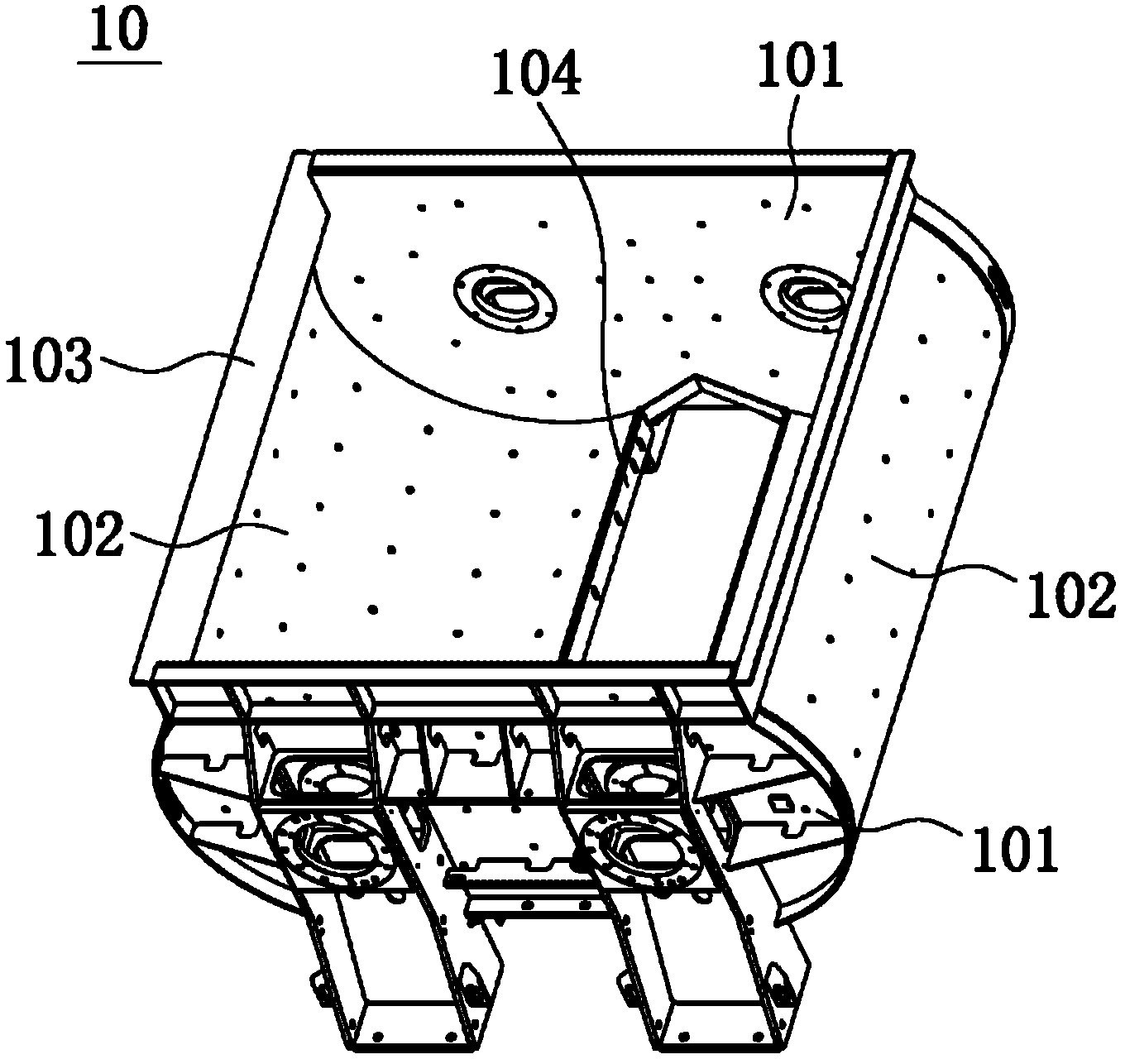

Heat setting device of pillow core

ActiveCN102029707AComfortable pillowAccelerated heat-melt setting timeDomestic articlesCold airTemperature control

The invention discloses a heat setting device of a pillow core, which enables a pillow core which uses loose materials of blended fiber cotton as main raw materials to quickly realize heat setting of the whole pillow core, thereby greatly improving the elastic comfort, product quality and production efficiency of the pillow core. The device has obvious energy-saving effect. The device comprises aheating furnace, a roller type conveying belt, a hot air circulating system, a heat setting mold and a cold air cooling device, wherein the heating furnace comprises a middle furnace chamber, a left furnace chamber and a right furnace chamber; the middle furnace chamber is provided with the hot air circulating system in the vertical direction; the upper part and the lower part of the middle furnace chamber are respectively provided with a row of far-infrared heating pipes; the heat setting mold on which a plurality of ventilated through holes are distributed is placed on the conveying belt; the left furnace chamber and the right furnace chamber are respectively provided with multiple movable heat insulation doors which are mutually parallel and are vertically arranged; the cold air cooling device is arranged above the outlet of the right furnace chamber; and the heating furnace, the conveying belt, the hot air circulating system and the cold air cooling device are fully automatically controlled by a program controller and a temperature controller.

Owner:FOSHAN SHUNDE ZHENMENGYUAN HOME TEXTILE CO LTD

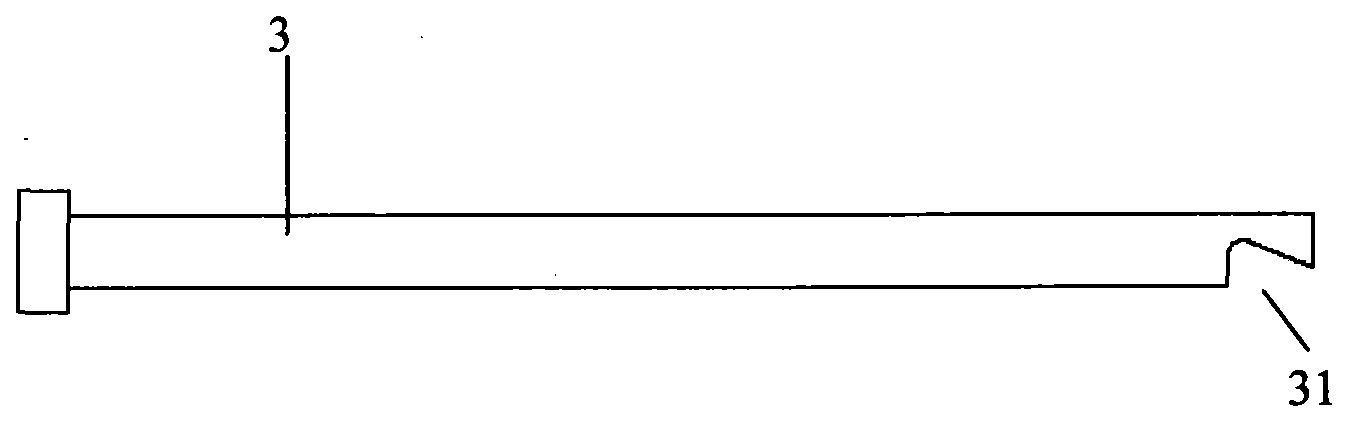

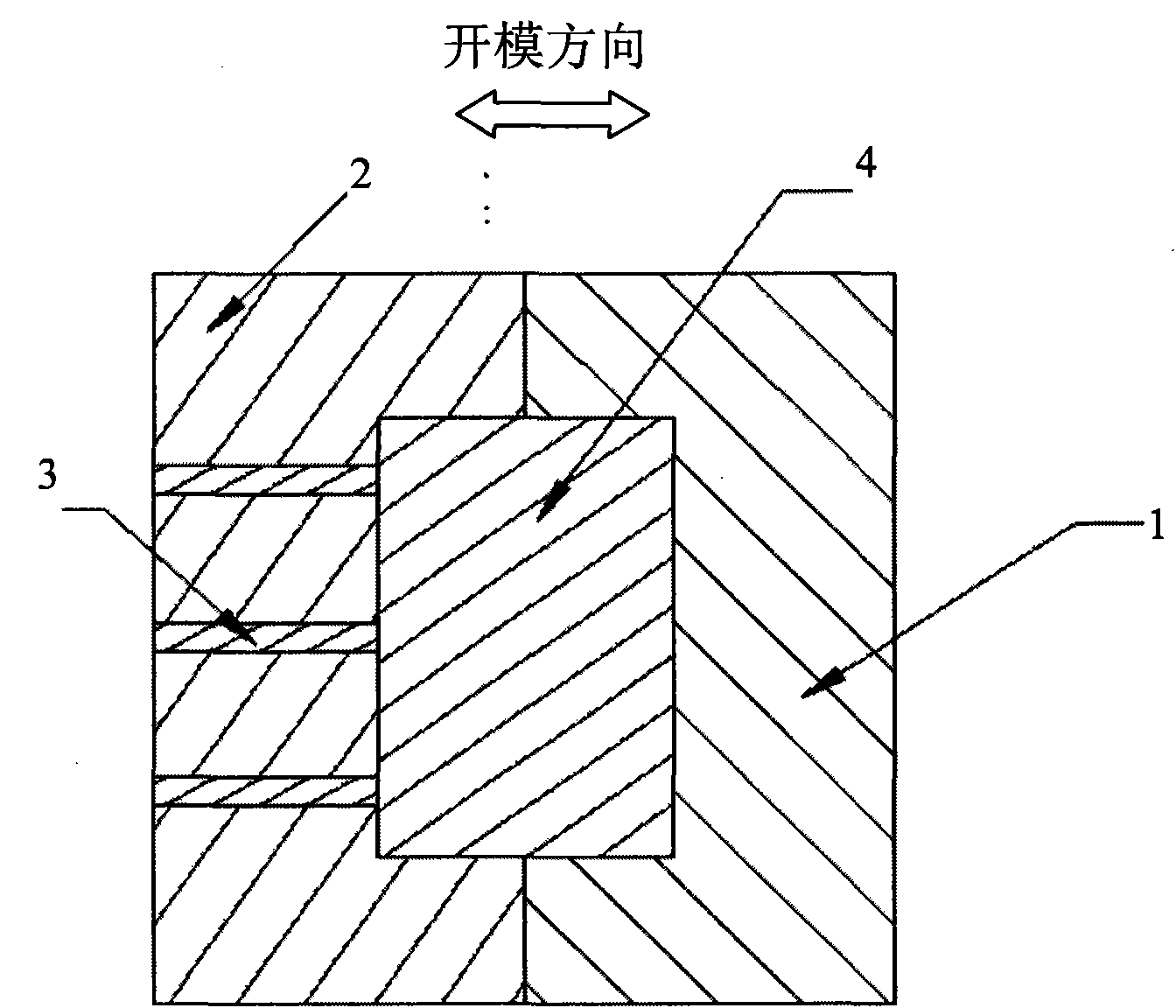

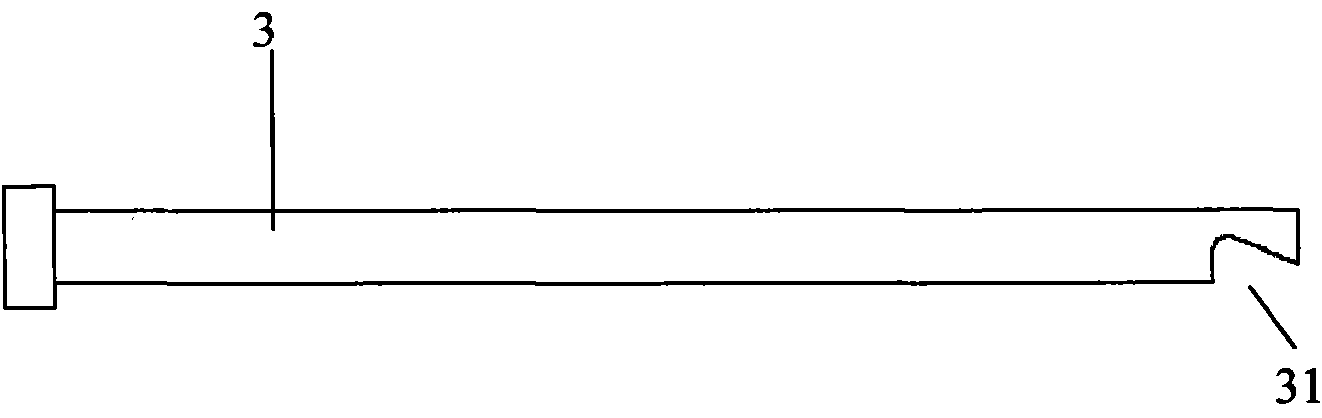

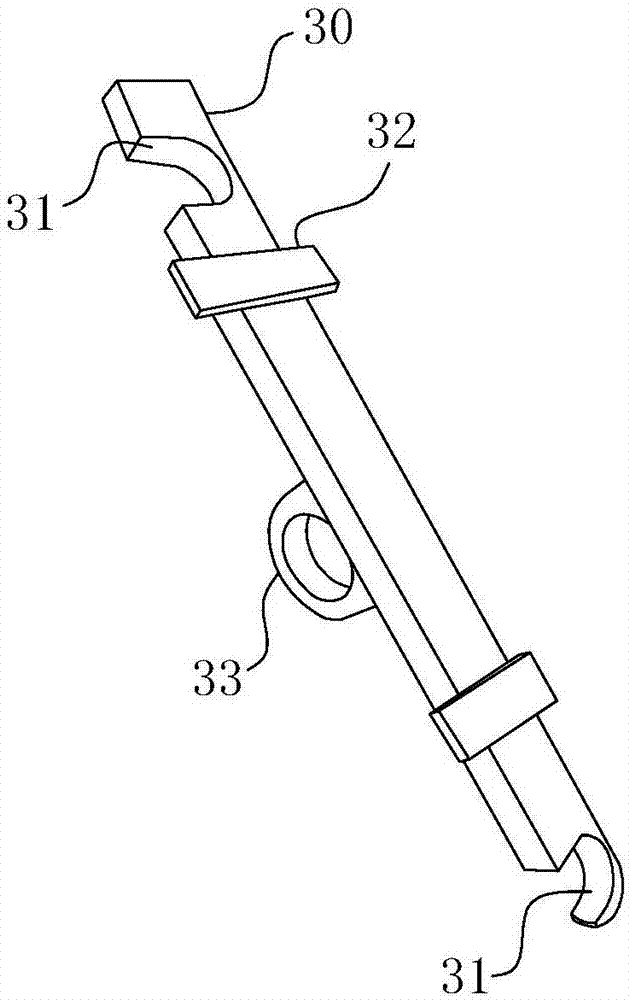

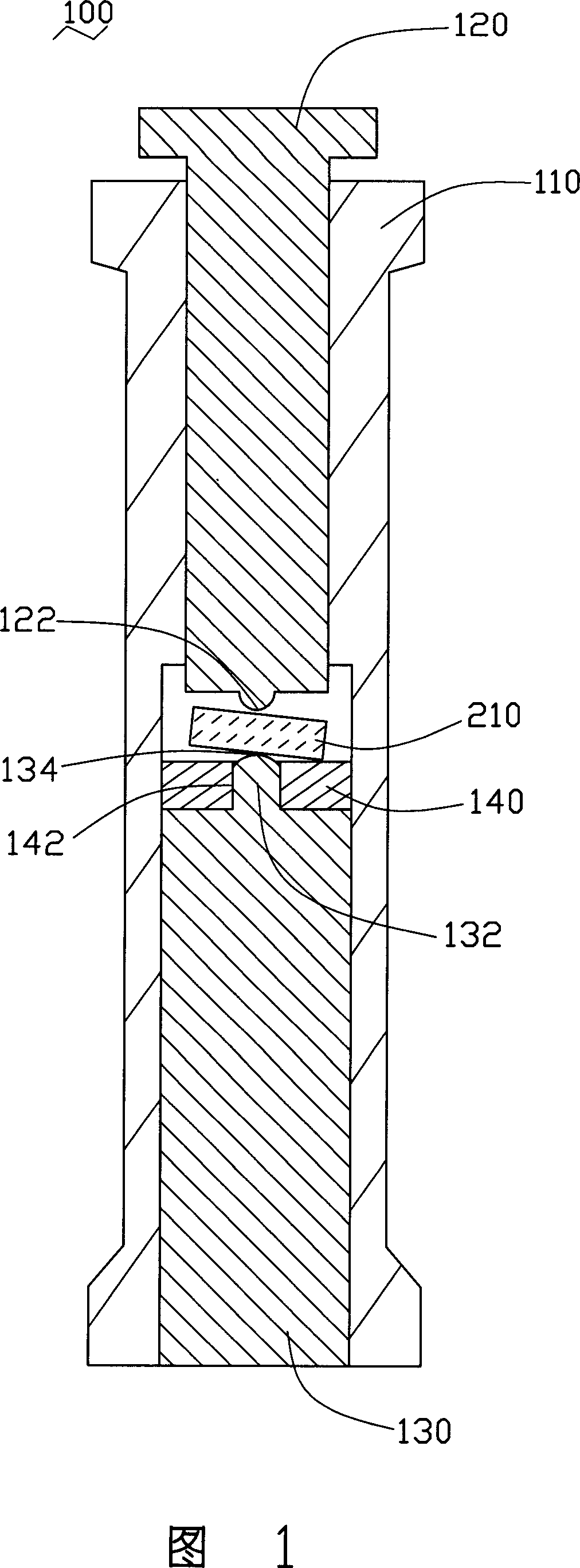

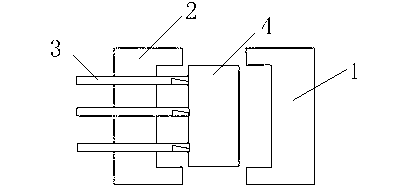

Thimble structure for die-casting mould

ActiveCN101811183AEasy demouldingImprove the phenomenon that cannot be taken outEngineeringMechanical engineering

The invention relates to die-casting mould, in particular to a thimble structure for the die-casting mould. The die-casting mould consists of a fixed die and a moving die, wherein the moving die is provided with a thimble capable of extending to a die cavity to perform ejection movement. The thimble structure is characterized in that the one end, close to the die cavity of the moving die, of the thimble is provided with a barb-shaped skew notch. The thimble structure mainly solves the technical problem that parts can be taken out of the die cavity of the moving die very difficultly when the conventional die is used, and when the die-casting mould is opened, the parts can be taken out of the die cavity smoothly by using the thimble structure to achieve the aim of improving the product production efficiency.

Owner:上海嘉朗实业有限公司

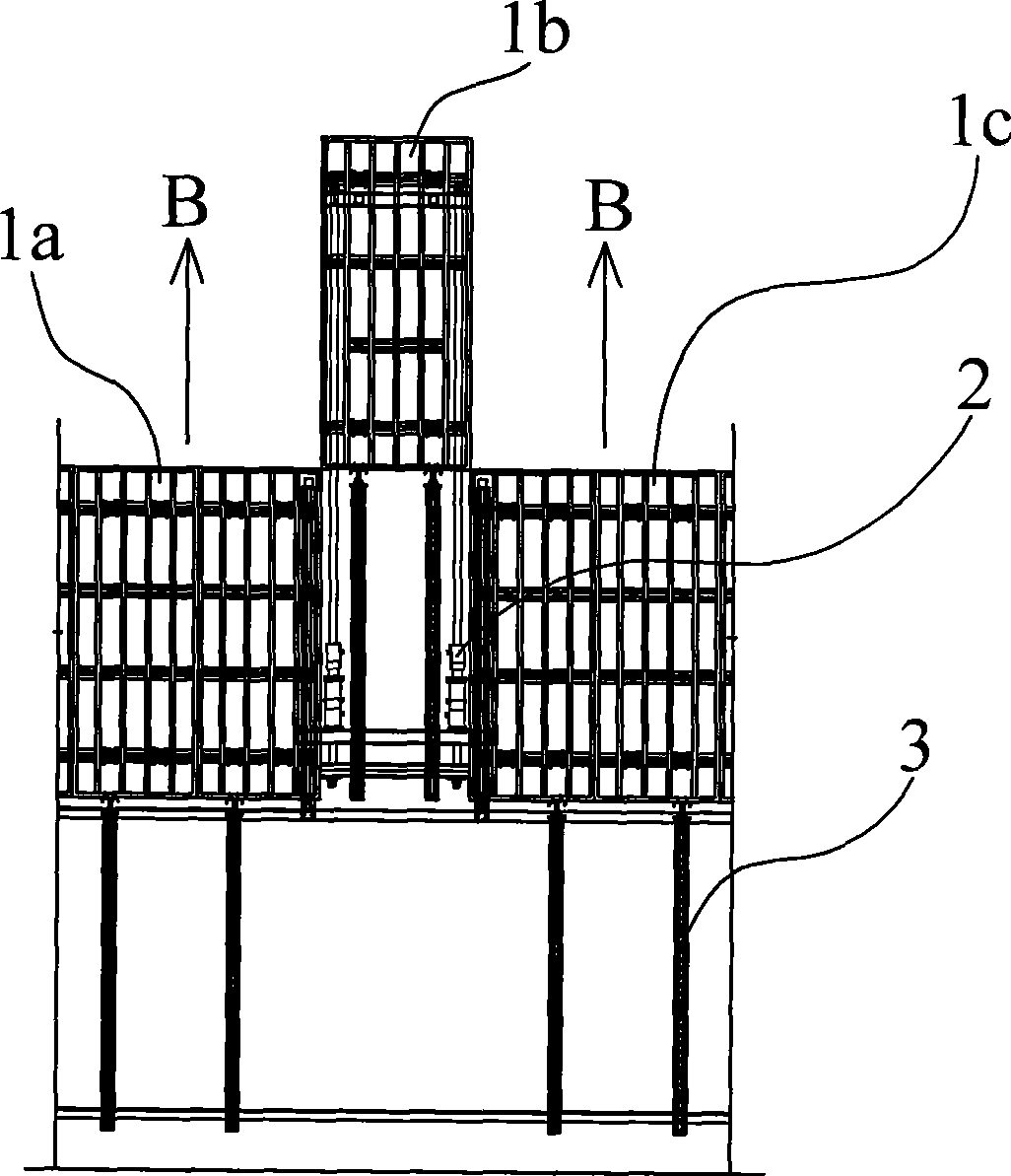

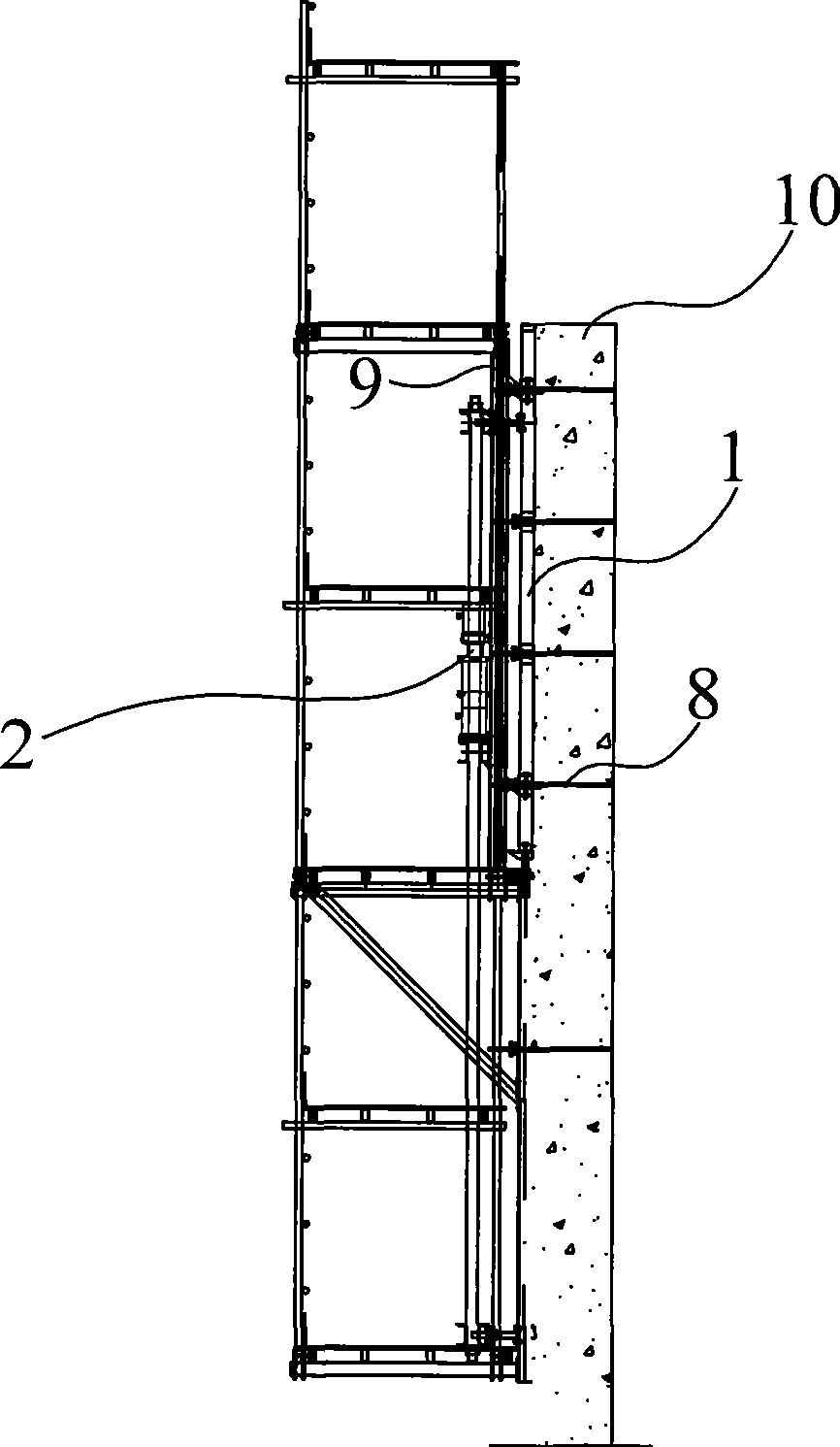

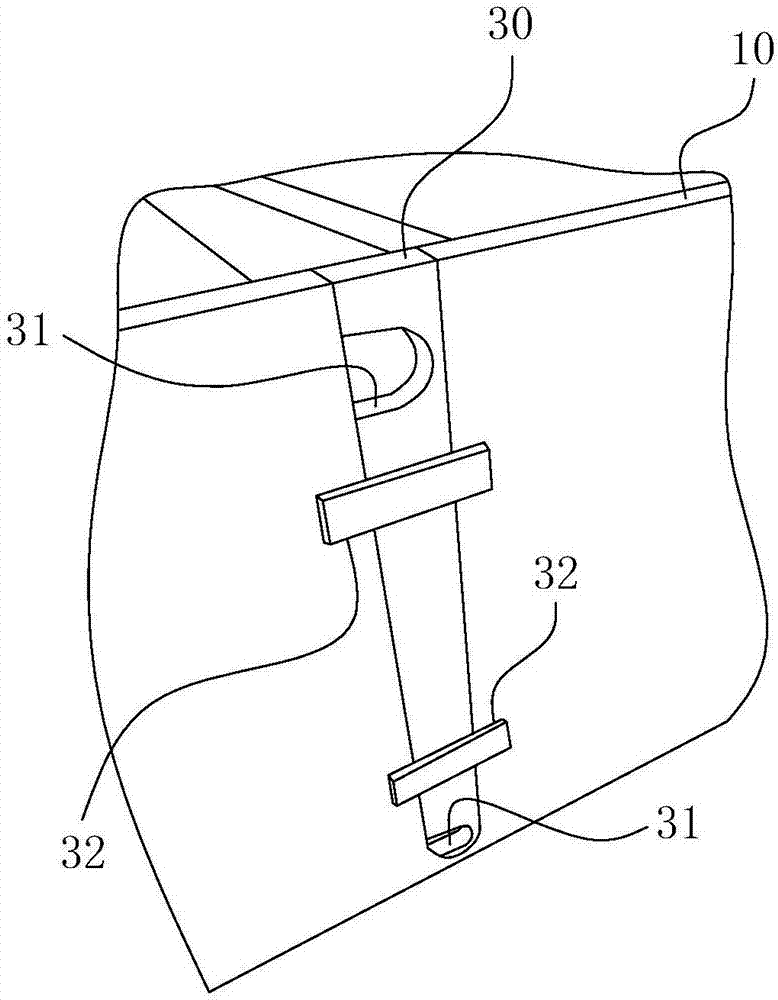

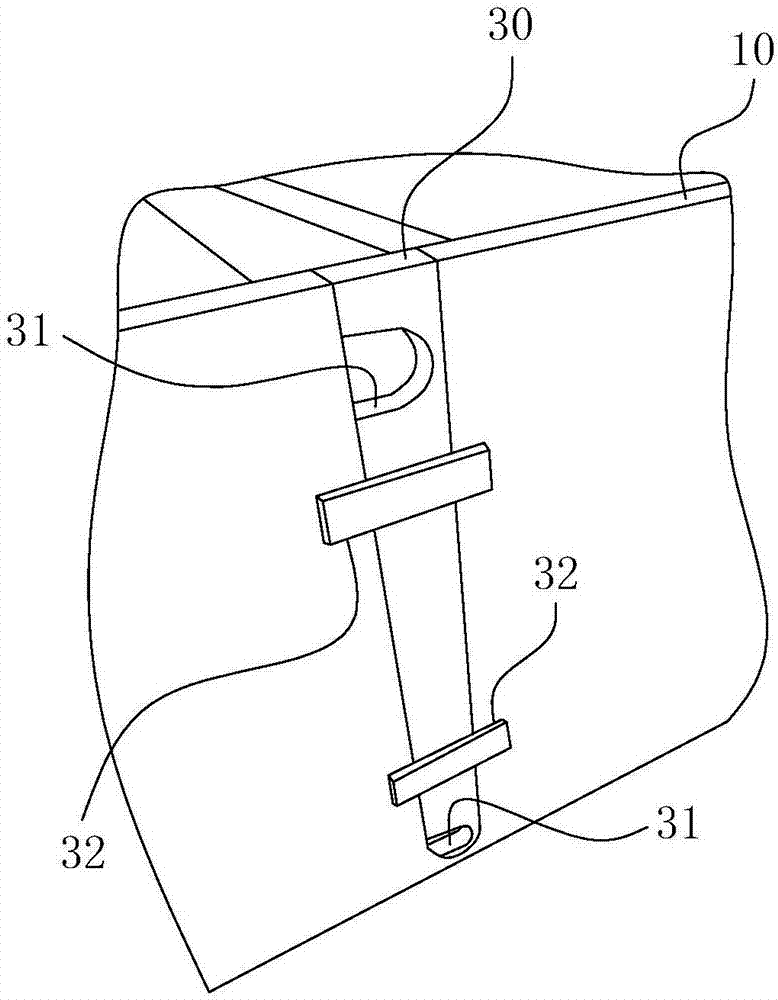

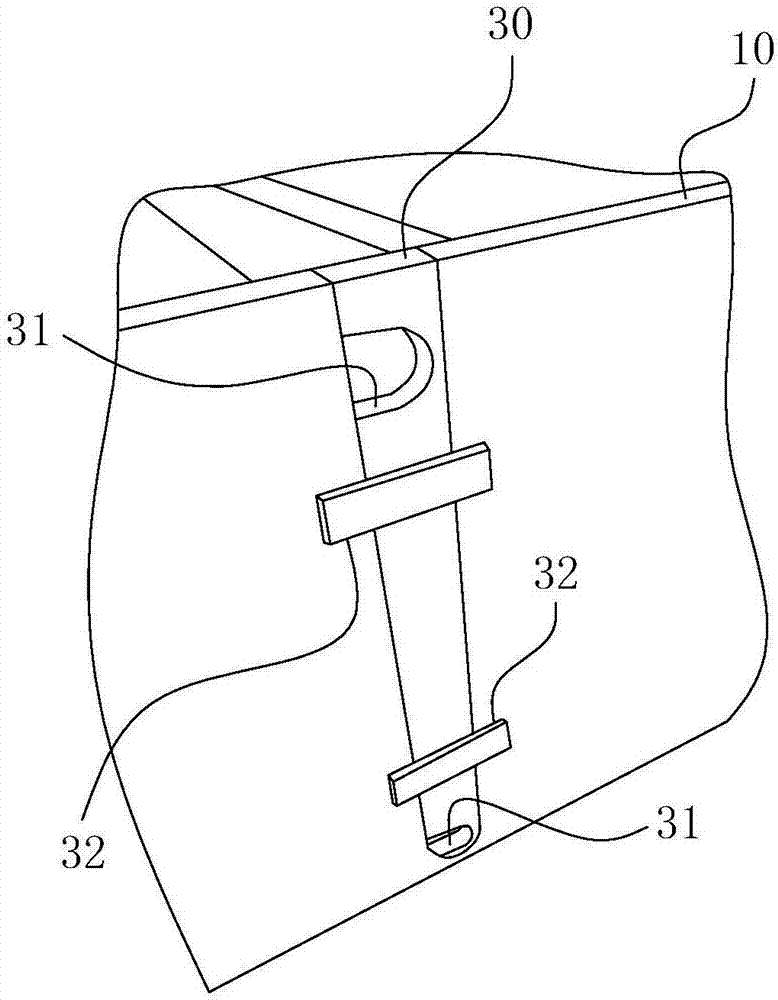

Template mutually lifting climbing apparatus and method

ActiveCN101457587ASimple structureImprove work efficiencyForms/shuttering/falseworksEngineeringPower equipment

The invention relates to a climbing formwork device with mutually-lifting formwork, comprising a formwork, a supporting body used for supporting the formwork and a power equipment which is used for driving the formwork to climb, wherein, the formwork is provided with a retractable cone-shaped supporting body which locates the formwork and bears dead load of the formwork, live construction load and wind load; the supporting body comprises a supporting rod which supports the formwork at one end of the formwork and tightens the formwork on a vertical backridge of the wall body by combining the supporting rod; during the process of operation, a lifting device provides the formwork with the power so that the formwork can climb; the supporting role supports the formwork at one end of the formwork so as to ensure that the formwork remains in a fixed position, cooperates with the vertical backridge to fix the formwork in a certain position and is positioned on and connected with the wall body by the retractable cone-shaped supporting body and a split bolt; is the formwork mutually serves as a motion orbit, namely, the non-climbing formwork serves as the motion orbit of the climbing formwork. The device has the advantages that the structure is simple and the corresponding operational platform is unnecessary to be too large during practical use, thus saving space, facilitating operation and having high working efficiency.

Owner:JIANGSU JIANGDU CONSTR GRP

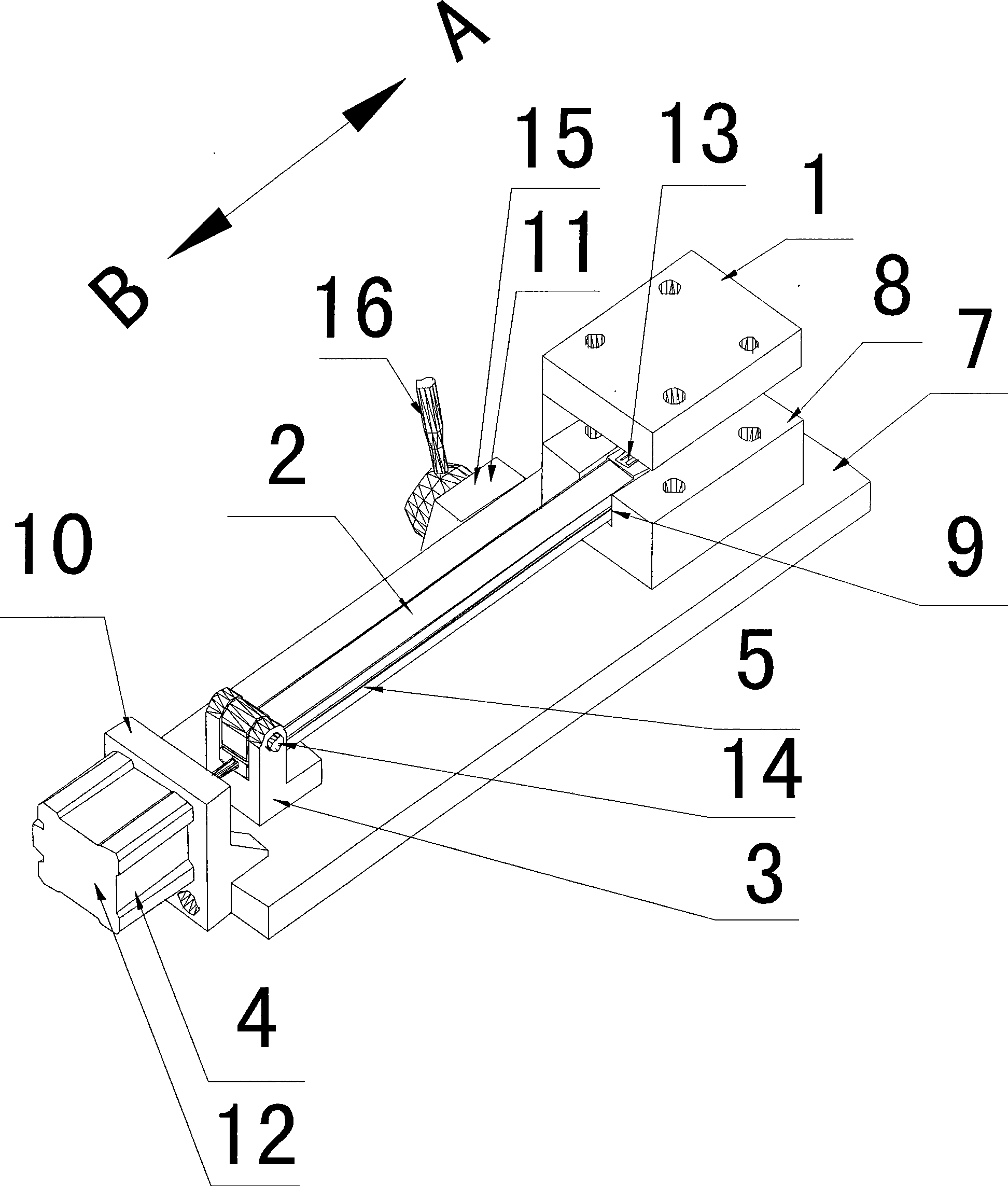

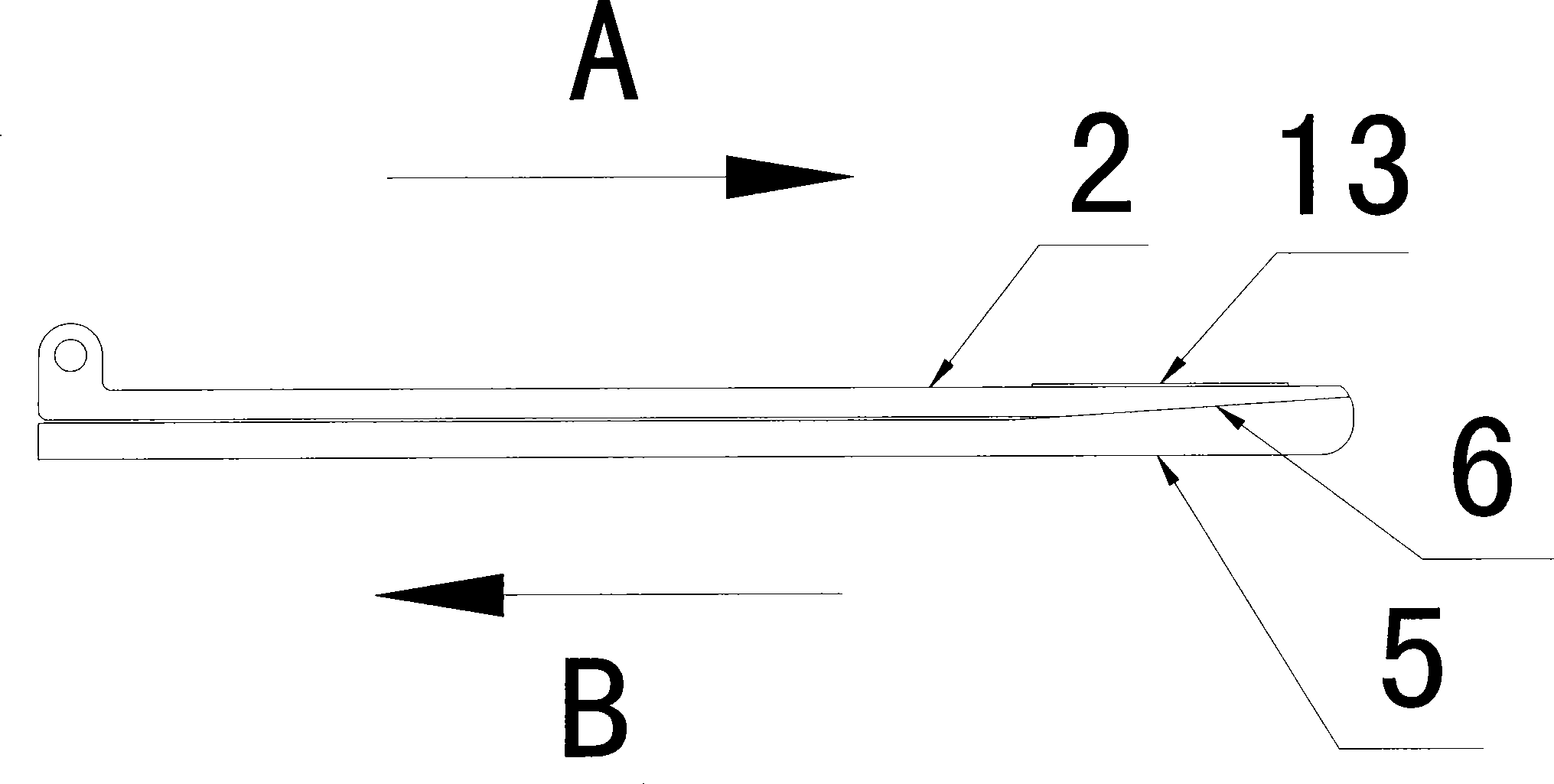

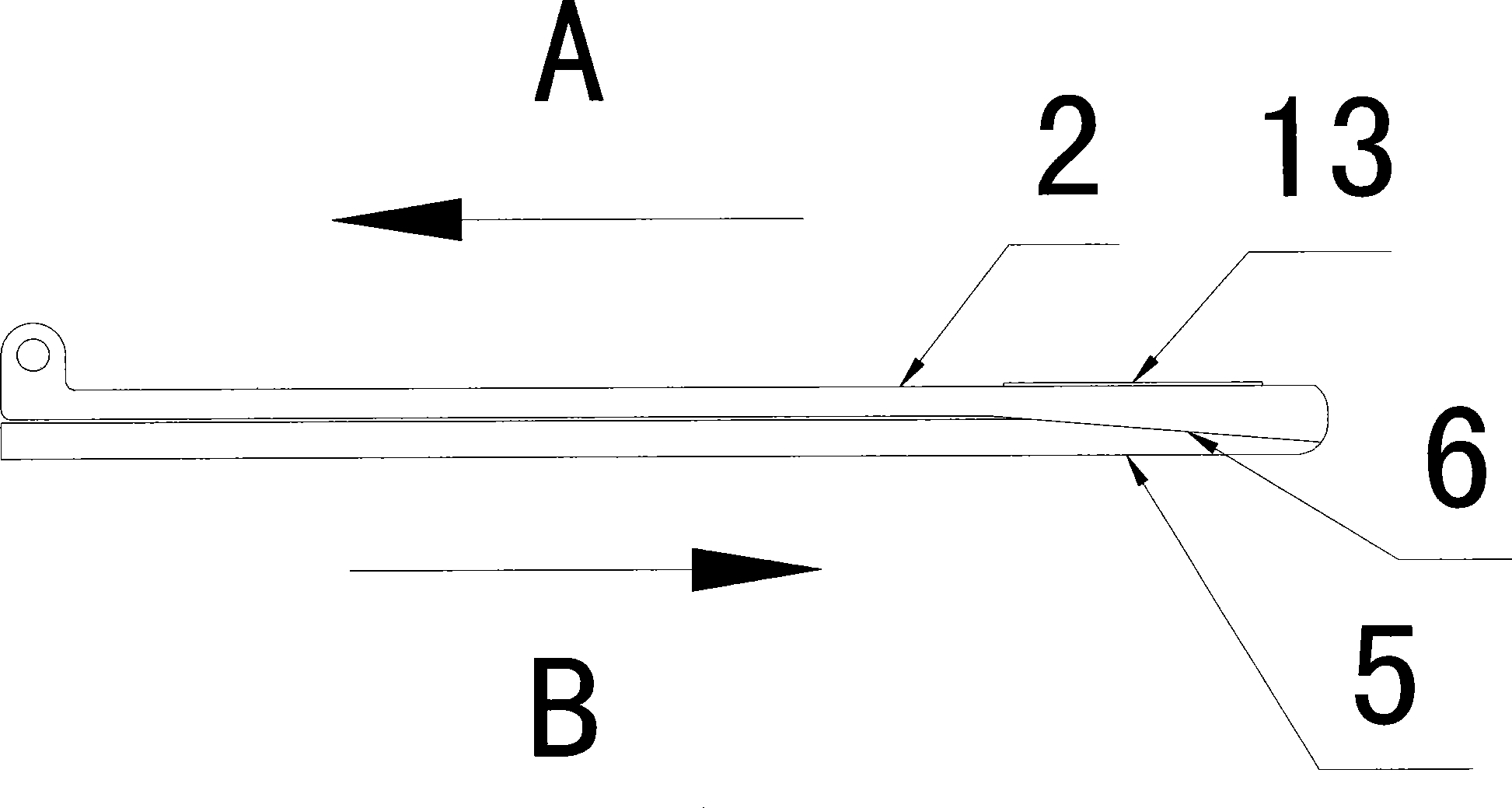

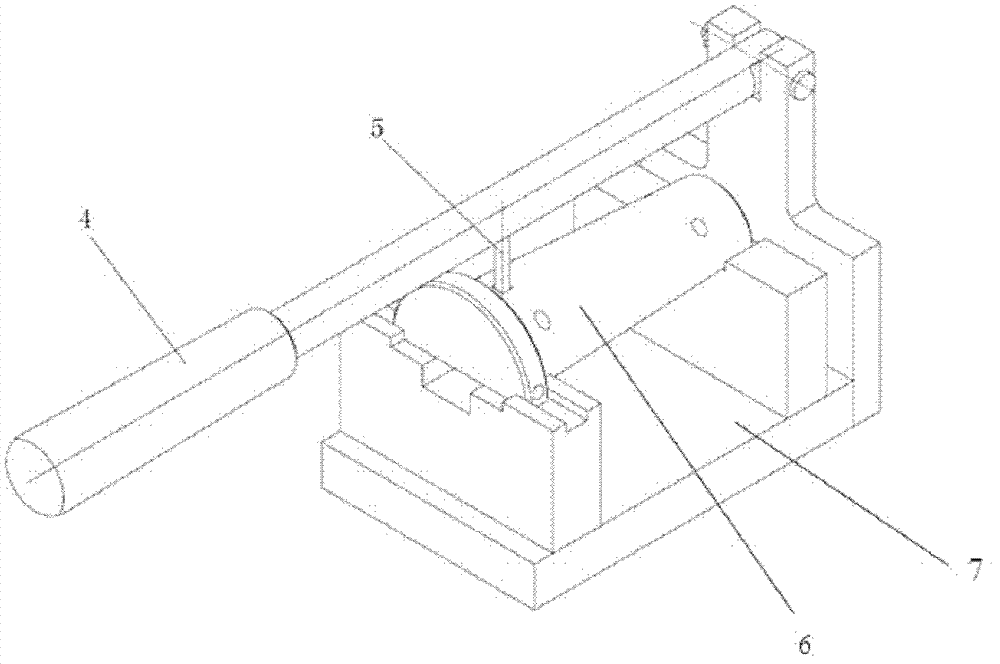

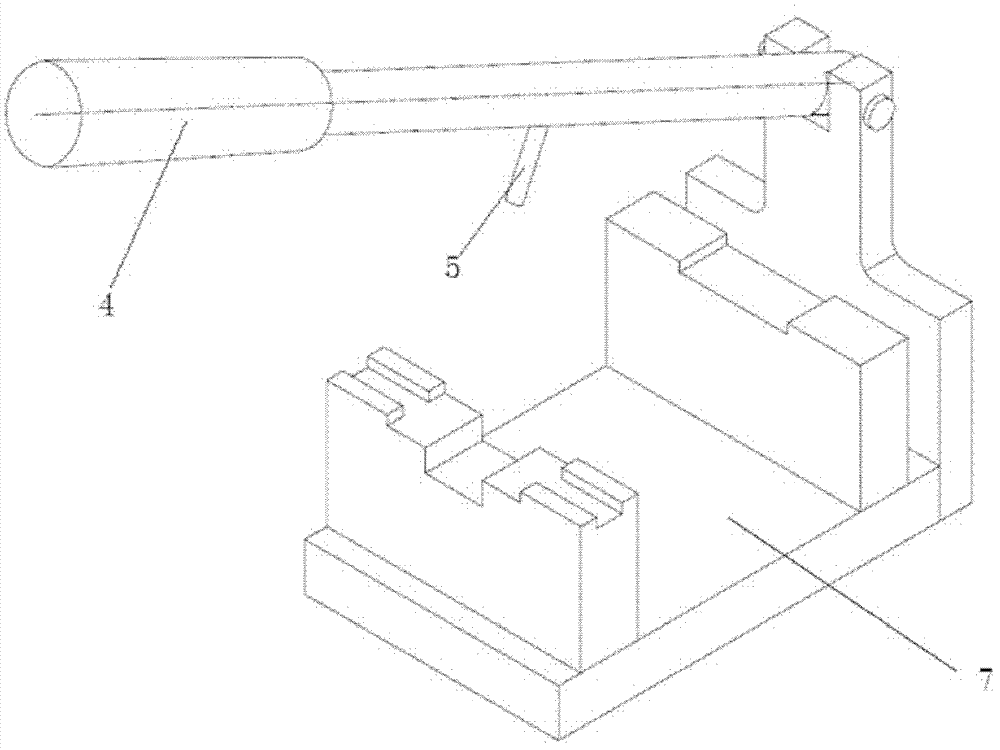

Tube stamping engraving die

InactiveCN101380854ASimple structureSimple and fast operationStampingEmbossing decorationsEngravingEngineering

The invention discloses a pipe stamping-engraving mould device, which comprises an upper module and a lower module; wherein, one end of the lower module is pin-connected with a support and can swing up and down. A core pulling block which is connected with a power mechanism and can move back and forth is arranged below the lower module; the upper part of the core pulling block and the lower part of the lower module are provided with inclined planes which can attach mutually. The pipe stamping-engraving mould device of the invention has the advantages of simple structure, easy operation, good engraving effect and convenient demoulding, thus improving the engraving efficiency greatly. Therefore, the invention has higher practicability.

Owner:SUZHOU ERMA MECHNICAL & ELECTRICAL

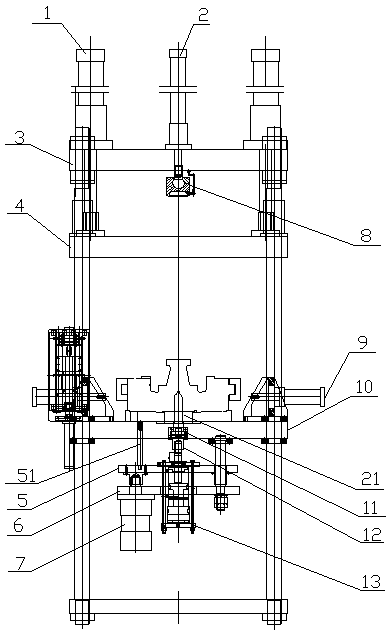

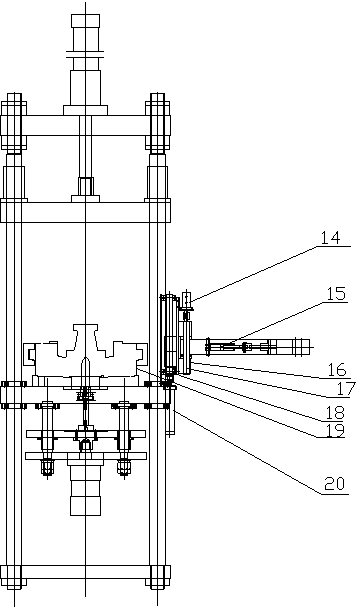

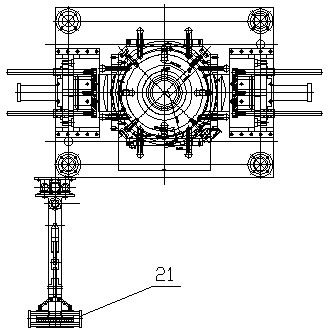

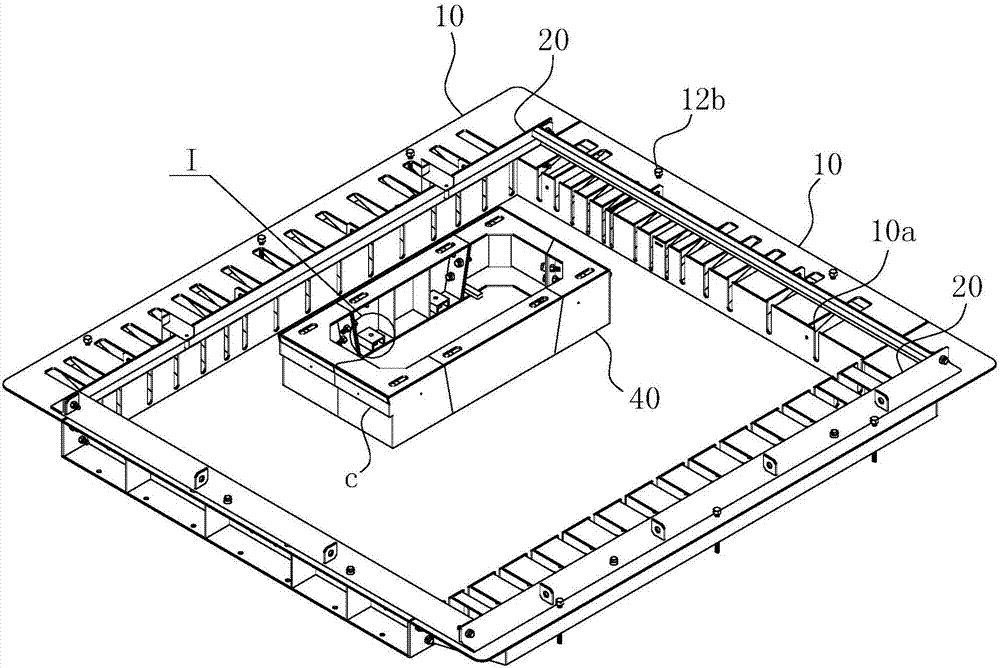

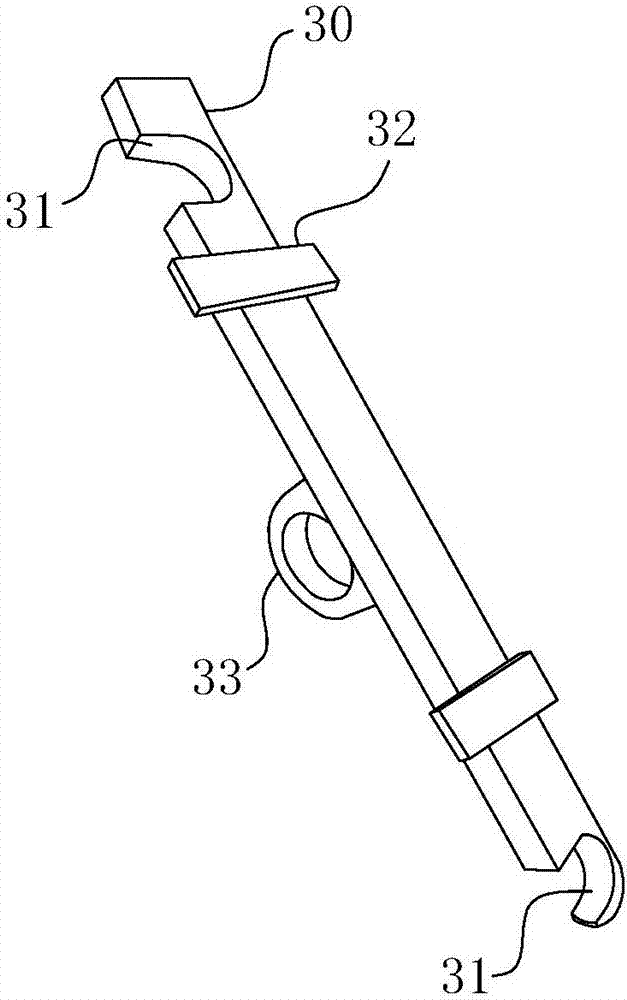

Tool for assembling and welding cylinder body

ActiveCN102500978AImprove general performanceConvenient and quick positioningWelding/cutting auxillary devicesAuxillary welding devicesEngineeringAutomation

The invention discloses a tool for assembling and welding a cylinder body. The tool for assembling and welding the cylinder body comprises a reference platform, a first movement support, a second movement support, and a control part; the first movement support and the second movement support can be arranged on the reference platform in a movable way to ensure that the first movement support and the second movement support can approach each other or move far away from each other; the first movement support and the second movement support are used for positioning and fastening end plates and side plates of the cylinder body; the control part is used for controlling the first movement support and the second movement support to position and fasten the end plates and the side plates, and move on the reference platform; and the tool for assembling and welding the cylinder body is high in generality and simple in structure, can assemble parts of the cylinder body conveniently, and is high in assembly accuracy, and automation degree.

Owner:SANY HEAVY IND CO LTD (CN)

Stator potting method and motor comprising stator produced by stator potting method

ActiveCN107465317APerformance is not affectedReduce the difficulty of cleaningNon-macromolecular adhesive additivesPretreated surfacesEngineeringSealant

The invention provides a stator potting method which comprises the following steps: (1) preparing a sealant; (2) sealing two axial ends of the stator, wherein a potting opening is reserved in one end; (3) applying the sealant to the outer side face of the axial direction of the stator; (4) coaxially inserting a sealing plug core in the middle of the stator, wherein the sealing plug core is in sealed contact with the inner side face of the stator; (5) potting into the stator from the potting opening; (6) feeding the stator into a curing furnace for performing high-temperature curing; and (7) cooling and demolding. The invention further provides a motor comprising the stator produced by the stator potting method, wherein glue is potted into the stator of the motor. The stator potting method disclosed by the invention has the advantages that the stator in easy adhesion with oil is potted by utilizing the sealant so as to form a smooth stator surface, and the cleaning difficulty of the motor is greatly reduced on premise of not influencing the motor performance.

Owner:JIANGSU WEITELI MOTORS MFG

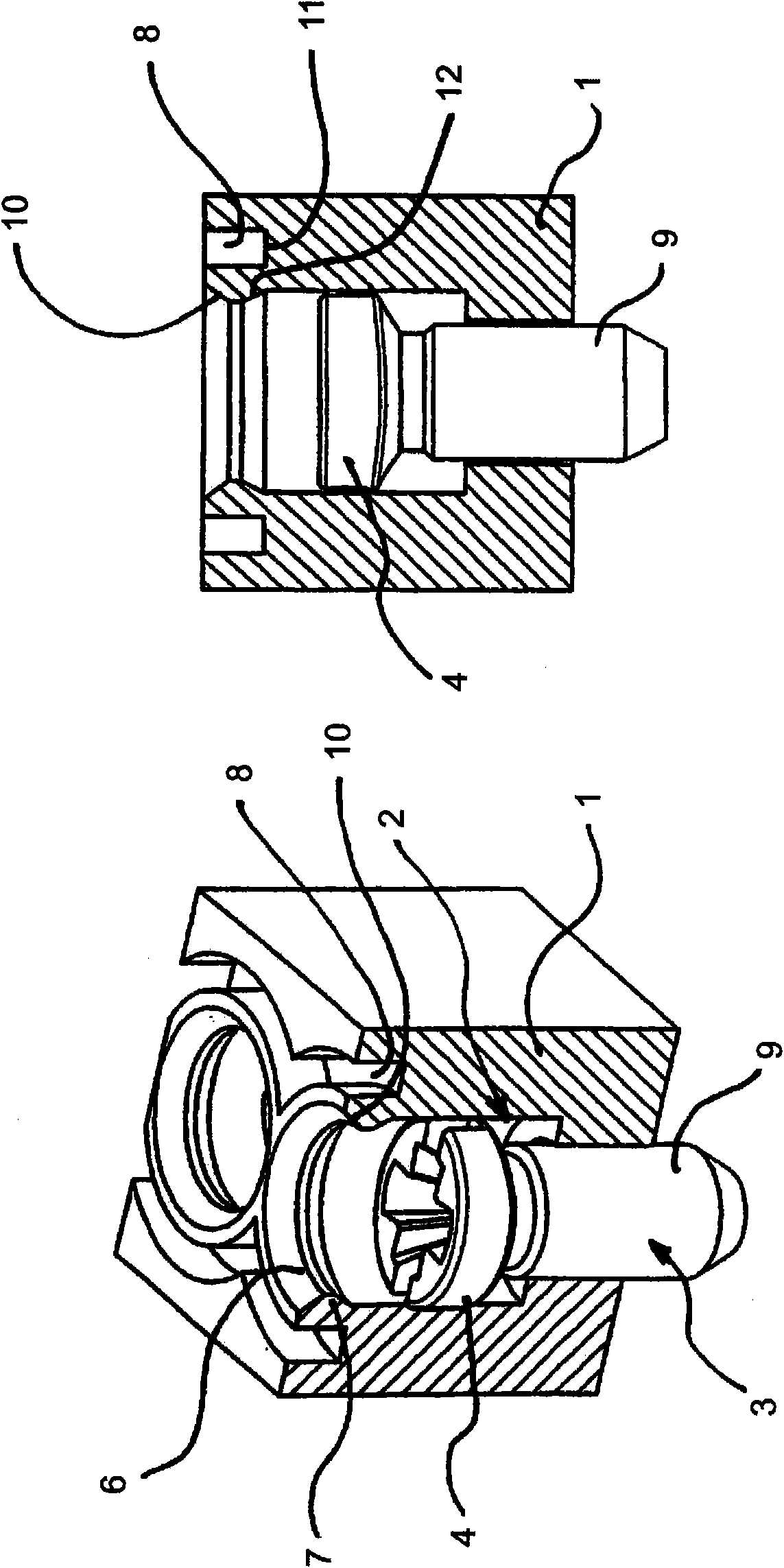

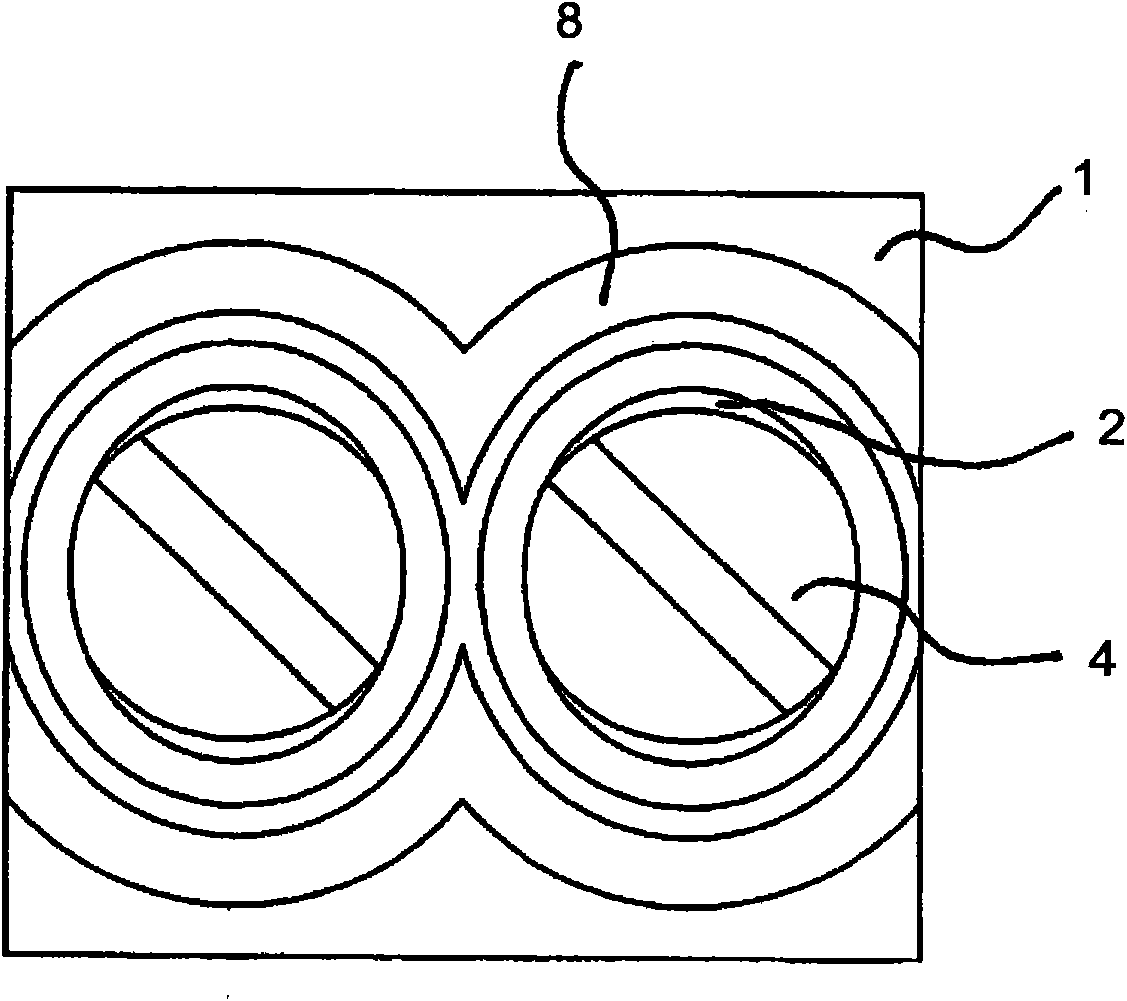

Arrangement for screw locking electric connecting terminals

Owner:PHOENIX CONTACT GMBH & CO KG

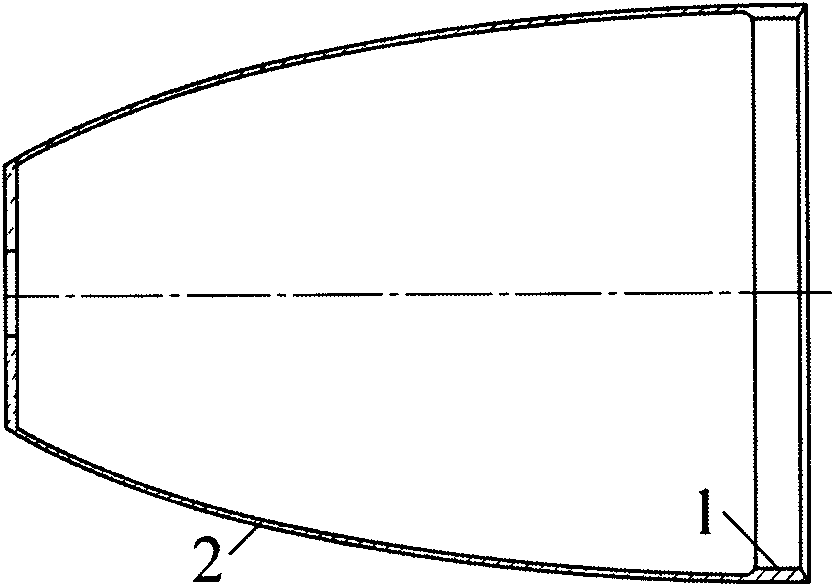

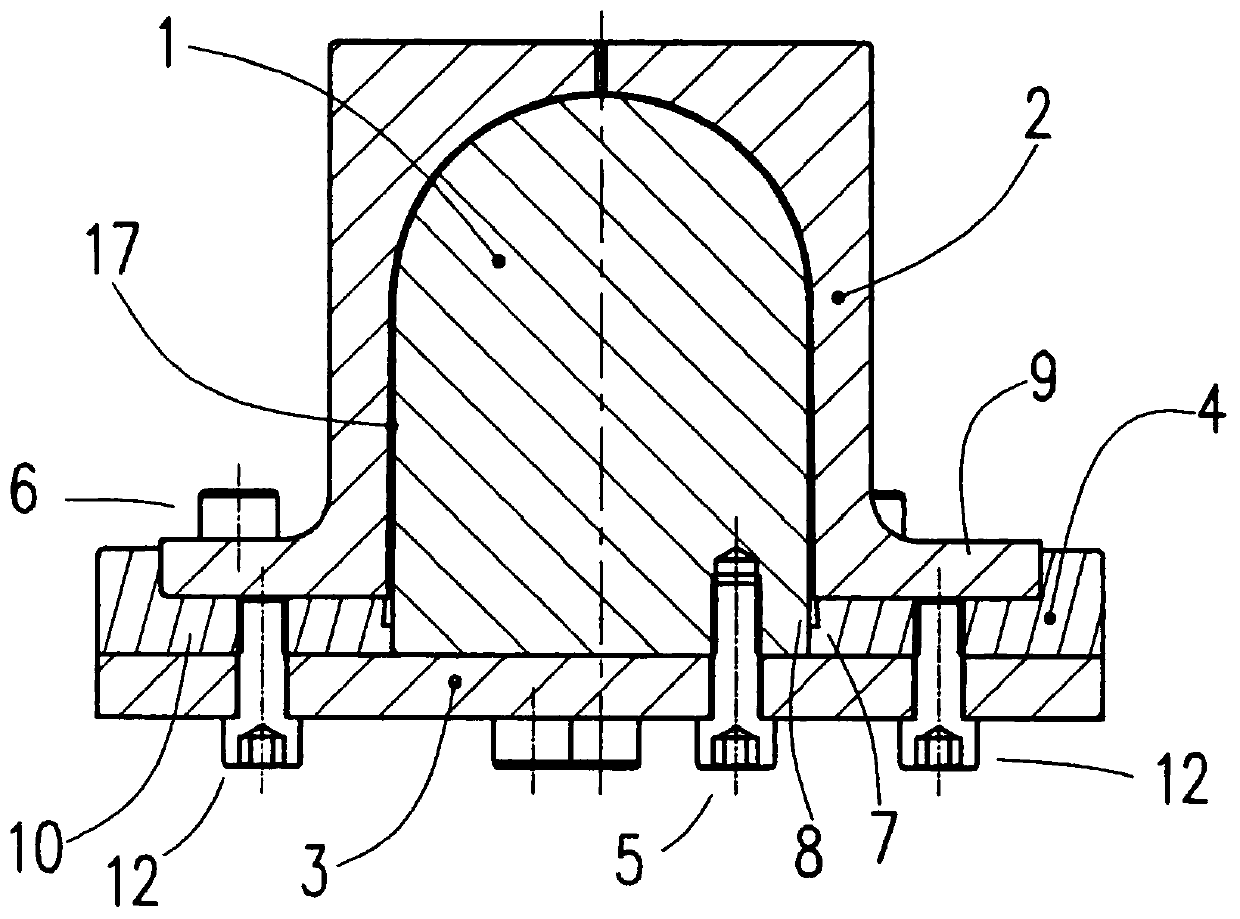

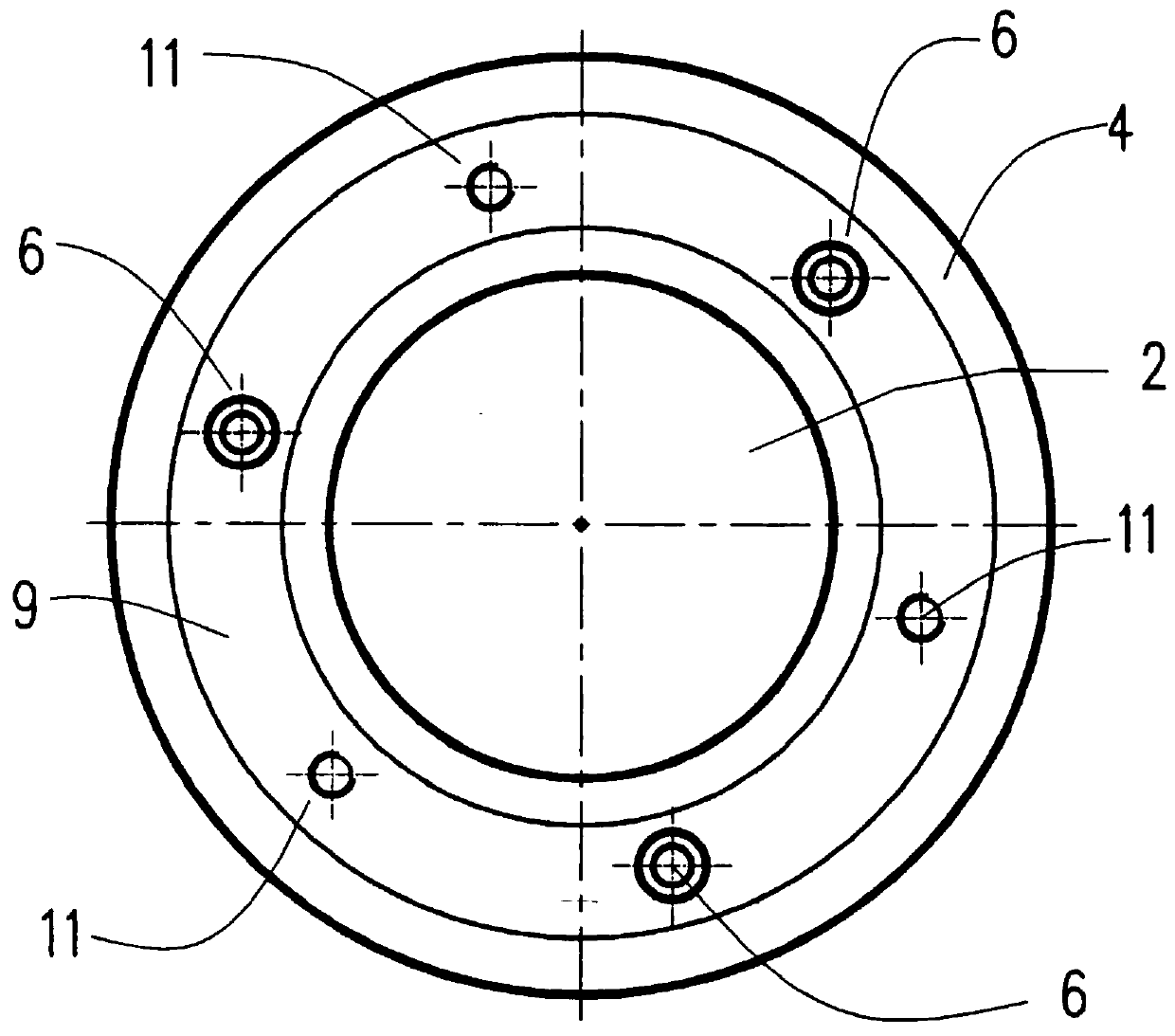

Molding die of resin-based composite radome

The invention relates to a molding die of a resin-based composite radome. The molding die comprises a male die, a female die, a bottom plate and a demolding ring; an inner circle edge opening of the demolding ring is matched with an outer circle edge opening of the male die in shape and size; the lower end of the female die is provided with a positioning ring piece, the upper end surface of the demolding ring is provided with a ring-shaped groove seat matched with the positioning ring piece in shape and size, and the female die can be clamped into the ring-shaped groove seat through the positioning ring piece; and the positioning ring piece is provided with a first demolding screw matched with a first demolding screw hole, the bottom plate is provided with a second demolding screw matched with a second demolding screw hole, the inner circle edge opening is a stepped hole, the stepped hole includes an upper hole opening and a lower hole opening, and the upper hole opening is of a horn mouth structure small in top and larger in bottom. The molding die has the following advantages that 1, the structure is simple, and demolding operation is convenient and quick; 2, a stress part of the demoulding process is designed reasonably, and protection of a main body part of a radome product is facilitated; 3, and the product yield rate is above 98%.

Owner:SICHUAN TIANYUAN MACHINERY CO LTD OF 081 ELECTRONICS GRP

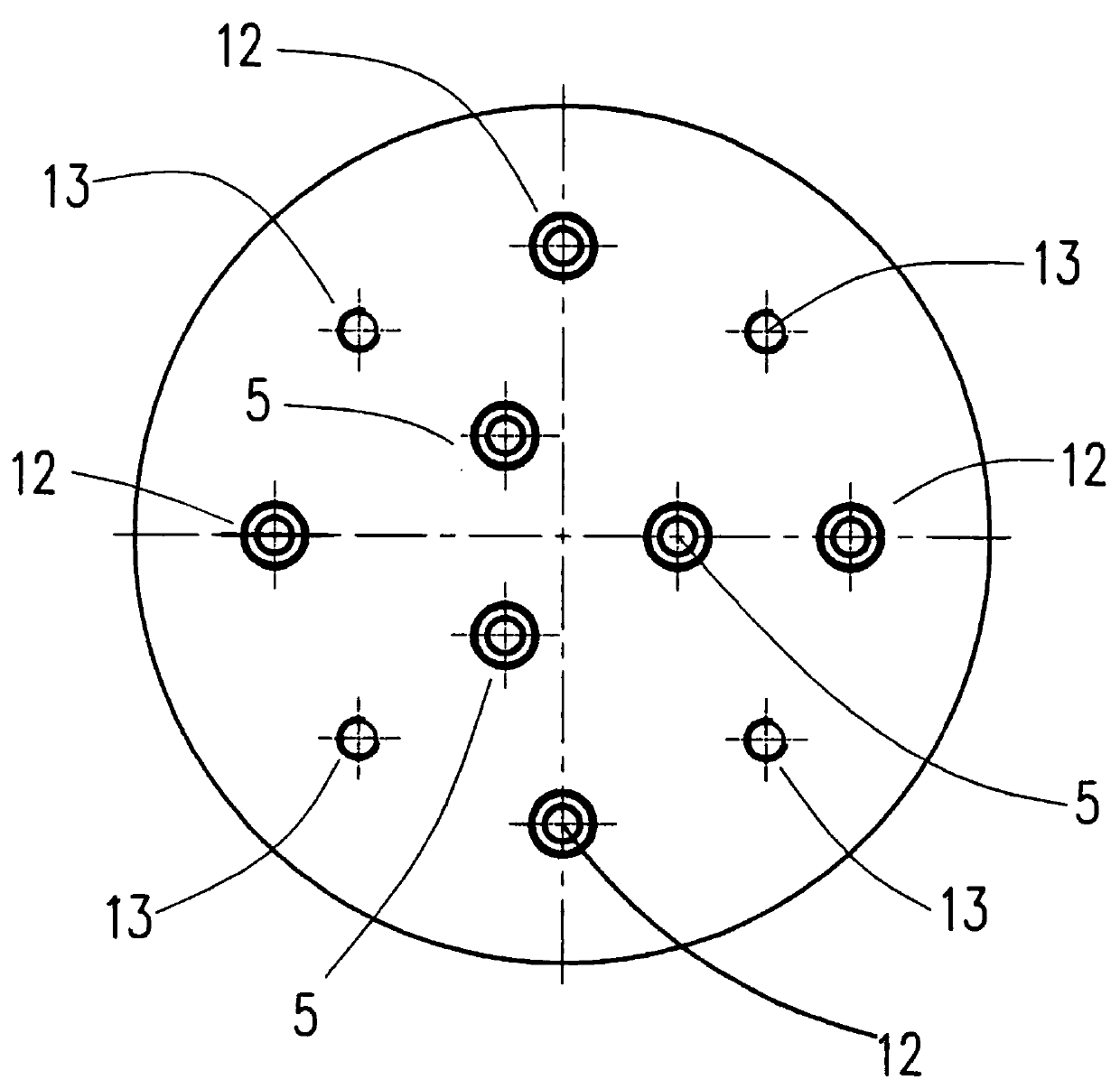

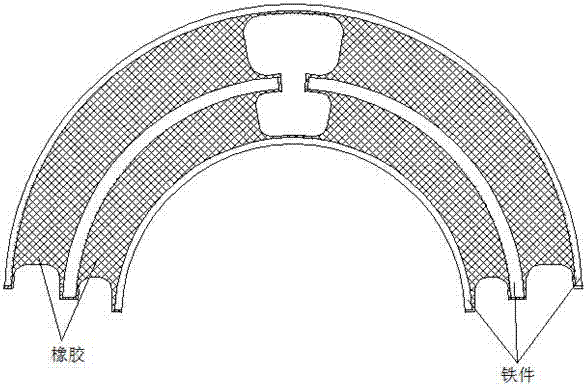

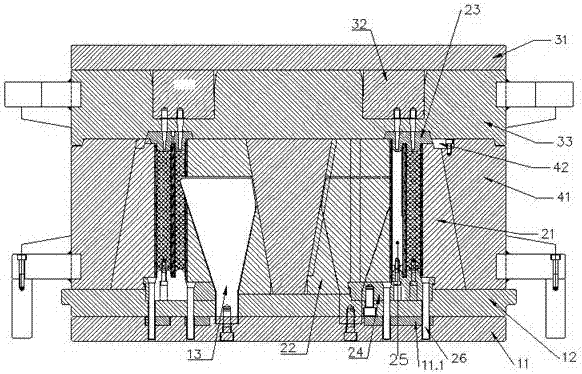

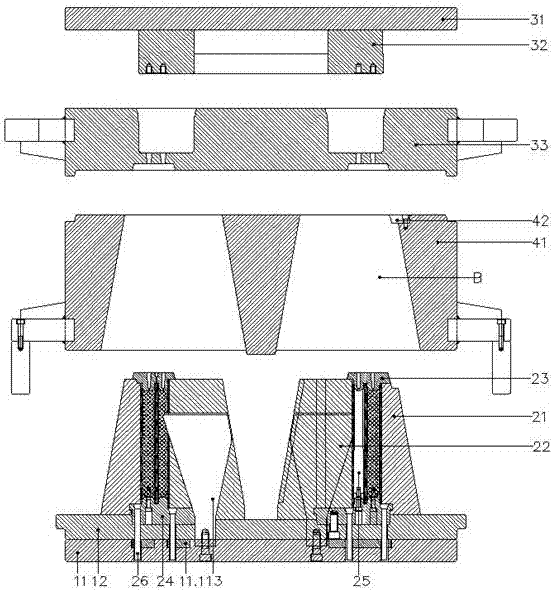

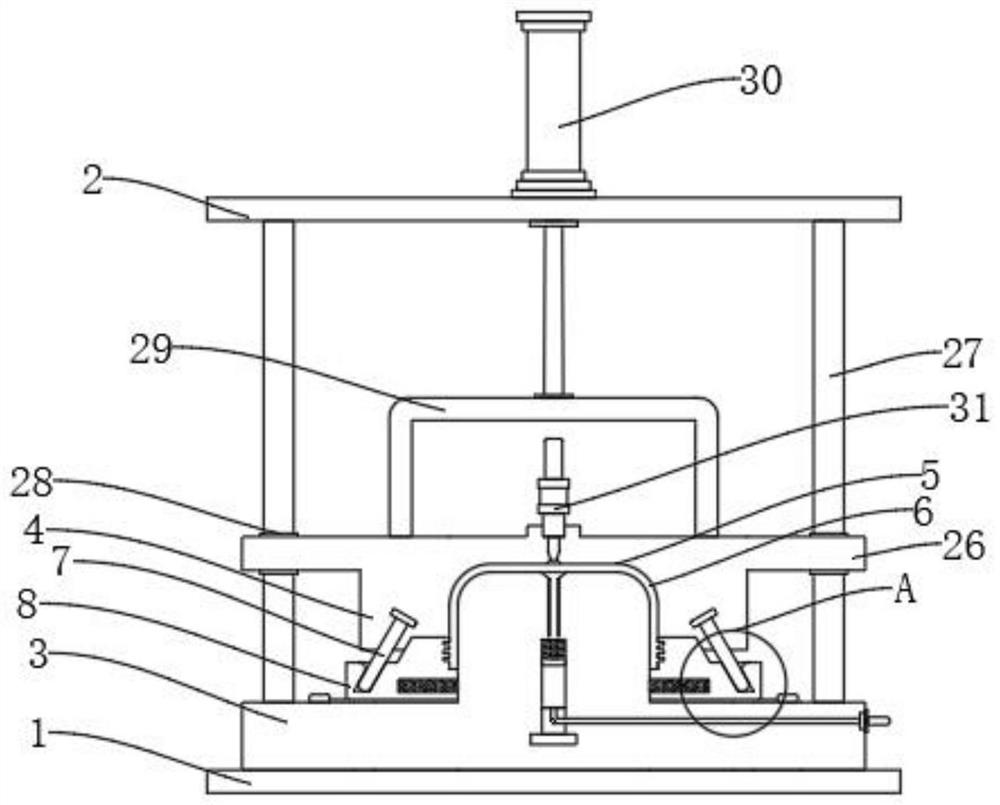

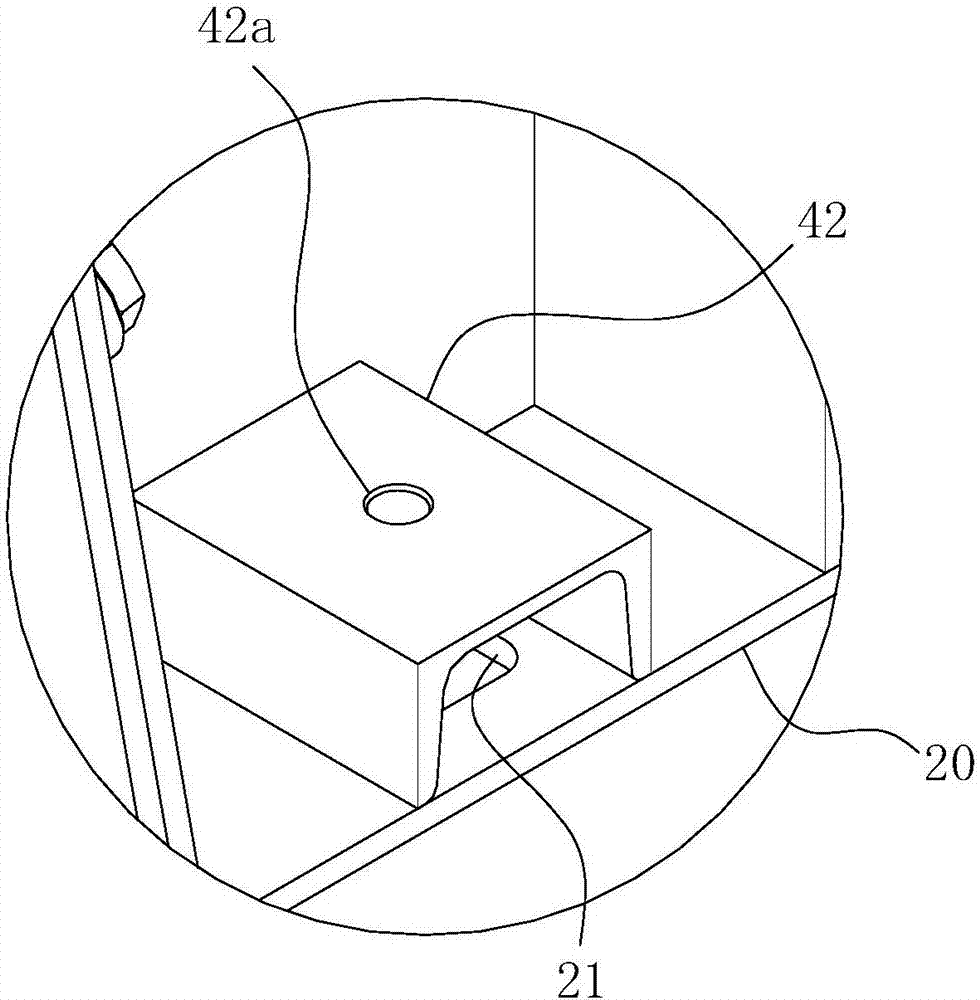

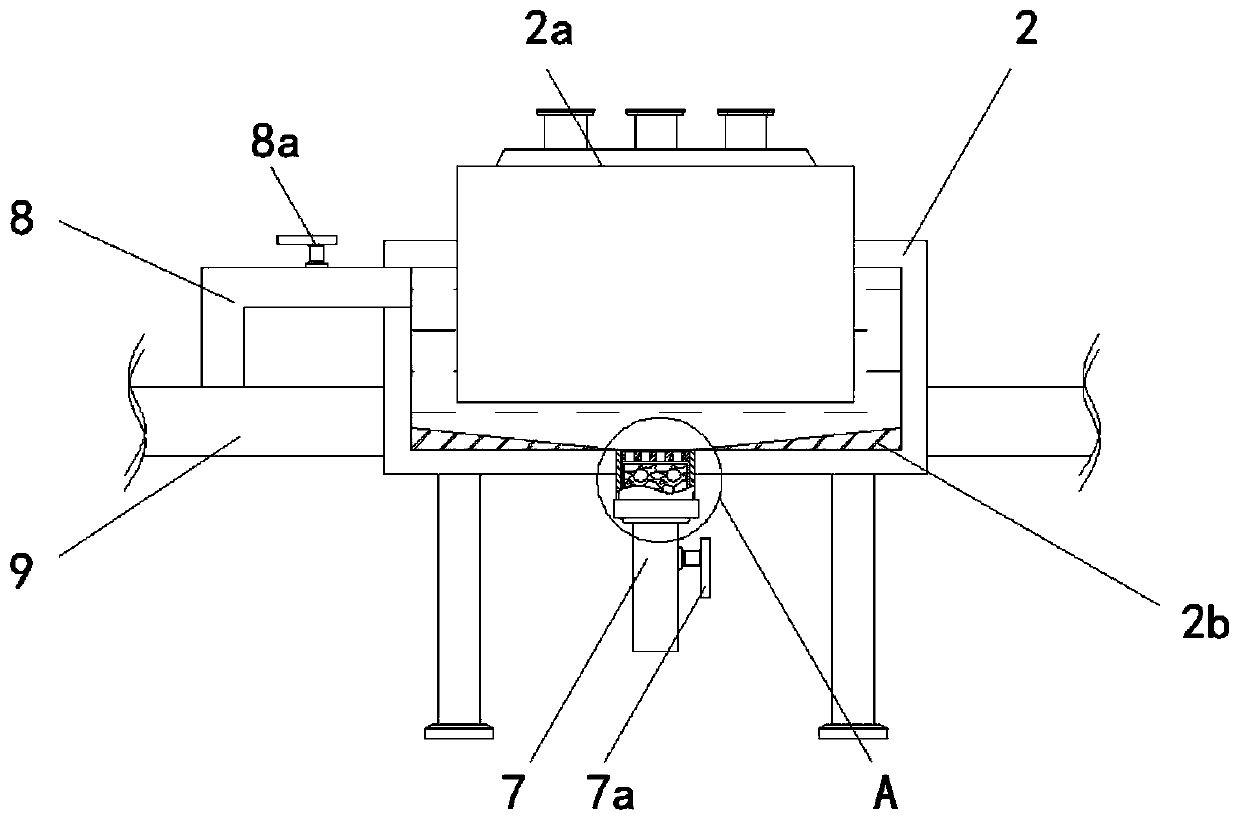

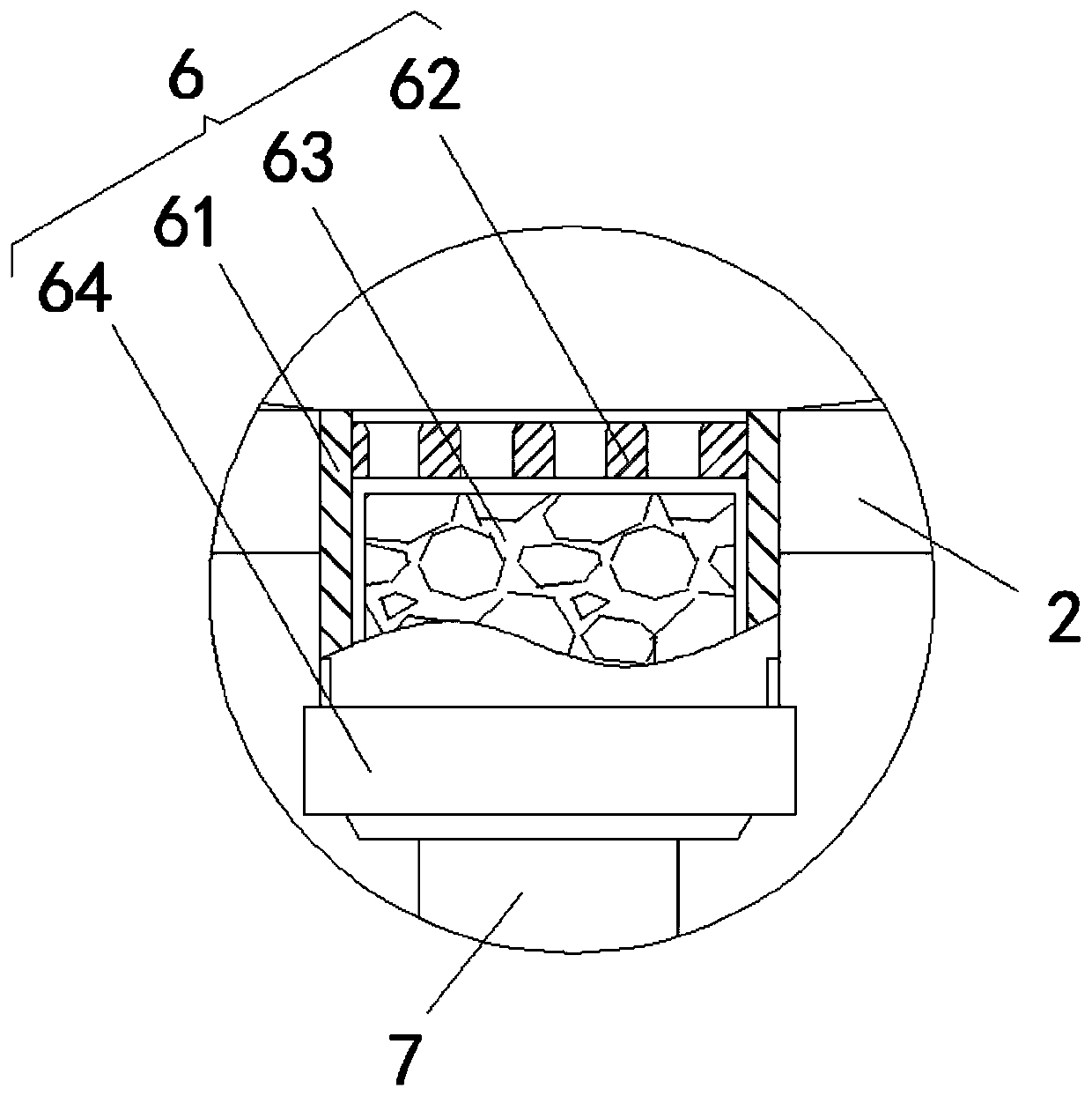

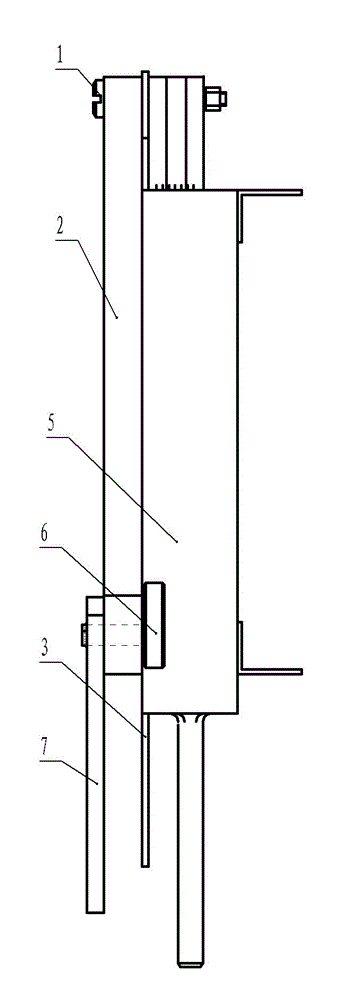

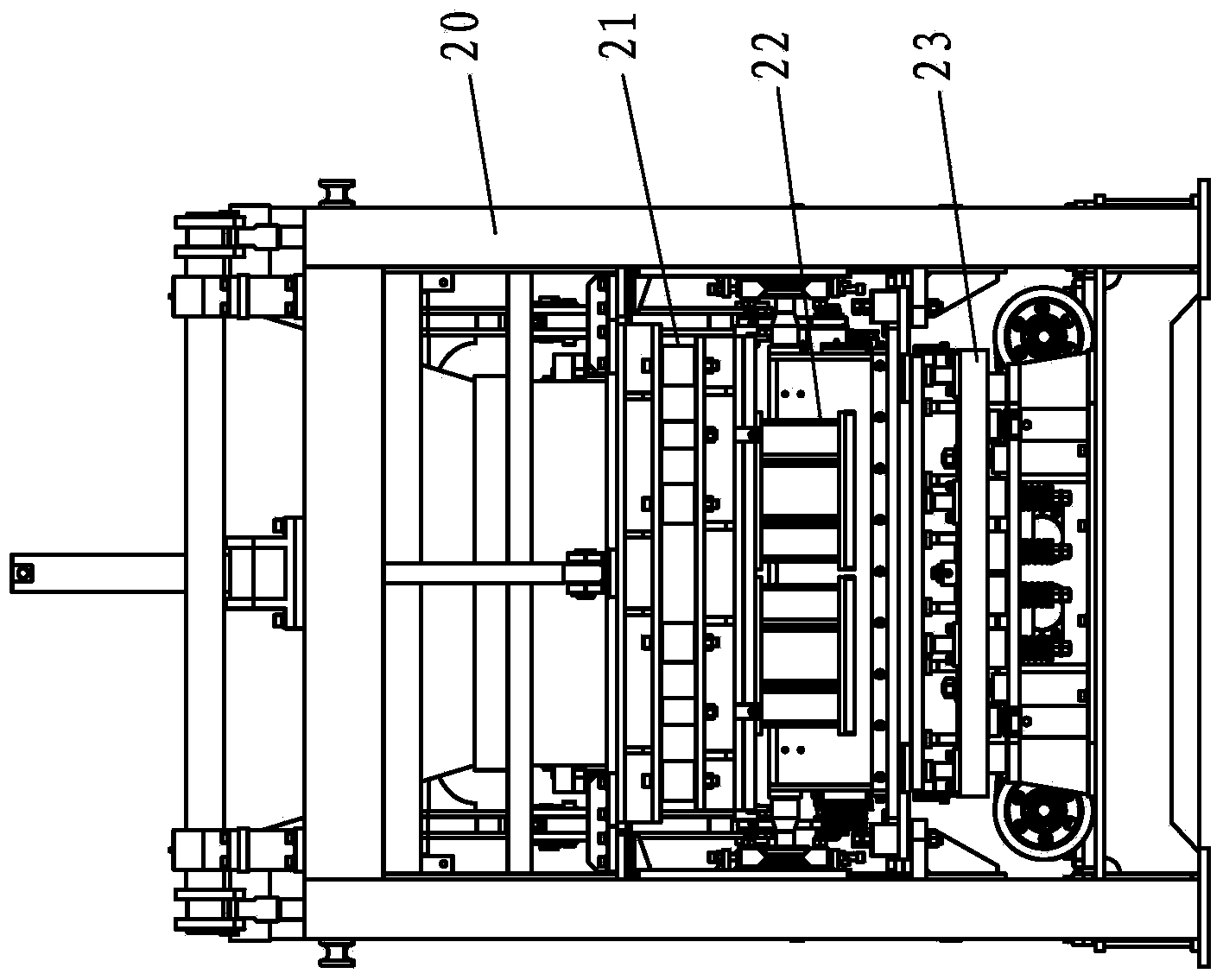

Bearing bush type gearbox elastic supporting automatic ejection die and automatic ejection method thereof

ActiveCN107139361AAchieve reverse movementRealize automatic demouldingVulcanizationPerpendicular direction

The invention discloses a bearing bush type gearbox elastic supporting automatic ejection die and an automatic ejection method thereof. The bearing bush type gearbox elastic supporting automatic ejection die comprises a bottom die assembly, a lower die assembly, an upper die assembly and a middle die assembly. The upper die assembly comprises a top plate, a glue injection stopper and a glue injection cylinder. The bottom die assembly comprises a bottom plate, a supporting plate and a cable-stayed plate. The lower die assembly comprises an outer-section die, an inner-section die, an upper insert, a lower insert, a die core and an ejection rod assembly. The lower insert is arranged between the outer-section die and the inner-section die, and a vulcanization cavity is formed by the lower insert, the outer-section die, the inner-section die and the upper insert. A glue injection hole is formed in the upper insert, and a die core is perpendicularly arranged in the vulcanization cavity, wherein the top of the die core makes contact with the upper insert. The lower insert is matched with the outer-section die and the inner-section die in the perpendicular direction in a draw hook manner. The ejection rod assembly penetrates the lower insert and the supporting plate and is inserted in the bottom plate. The outer-section die and the inner-section die are in conical fit with the cable-stayed plate. The cable-stayed plate penetrates the supporting plate and is fixed to the bottom plate. The middle die assembly is arranged between the supporting plate and the glue injection cylinder, and the lower die assembly is clamped in the middle die assembly.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

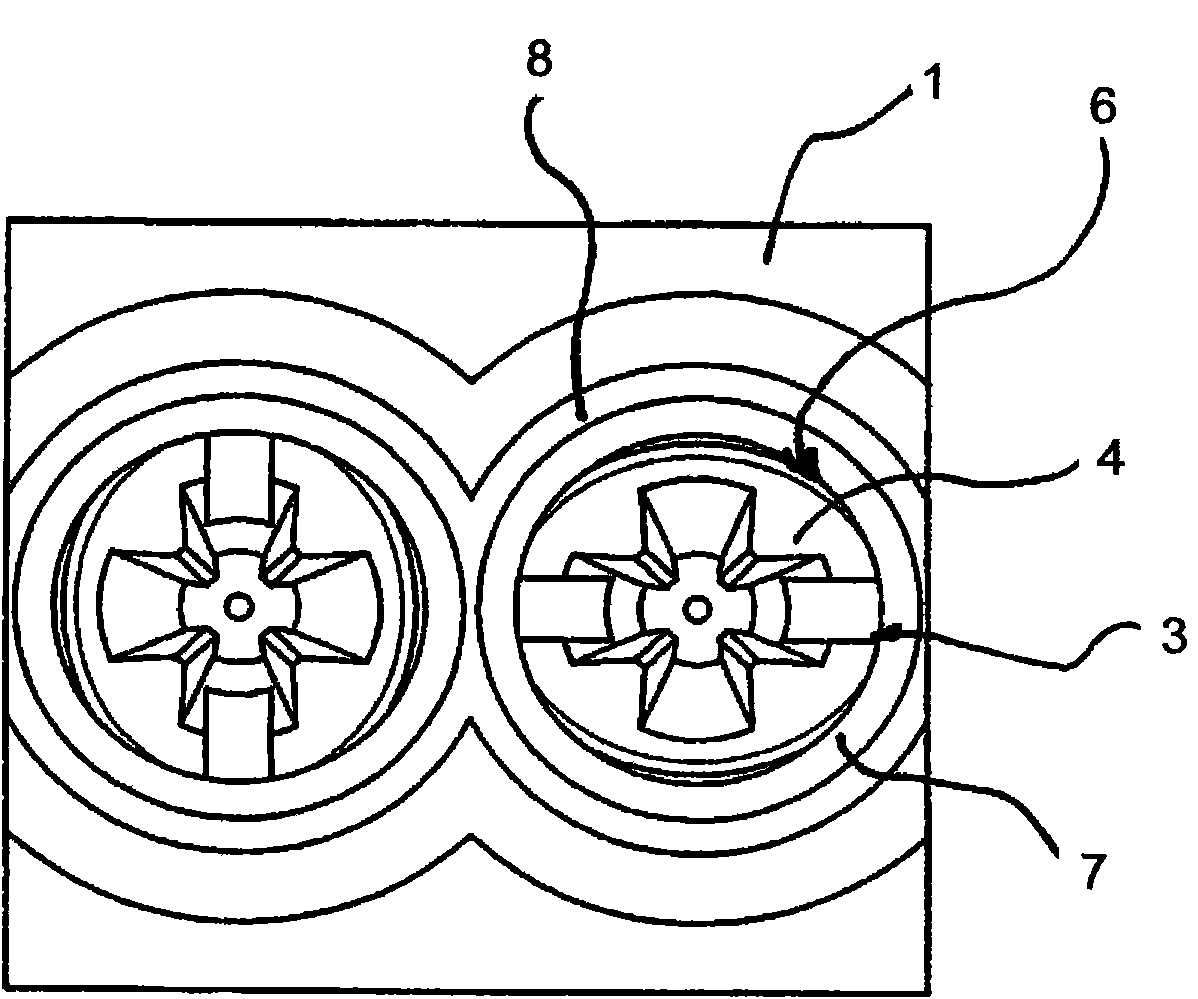

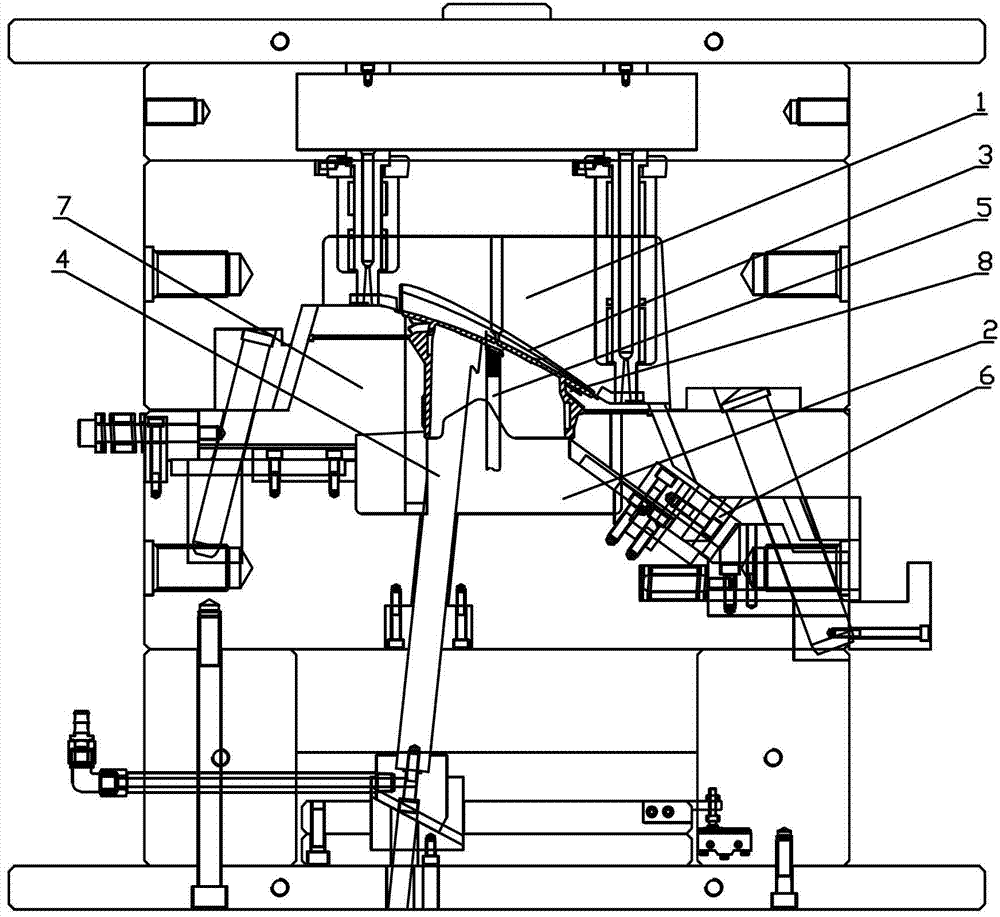

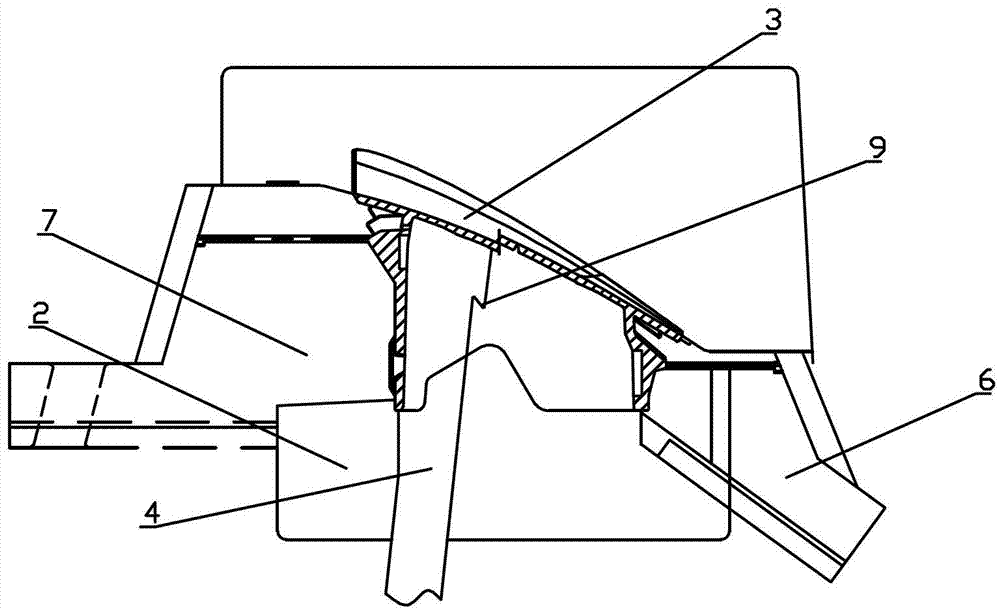

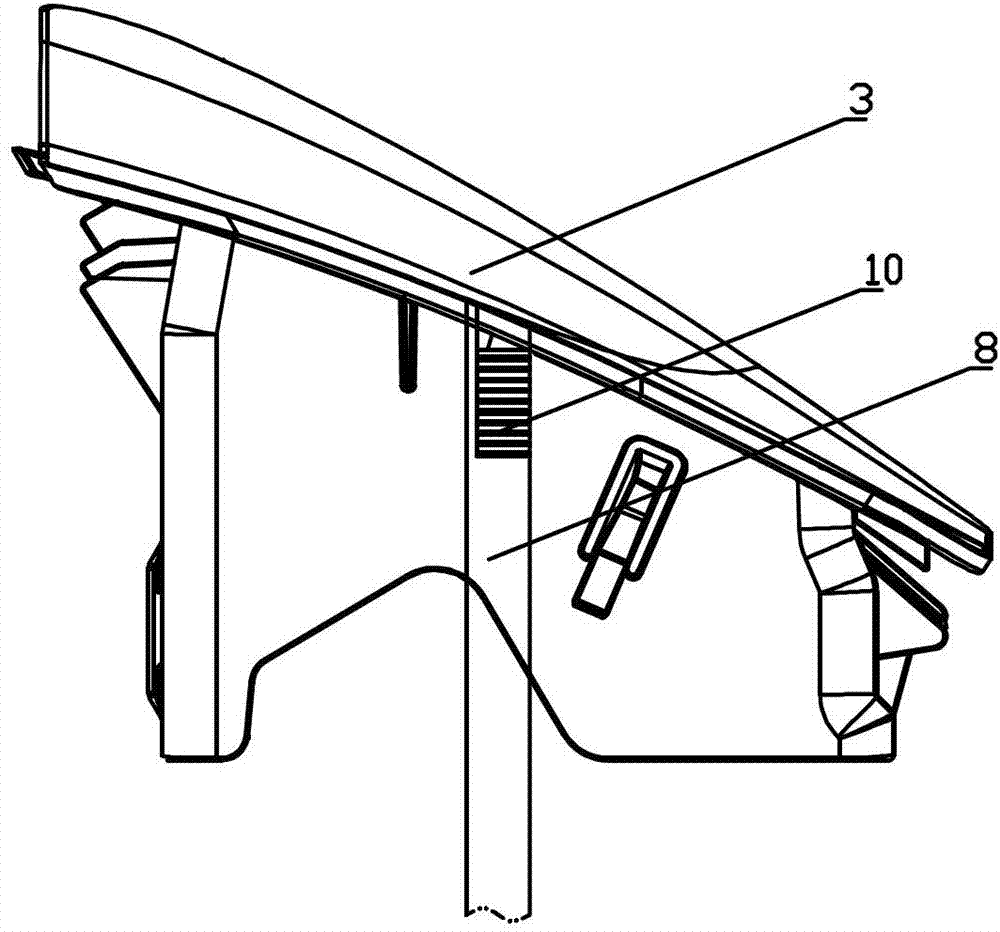

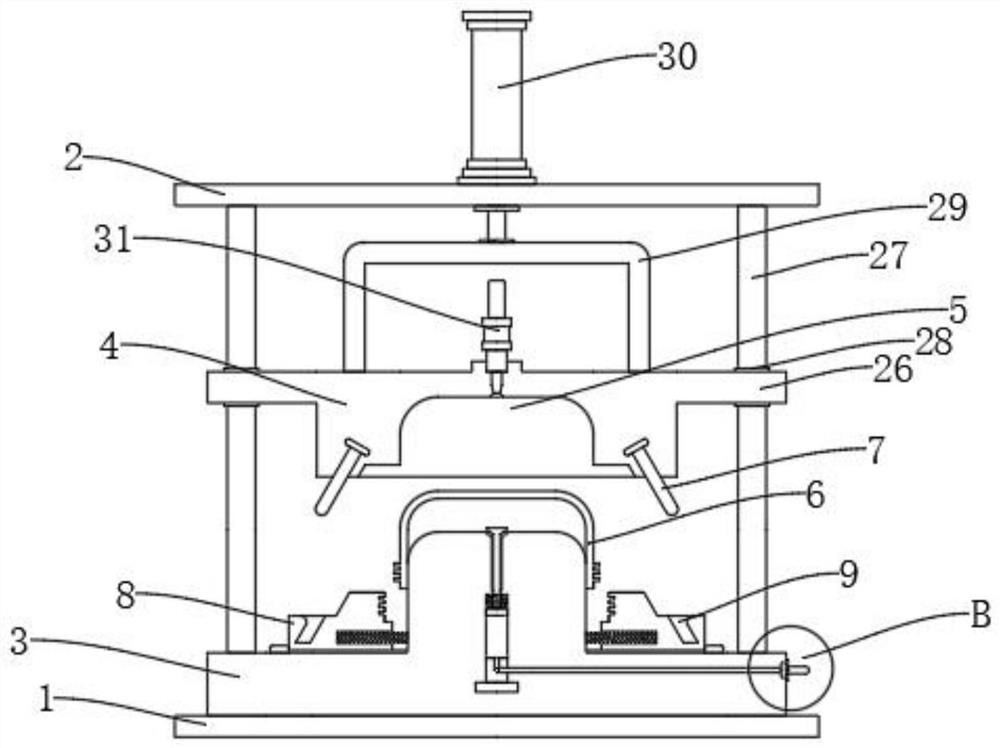

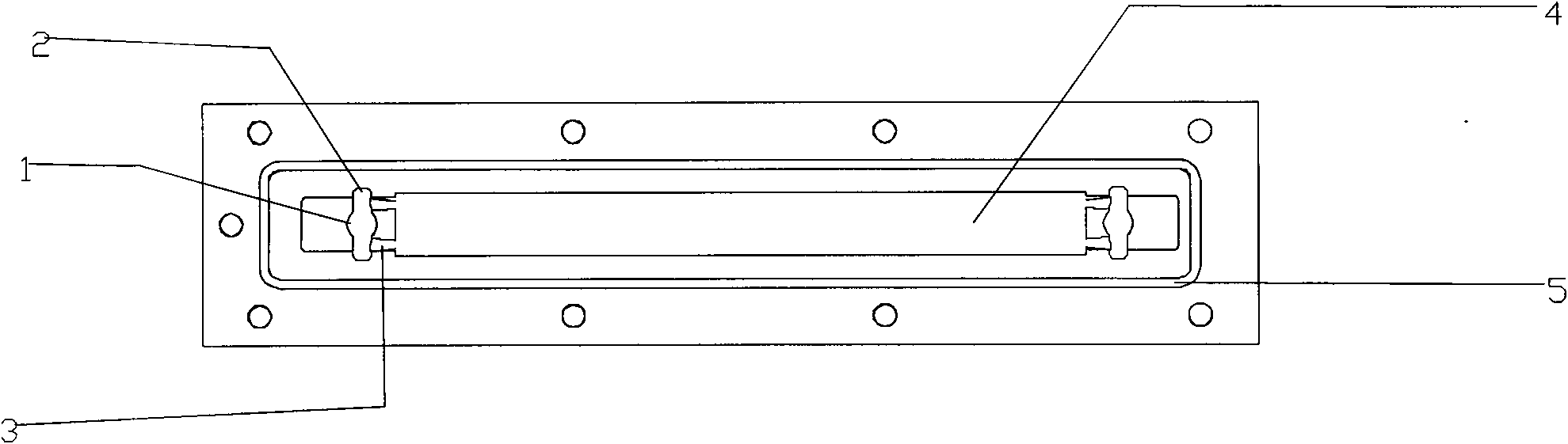

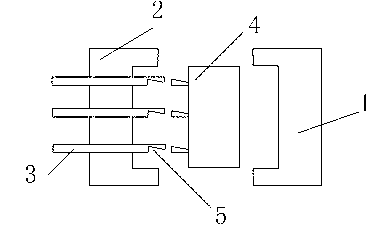

Airbag plastic mould

The invention provides an airbag plastic mould in which junctures of a lifter and a product as well as a moving core are less prone to generation of flash and the product is less prone to falling when ejected out. The airbag plastic mould comprises a fixed core (1), the moving core (2) and a product cavity (3) positioned between the fixed core and the moving core, the lifter (4), a right slider (6) and a left slider (7) are connected onto the product cavity (3) respectively, the lifter (4) is in sliding sleeved fit with the moving core (2), and one side of the upper end of the lifter (4) is directly connected with the product cavity (3) while the other side of the same is attached to the moving core (2). The airbag plastic mould is characterized in that a reverse button (9) is arranged on one side, attached to the moving core (2), of the lifter (4), a button buttoned with the reverse button (9) is arranged on the moving core (2), an anti-falling needle (5) is further connected onto the product cavity (3), and saw teeth (10) are arranged at a contacting position of the side face of the anti-falling needle (5) and the product cavity (3).

Owner:宁海县现代模具有限公司

Demolding device for injection molding production of daily necessities and using method thereof

Owner:苏州锦坤模塑有限公司

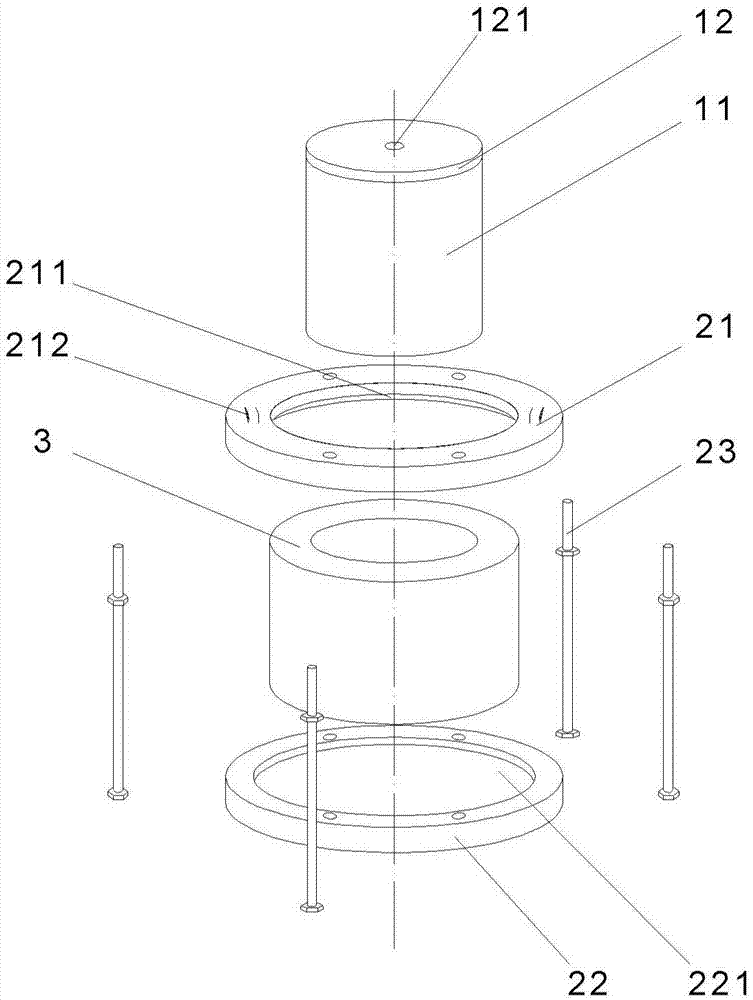

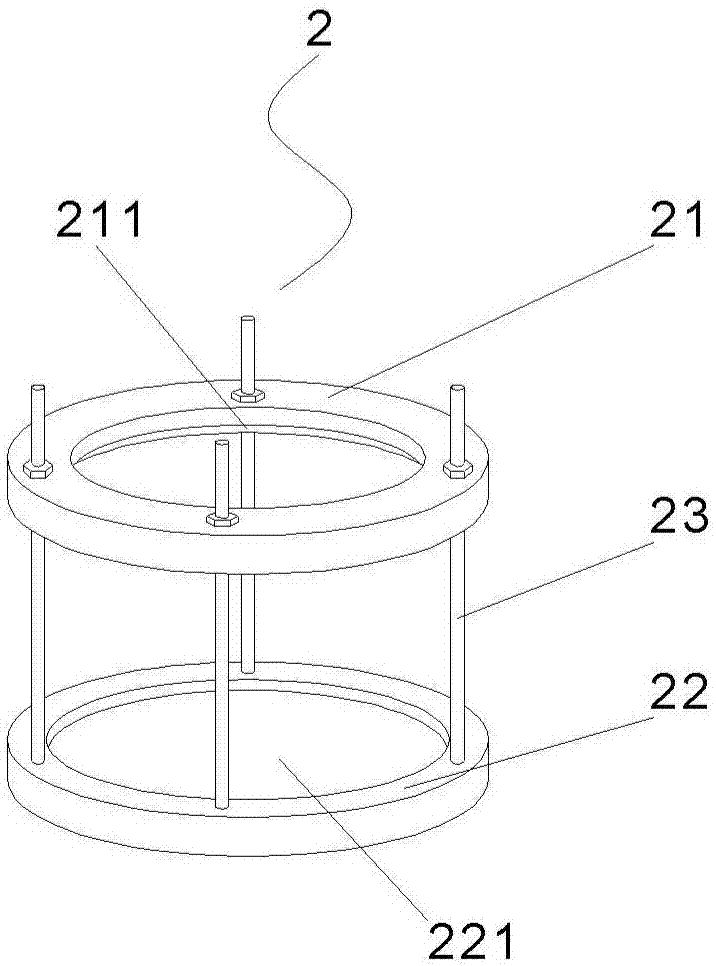

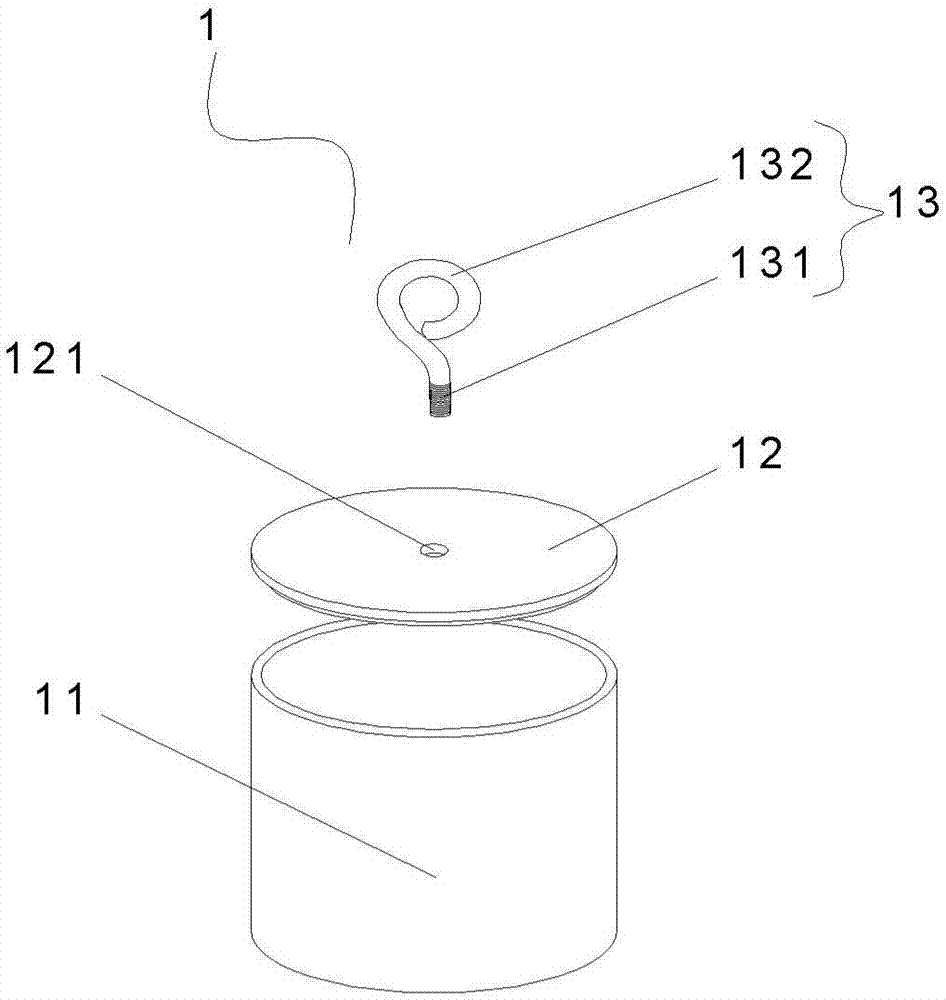

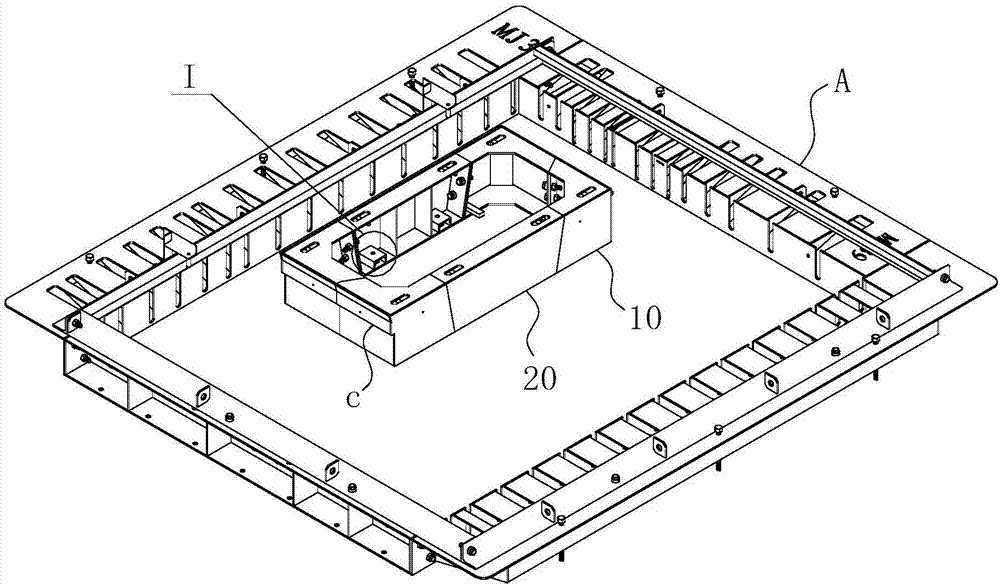

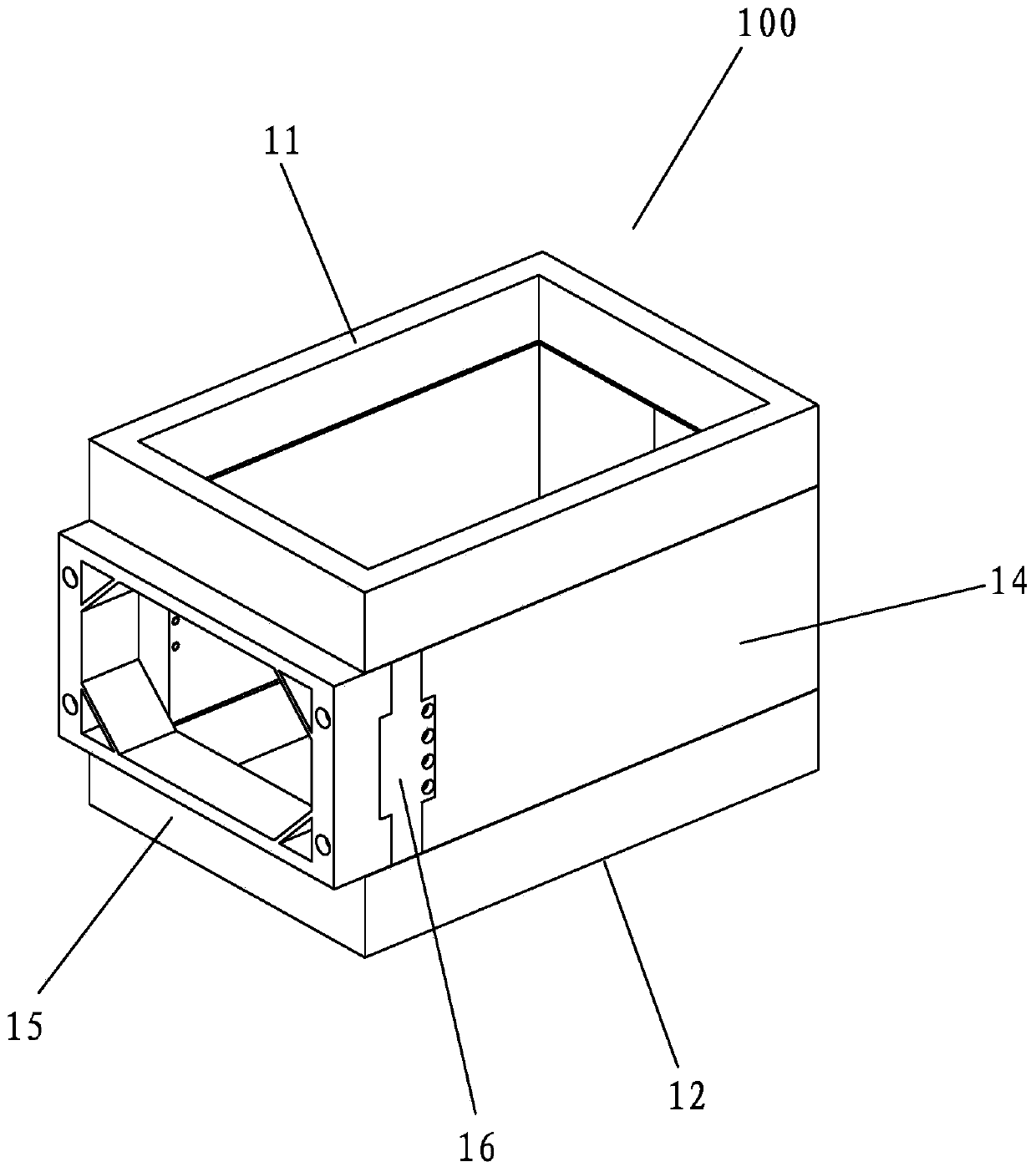

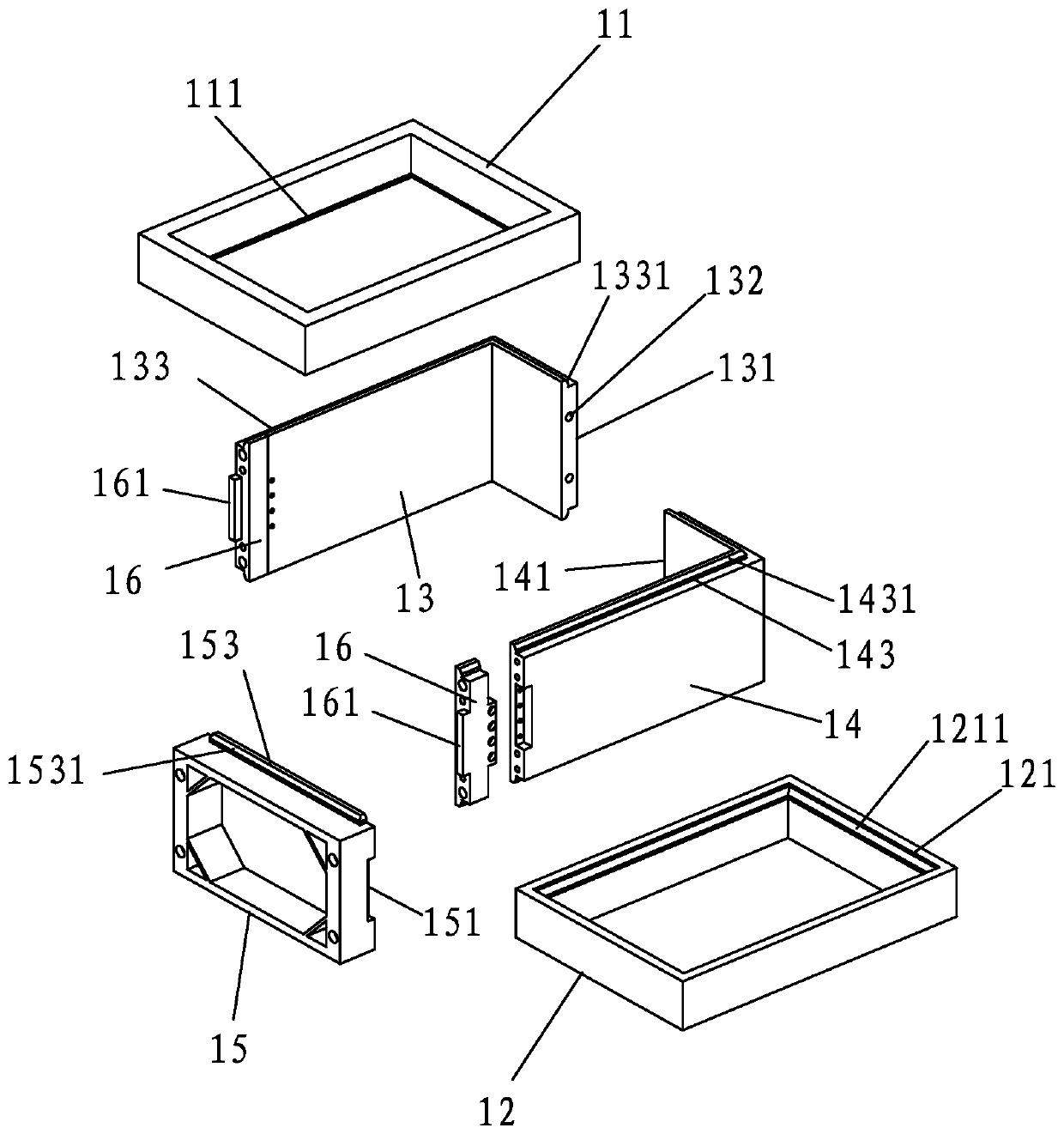

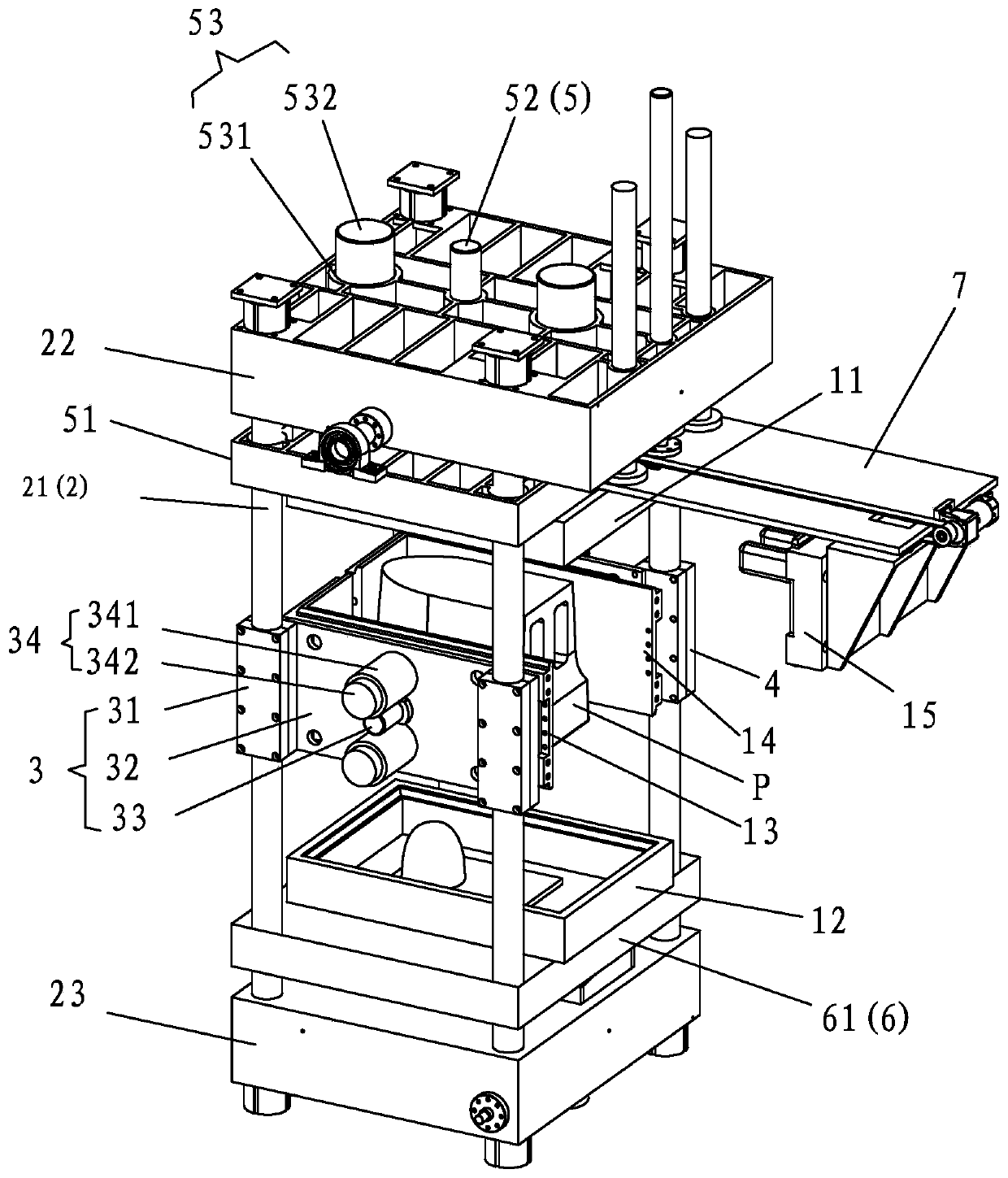

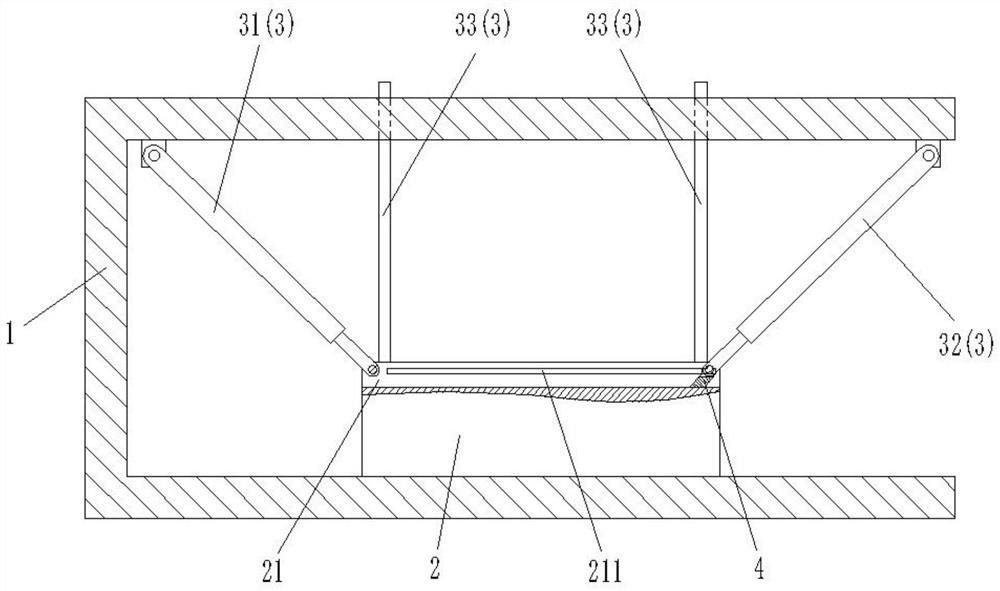

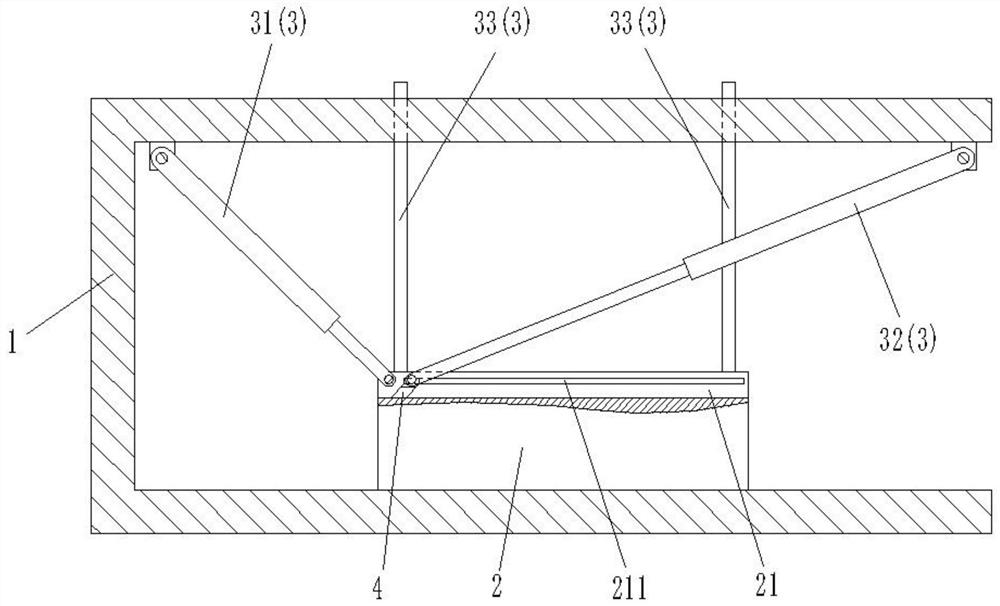

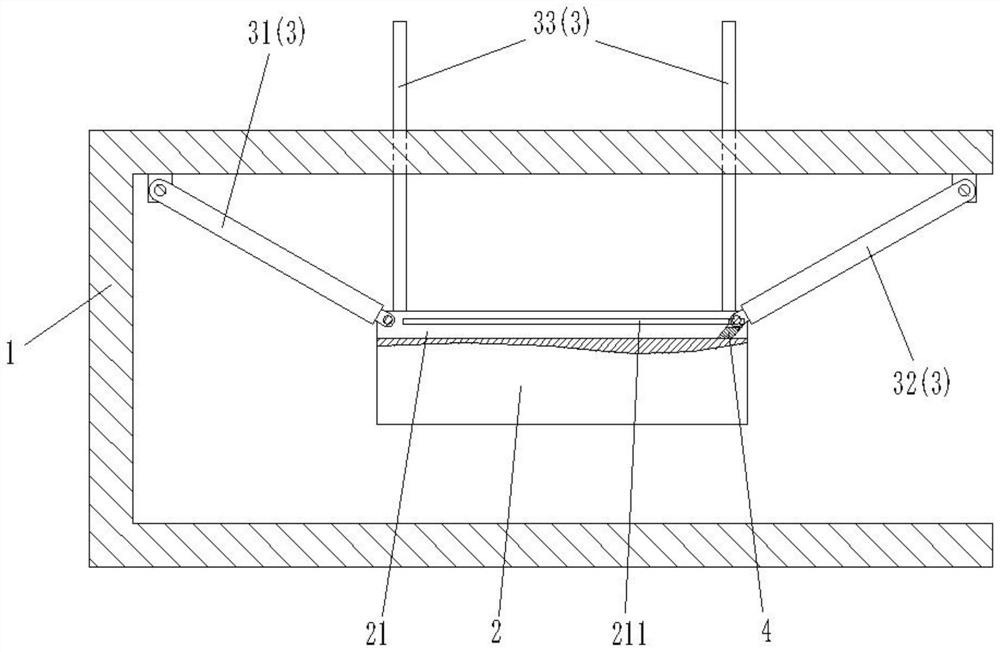

Window hole combined mold for prefabricated components

ActiveCN107116670AGuarantee molding qualityAvoid breakingCeramic shaping mandrelsCeramic shaping coresBuilding productProjection line

The invention belongs to the technical field of building products, and in particular, relates to a window hole combined mold for prefabricated components. The mold comprises a mold body; the outer wall of the mold body forms a mold cavity surface; a vertical section is arranged on two parallel straight edges of the mold body, and two straight edge sections are arranged on the other two parallel straight edges in the vertical direction, so that the mold body is divided into four sets of angular end submolds and two sets of straight edge submolds; the angular end submolds are L-shaped to form four angular ends of the mold body; and on a projection in the vertical direction, a projection line formed by the vertical section is parallel to a direction pointed by the tip end of one cut angular end submold. The mold has the advantages of simple mold disassembly, convenient and fast operation and low manufacturing cost, can effectively prevent the concrete damage phenomenon at the inside corner parts of window holes to reduce or even eliminate later repair cost, and meanwhile, can realize once forming effect of water return slopes and water dripping grooves in the window holes.

Owner:HEFEI ZHONGBAO MACHINERY MFG

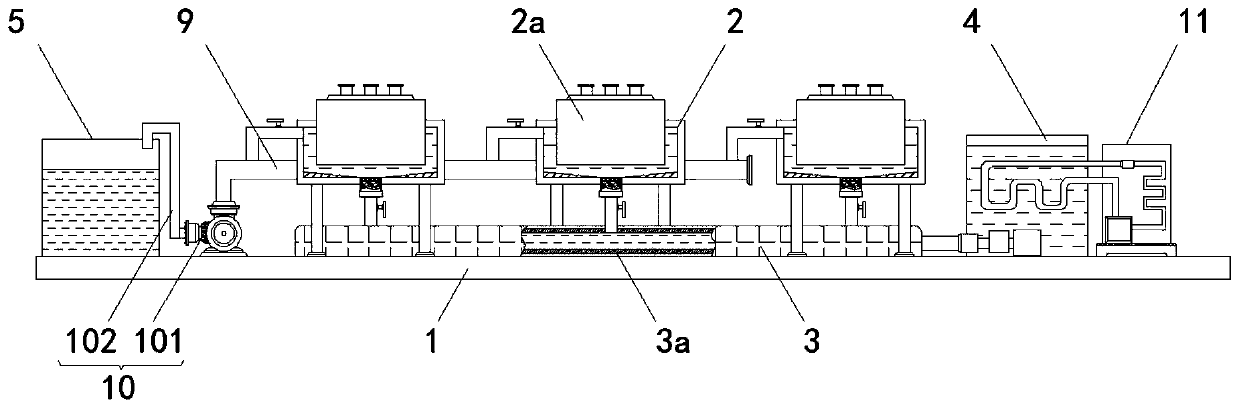

Pipe valve shell casting cooling device

The invention relates to a pipe valve shell casting cooling device. The device comprises a bearing table, a cooling cavity used for cooling a pouring bottom die, a water tank used for transferring andstoring cooling water, a water inlet chamber used for storing the cooling water and a water outlet chamber used for collecting residual water. The cooling cavity, the water tank, the water inlet chamber and the water outlet chamber are all erected on the bearing table, wherein the number of the cooling cavities is at least one, and a pouring bottom die is installed in the cooling cavity. The device can be applied to the casting process of a pipe valve shell; the cooling water circulation is adopted for cooling treatment, so the continuous cooling state of the cooling cavity can be ensured. According to the invention, the modes of pre-cooling, total conveying, graded conveying and residual water recycling are adopted for cooling the pouring bottom die which is produced at the same time, thereby guaranteeing that a casting part can be rapidly cooled, demolding treatment can be conveniently conducted on the casting part, and the production efficiency of casting of the pipe valve shell isimproved.

Owner:HUBEI FANCHAO AUTOMOTIVE IND

Grouting closestool mold capable of achieving precise and rapid mold closing and opening

PendingCN109940736ANovel structural designFast and accurate alignmentDischarging arrangementAuxillary shaping apparatusButt jointAgricultural engineering

The invention discloses a grouting closestool mold capable of achieving precise and rapid mold closing and opening. The grouting closestool mold comprises a mold body. The mold body is provided with an upper cover plate, a lower cover plate, a rear side plate, a left side plate and a right side plate. The left side plate and the right side plate are each of an L-shaped structure. The left side plate and the right side plate achieve left-and-right mold closing in a manner that one sides are in butt joint, and a movable connecting mechanism used for mold closing and alignment is arranged on thebutt-joint sides. The rear side plate is spliced between the left side plate and the right side plate so as to form a square structure, and lateral limiting structures beneficial to alignment and moldclosing are arranged between the rear side plate and the left side plate and between the rear side plate and the right side plate. The upper cover plate and the lower cover plate are arranged on thetop face and the bottom face of the square structure in a covering manner, and covering and limiting structures beneficial to alignment and mold closing are arranged on corresponding covered cooperation portions. The mold is flexible and exquisite in structural design, good in mold opening and closing operability, high in efficiency, low in product defect rate and excellent in quality, and operation is precise and rapid.

Owner:林铭兰

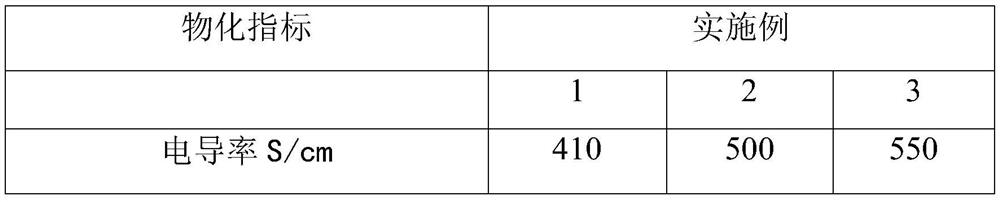

Ultrathin graphite composite bipolar plate base material capable of being quickly cold-pressed and molded and preparation method thereof

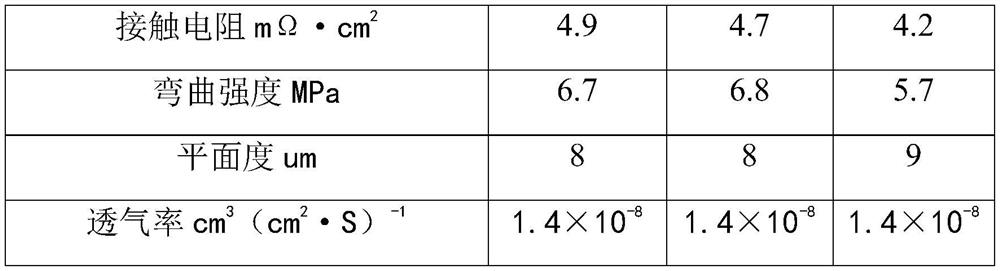

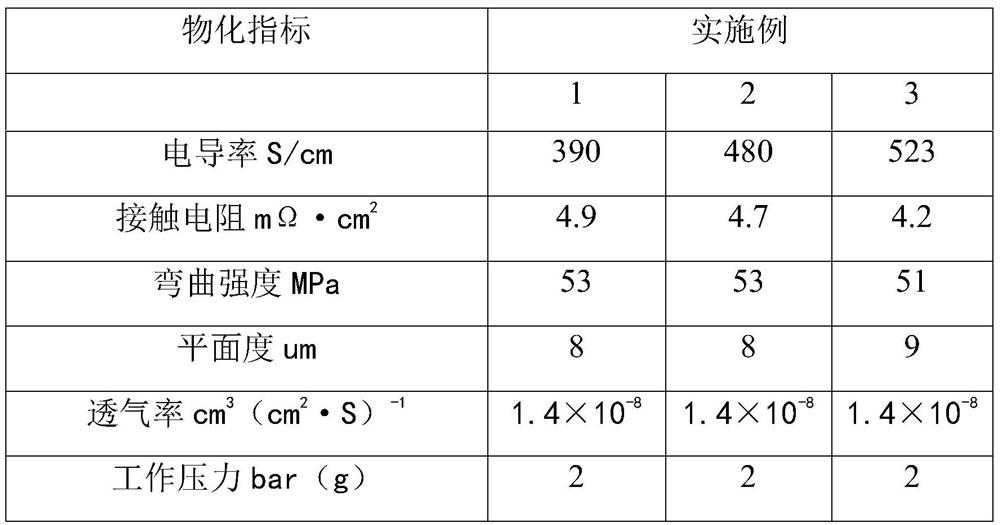

The invention provides an ultra-thin graphite composite bipolar plate base material capable of being quickly cold-pressed and molded. The base material comprises the following components and raw materials in percentage by weight: 40-60% of 150-200-mesh natural flake graphite powder, 5-20% of 100-150-mesh graphite worms, 5-15% of 200-300-mesh graphite worms, 15-35% of synthetic resin and 1-3% of asurfactant. The invention also discloses a preparation method of the base material. The bipolar plate base material can be directly subjected to cold press molding in a mold with a runner through a hydraulic machine, the molding time is less than or equal to 2 minutes, the molding pressure is 100-120MPa, the moldable thickness is greater than or equal to 0.6 mm, the thinnest part of a mold pressing composite plate is 0.2 mm, and the cold press molded composite plate has initial strength, and can be easily demolded without a mold release agent. The molded composite plates can enter an oven in batches to be cured, the conductivity of the cured composite plates is greater than or equal to 350 S / cm, the contact resistance is less than or equal to 6 milliohm.cm<2>, the flatness is smaller thanor equal to 10 microns, the bending strength is larger than or equal to 50 MPa, the air permeability is smaller than or equal to 2 * 10<-8>cm<3> (cm<2>*S) -1, and the working pressure is greater thanor equal to 1 bar, and the thickness of a bipolar plate which can be formed is less than or equal to 1.4mm.

Owner:青岛杜科新材料有限公司

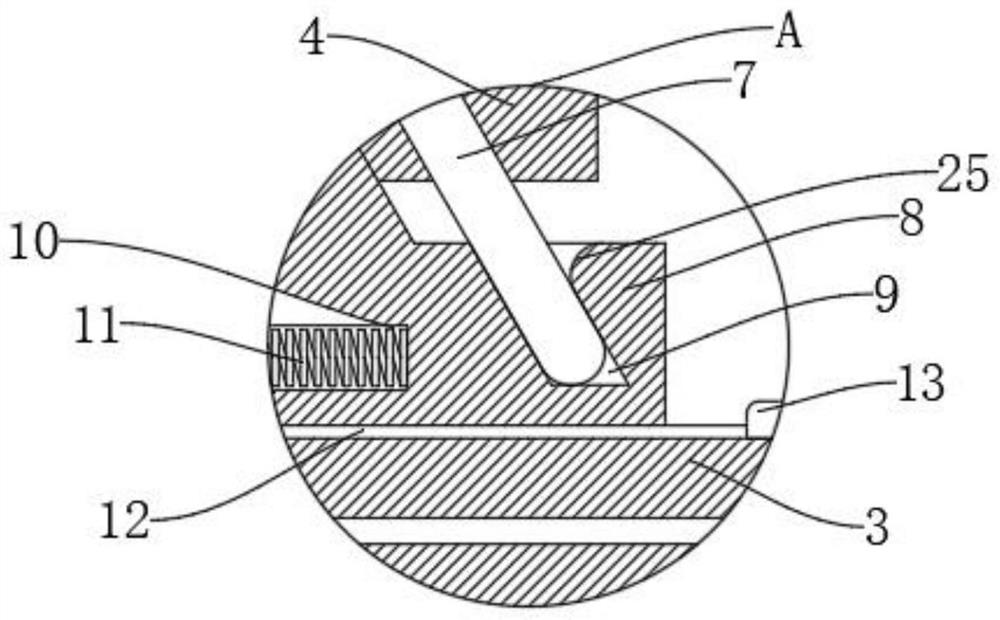

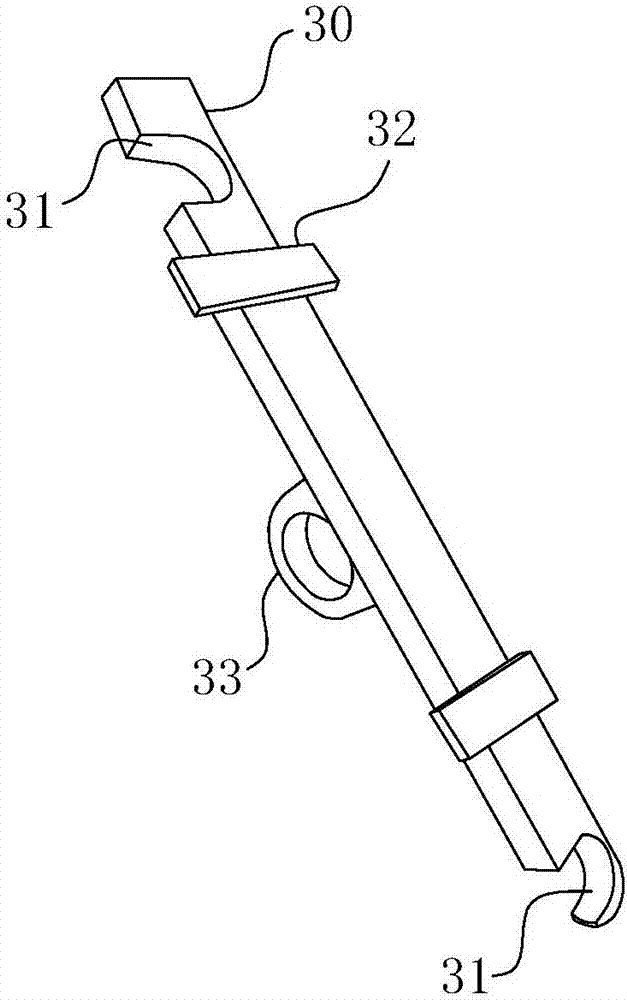

PC wallboard mould with window opening module

ActiveCN107415029AEasy demouldingImprove efficiencyMoulding surfacesMould auxillary partsRebarBuilding product

The invention belongs to the technical field of a building product, in particular to a PC wallboard mould with a window opening module. The mould comprises four internal wall side dies and positioning pieces, wherein a U-shaped positioning groove is concavely formed in the die cavity surface of each internal wall side die; a positioning arc groove is concavely formed in the long edge side of each positioning piece, and the positioning pieces are fixedly inserted into the U-shaped positioning grooves. The mould further comprises the window opening module, and the window opening module is divided into four groups of corner end submodules and two groups of straight edge submodules. Each corner end submodule is L-shaped, and therefore the corner end submodules form the four corner ends of the window opening module. On the projection of the vertical direction, a projection line formed by a vertical truncation surface is parallel with the direction pointed by the pointed end of one truncated corner end submodule. The mould has the advantages of simple mould disassembly, convenience and fastness in operation and low manufacture cost. One-step pouring forming of a winding opening can be ensured, and meanwhile the prefabrication of a framework of steel reinforcement and integral operation of putting into the mould are realized. The fabrication efficiency of a prefabricated wall can be greatly improved.

Owner:ANHUI BAOYE CONSTR ENG GRP CO LTD

End pole mould

The invention discloses an end pole mould which relates to the technical field of storage battery production. The end pole mould comprises a fixed mould body, a movable mould body and a pouring plate which are respectively provided with a hinge plate; the movable mould body is positioned on one side of the fixed mould body, and the hinge plate of the movable mould body is inserted into the hinge plate of the fixed mould body; a fixed top mould with a hinge plate is arranged above the fixed mould body, and the pouring plate is arranged above the fixed top mould and the movable mould body; the pouring plate, the fixed top mould, the fixed mould body and the movable mould body are hinged with each other through articulated shafts; and the fixed mould body and the movable mould body are respectively provided with a plurality of cavities, a plurality of sprue gates are formed in the pouring plate, and the cavities are communicated with the sprue gates of the pouring plate when the fixed top mould, the fixed mould body and the movable mould body are closed. Compared with the prior art, the cavities are formed in the fixed top mould and the movable mould body, the sprue gates are directly communicated with the cavities, pouring gates are eliminated, so that the usage of raw alloy lead is reduced, and the production cost is lowered.

Owner:骆驼集团华南蓄电池有限公司

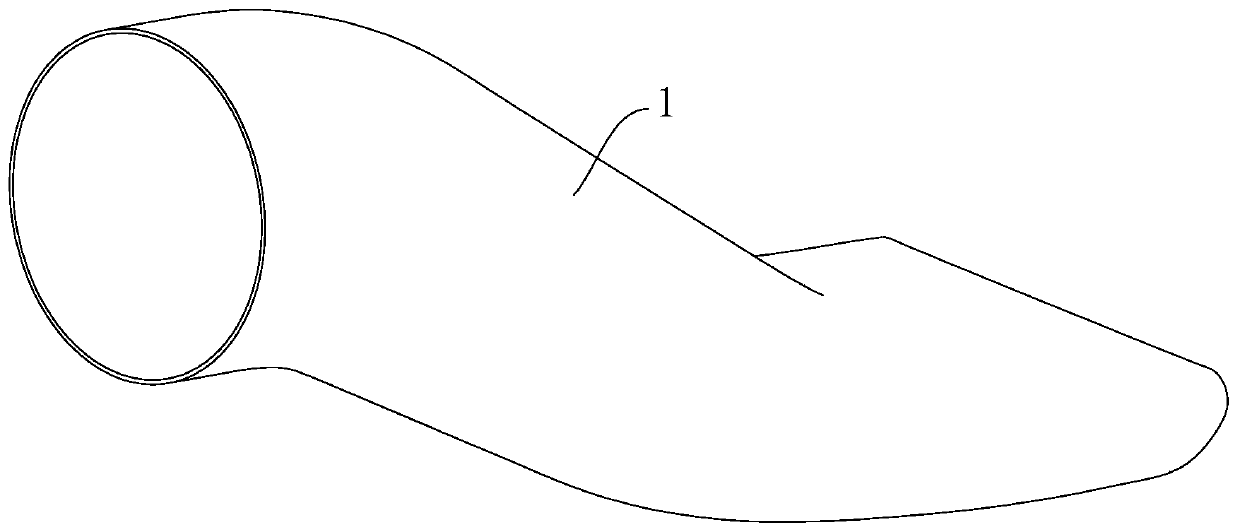

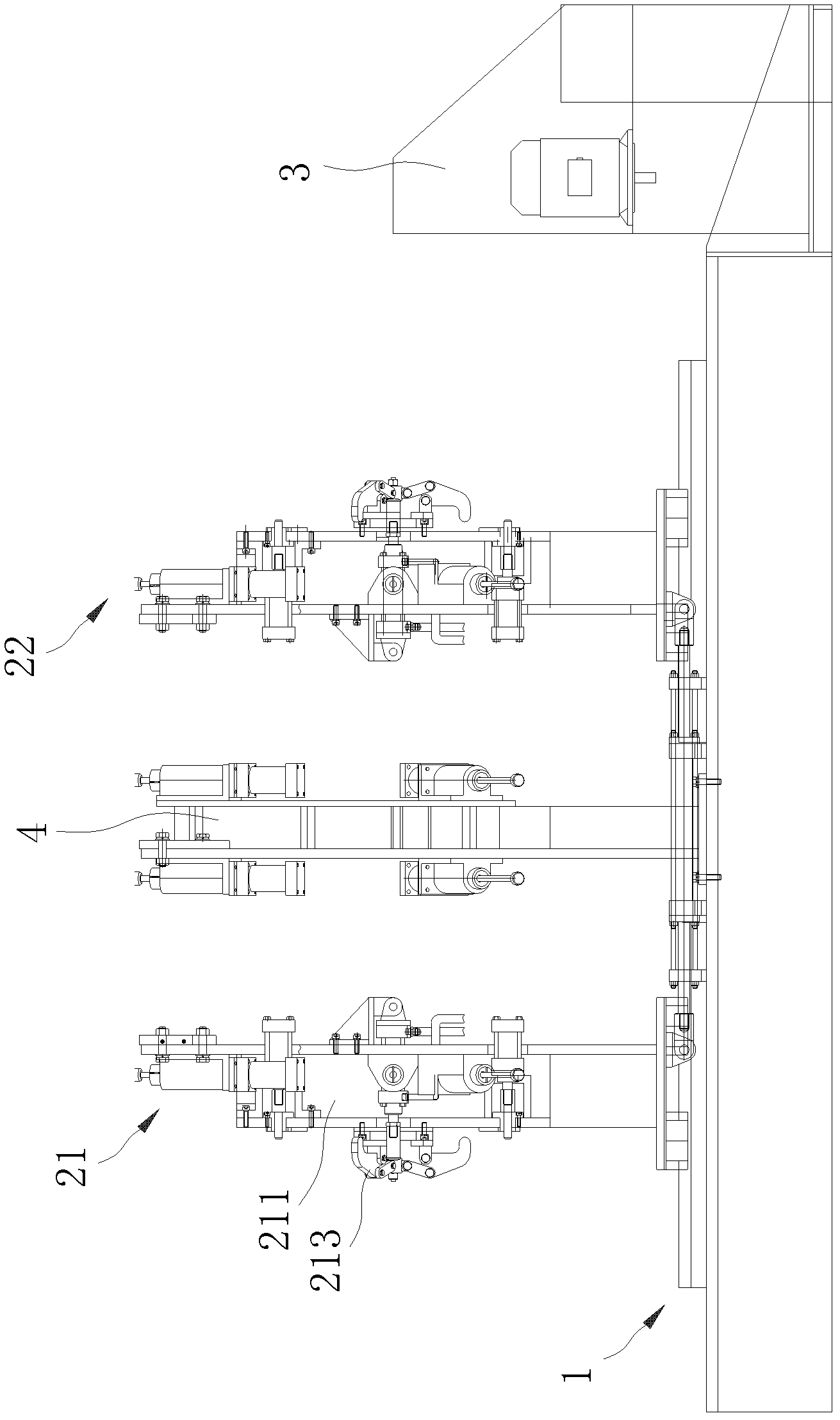

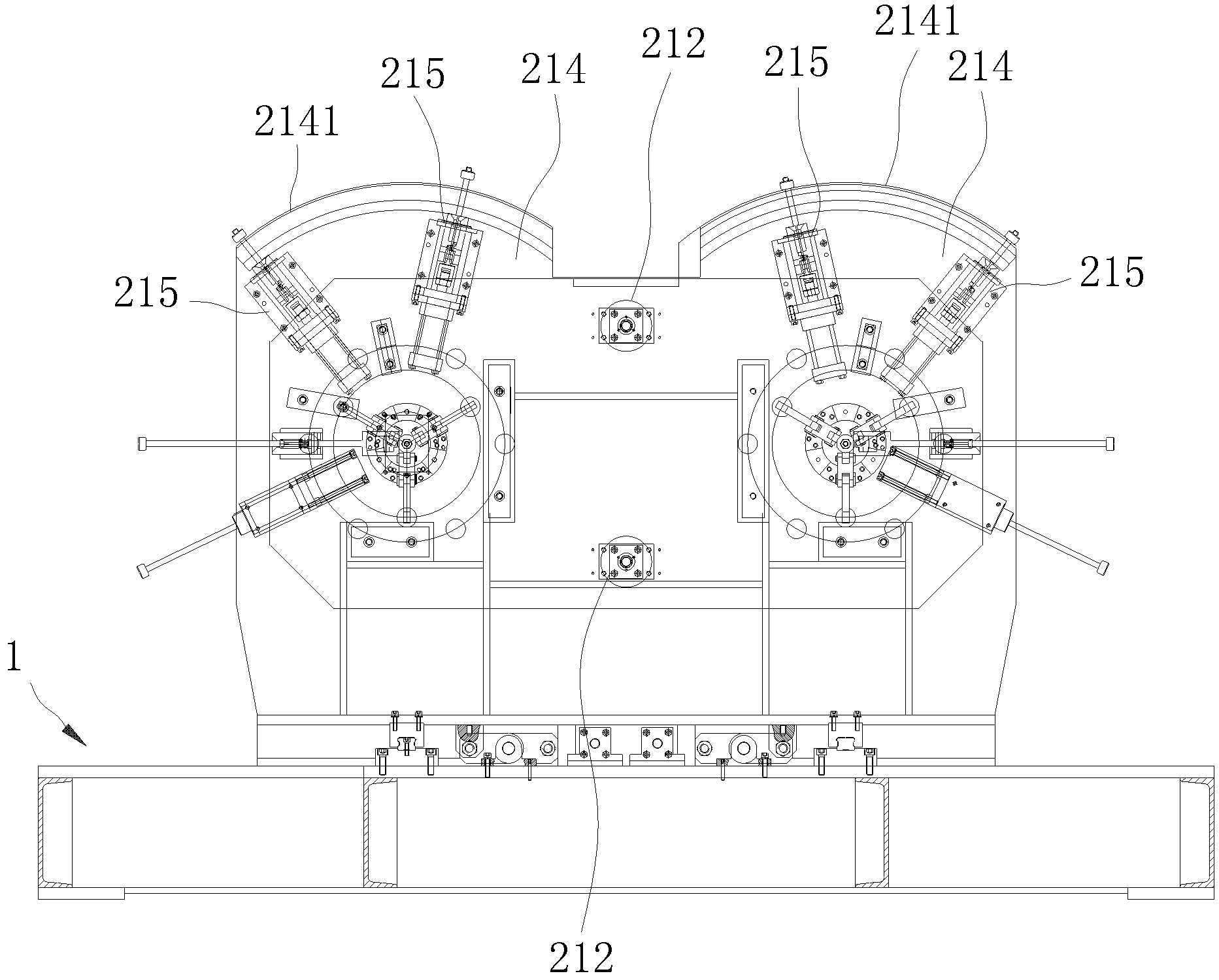

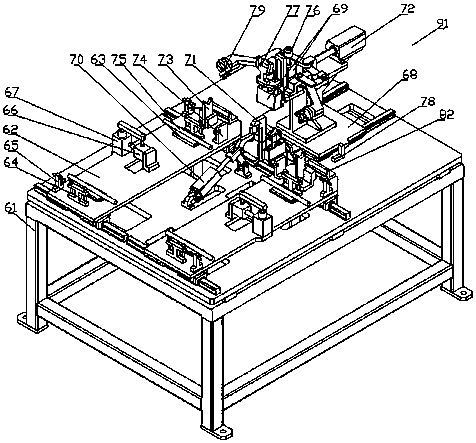

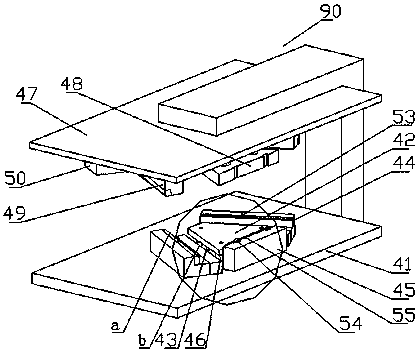

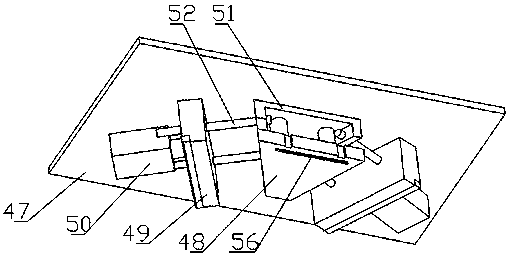

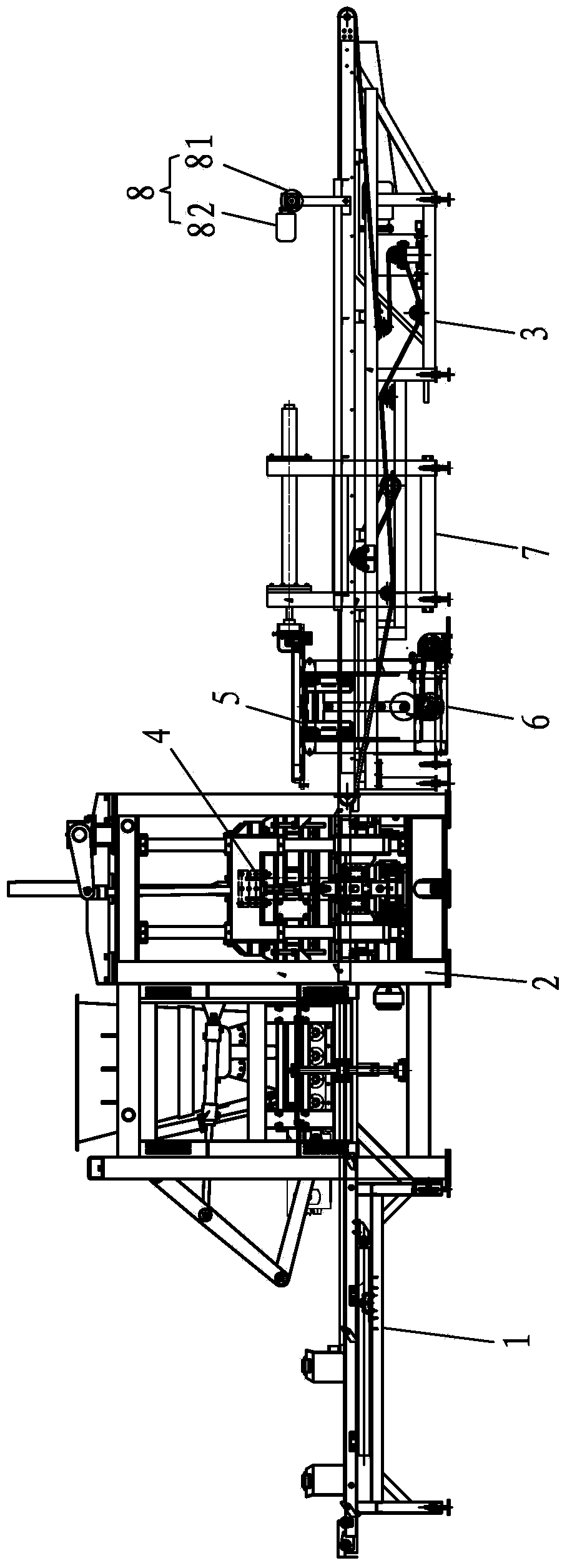

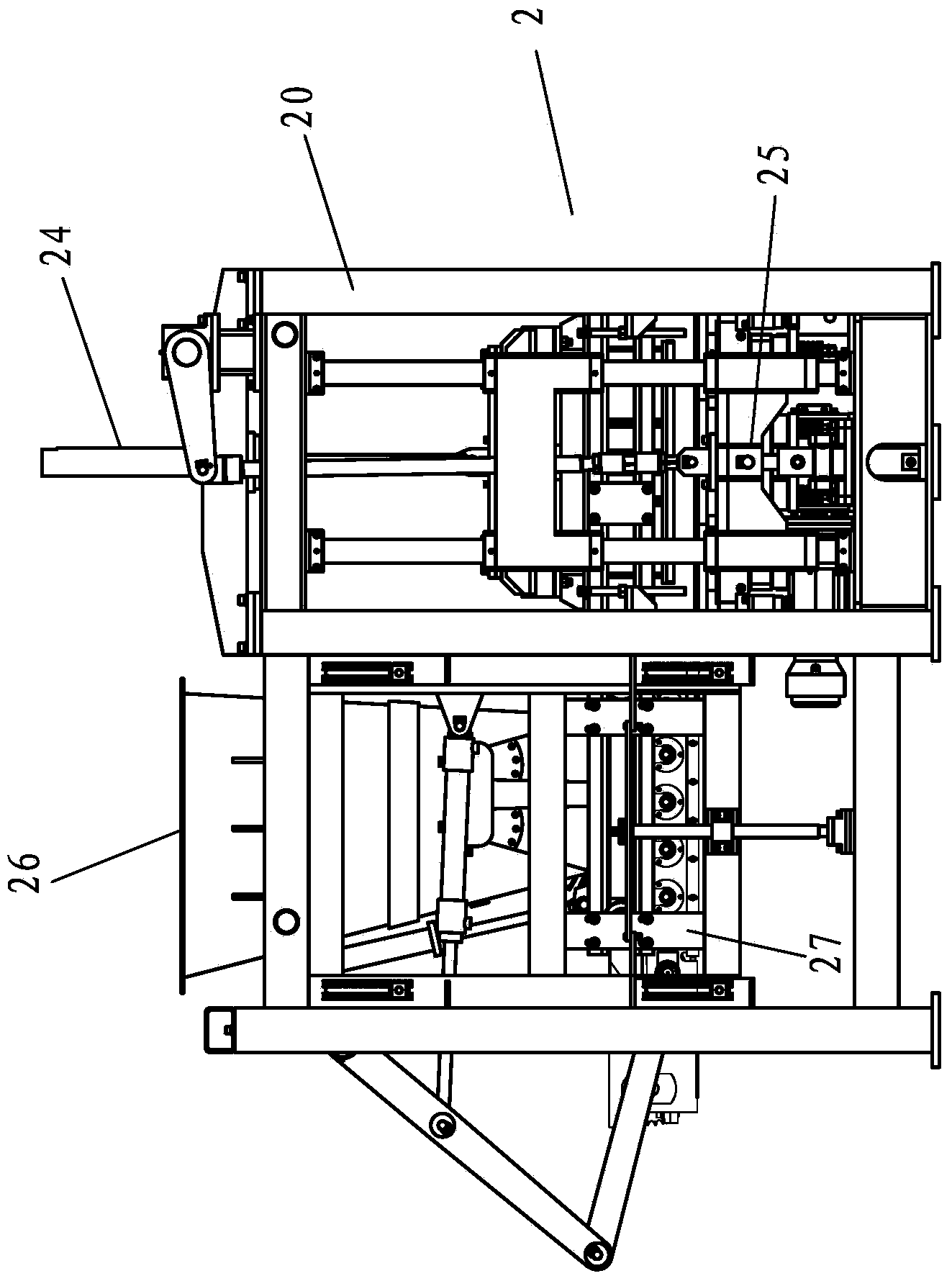

Forklift pallet fork stamping and combined weld production line

InactiveCN107737835APrecise positioningEasy demouldingShaping toolsWelding/cutting auxillary devicesManipulatorPallet fork

The invention provides a forklift pallet fork stamping and combined weld production line comprising a stamping machine (90) and a pallet fork welding tool (91). A carrying manipulator (92) is arrangedbetween the stamping machine (90) and the pallet fork welding tool (91), the stamping machine (90) is provided with a tripod stamping die which comprises a lower die body and an upper die body, and the pallet fork welding tool (91) comprises a rack (61), a pair of fork body limiting and locking mechanisms, a fork body connecting box pneumatic clamp (70), a bearing plate limiting and locking mechanism and a tripod limiting and locking mechanism. The forklift pallet fork stamping and combined weld production line has the advantages that through multi-time stamping forming of the stamping die, positioning is accurate, and die release is convenient and rapid; and through a plurality of limiting and locking air cylinders, all parts of a pallet fork are rapidly positioned and clamped, the structure is simple, all weld joints are even, and the welding quality is improved.

Owner:荆门市双创专利技术服务有限公司

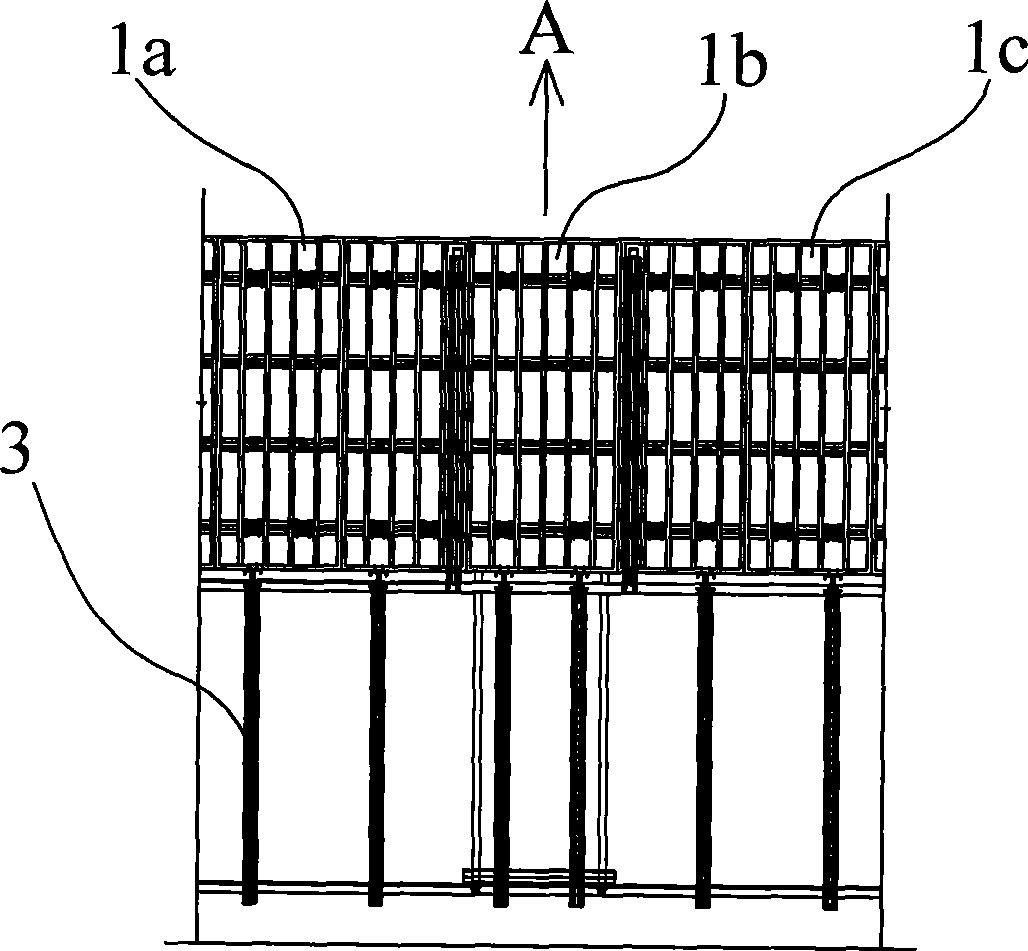

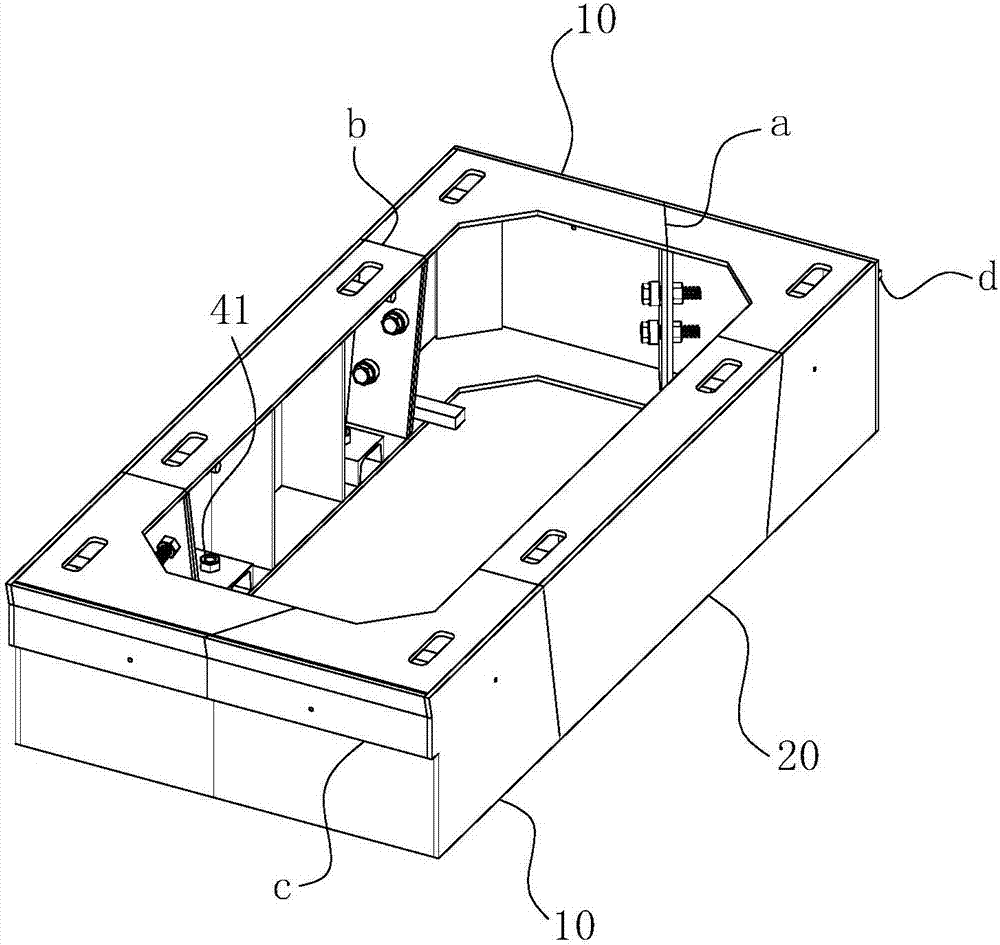

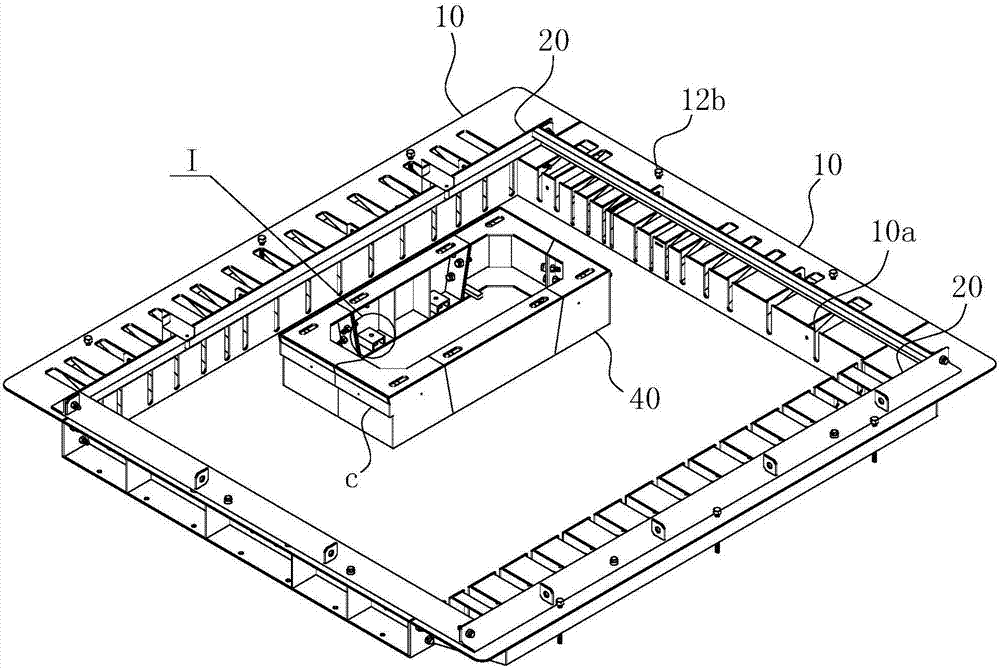

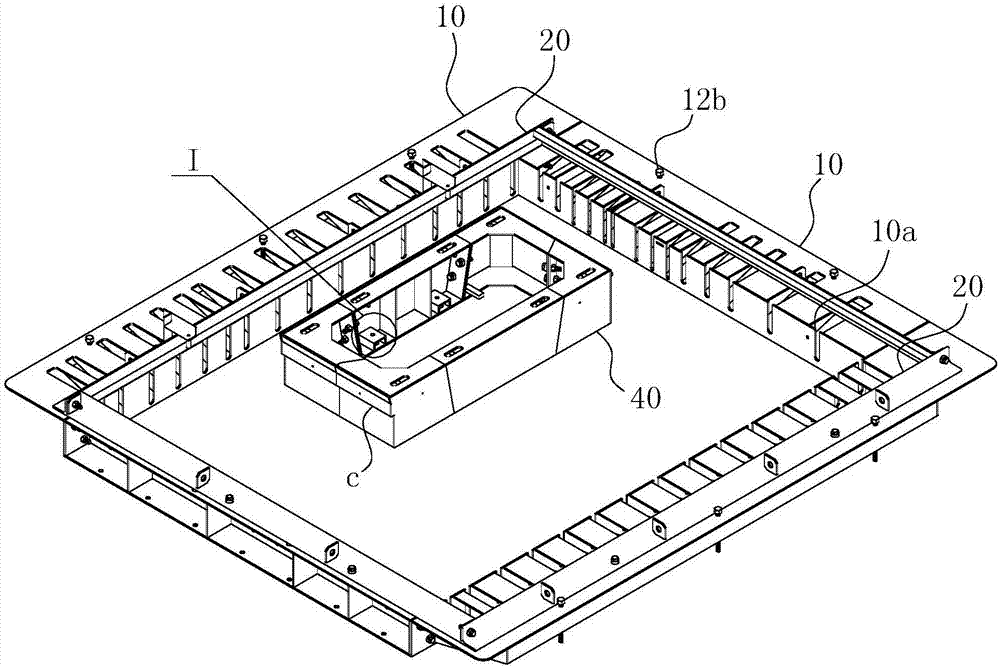

Quick-release-type PC wallboard mold with integral mold-in function of steel reinforcement framework

ActiveCN107263681AAchieve a molding effectGuarantee molding qualityMoulding surfacesMould auxillary partsBuilding productEngineering

The invention belongs to the technical field of building products, and particularly relates to a quick-release-type PC wallboard mold with the integral mold-in function of a steel reinforcement framework. The quick-release-type PC wallboard mold comprises four inner wall side molds and positioning pieces. U-shaped positioning grooves are formed in the mold cavity surfaces of the inner wall side molds in a recessed mode. Positioning arc grooves are formed in the long edge side positions of the positioning pieces in a recessed mode, and the positioning pieces are fixedly inserted into the corresponding U-shaped positioning grooves. Cross sections are made perpendicular to the length direction of the inner wall side molds. The cross sections of the inner wall side molds are in an L shape in appearance. The board surfaces at one sides of plumb plates of the inner wall side molds form inner wall mold cavity surfaces. The quick-release-type PC wallboard mold has the advantages that mold disassembly is simple, operation is easy, convenient and fast, and manufacturing cost is low; forming quality of a prefabrication wall body can be guaranteed while prefabrication and integral mold-in operation of the steel reinforcement framework are achieved; and moreover the manufacturing efficiency of the prefabrication wall body can be greatly improved.

Owner:ANHUI BAOYE CONSTR ENG GRP CO LTD

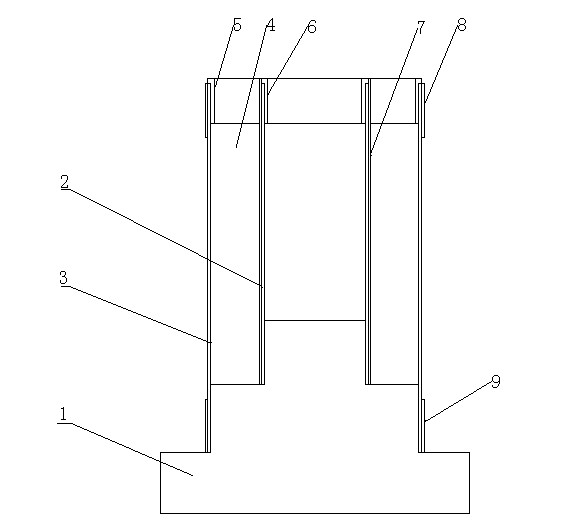

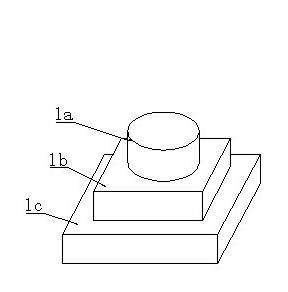

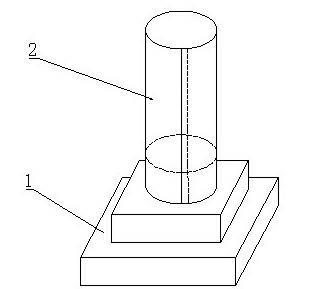

Mold for manufacturing unsaturated polyester resin products

The invention discloses a mold for manufacturing unsaturated polyester resin products. The mold is characterized by comprising a mold base, an inner mold tube, an outer mold tube and a mold cavity, wherein the mold base is in a shape of at least three steps gradually enlarged from top to bottom, the inner mold tube is made of resin materials or soft metal, the lower end part of the inner mold tube is surrounded and sheathed on the first step of the mold base for forming a straight tubular inner mold, the outer mold tube is made of resin materials or soft metal, the lower end part of the outer mold tube is surrounded and sheathed on the step arranged under the step sheathed by the inner mold tube for forming a straight tubular outer mold, the mold cavity forms a casting mold cavity with an annular space surrounded by the inner mold tube, the outer mold tube and the mold base, and the upper part of the annular space is provided with an opening. The mold has the advantages that the structure is simple, the weight is light, the cost is low, the product dimension precision is high, the mold can be used for making standard perfect round products and polygonal products, and the surfaces of manufactured blank products are clean and smooth.

Owner:东莞市双知艺坊洁具有限公司

Aerated concrete block preparation system and preparation process

InactiveCN113119281AImprove efficiencyImprove efficiency and qualityDischarging arrangementMouldsStructural engineeringMechanical engineering

The invention discloses an aerated concrete block preparation system which comprises a support, a mold mechanism and a lifting mechanism, wherein the mold mechanism comprises a mold frame, a driving unit, connecting rings, connecting rods, sliding rods and mold side plates; the connecting rings are positioned on the mold frame and can rotate; the driving unit drives the connecting ring to rotate; the multiple mold side plates are arranged in the connecting ring and are sequentially arranged in the circumferential direction of the connecting ring to define a mold cavity, and the adjacent mold side plates are in sliding connection; and the sliding rods are located between the connecting rings and the mold side plates and are in sliding connection with the mold frame in the radial direction of the connecting rings, one end of each sliding rod is in sliding connection with the corresponding mold side plate in the horizontal direction, the other end of each sliding rod is rotationally connected with one end of the corresponding connecting rod, and the other end of each connecting rod is rotationally connected with the corresponding connecting ring. According to the aerated concrete block preparation system, preparation of aerated concrete blocks of different sizes can be met, rapid demolding can be achieved, and the preparation efficiency and quality of the aerated concrete blocks are improved.

Owner:王修东

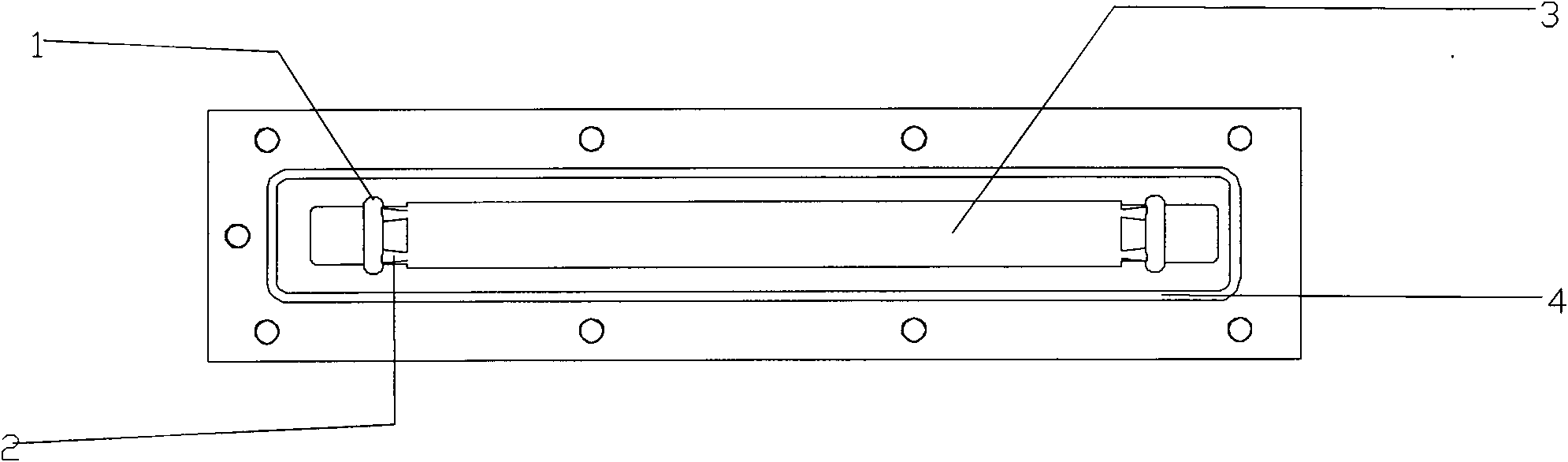

Design and preparation of mold for pipy composite materials suitable for RTM (resin transfer molding) process

The invention designs a mold for pipy composite materials suitable for resin transfer molding (RTM), which can enable the prepared pipy composite materials to achieve the required standard and the requirements. The invention relates to the mold for the pipy composite materials and belongs to the technical field of design and preparation of the molds of the resin transfer molding (RTM) of the pipy composite materials. The structure of the mold disclosed by the invention is characterized in that a male mold and a female mold are closed for forming a pipy mold cavity, and the outer ring of the mold is provided with a sealing strip for sealing and a fixing screw, so that the overall sealing property of the mold can be well ensured. In addition, the mold adopts the design of a unique annular groove at a resin injection port, on the basis of ensuring the injection stability during the preparation of the pipy composite materials, resin can better and uniformly infiltrate pipy fabric, the production of bubbles can be prevented, and the resin can finally flow out of a resin outlet. Simultaneously, a unique cylindrical male mold inner core of the mold disclosed by the invention can enable the demolding operation to be simple and easy to operate, and the operation is easy.

Owner:JIANGNAN UNIV

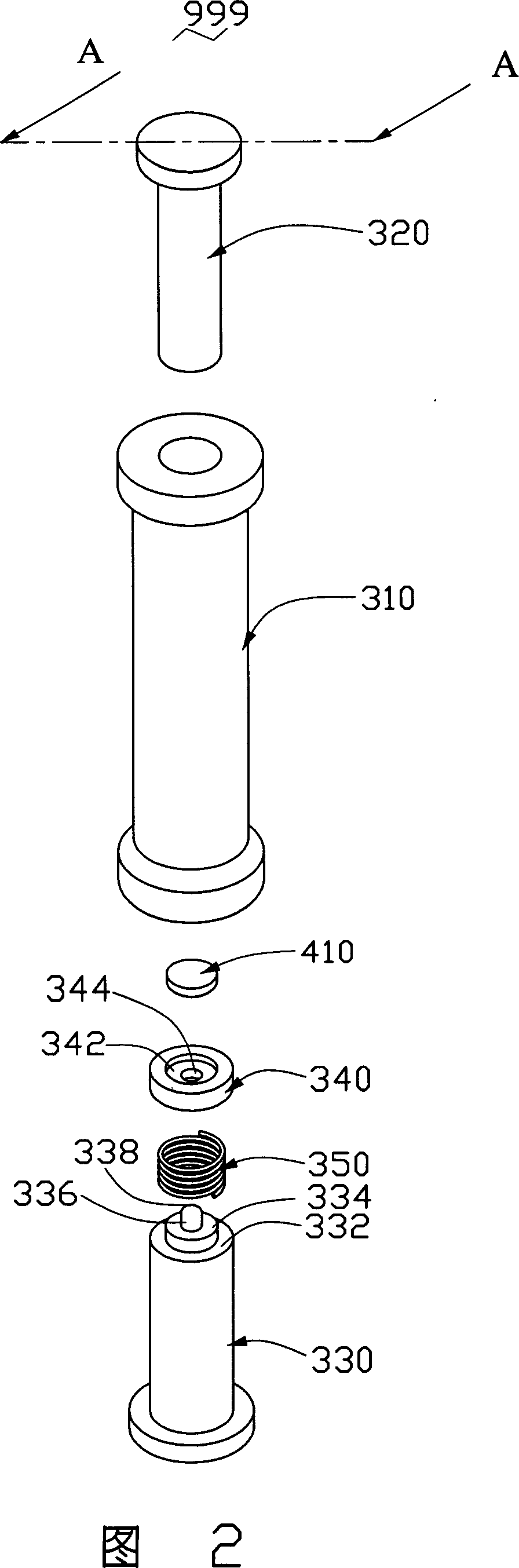

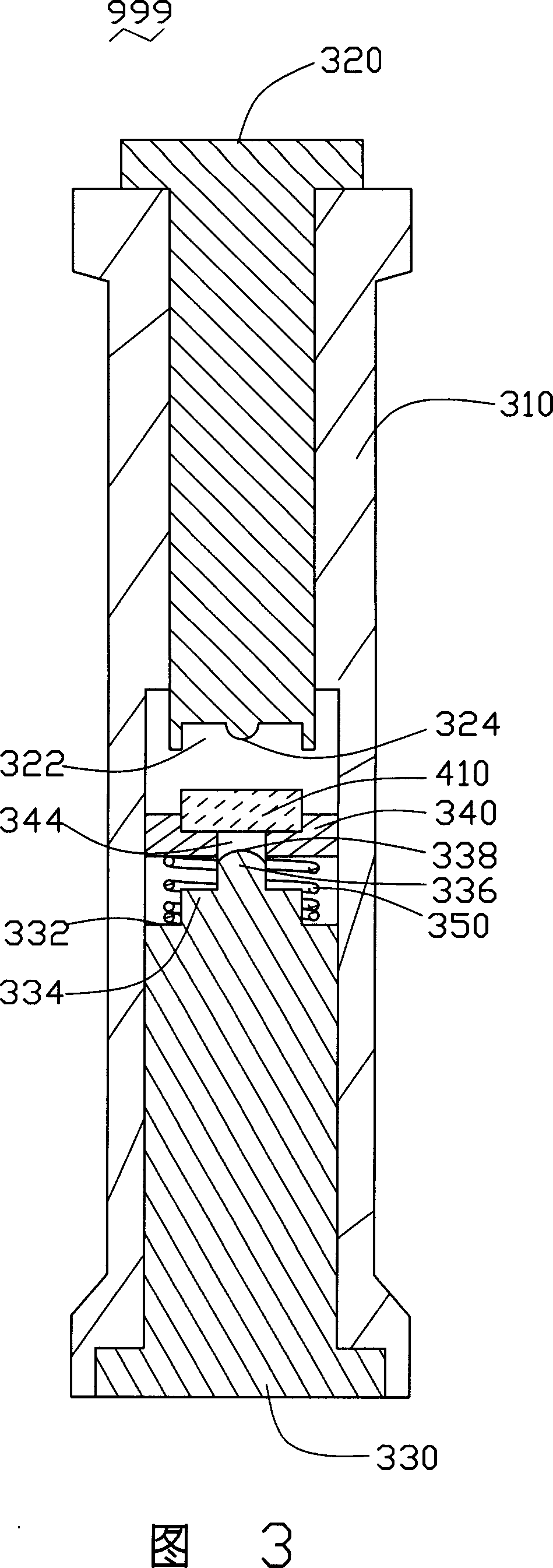

Optic element forming device

The invention discloses an optical element moulding device, which comprises the following parts: first mould core, second mould core, stripping component and elastic element, wherein the first mould core mates the second mould core as optical element shape; the stripping component bears the pre-shaping piece; the elastic element lies between stripping piece and second mould core, which bears the stripping piece on the second mould core elastically.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Demoulding device specially for micro-injection forming instrument

The invention discloses a demoulding device specially for a micro-injection forming instrument. The demoulding device mainly comprises a mould petal and a demoulding bed base, wherein the mould petal is a half of an axle bisection composite structure mould and provided with a mould cavity and a spline demoulding thimble; the demoulding bed base is provided with a mould petal positioning mounting structure and an ejection mechanism, an ejection component of the ejection mechanism is matched with the spline demoulding thimble, the mould petal positioning mounting structure is matched with the mounting part of the mould petal, and the mould petal is mounted on the demoulding bed base in a way that an assembling surface faces downwards and the mould cavity is suspended. The demoulding device disclosed by the invention is capable of well solving the problems that when a contractile tiny high polymer material melt is injected into the mould, a cooled spline is firmly embedded in the mould and is hard to demould; the high polymer material spline hard to demould can be safely and conveniently demoulded from the mould cavity while ensuring geometric shape, size precision and perfect appearance of the spline, any damage is avoided, and the reliable guarantee is provided for the high polymer material performance testing.

Owner:SICHUAN UNIV

Easy-disassembly type PC wall board mold with window aperture mold set

ActiveCN107127867ARealize the processing effectRealize functionMouldsCeramic shaping mandrelsBuilding productProjection line

The invention belongs to the technical field of building products, and particularly relates to an easy-disassembly type PC wall board mold with a window aperture mold set. The easy-disassembly type PC wall board mold comprises four inner wythe wall side molds and positioning blades; U-shaped positioning grooves are formed in the mold cavity face of the inner wythe wall side molds in a concaved mode; positioning arc grooves are formed in the side position of the longer side of each positioning blade, and the positioning blades are fixed in the U-shaped positioning grooves in an inserted mode; the easy-disassembly type PC wall board mold further comprises the window aperture mold set, the window aperture mold set is divided into four sets of corner end sub-molds and two sets of straight flange sub-molds; on the projection in the perpendicular direction, the projection line formed by vertical truncation surface is parallel to the direction pointed by the top end of one of the truncated corner end sub-molds; and the outline of the cross section of the inner wythe wall board mold is a L shape. The easy-disassembly type PC wall board mold has the advantages of being easy to disassemble, easy and rapid to operate and low in production cost, one-time pouring forming of a window aperture is guaranteed, at the same time, the prefabrication, the integral installation and rapid mold removal operation of steel reinforcement frameworks are achieved, and the production efficiency of prefabricated walls can be improved greatly.

Owner:合肥宝德建筑工业化有限公司

Easy-to-remove type die-casting die

The invention relates to an easy-to-remove type die-casting die. The easy-to-remove type die-casting die comprises a fixed die component and is characterized in that a moving die component is arranged on a machining face of the fixed die component. A cavity is formed between the fixed die component and the moving die component. A through hole is formed in the moving die component. An ejector pin component is arranged in the through hole. A die removing joint end is distributed on a working end head, located in the cavity, of the ejector pin component. Therefore, die removing operation of parts of a die-casting die is simple, machining is convenient, cost is not added basically in the process of die manufacture, the phenomenon that the die-casting parts are remained in a fixed die and can not be taken out is thoroughly changed and therefore production efficiency is improved.

Owner:春兴铸造(苏州工业园区)有限公司

Special-shaped brick manufacturing device and method

ActiveCN104015245AReliable demoulding operationImprove yieldDischarging arrangementMouldsMechanical engineeringBrick

The invention discloses a special-shaped brick manufacturing device and method. The special-shaped brick manufacturing device comprises a building block forming machine, a plate conveying machine, a composite conveyor, a pressing die connecting body device, a forming bottom plate, a bottom plate lifting device and a plate taking component arranged on the composite conveyor. During brick manufacturing, a die frame is arranged on the forming bottom plate in an overlapping mode, a cavity is formed, building block forming is carried out, the pressing die connecting body device is matched with the plate taking component, the forming bottom plate is sent out, a supporting plate bears formed bricks obtained by demoulding, and at last, the supporting plate and the bricks are sent out. The device is simple in structure, process operation is easy, efficiency is high, the finished product rate is high, and the innovative device and method are provided for manufacturing of special-shaped bricks.

Owner:FUJIAN QUNFENG MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com