Patents

Literature

31results about How to "Quick and accurate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

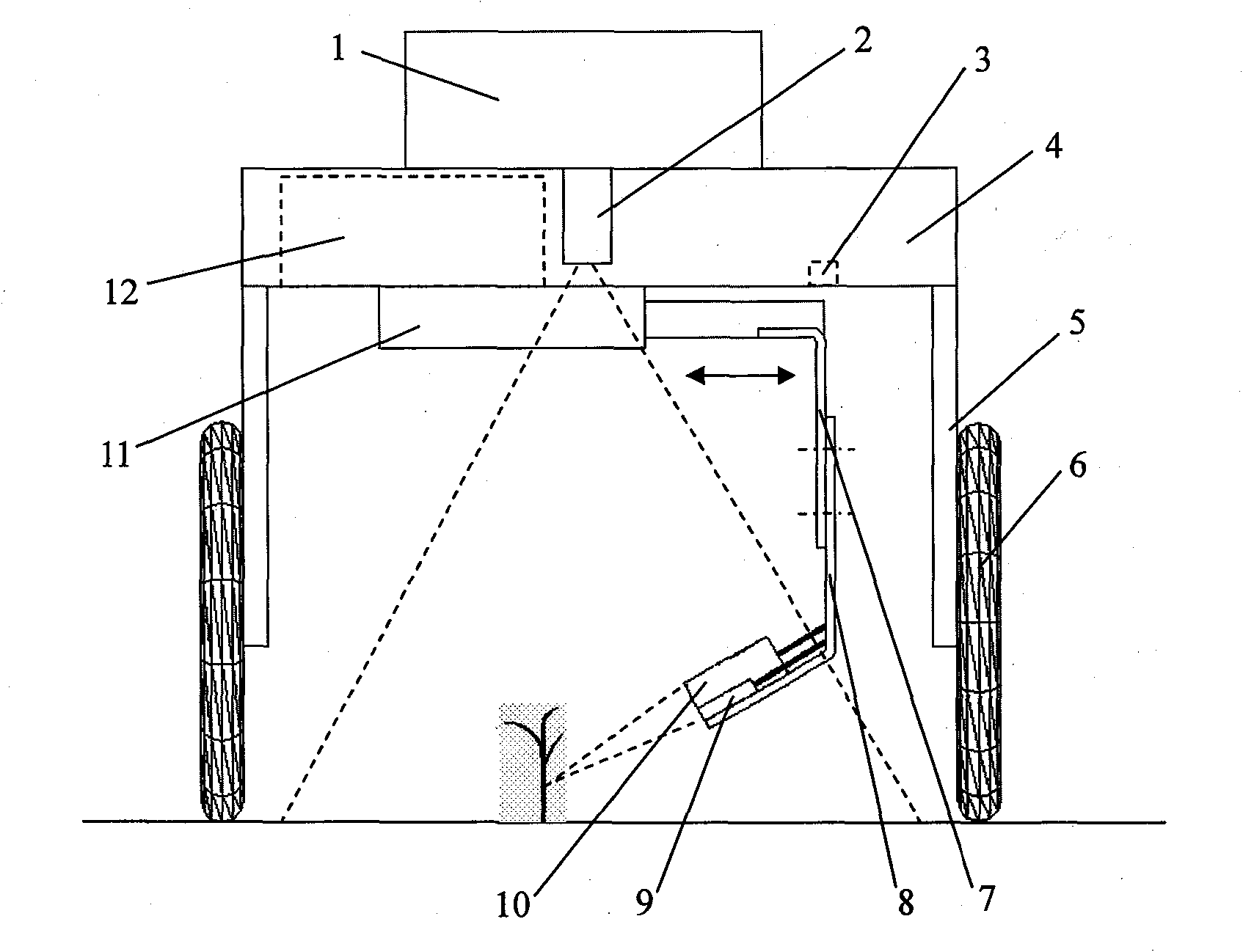

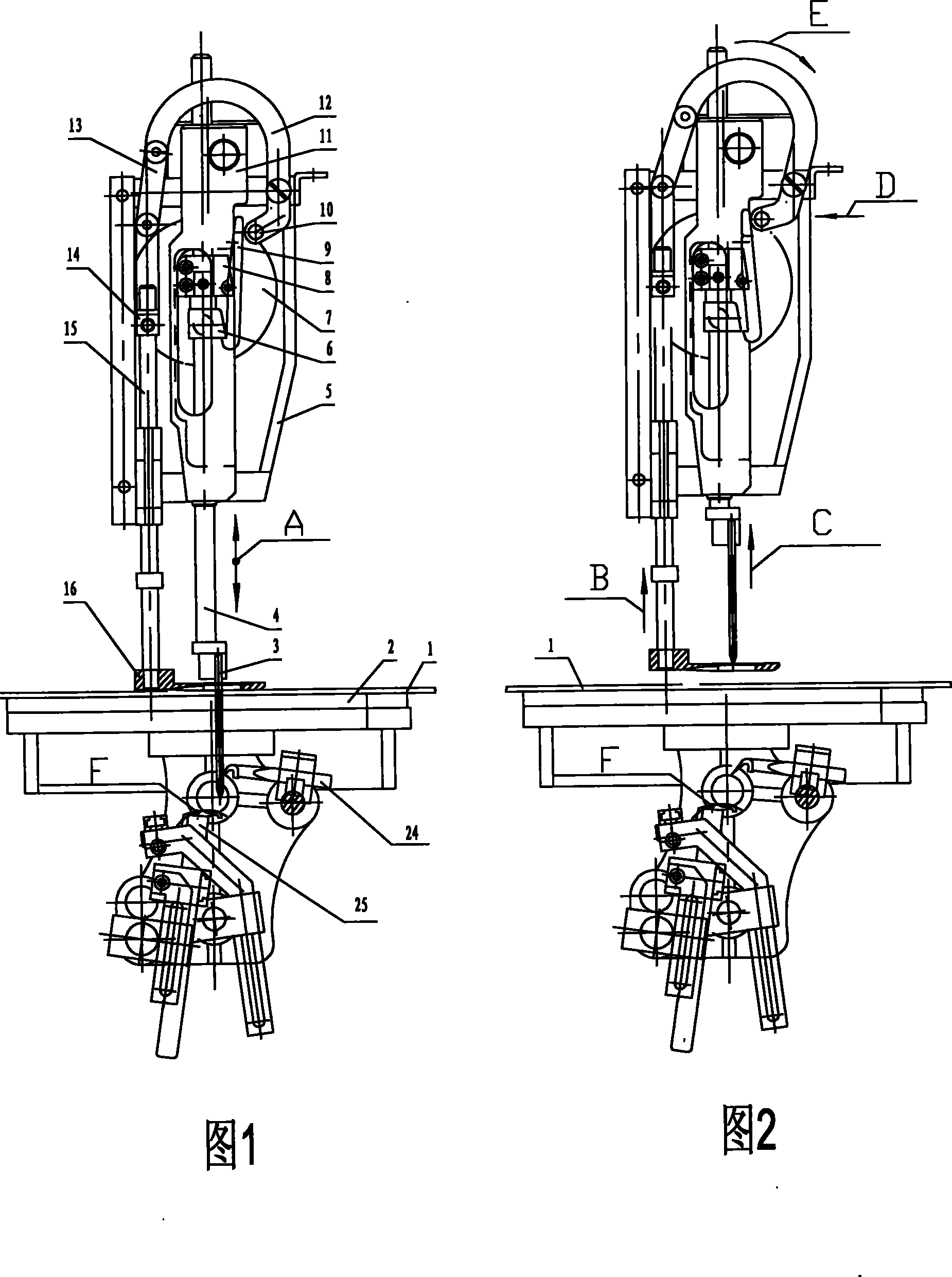

Laser weeding robot

InactiveCN101589705AReduce damage rateReduce energy consumptionWeed killersMobile vehicleControl system

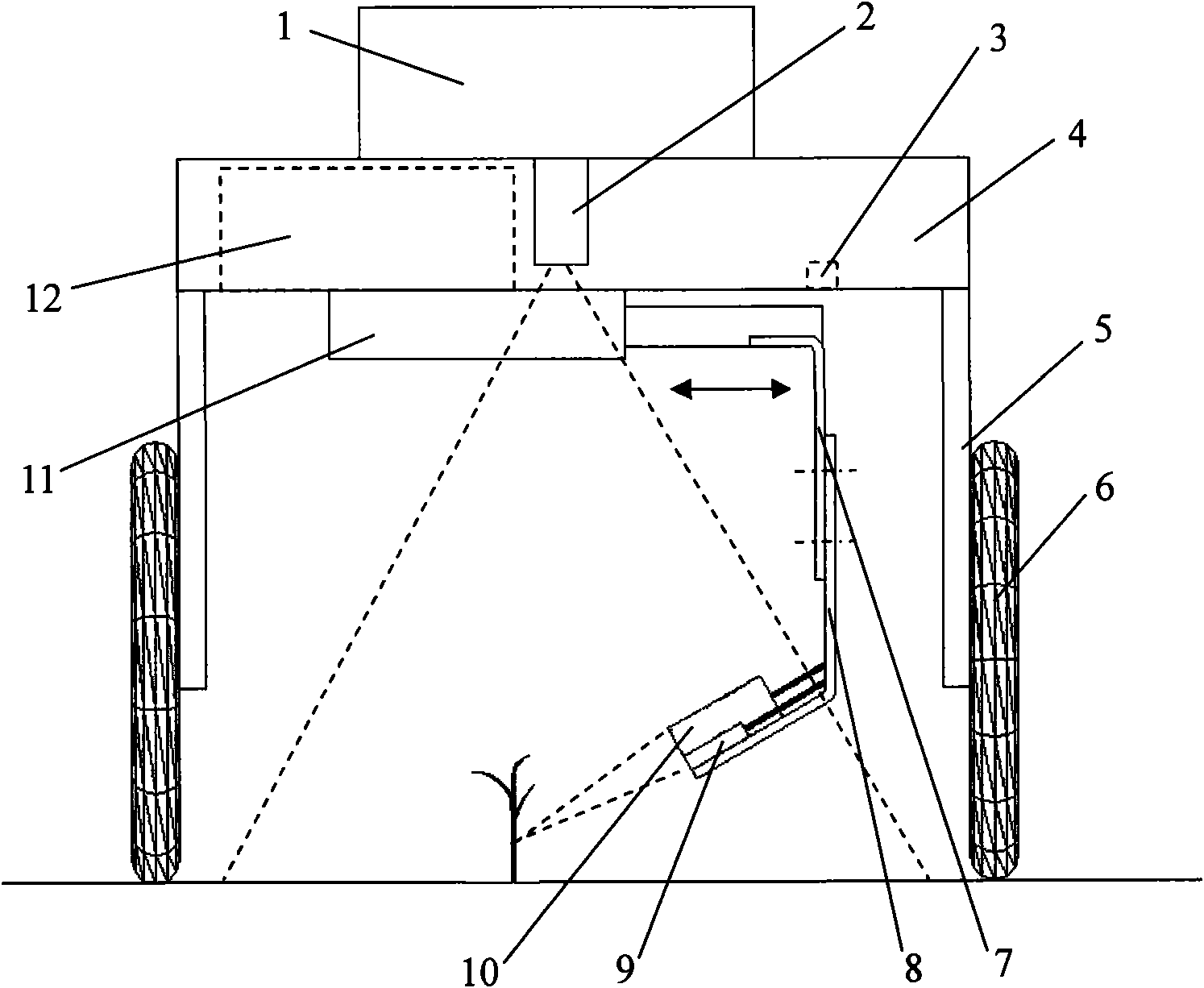

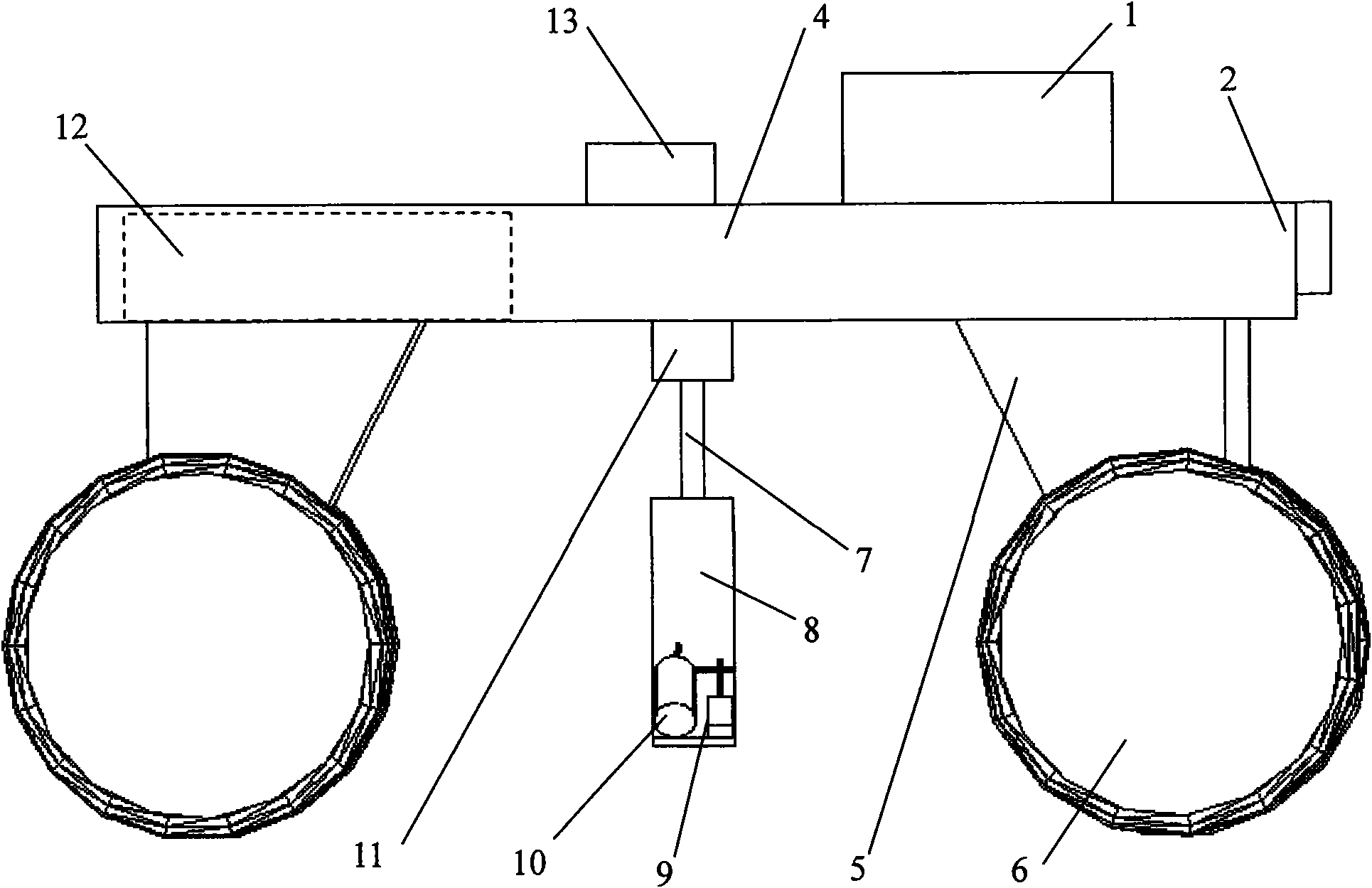

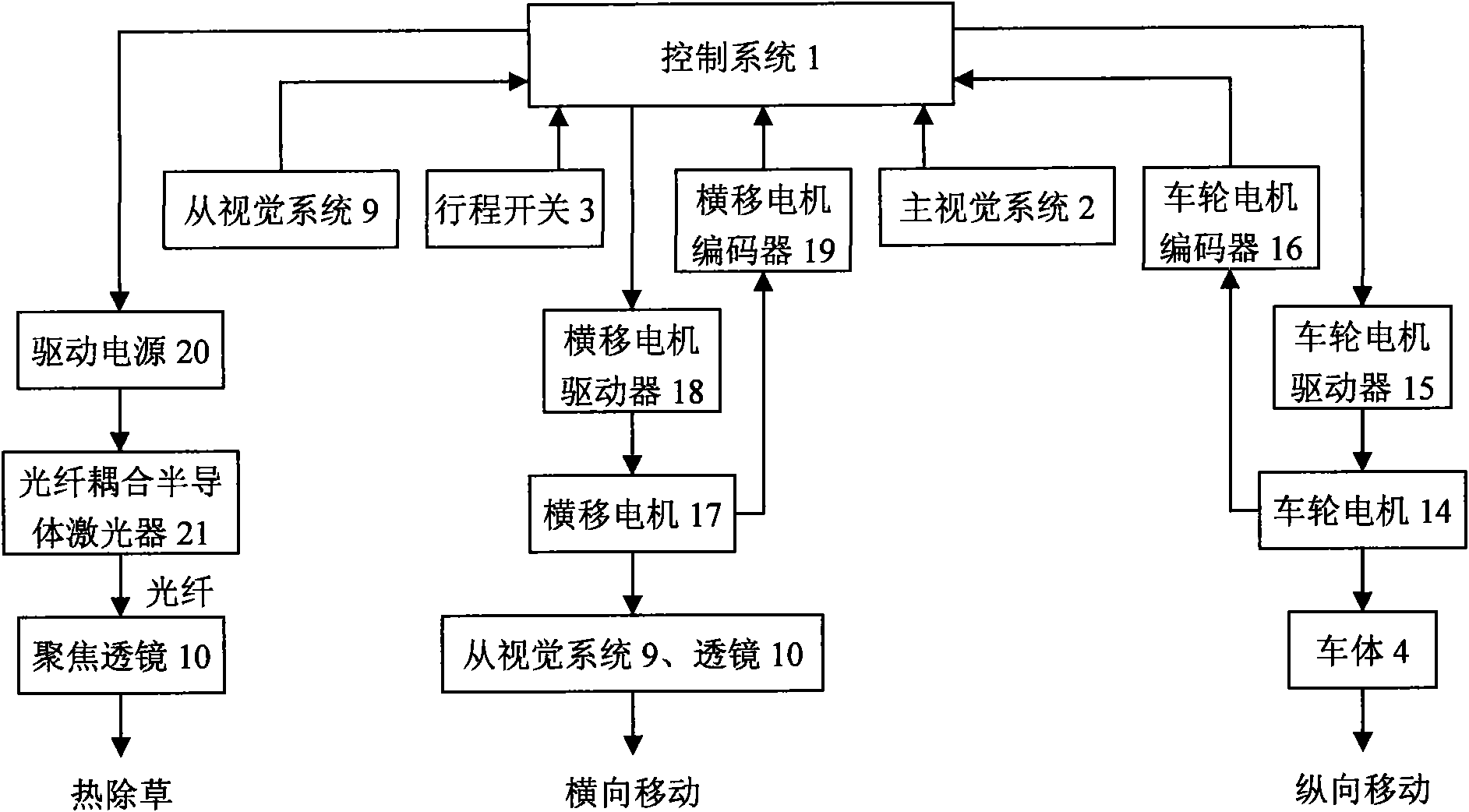

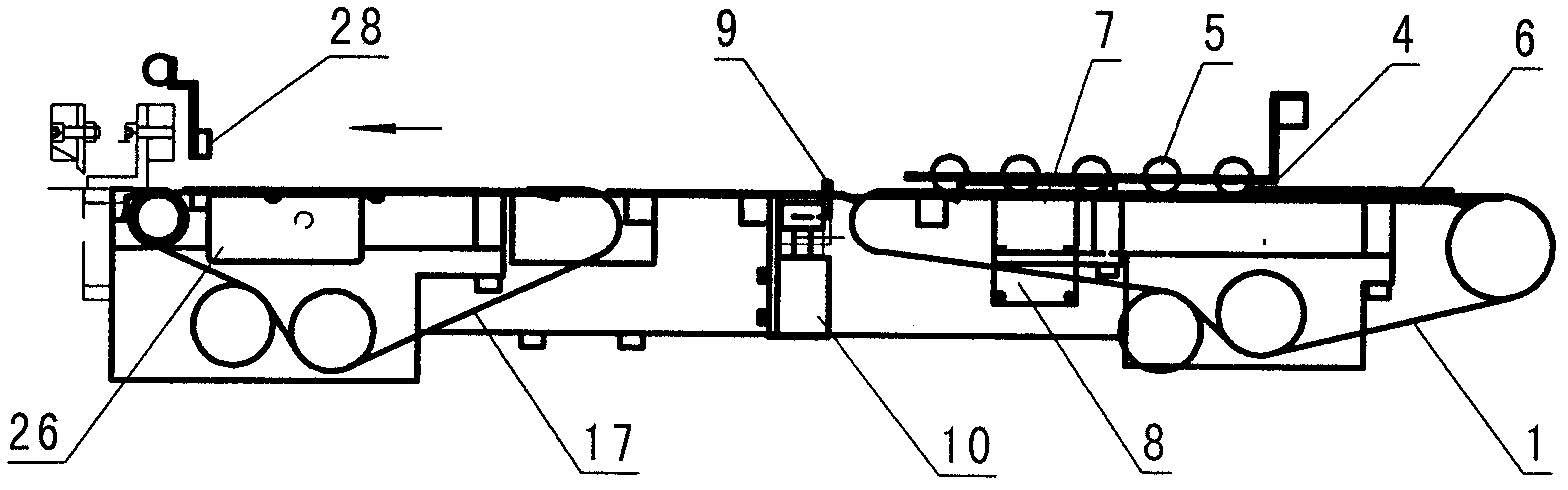

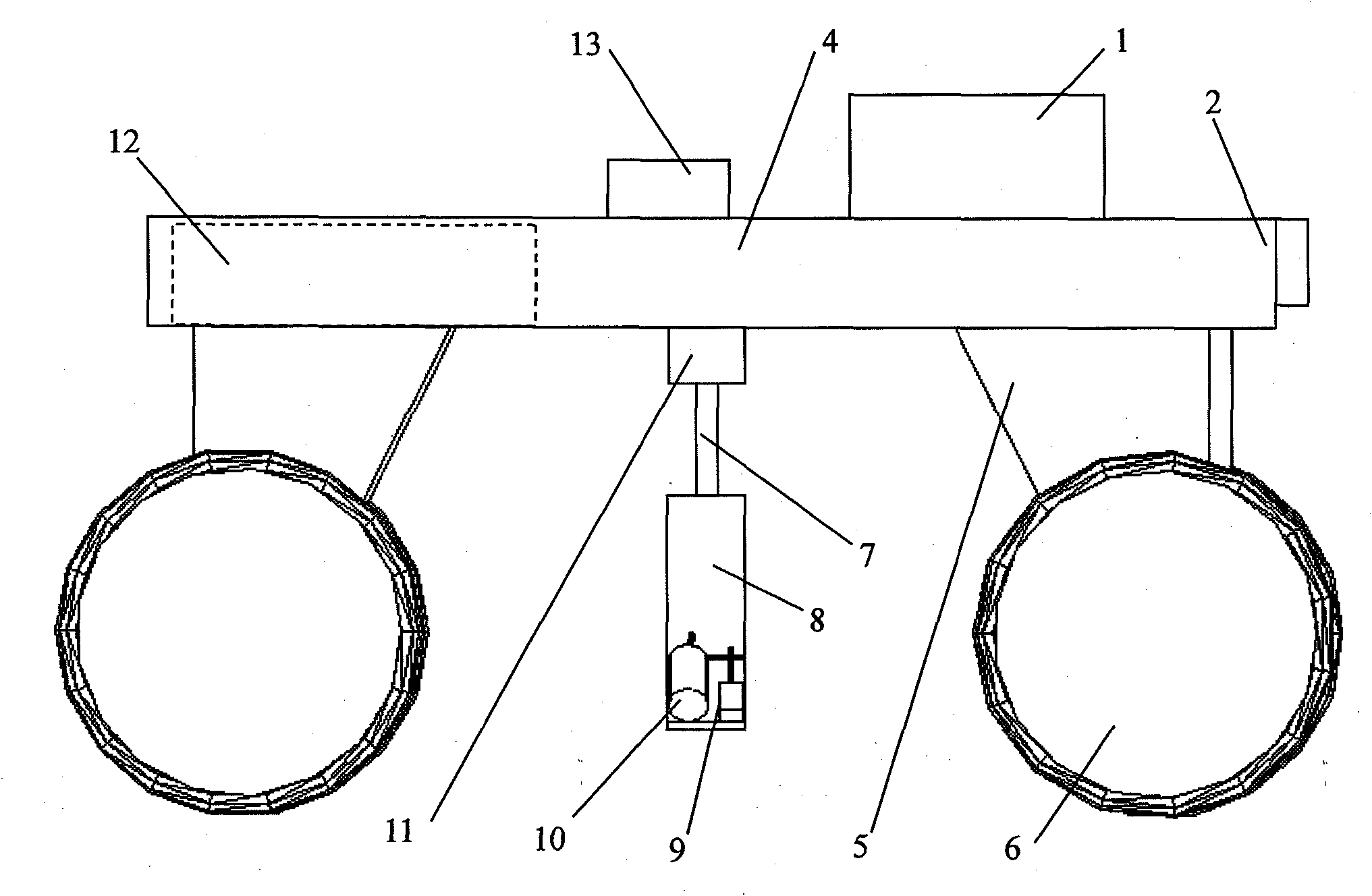

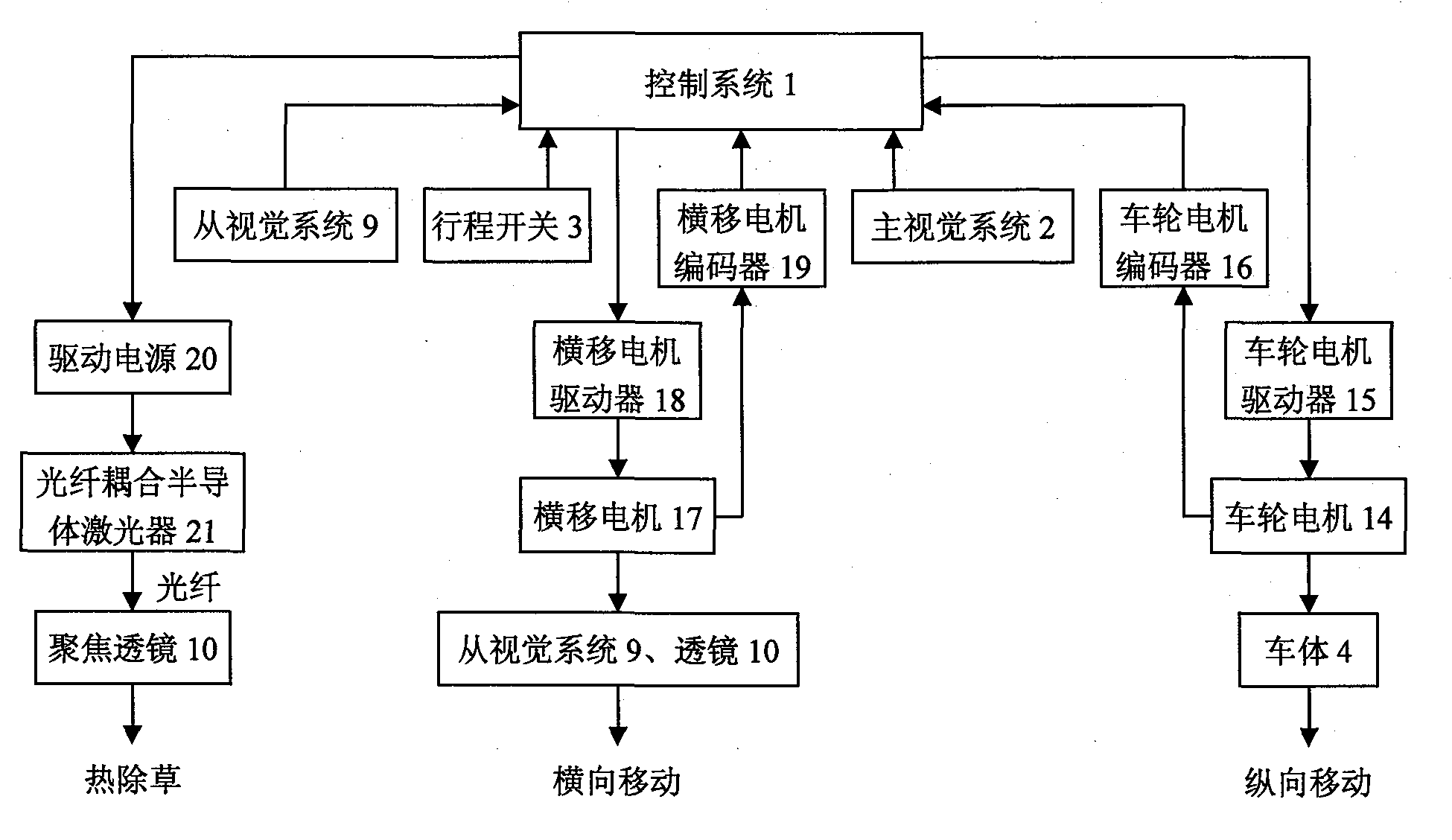

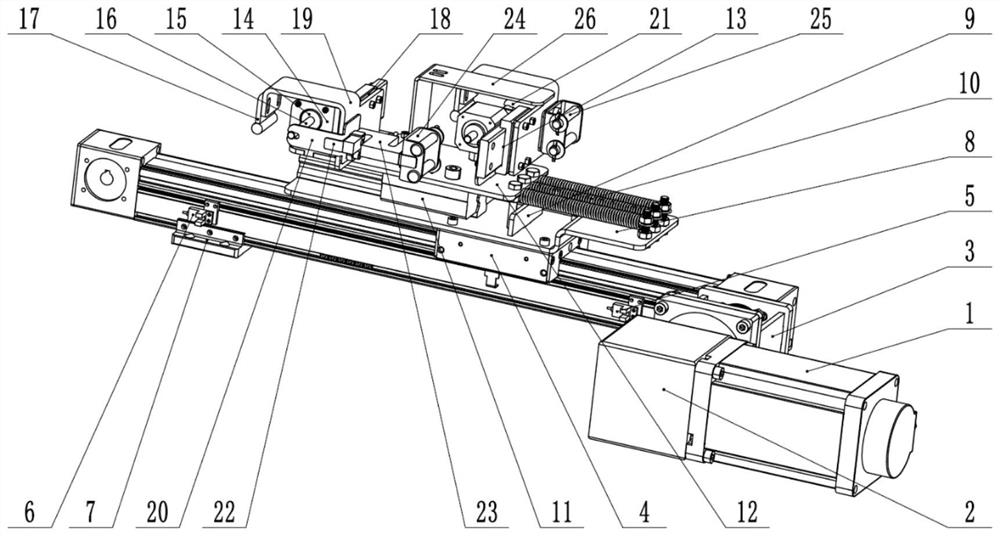

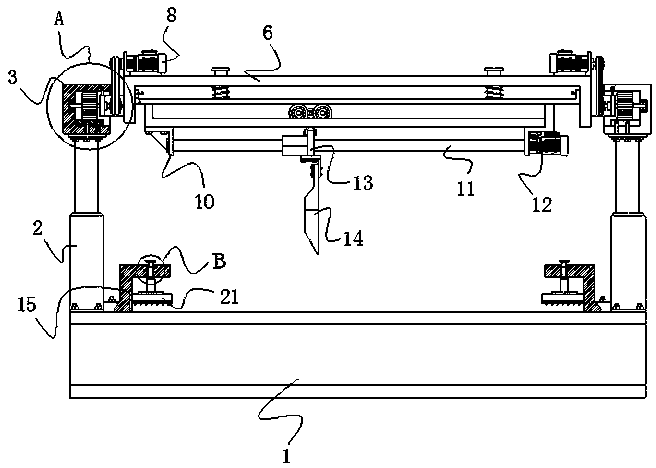

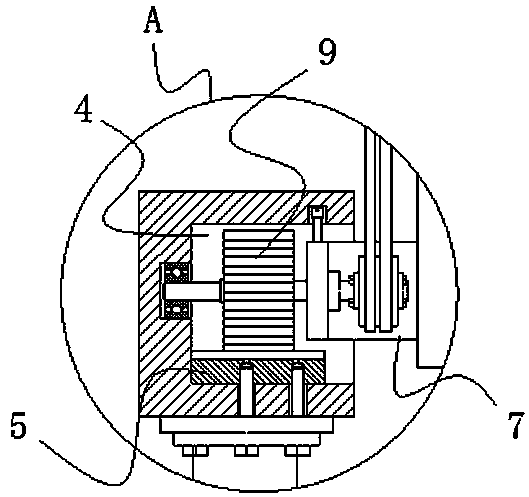

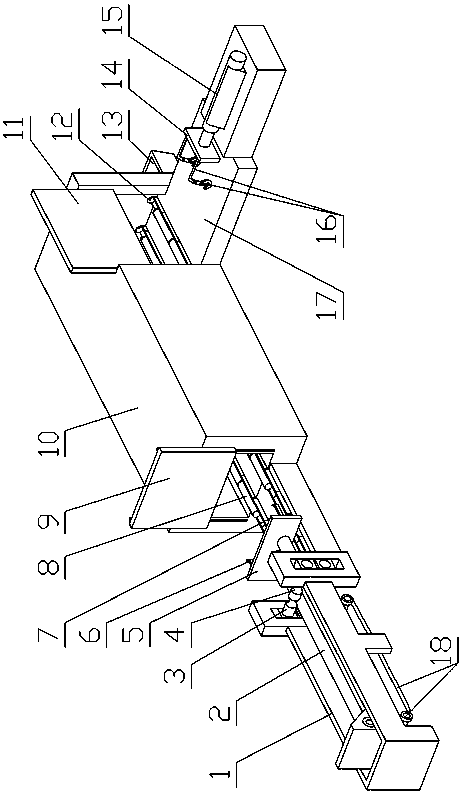

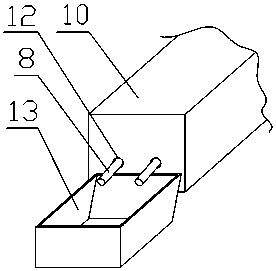

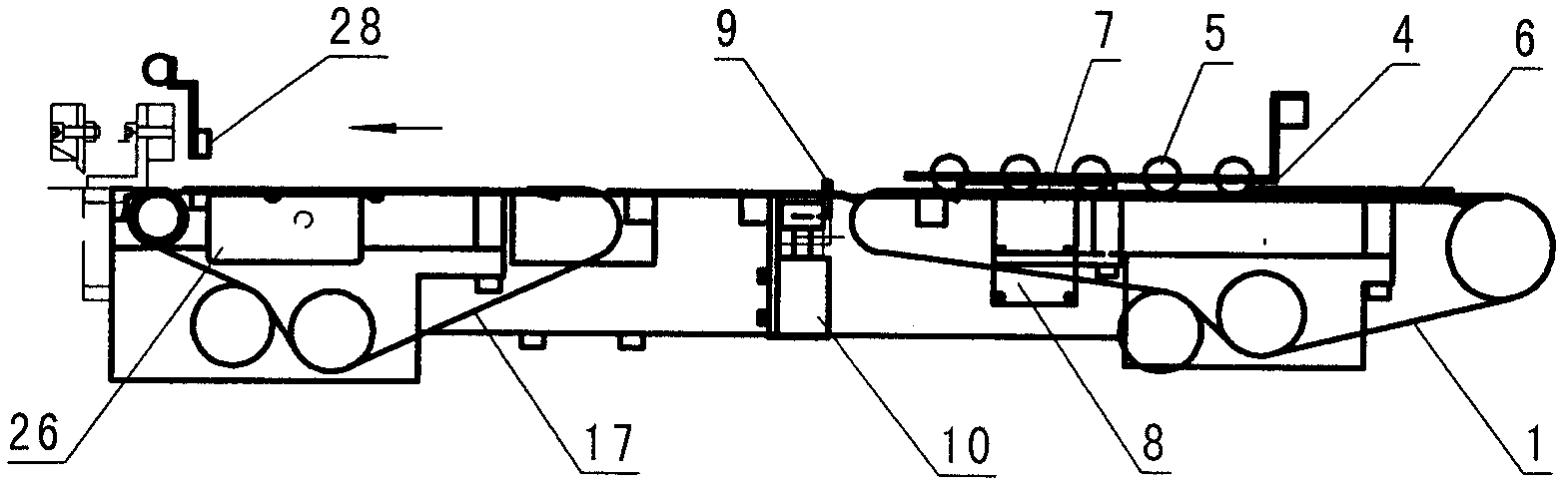

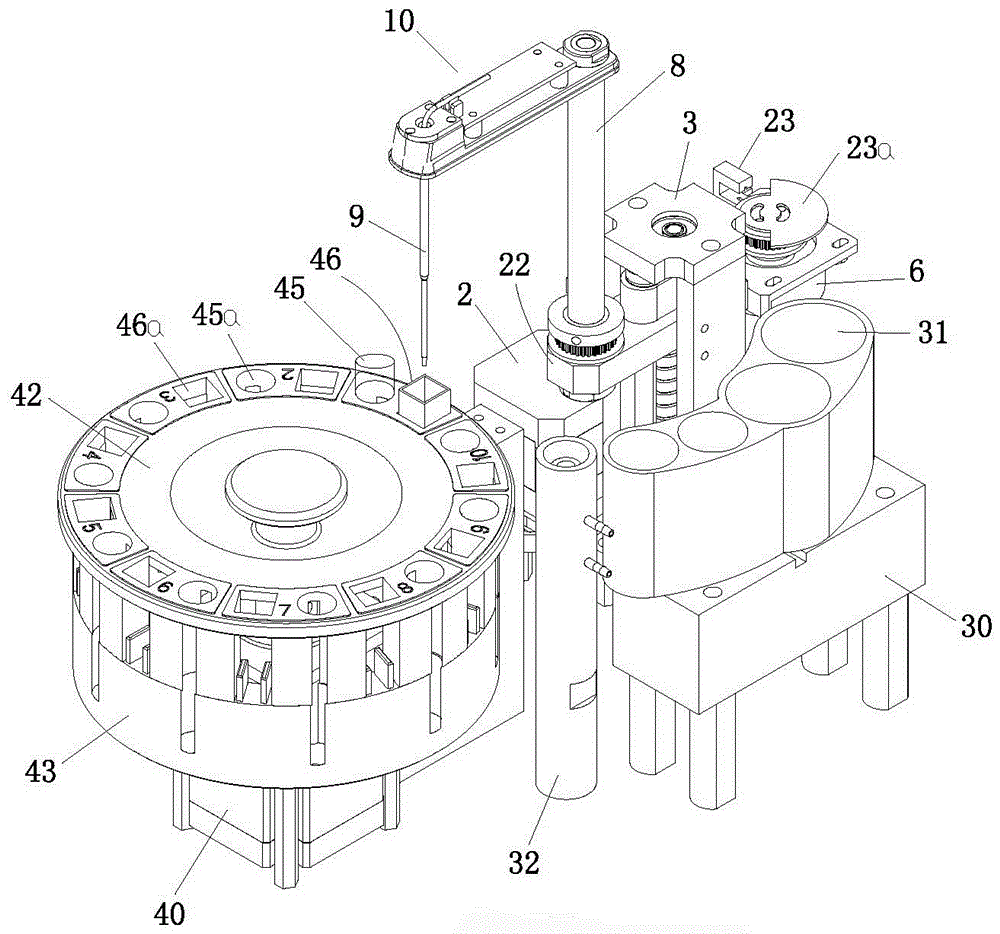

The invention discloses a laser weeding robot and relates to the field of agricultural robots. The laser weeding robot consists of an autonomous mobile vehicle, a transverse motion device, a laser weeding device and a control system (1). A primary vision system (2) detects forward information so as to guide the autonomous mobile vehicle to move forward along the row direction of crops and a secondary vision system (9) identifies and positions grass at the same time; the control system (1) controls the forward motion of the autonomous mobile vehicle along the row direction of the crops according to the position information of grass; and at the same time, the transverse motion device controls a focus lens (10) to move transversely in a direction perpendicular to the row direction of the crops to focus a laser beam on the grass accurately to cut or burn the grass by the heat effect generated by the laser on the grass. The laser weeding robot is accurate and quick in action and suitable for weeding between rows and around crop seedlings, avoids plowed earth covering the seedlings, greatly reduces the rate of damage to the crop seedlings, and is low in energy consumption and high in universality.

Owner:JIANGSU UNIV

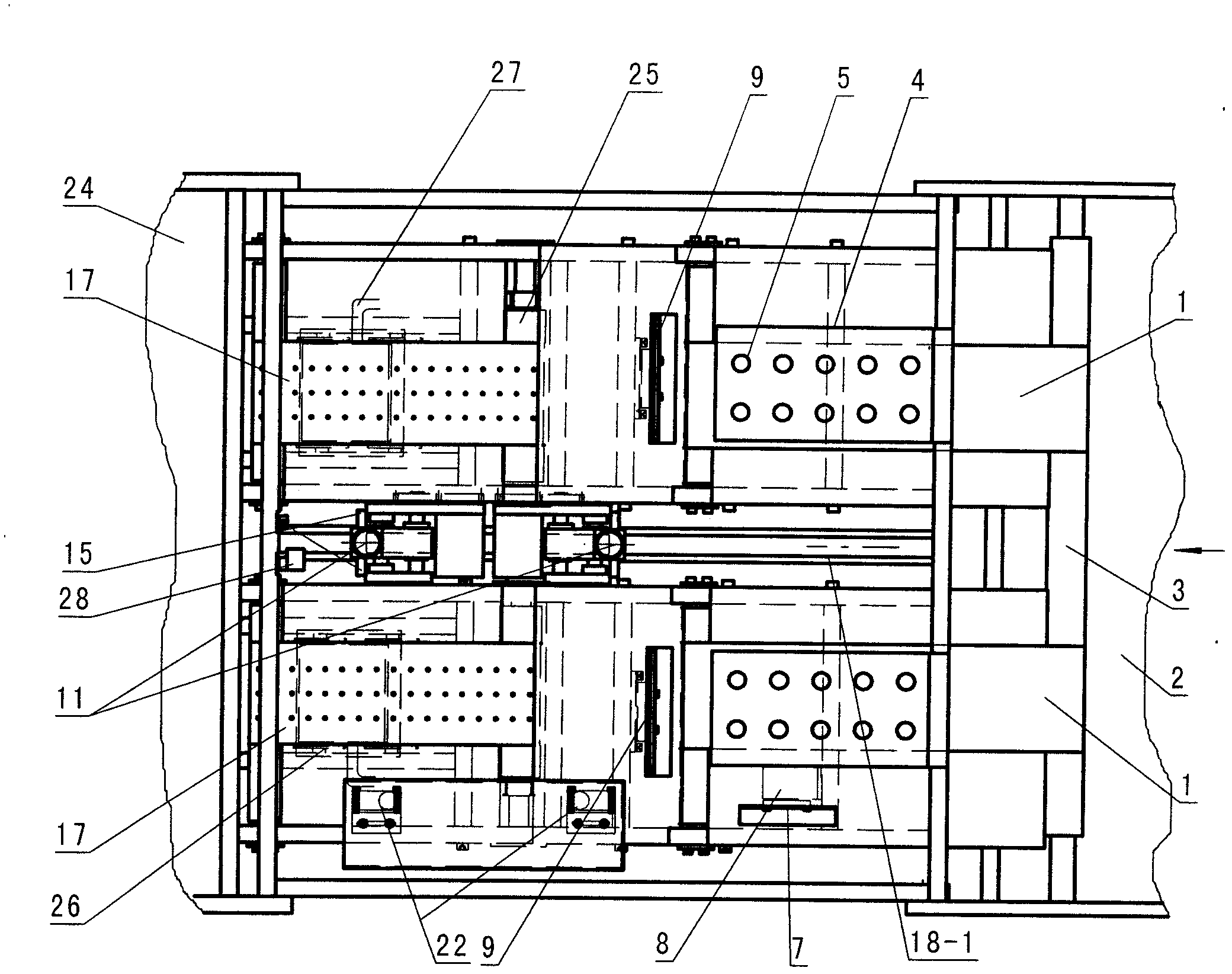

Aluminum product high-pressure casting device and method

The invention discloses a novel aluminum product high-pressure casting machine and relates to the field of metal product casting. A traditional structure is improved, operation is more convenient and accurate, casting efficiency is improved, the density of products is improved by applying high pressure in a sequential increasing mode, the surface quality and the mechanical performance of the products are improved, the weight of the products is reduced under the premise that quality of the products is improved, and energy is saved.

Owner:TAIAN XINCHUANG ALUMINUM PROD CO LTD

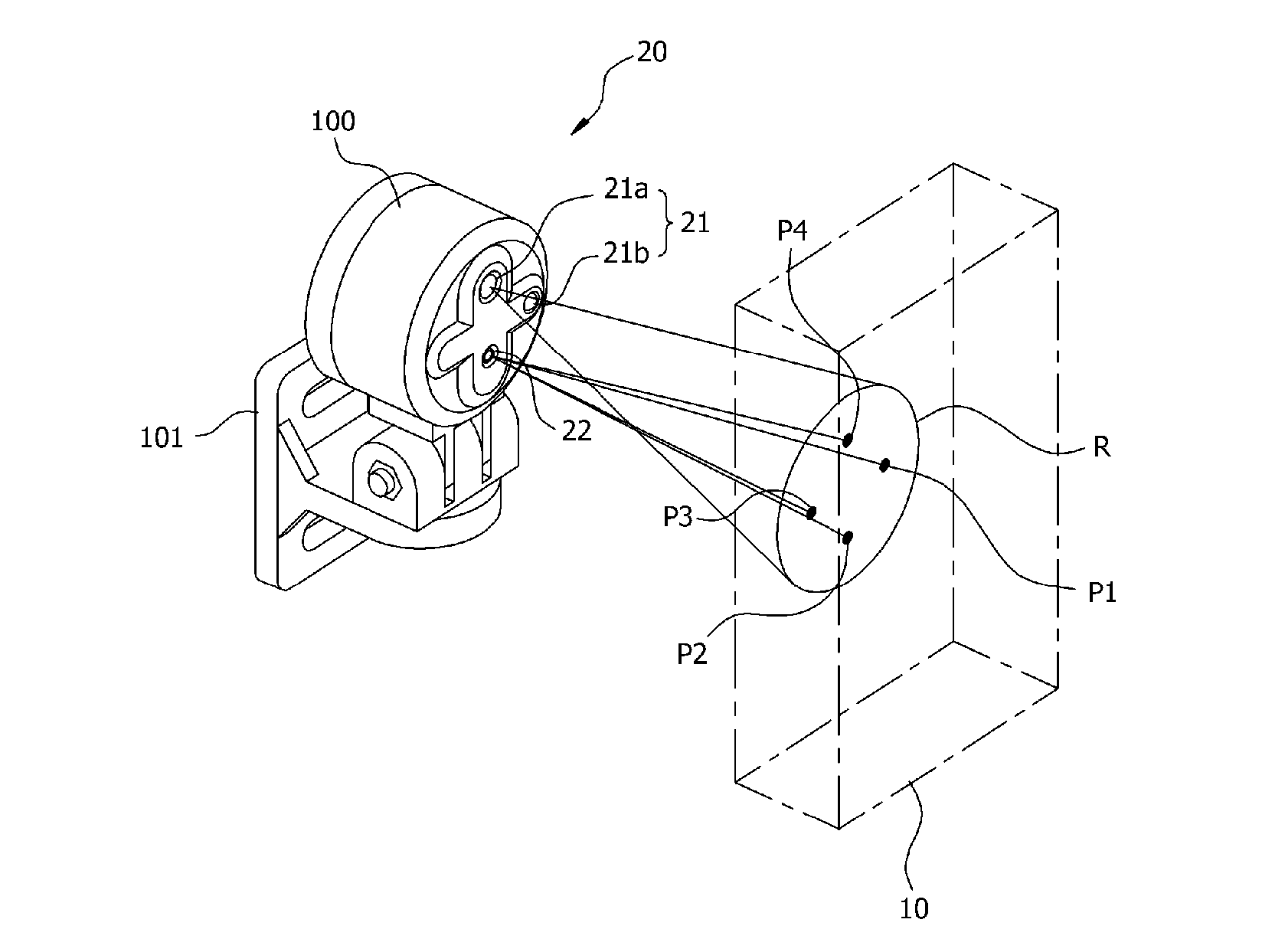

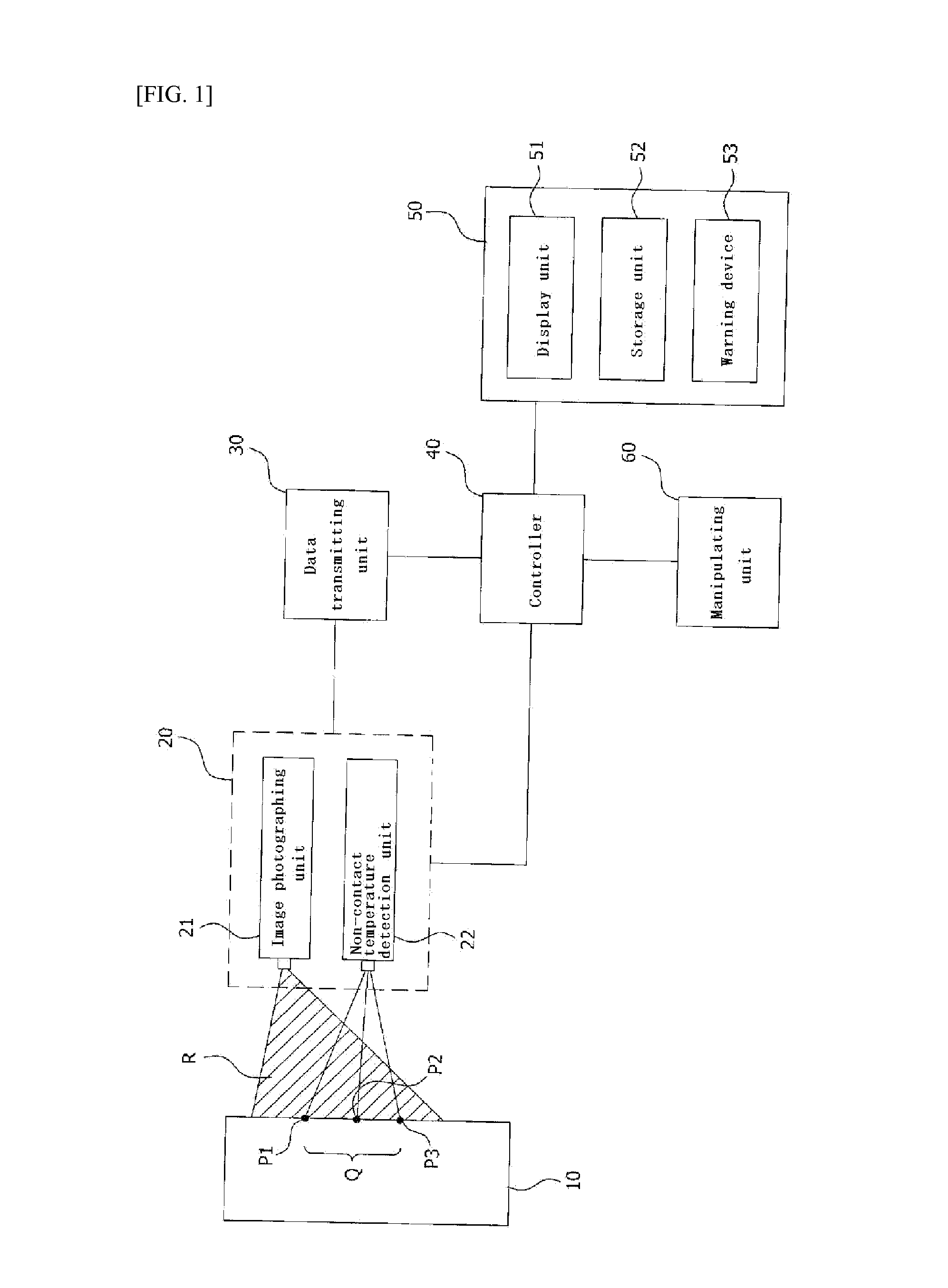

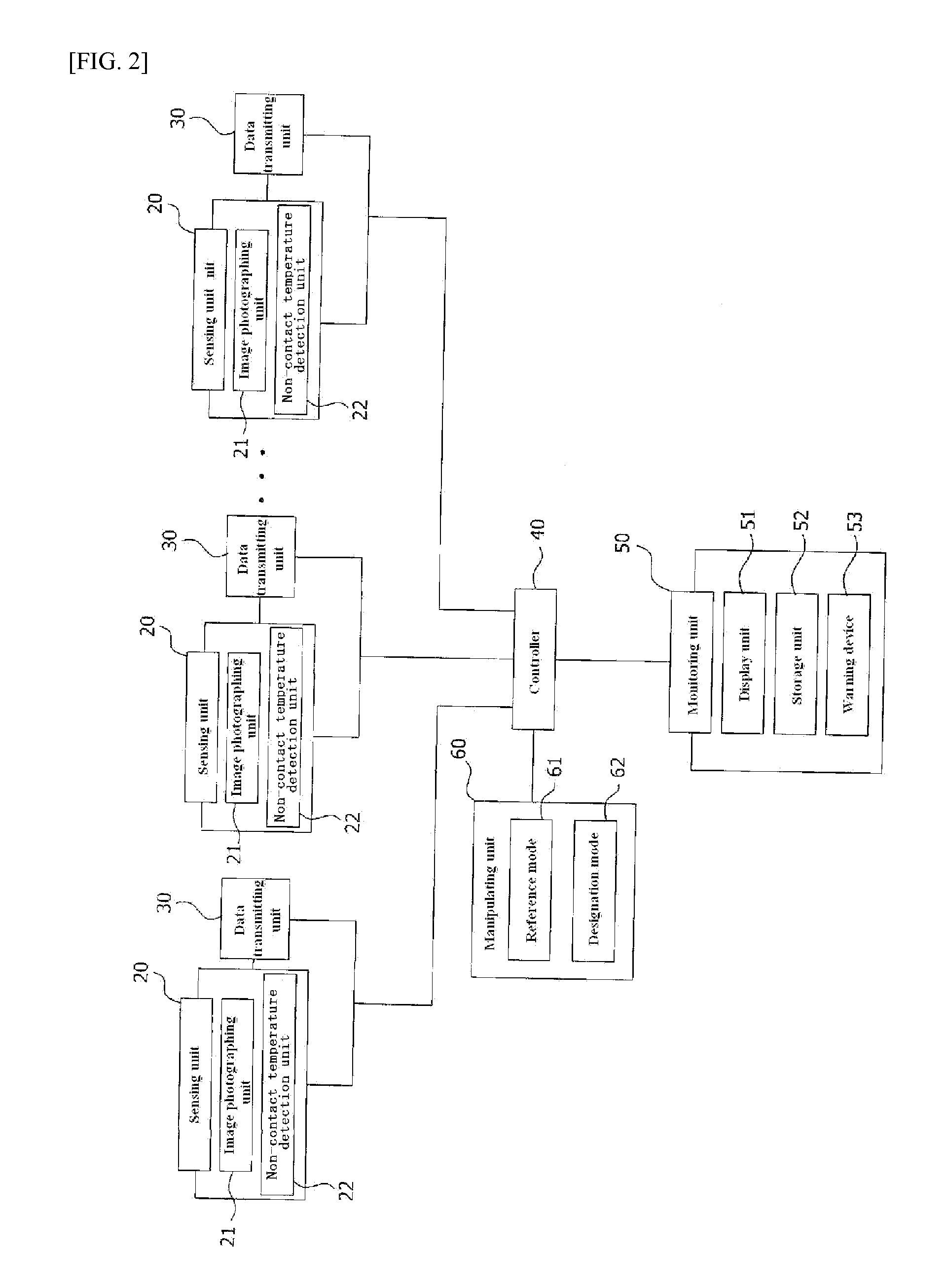

Non-contact temperature monitoring device

InactiveUS20140219314A1Accurate graspQuick and accurateThermometer detailsElectric signal transmission systemsEngineeringSTI Outpatient

The present invention pertains to a non-contact temperature monitoring device, wherein: temperature data and image data are simultaneously outputted to a monitoring unit by simultaneously photographing a temperature detection target and detecting the temperature of the temperature detection target in a non-contact manner, in which the temperature state of the temperature detection target and on-site conditions can be monitored in real time; the state of the temperature detection target is photographed using an image capturing unit only when the temperature state of the temperature detection target is abnormal, thereby simplifying an operation in a normal state and more accurately detecting on-site conditions using image information in emergency situations. Accordingly, quicker and more accurate responses are possible, thereby preventing fire accidents in industrial settings.

Owner:RYOU DEOG BONG

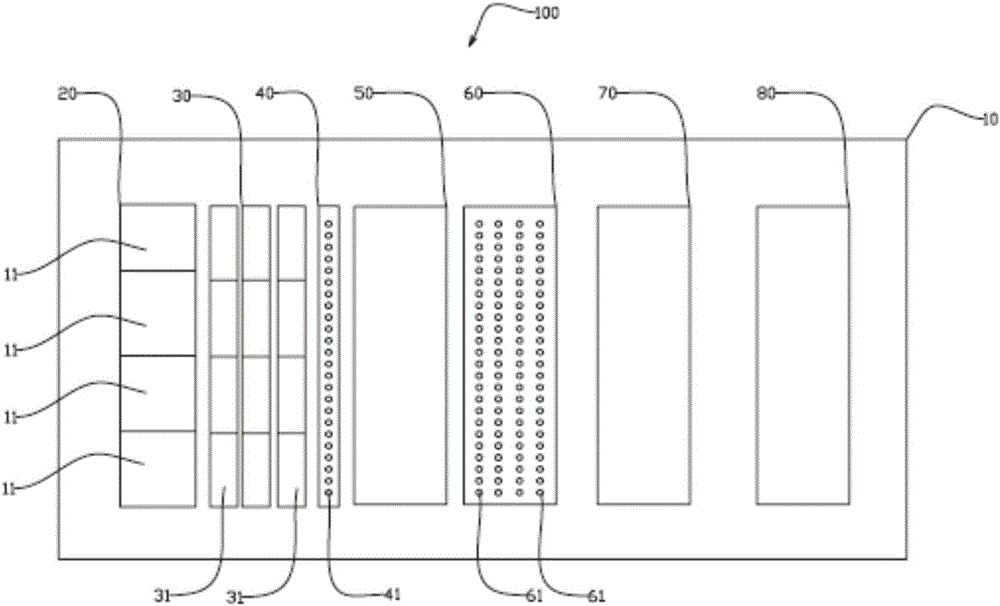

Fully-automatic card conveying, detecting and locating device

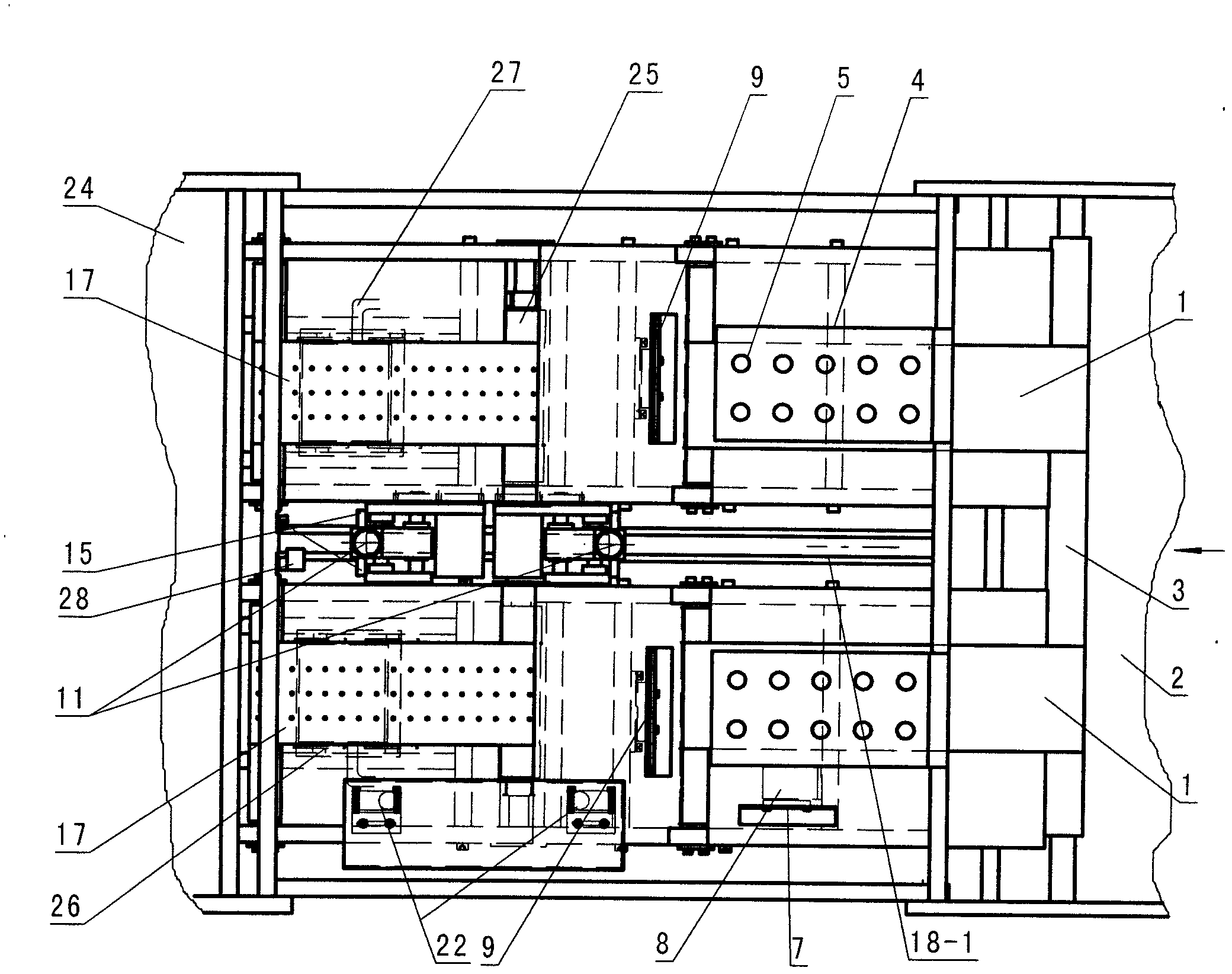

ActiveCN102874620AQuick and accurateImprove work efficiencyRegistering devicesMetal working apparatusEngineeringFully automatic

The invention relates to a conveying, detecting and locating device for a hard sequence card. The device is used on a fully automatic dividing and cutting machine for the hard card which is made of a polyvinyl chloride (PVC) material as a representative, belongs to the field of printing and packaging machinery, and comprises a conveyor belt, a side locating plate, a front locating plate, a nozzle assembly, a side detection switch, an induced-draught belt, a front detection switch and a control system. The device overcomes the defects of low efficiency, time and labor waste and low precision due to manual card conveying of the conventional card cutting machine, implements the automatic conveying, detection, location and adjustment for the hard sequence card, is fast and precise in action, and can obviously improve the working efficiency and effectively improve the process precision of conveying the card, so as to ensure the dividing and cutting qualities, avoid manual card conveying and location, and liberate the productivity. The device can also be used for the automatic conveying, detection, location and adjustment of the hard card made of a non-PVC material or a common paper card.

Owner:YUTIAN UANCHOR PACKAGING MACHINERY

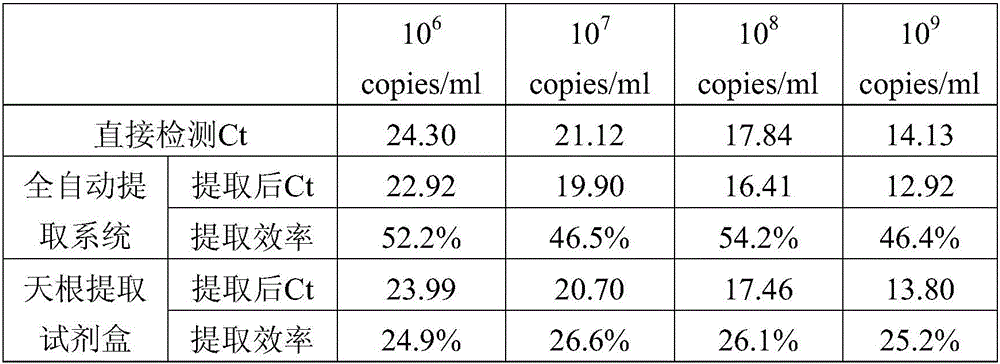

Free DNA extraction kit and application thereof

InactiveCN105861493ASimple compositionEasy to operateMicrobiological testing/measurementDNA preparationLysisAlcohol

The invention discloses a free DNA extraction kit. The kit comprises a lysis solution, a scrubbing solution A, a scrubbing solution B, an inhibitor, magnetic beads and eluent, wherein the concentration of alcohol in the scrubbing solution B can be lower than 1%, or the scrubbing solution B is completely free of alcohol and surfactant. The invention further provides a full-automatic nucleic acid extraction system which is used in cooperation with the kit or comprises or integrates the kit. The kit is particularly suitable for extracting short-fragment DNA like plasma free DNA, does not adversely affect following PCR reaction and has the advantages of being safe and easy to use, fast, low in cost and the like.

Owner:SHANGHAI KEHUA BIO ENG

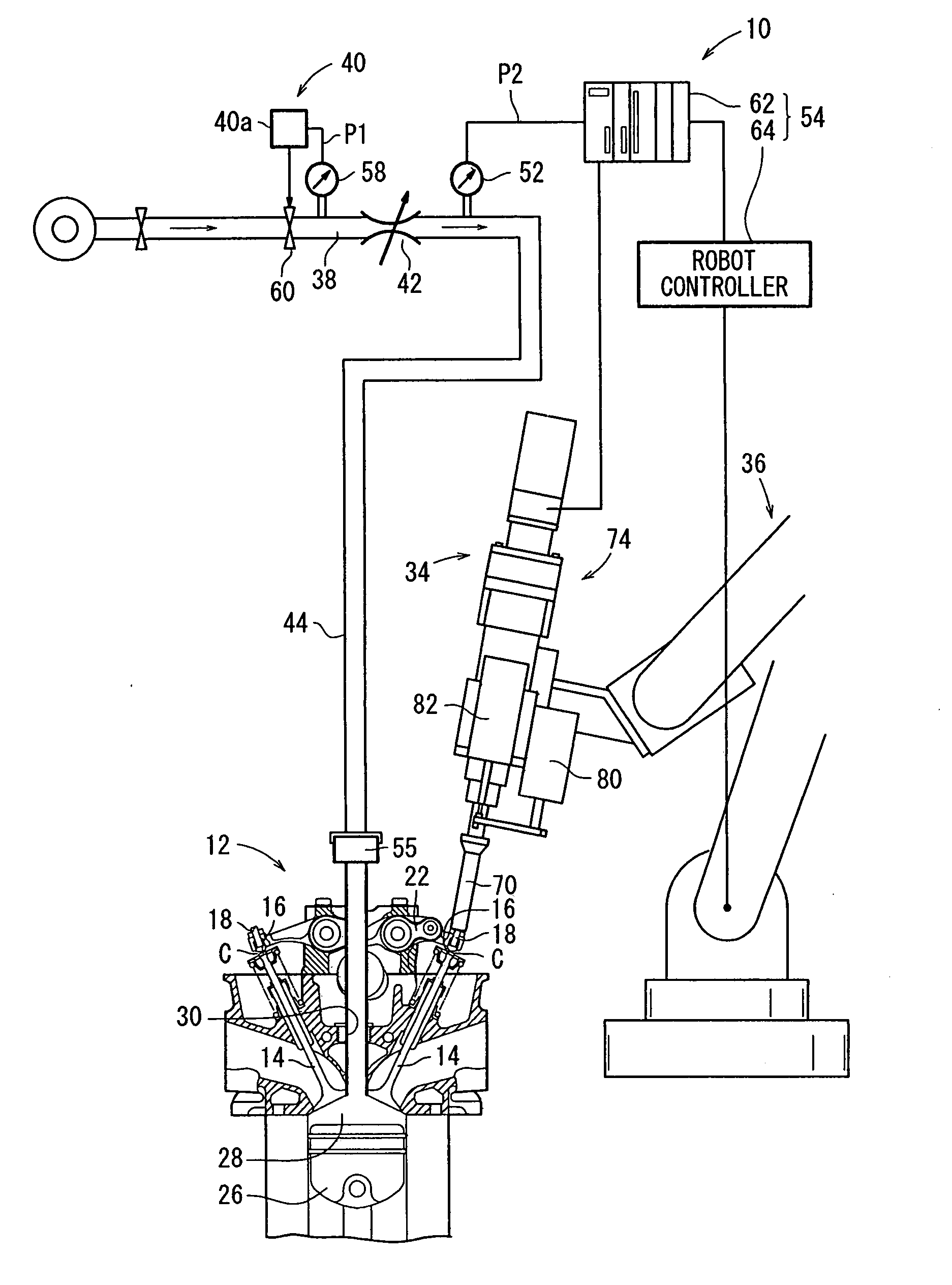

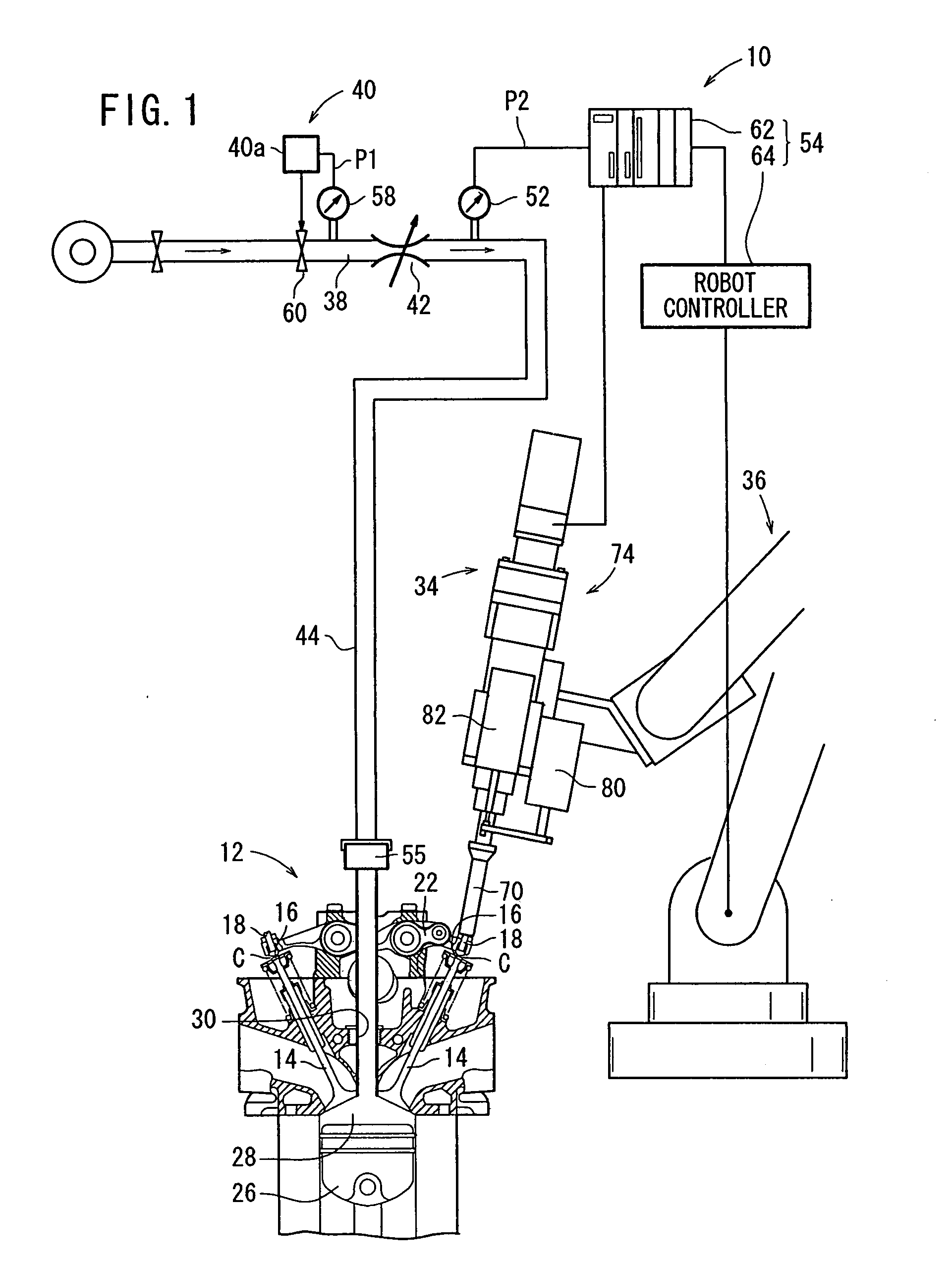

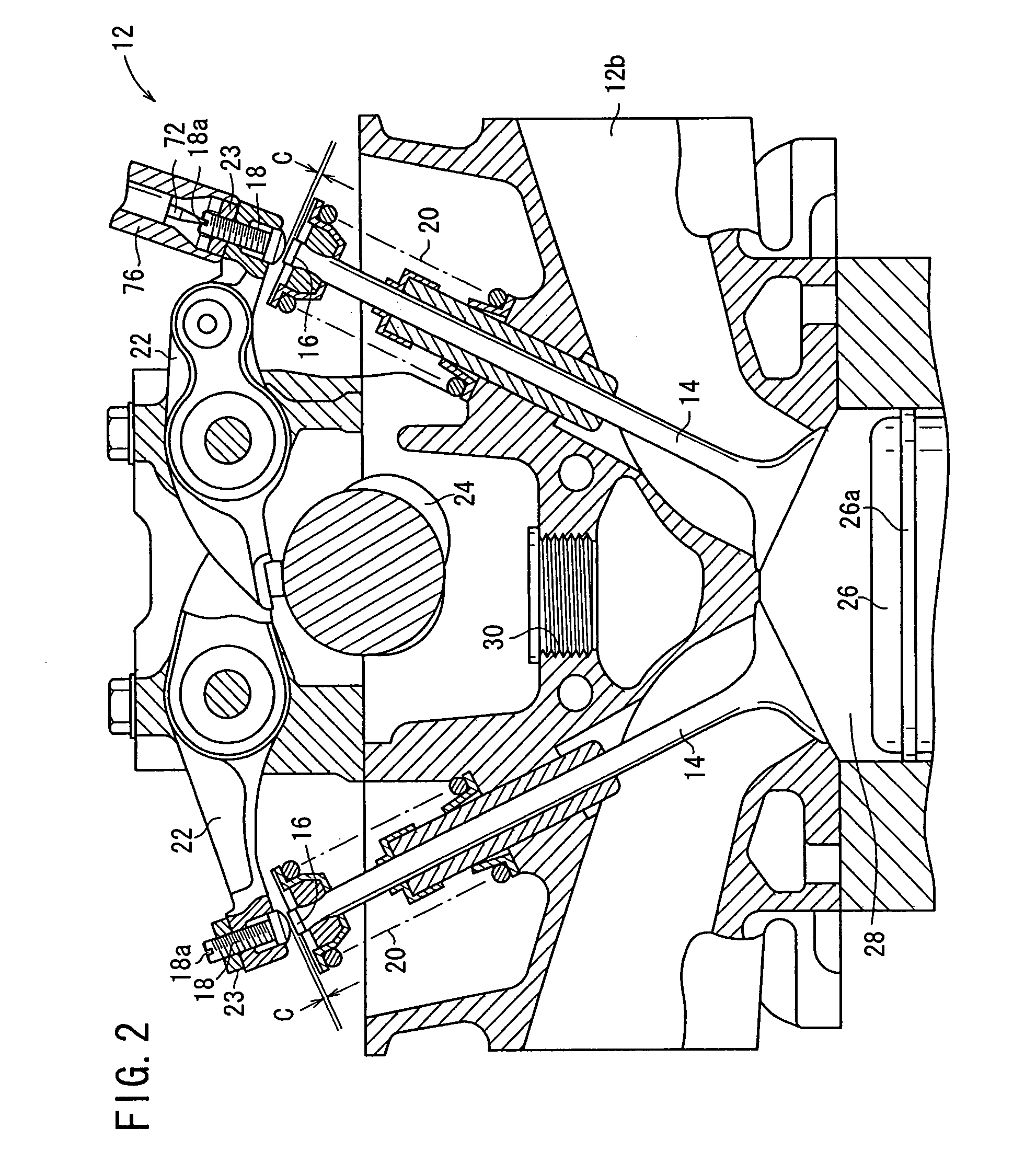

Automatic Tappet Clearance Adjusting Device

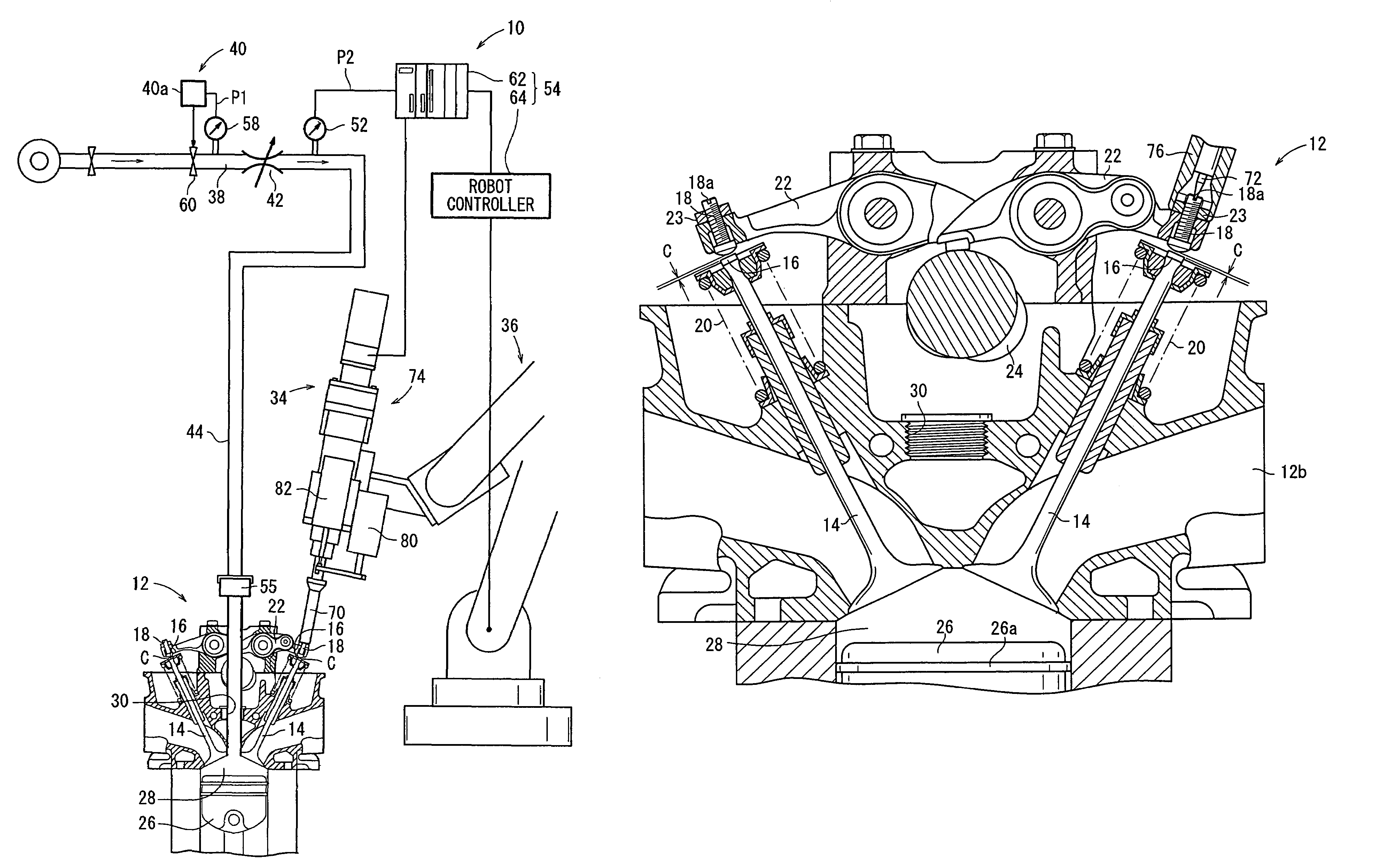

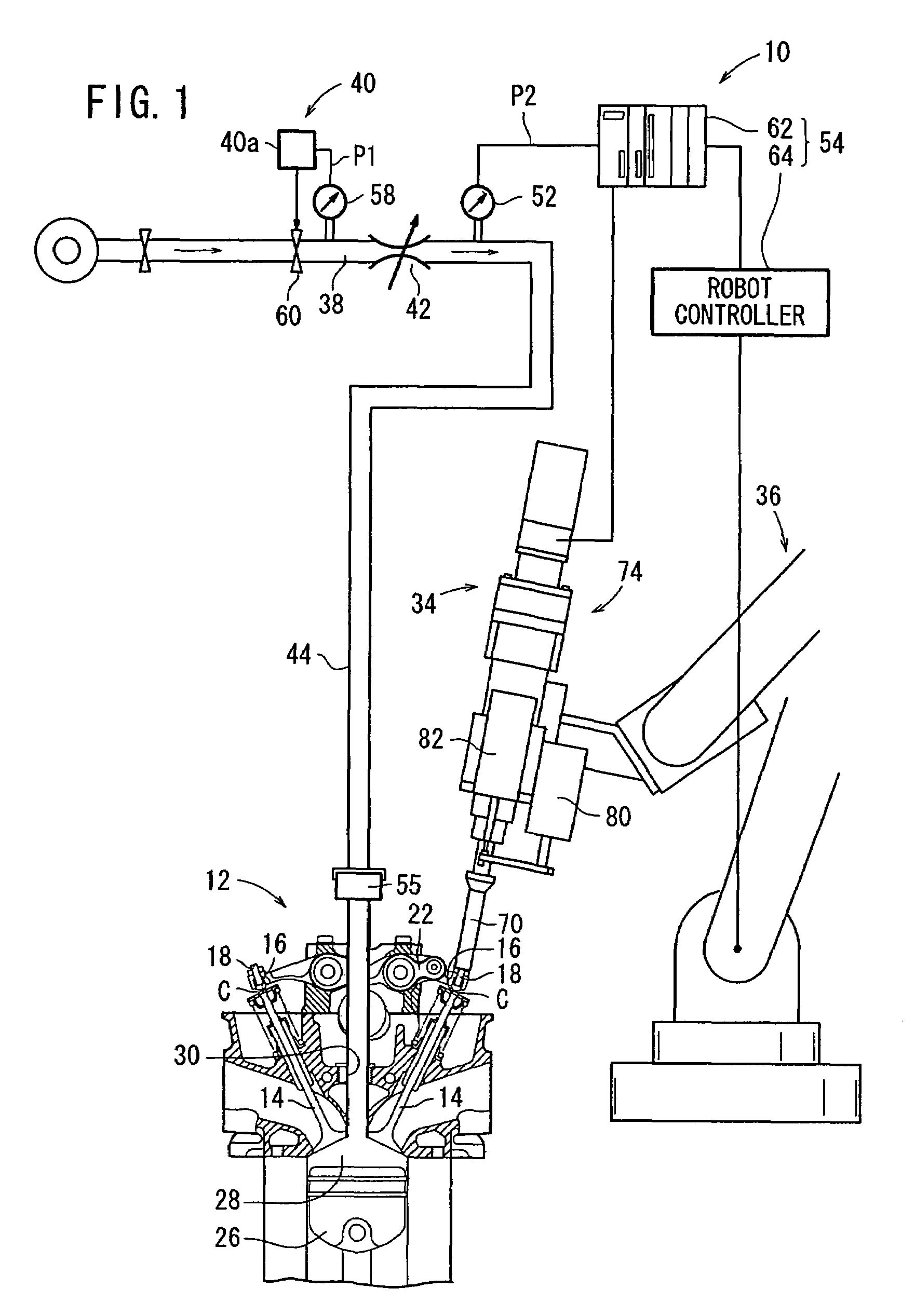

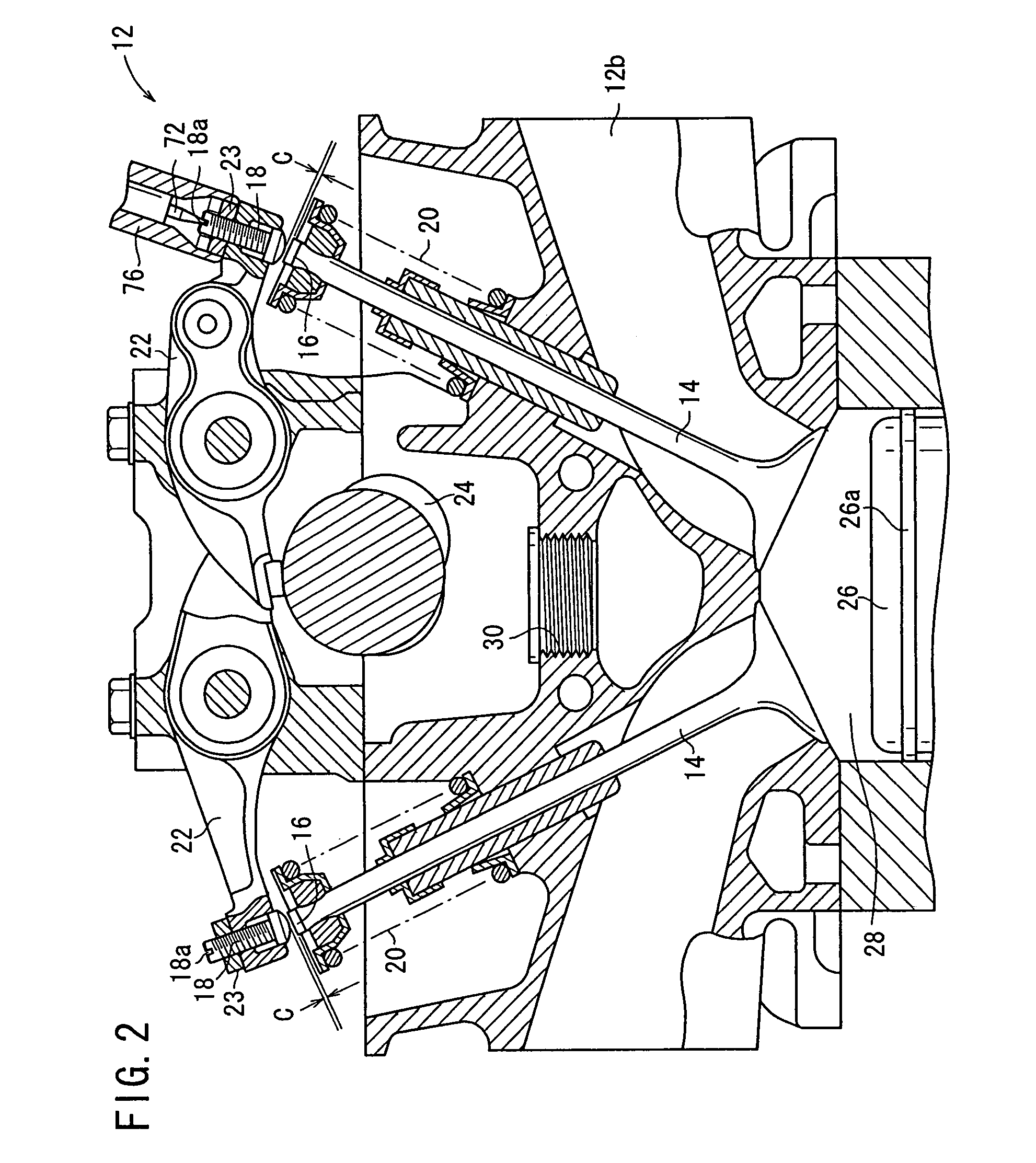

InactiveUS20080022956A1Stable pressureEasy to adjustValve arrangementsMachines/enginesCombustion chamberEngineering

An automatic tappet clearance adjusting device, comprising an adjusting unit adjusting the projected amount of a rocker arm by advancing and retreating an adjust screw to and from the tip of the rocker arm, a pressure setting part electrically controlling the pressure of an air supply source part based on the measurement signals of a primary side pressure sensor measuring the pressure of the air supply source part so that the pressure becomes a specified one, a supply pipeline allowing the air supply source part to communicate with a combustion chamber through a variable orifice, and a control mechanism part controlling the adjusting unit based on measurement signals of a secondary side pressure sensor measuring the pressure of the supply pipeline. The pressure is set to 1.5 kPa by the pressure setting part and the variable orifice.

Owner:HONDA MOTOR CO LTD

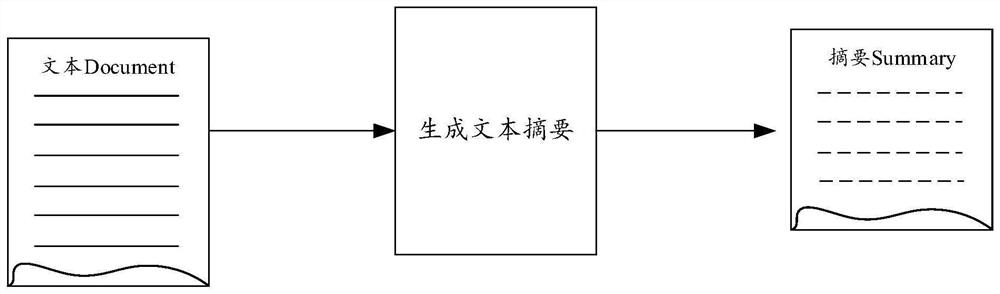

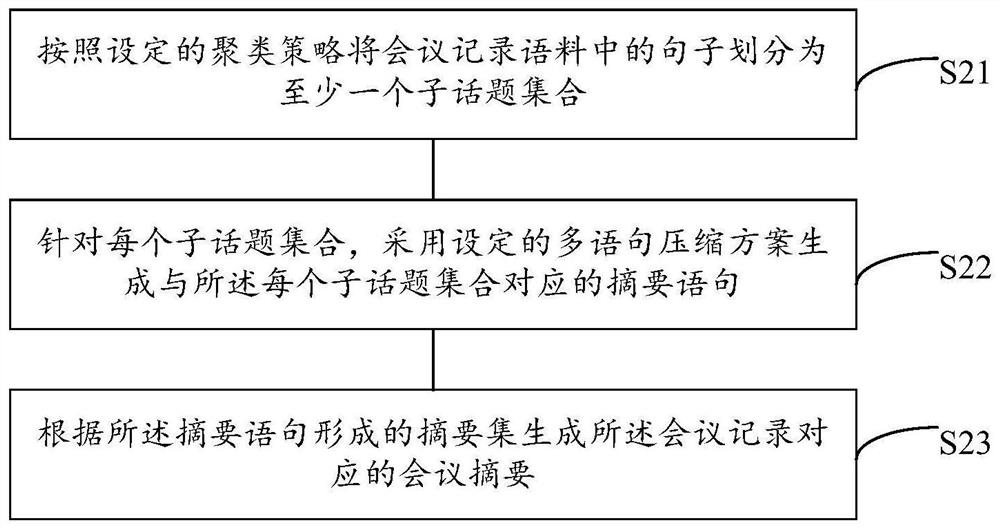

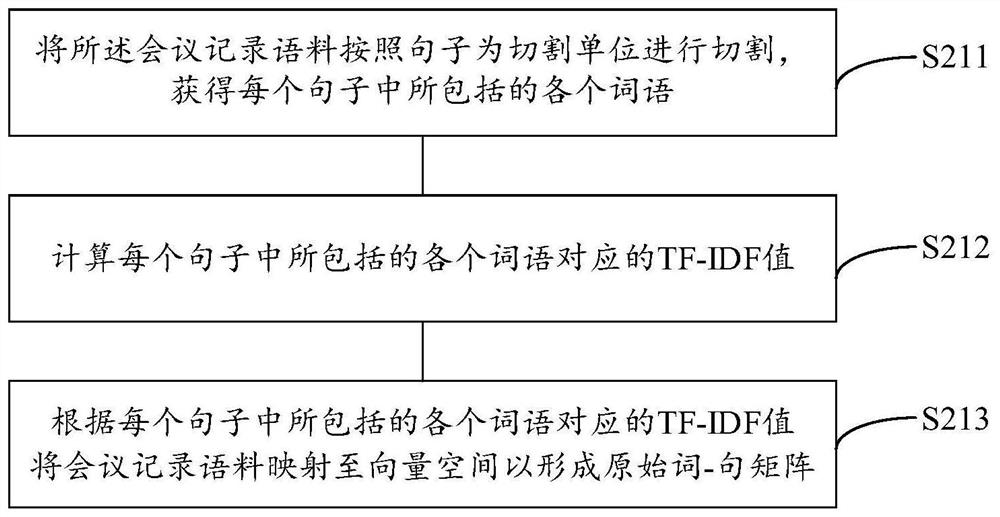

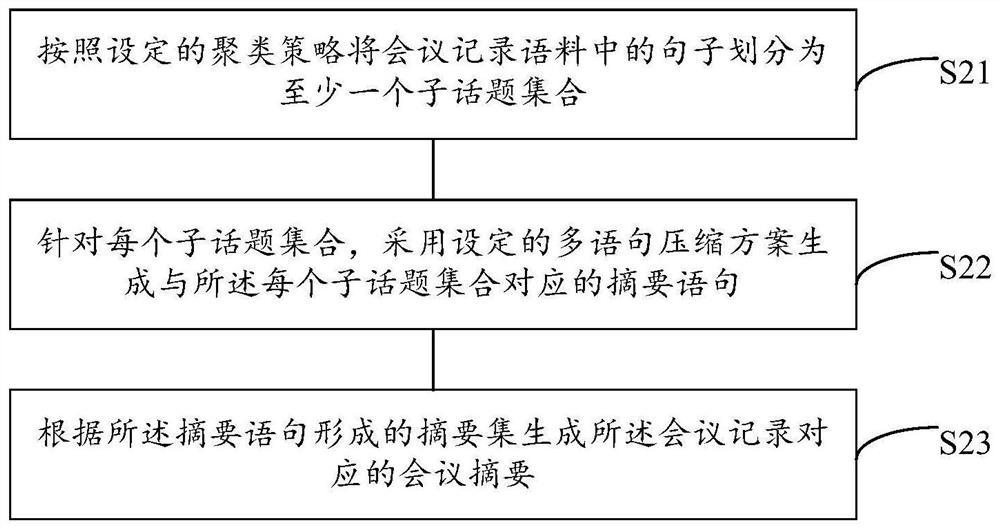

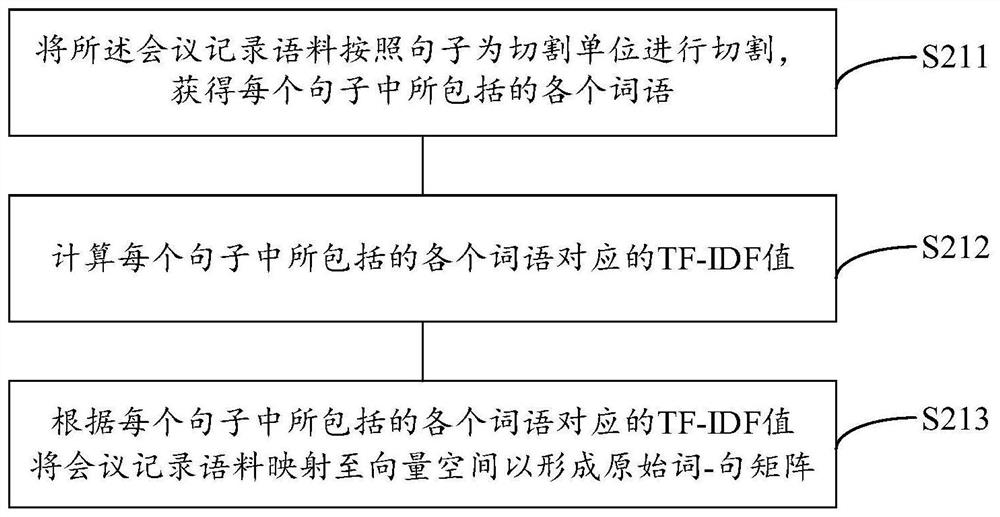

Method and device for generating conference summary based on conference records and storage medium

ActiveCN112765344AQuick and accurateImprove efficiencySemantic analysisCharacter and pattern recognitionSoftware engineeringConference note

The embodiment of the invention discloses a method and device for generating a conference summary based on conference records and a storage medium. The method can comprise the following steps: dividing sentences in a conference record corpus into at least one subtopic set according to a set clustering strategy; for each subtopic set, generating an abstract statement corresponding to each subtopic set by adopting a set multi-statement compression scheme; and generating a conference summary corresponding to the conference record according to a summary set formed by the summary statements.

Owner:HARBIN INST OF TECH

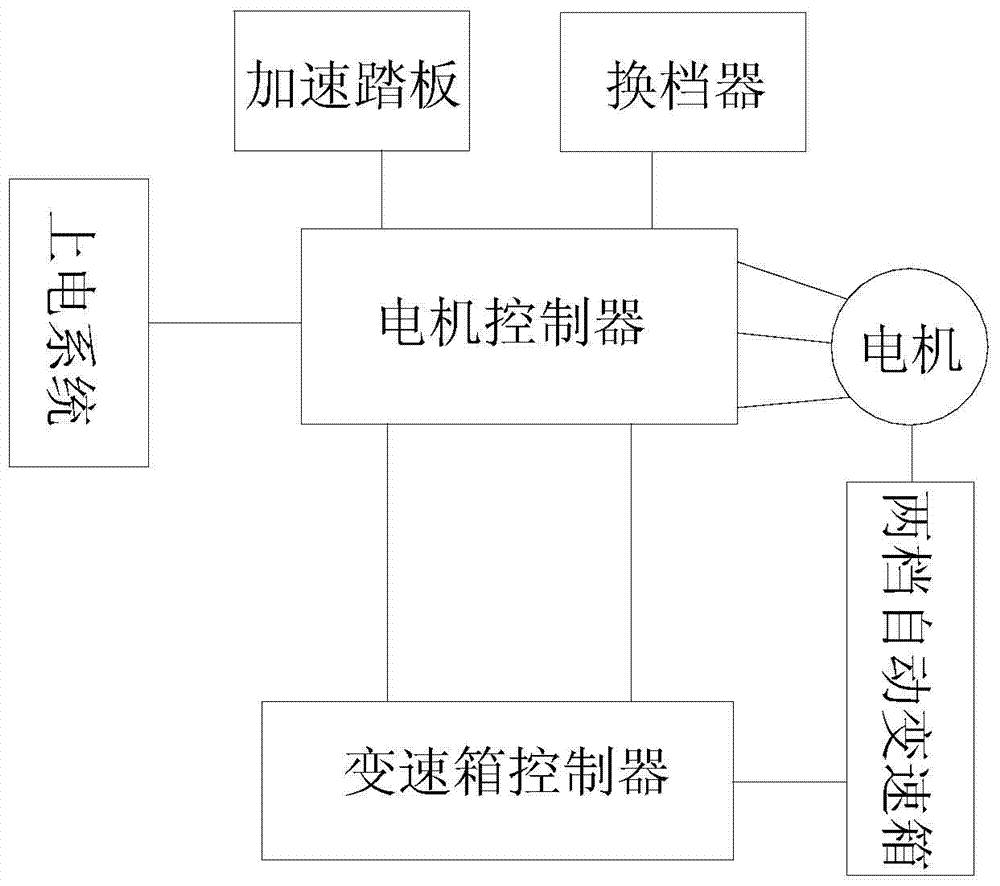

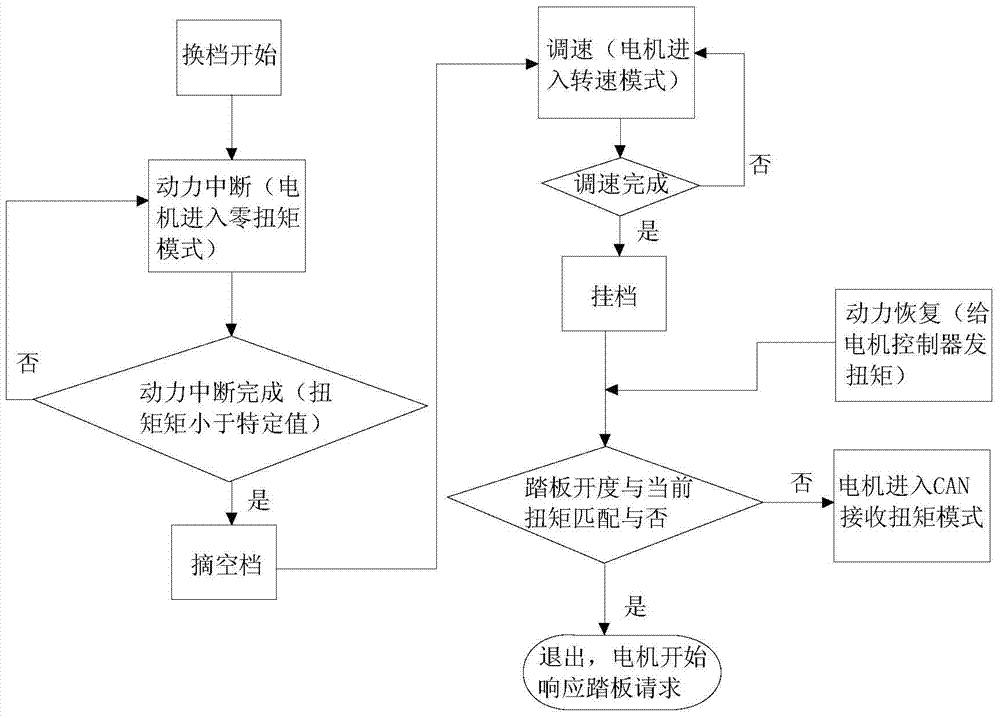

A control method and control system for automatic shifting of a two-speed transmission of an electric vehicle

InactiveCN104590265BImprove drivabilityWork lessDriver input parametersElectric machineControl system

The invention provides a control method for automatic gear shifting of an electric vehicle two-gear transmission. The control method includes the steps that after a finished vehicle is normally supplied with power, a gear shifting device is propelled to the forward gear, an accelerator pedal is treaded, a motor controller controls the output of a motor, and a transmission controller detects the rotating speed of the motor and the input quantity of the accelerator pedal. The transmission controller judges whether the finished vehicle meets the gear shifting condition or not according to the rotating speed of the motor and the input percentage of the accelerator pedal, and gear shifting is conducted when the rotating speed of the motor and the input percentage of the accelerator pedal meet the gear shifting condition; if the rotating speed of the motor and the input percentage of the accelerator pedal do not meet the gear shifting condition, the current status is maintained; the transmission controller is in communication with the motor controller, speed regulating and gear shifting begin, and the driving force of the finished vehicle is reduced to be zero; after gear shifting is completed, the finished vehicle recovers the driving force, and the finished vehicle runs continuously. The intention of a driver can be prejudged effectively, and the driving performance of the finished vehicle is good.

Owner:CHONGQING SOKON IND GRP CO LTD

Laser weeding robot

InactiveCN101589705BReduce damage rateReduce energy consumptionWeed killersMobile vehicleControl system

The invention discloses a laser weeding robot and relates to the field of agricultural robots. The laser weeding robot consists of an autonomous mobile vehicle, a transverse motion device, a laser weeding device and a control system (1). A primary vision system (2) detects forward information so as to guide the autonomous mobile vehicle to move forward along the row direction of crops and a secondary vision system (9) identifies and positions grass at the same time; the control system (1) controls the forward motion of the autonomous mobile vehicle along the row direction of the crops according to the position information of grass; and at the same time, the transverse motion device controls a focus lens (10) to move transversely in a direction perpendicular to the row direction of the crops to focus a laser beam on the grass accurately to cut or burn the grass by the heat effect generated by the laser on the grass. The laser weeding robot is accurate and quick in action and suitable for weeding between rows and around crop seedlings, avoids plowed earth covering the seedlings, greatly reduces the rate of damage to the crop seedlings, and is low in energy consumption and high in universality.

Owner:JIANGSU UNIV

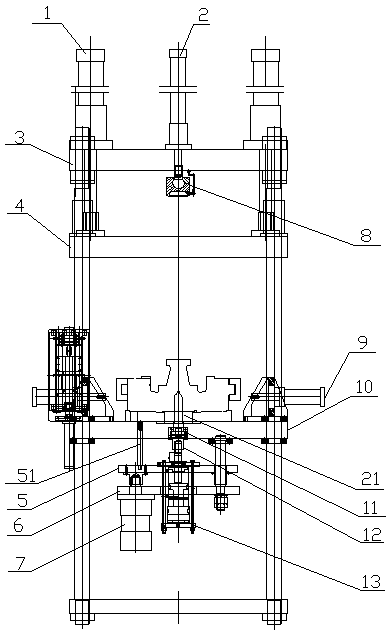

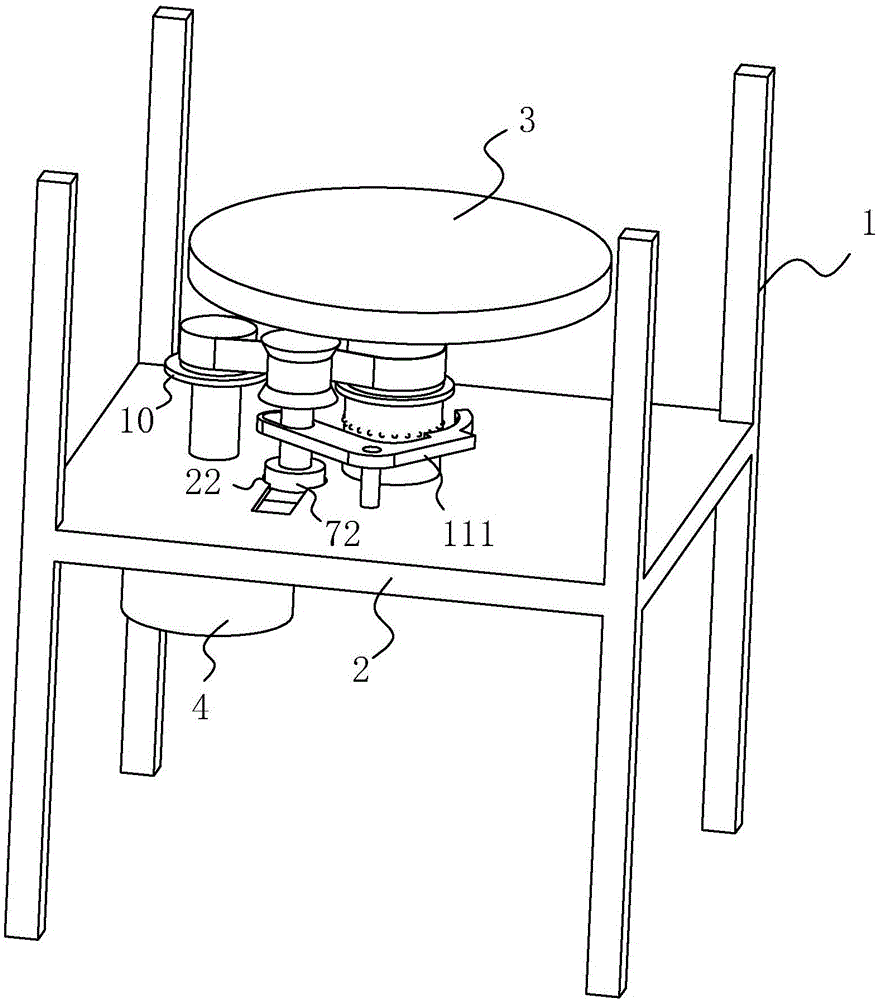

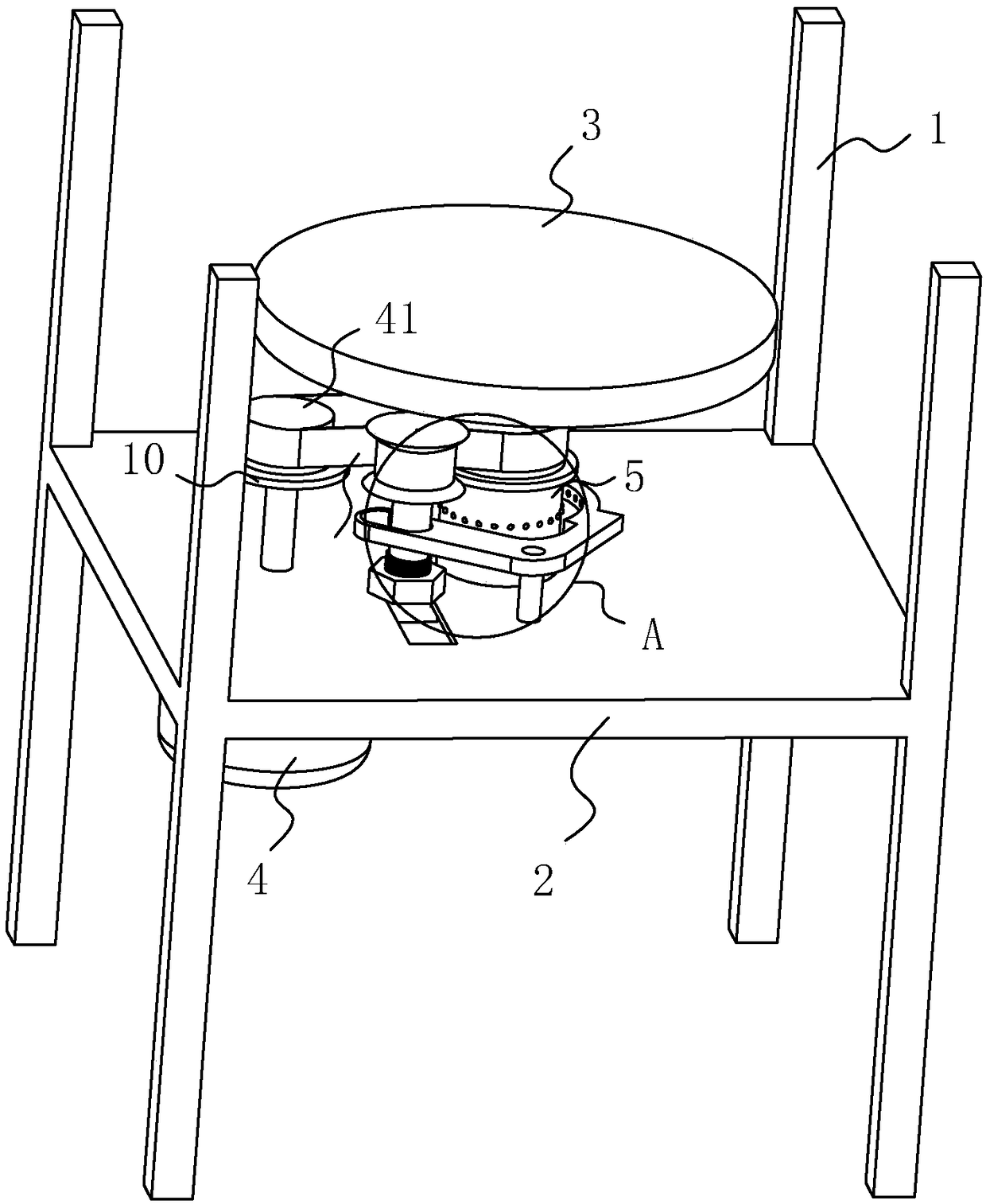

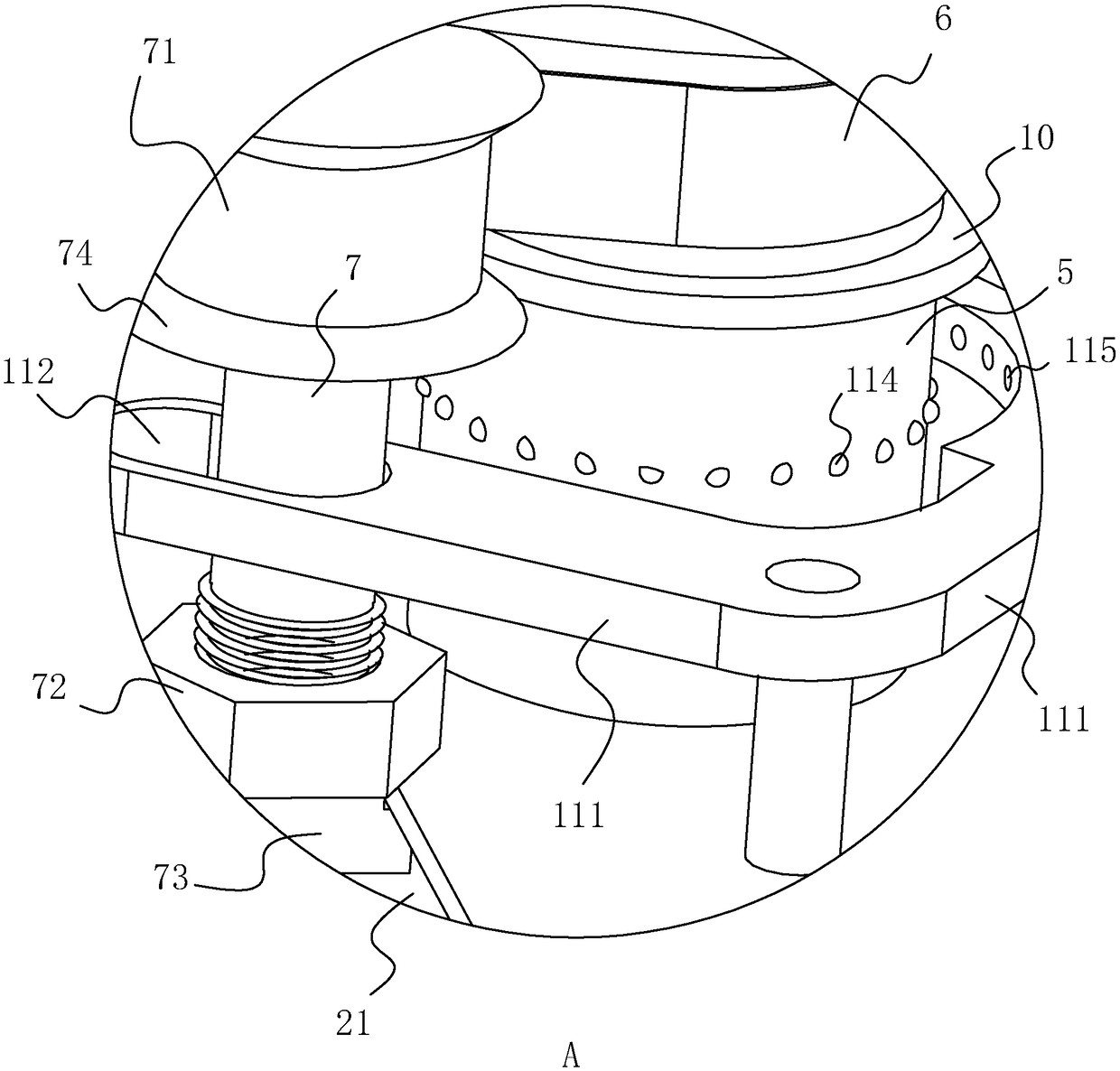

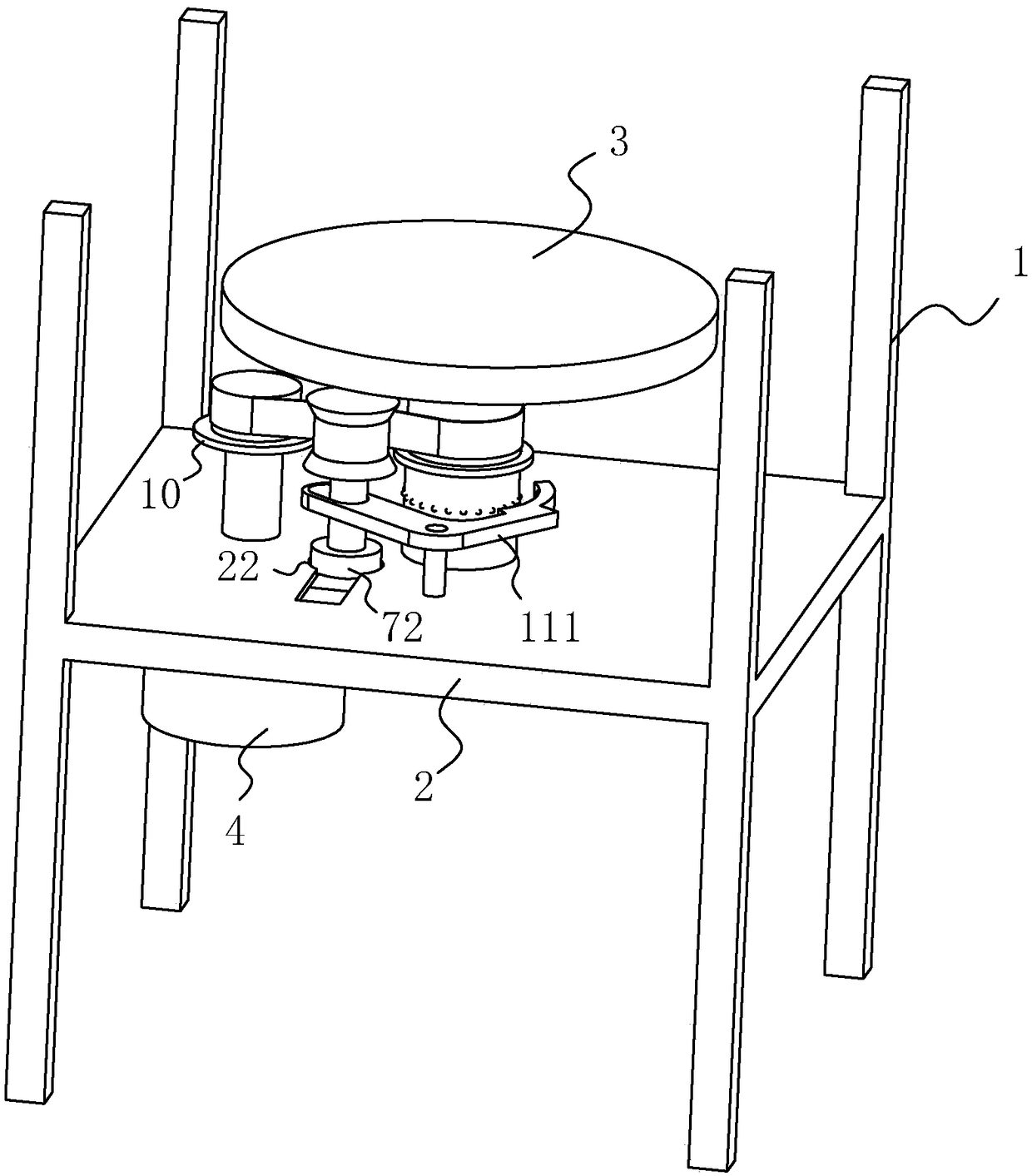

Pitch gyratory compactor

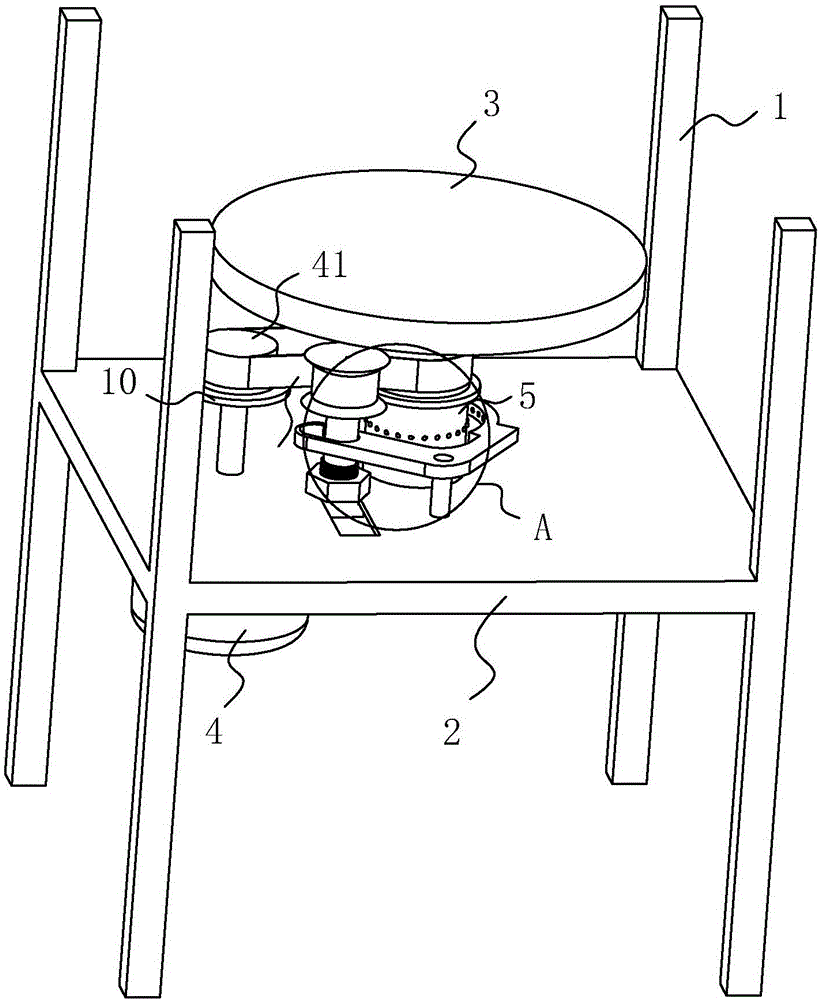

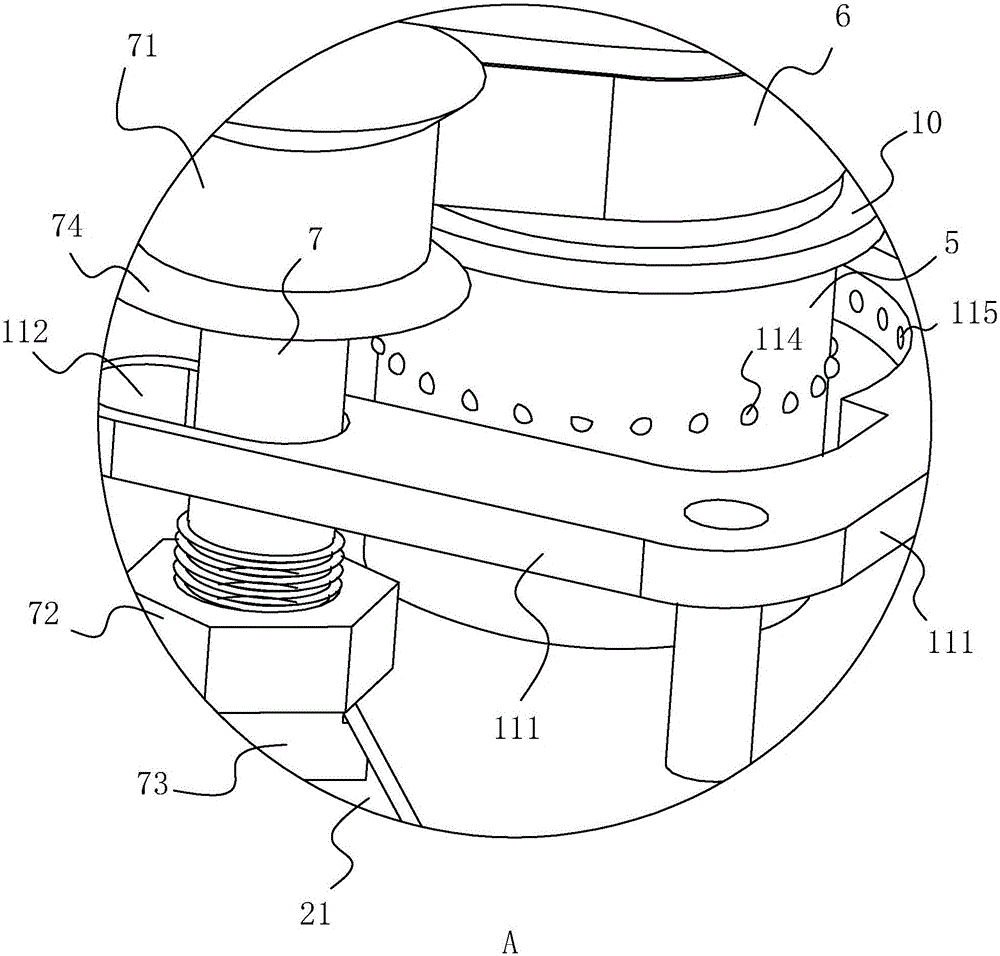

ActiveCN106769333AReduce lossPower transmission is convenientPreparing sample for investigationDrive wheelEngineering

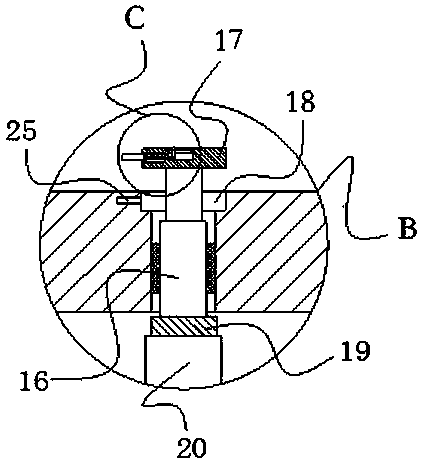

The invention discloses a pitch gyratory compactor, aims at solving the defects that an existing gyratory compactor is difficult to brake, and is technically characterized in that the pitch gyratory compactor comprises a bottom plate, a rotary table and a driving motor for driving the rotary table to rotate, wherein the rotary table is fixedly connected with a roller, the roller is rotationally connected with the bottom plate, a spindle of the driving motor penetrates through the bottom plate, and is fixedly provided with a driving wheel, the driving wheel and the roller are provided with a driving belt, used for realizing power transmission, in a sleeving manner, and the bottom plate is provided with a tension device for controlling the tightness of the driving belt. The pitch gyratory compactor is convenient to brake and also improves the detection efficiency for road samples, so that data about various properties of road surfaces can be quickly and accurately obtained, thereby providing effective reference value for road construction.

Owner:昆山市交通工程集团有限公司 +1

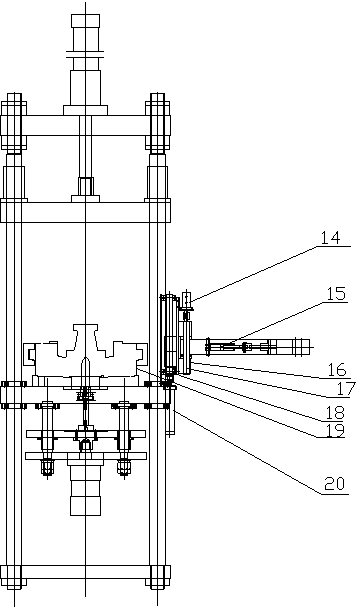

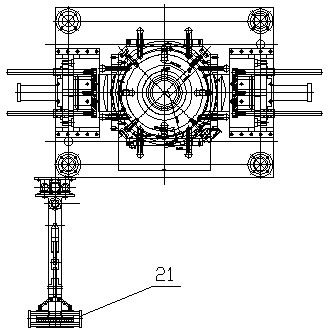

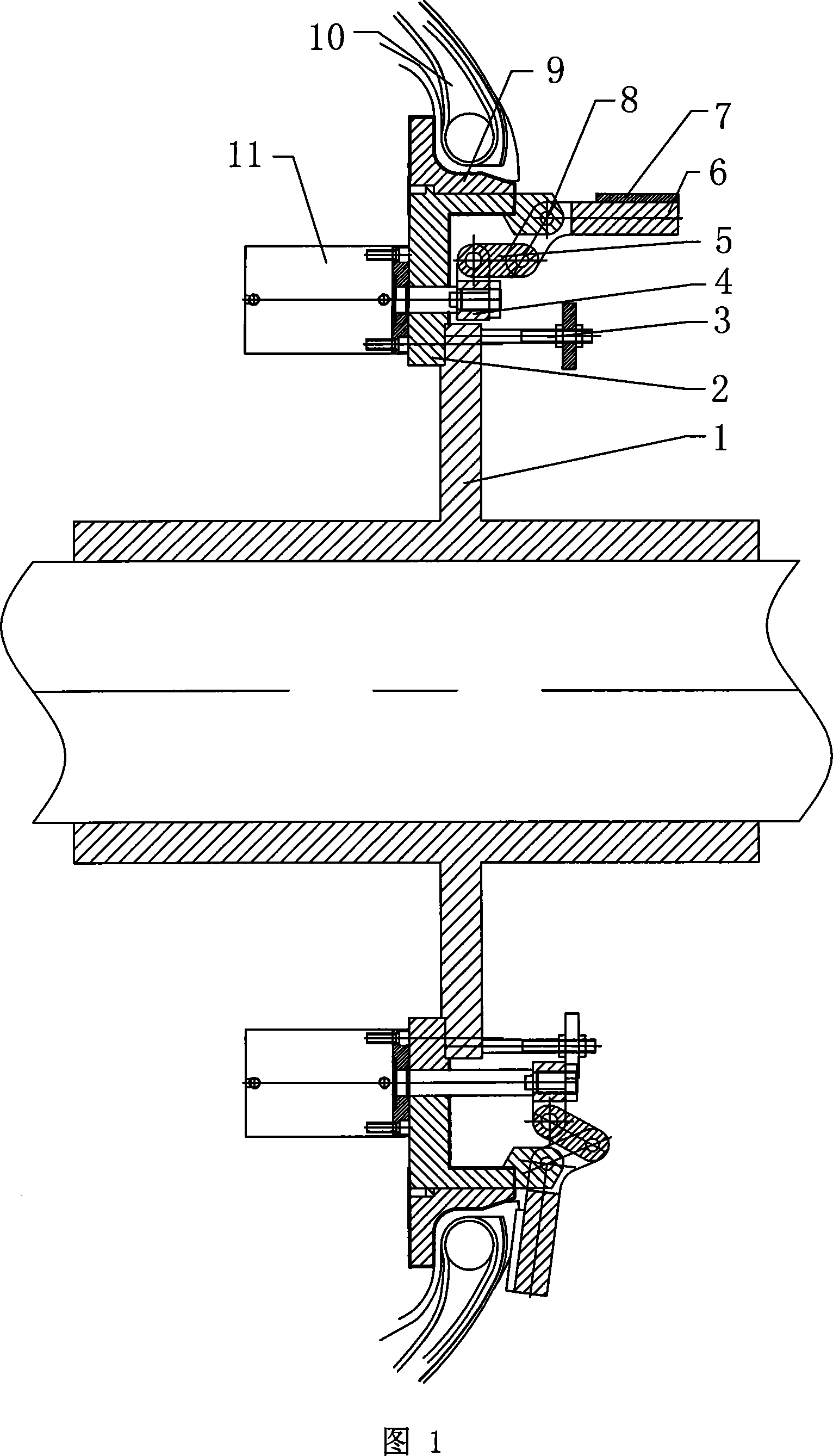

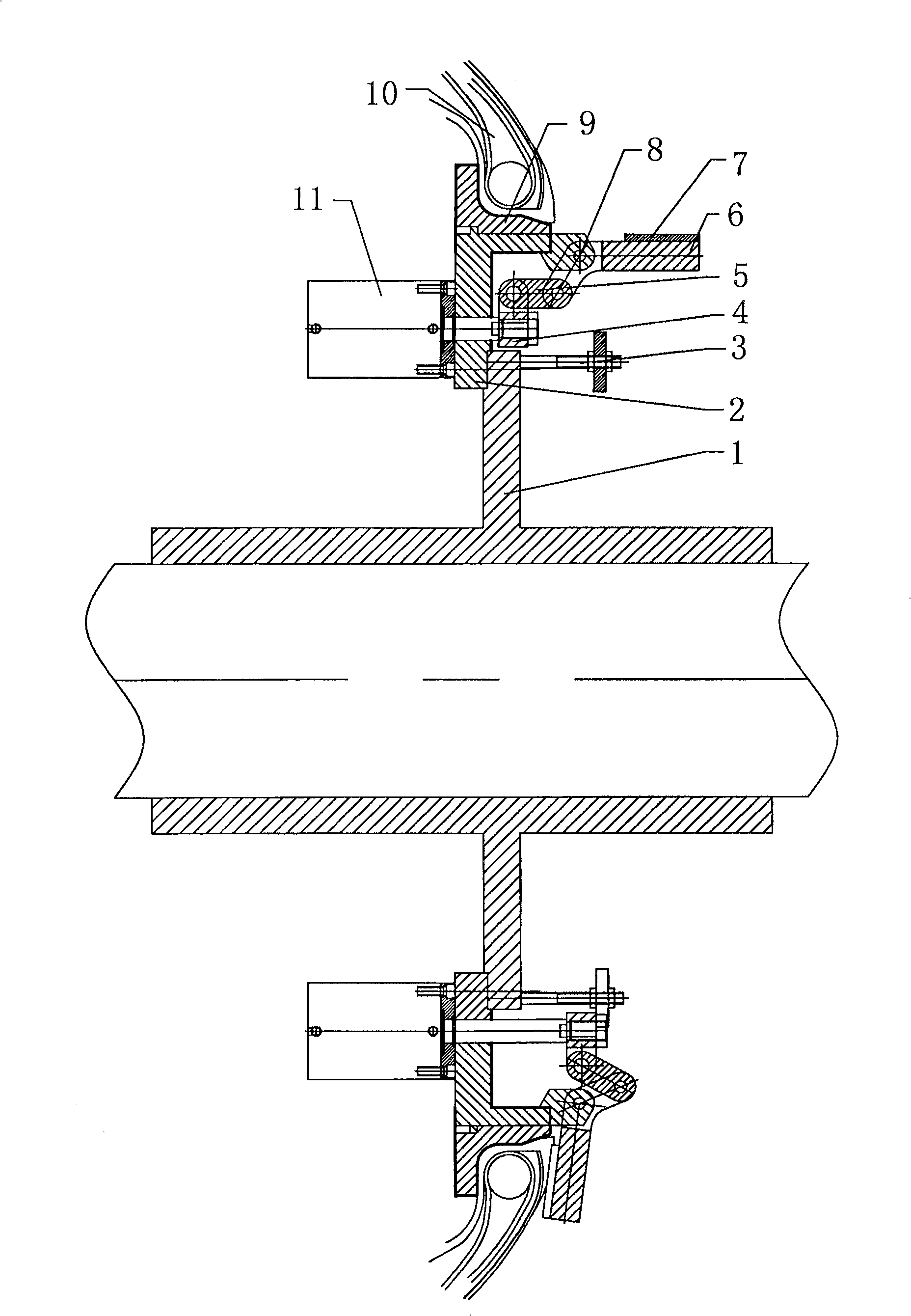

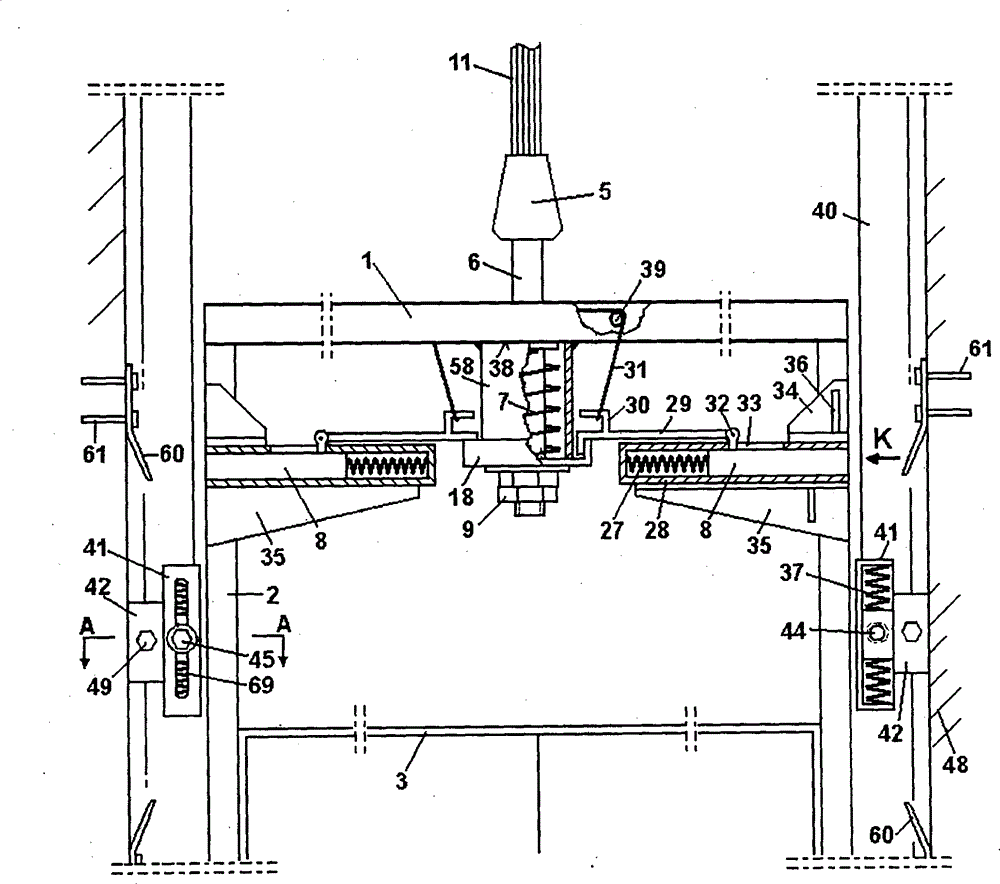

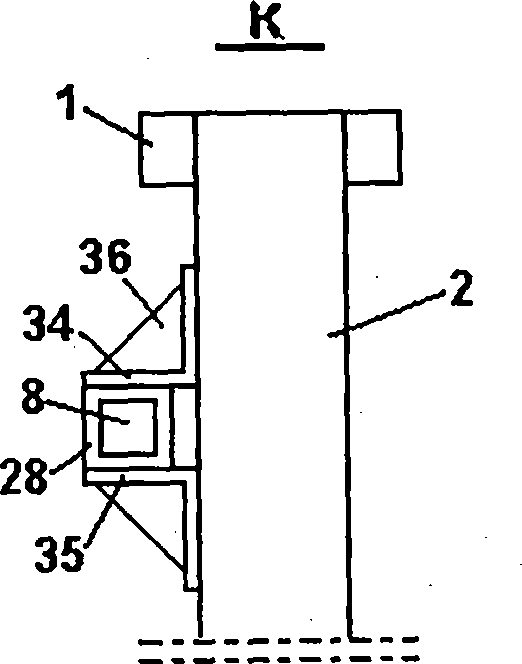

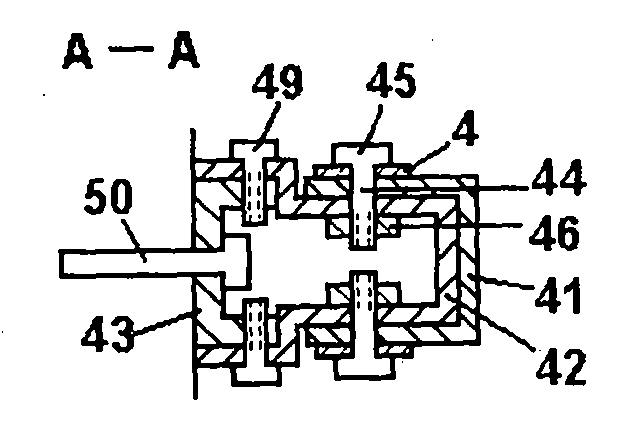

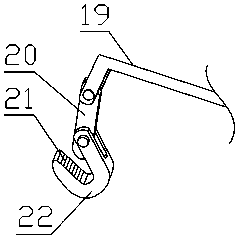

Device for locking traveler of tyre builder

The invention relates to a steel wire ring locking device for the tire building machine, which is characterized in that a slipcover of the sliding flange is sleeved on the main shaft of the boarding drum; the outside of the location platform is fixedly connected with the inner side of the location platform of an annular joint sleeve; a plurality of driving cylinders are evenly distributed on the outside of the joint sleeve; a positioning chuck is fixedly connected with outside edge of the joint sleeve. The cylinder rod of each cylinder passes through the hole of the joint sleeve; a plurality of connecting rods and crank pusher dogs are hinged with the thrusting plate; the turning part of the crank pusher dog is hinged with the transposition of the joint sleeve. The body of the tire tube steel wire ring reaches the location chuck; the driving cylinder simultaneously pushes a plurality of crank pusher dogs of the thrusting plate to swing forth simultaneously; the patulous pressing board lock the steel wire ring tightly on the location chuck. The slipcover of the sliding flange moves inward and takes molding operation. After completion, each cylinder shrinks and drives each crank pusher dog swing inward; the pressing board folds simultaneously and disengages from the steel wire. The slipcover of the sliding flange moves outwards; the steel wire ring separates from the location chuck and the tire can be removed. The invention has the advantages of replacement for the capsule to realize the tightly lock and location of the steel wire ring, high efficiency, better reliability, long service life, few maintenance and favorable quality of the tire.

Owner:GUILIN RUBBER MACHINERY CO LTD

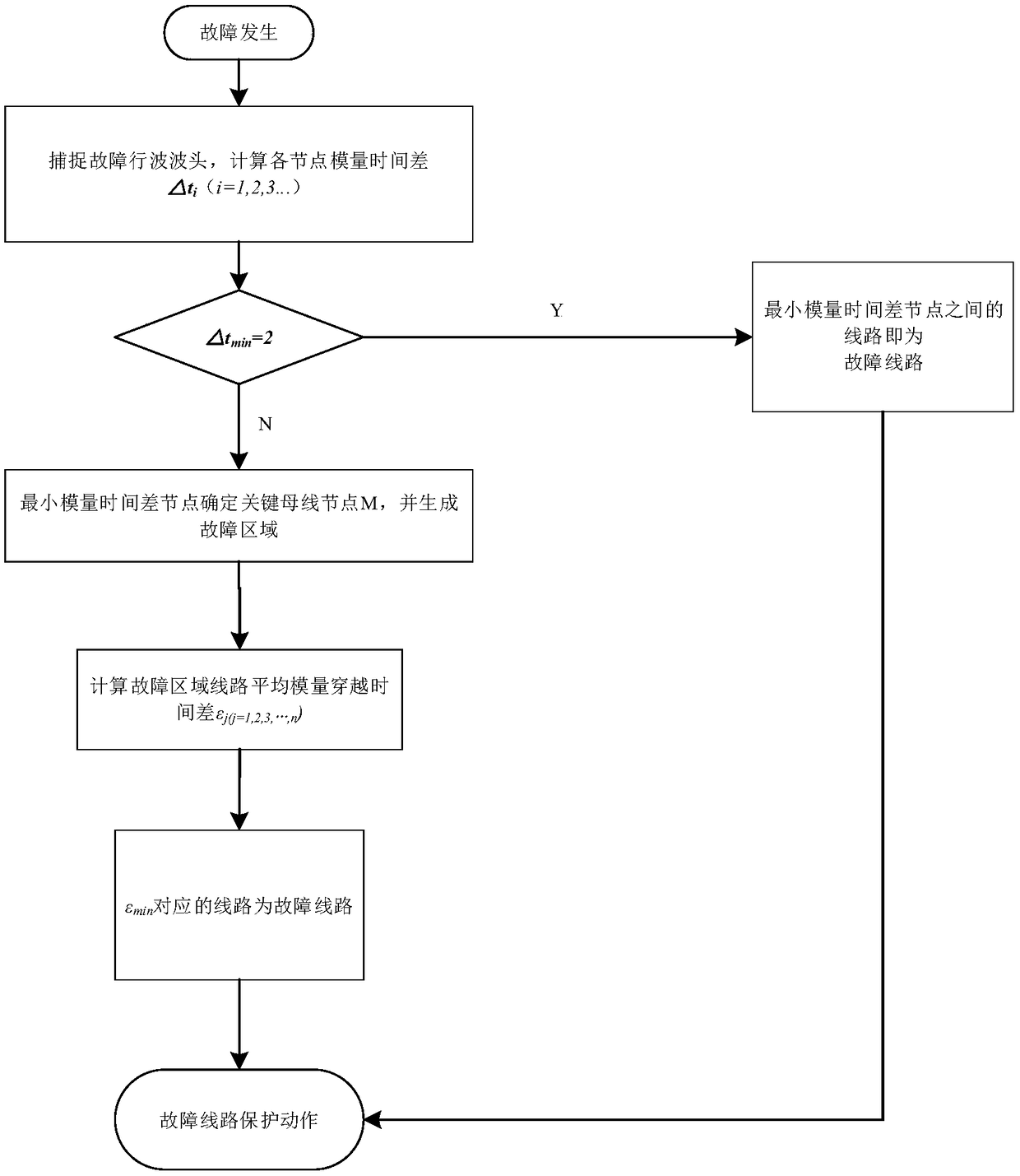

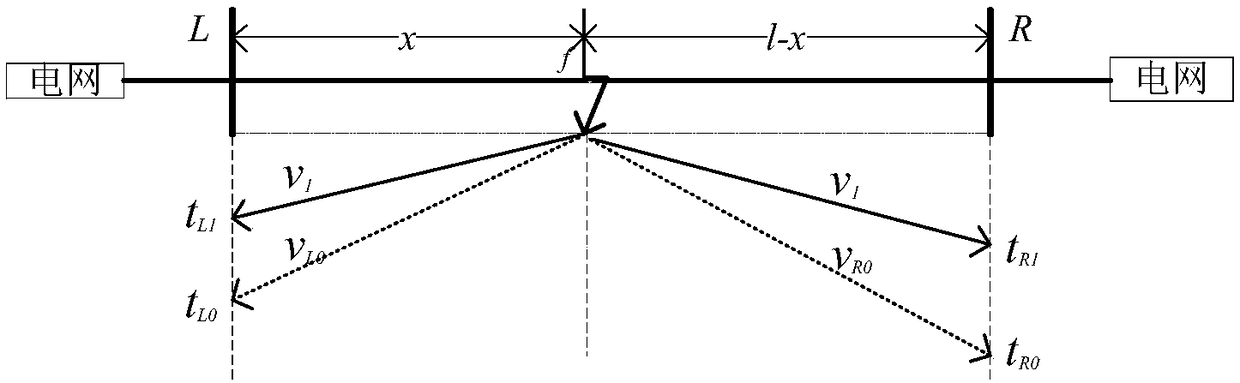

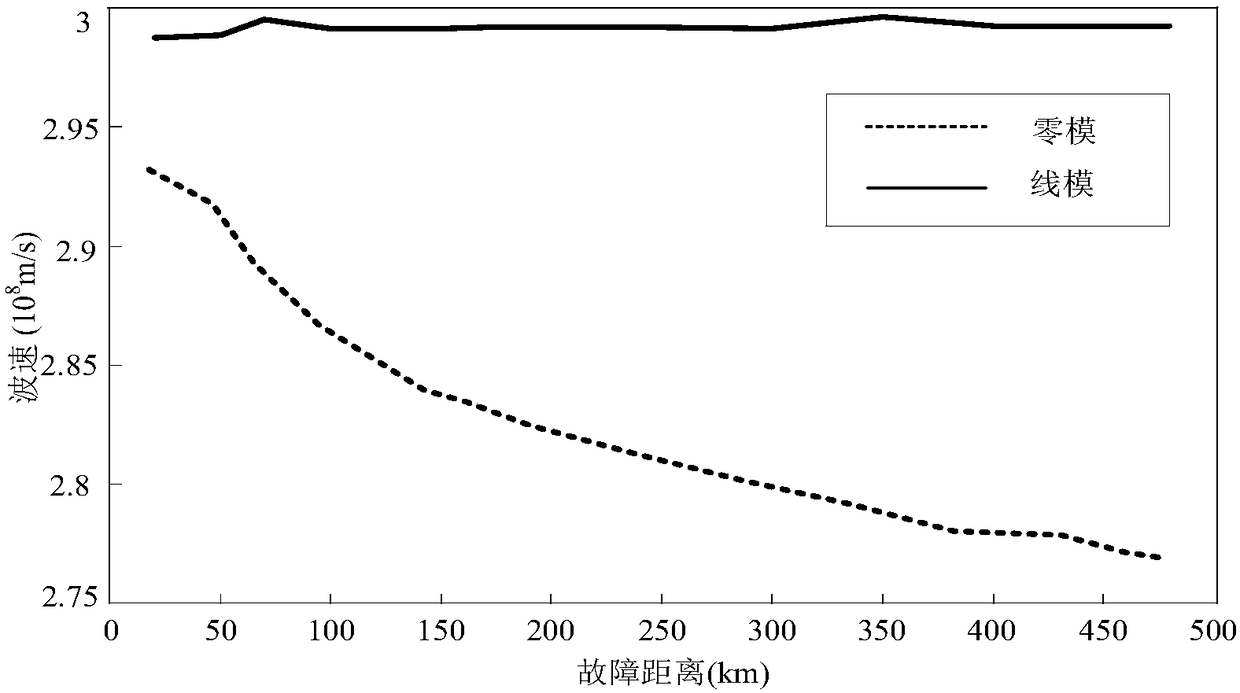

Power transmission line travelling wave protection method considering travelling wave speed characteristic

ActiveCN108767819ARapid positioningImprove applicabilityEmergency protective circuit arrangementsEmbedded systemTransient current

The invention discloses a power transmission line travelling wave protection method considering travelling wave speed characteristic. The method comprises the steps of acquiring a transient current travelling wave signal at each bus node in a power grid after a fault occurs in a line, and calculating to obtain modulus time difference between initial wavefront which are reached of a zero-mode travelling wave and a line-mode travelling wave of each bus node; taking the bus node with minimum modulus time difference as a key bus node; and determining a fault region according to the key bus node, calculating average modulus ride-through time difference of each circuit in the fault region, determining the circuit with minimum average modulus ride-through time difference as a fault circuit, and performing circuit protection action on the fault circuit. By the travelling wave protection method, two ends of the circuit do not need to be synchronous, the travelling wave protection method is freefrom influence of factors such as a system load, a fault initial phase angle and transition resistance, is high in reliability and accuracy and rapid in action speed and has relatively high economy and relatively high practical value.

Owner:CHINA UNIV OF MINING & TECH

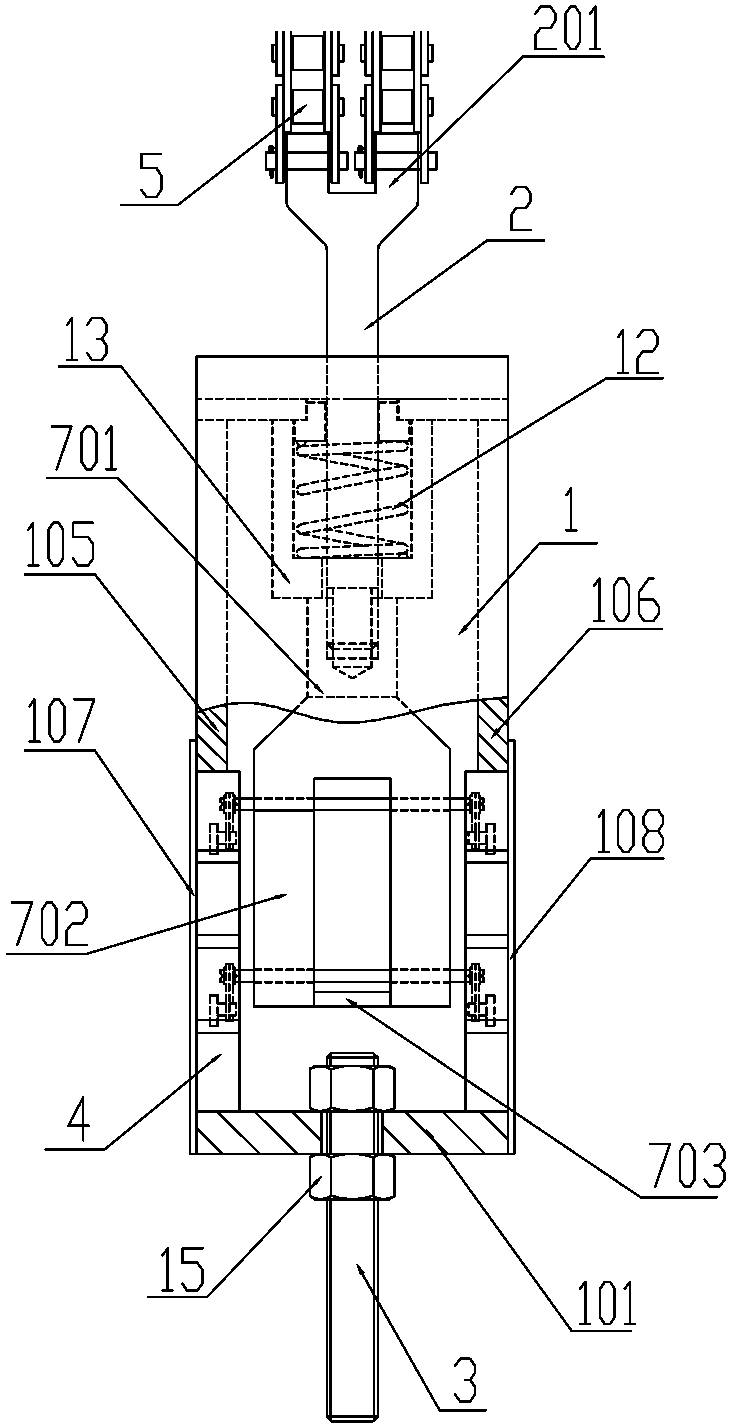

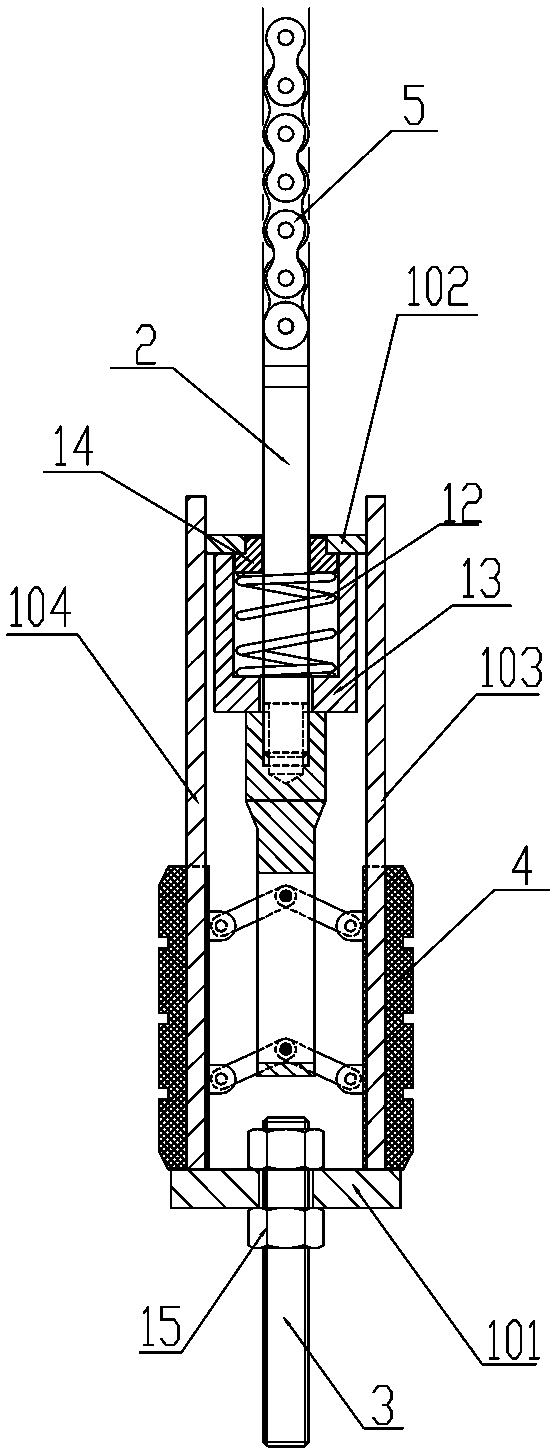

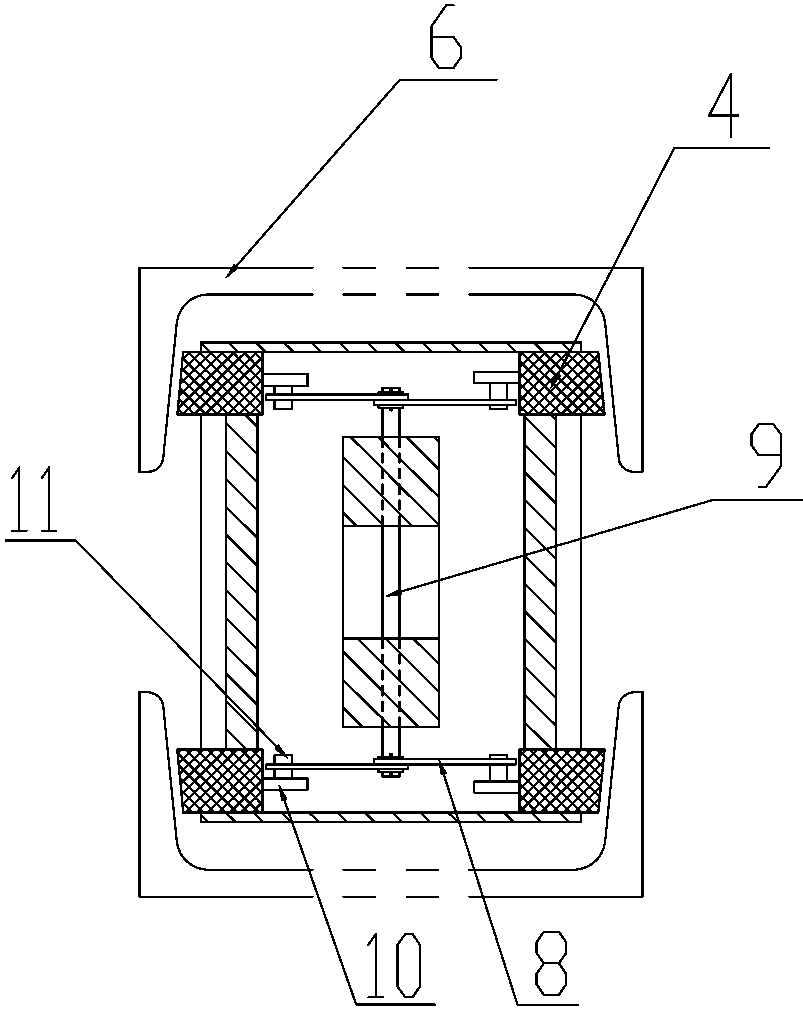

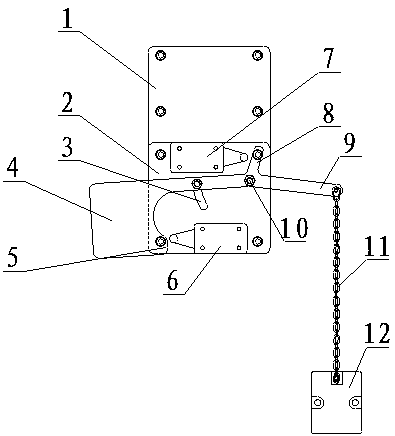

Anti-falling device in guide rail

PendingCN109869027AMechanism and manufacturing are simpleQuick and accurateParkingsFall protectionEngineering

The invention discloses an anti-falling device in a guide rail. The anti-falling device in the guide rail comprises a shell, a top suspender, a bottom suspender and more than two brake pads. The top suspender is arranged on the upper part of the shell and forms a vertical moving pair with the shell, the upper part of the top suspender is used for connecting a pull rope or a pull chain, and the brake pads are arranged on both sides of the shell. The brake pads on both sides of the shell can be moved from the top suspender up and down to the opposite direction on the shell in the horizontal direction at the same time. The horizontal movement of the brake pads is used for squeezing or detaching from the guide rail, and the bottom suspender is arranged at the bottom of the shell and used for connecting a load-bearing disc. The anti-falling device in the guide rail has the beneficial effects that mechanism and manufacture are simple, the action of the brake pad is rapid and accurate, the braking effect is good, reusable use can be achieved, and additionally arranging electrical equipment and cables are not required to perform convenient anti-falling protection on a pulling and drawing system; and according to the anti-falling device in the guide rail, the anti-falling device is installed conveniently and quickly, special structural design and manufacture are not required to be carried out, an existing space is not occupied, and installing and using are carried out at the same time.

Owner:NANJING C HOPE ENVIRONMENTAL SCI & TECH

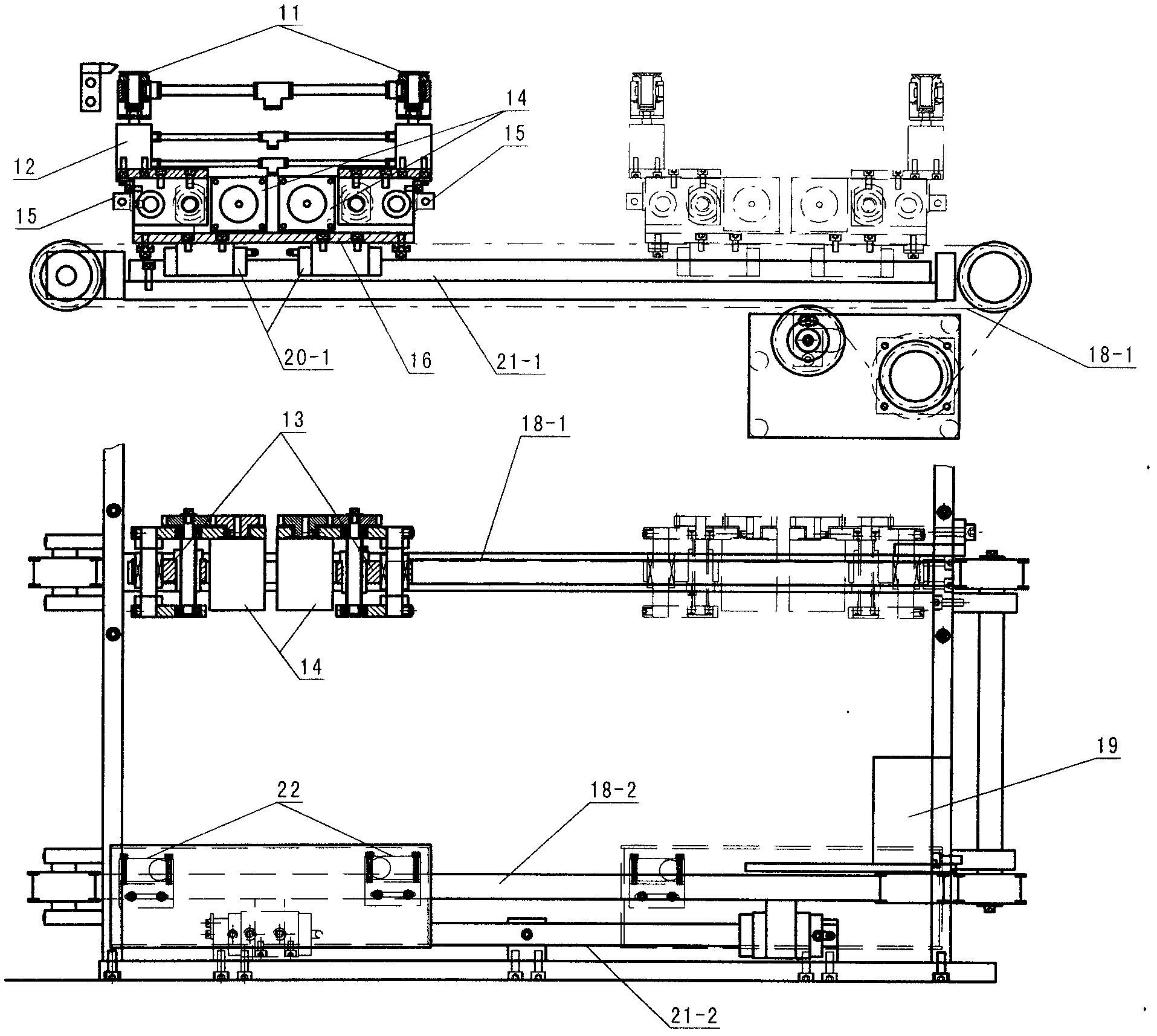

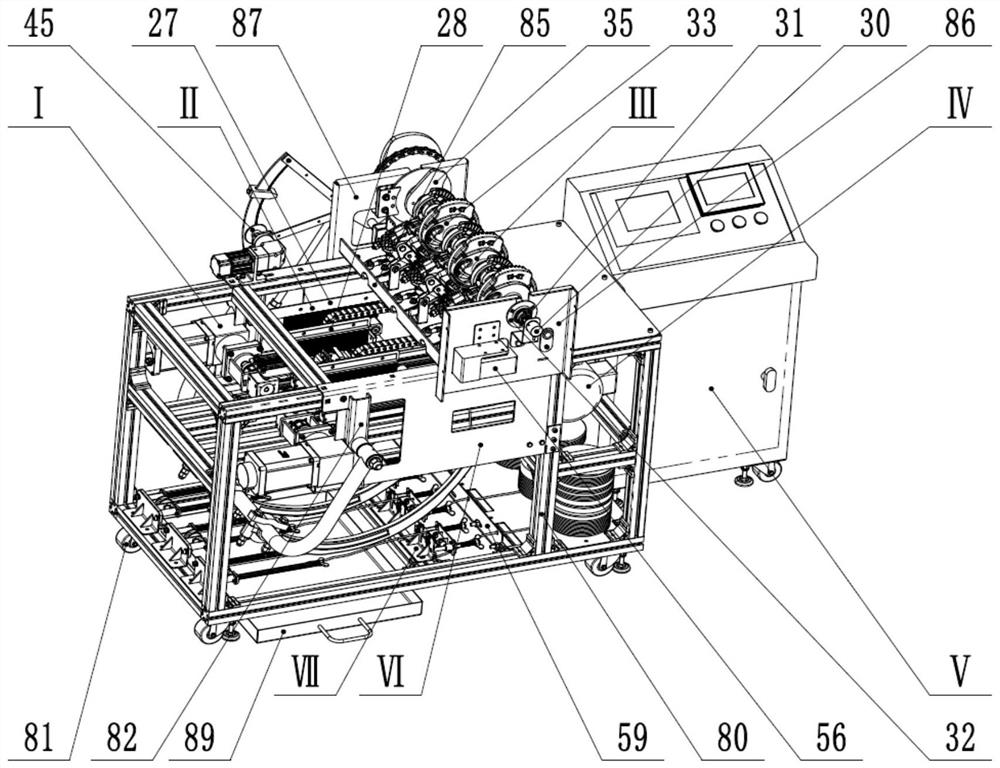

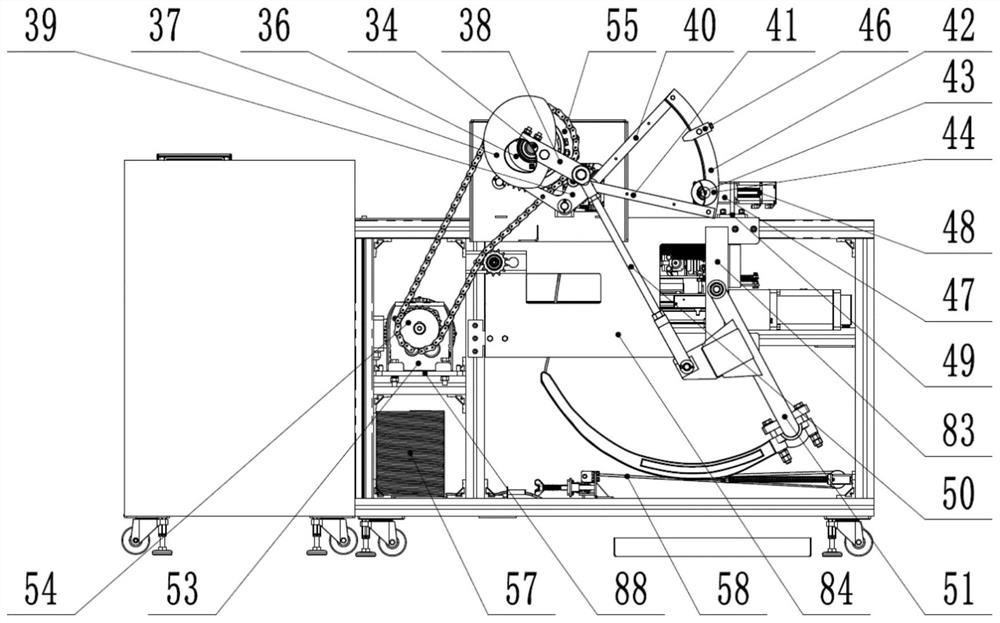

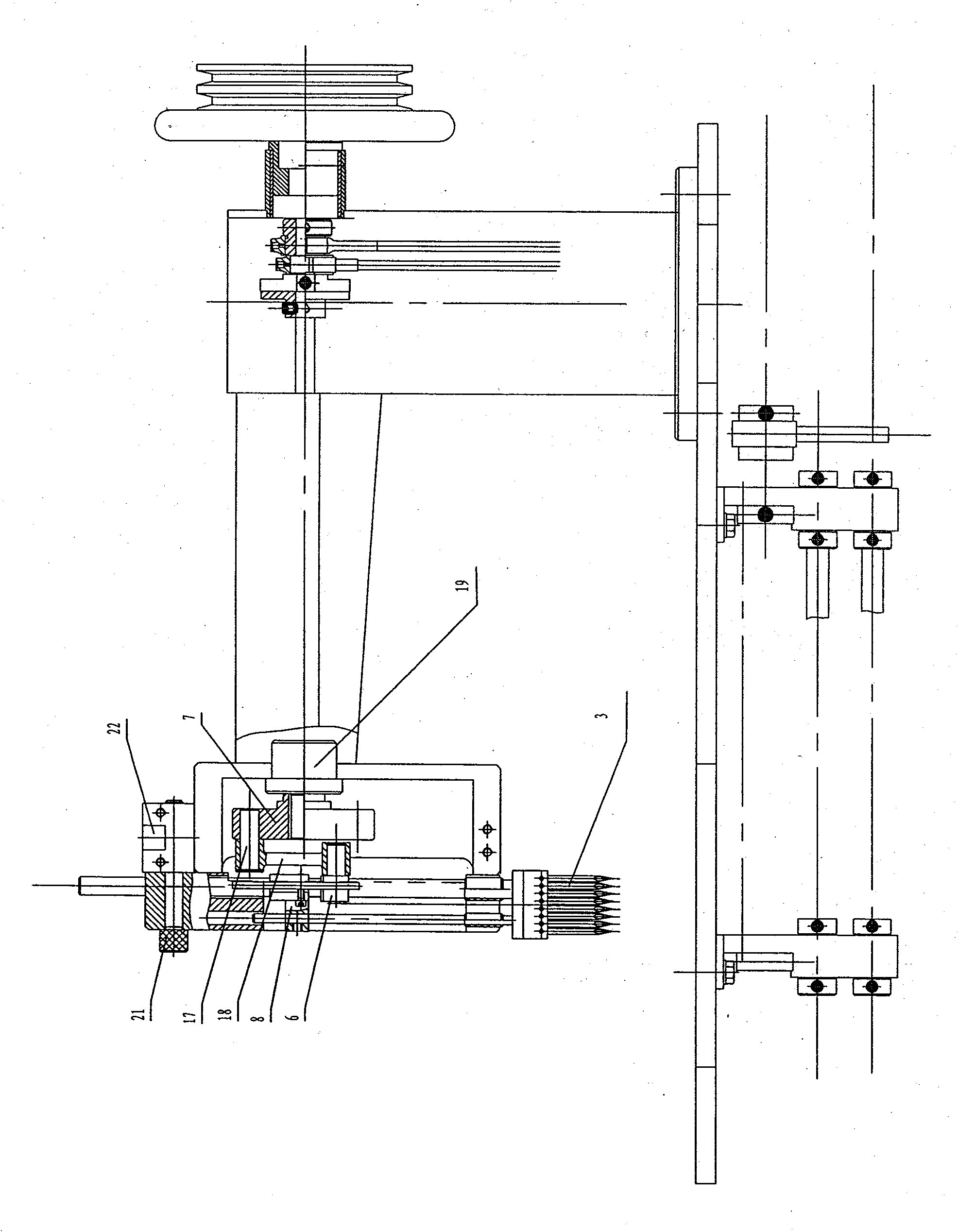

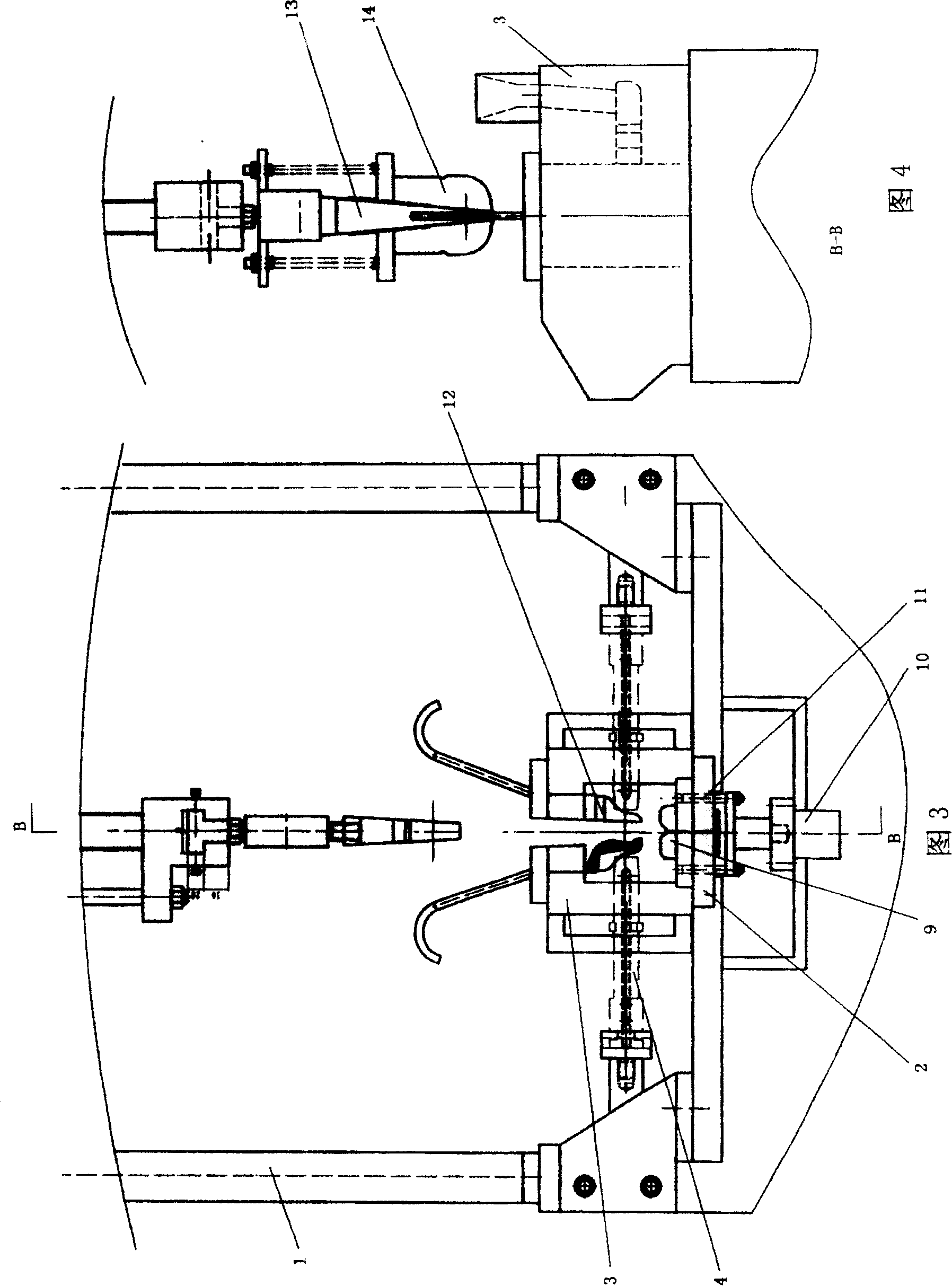

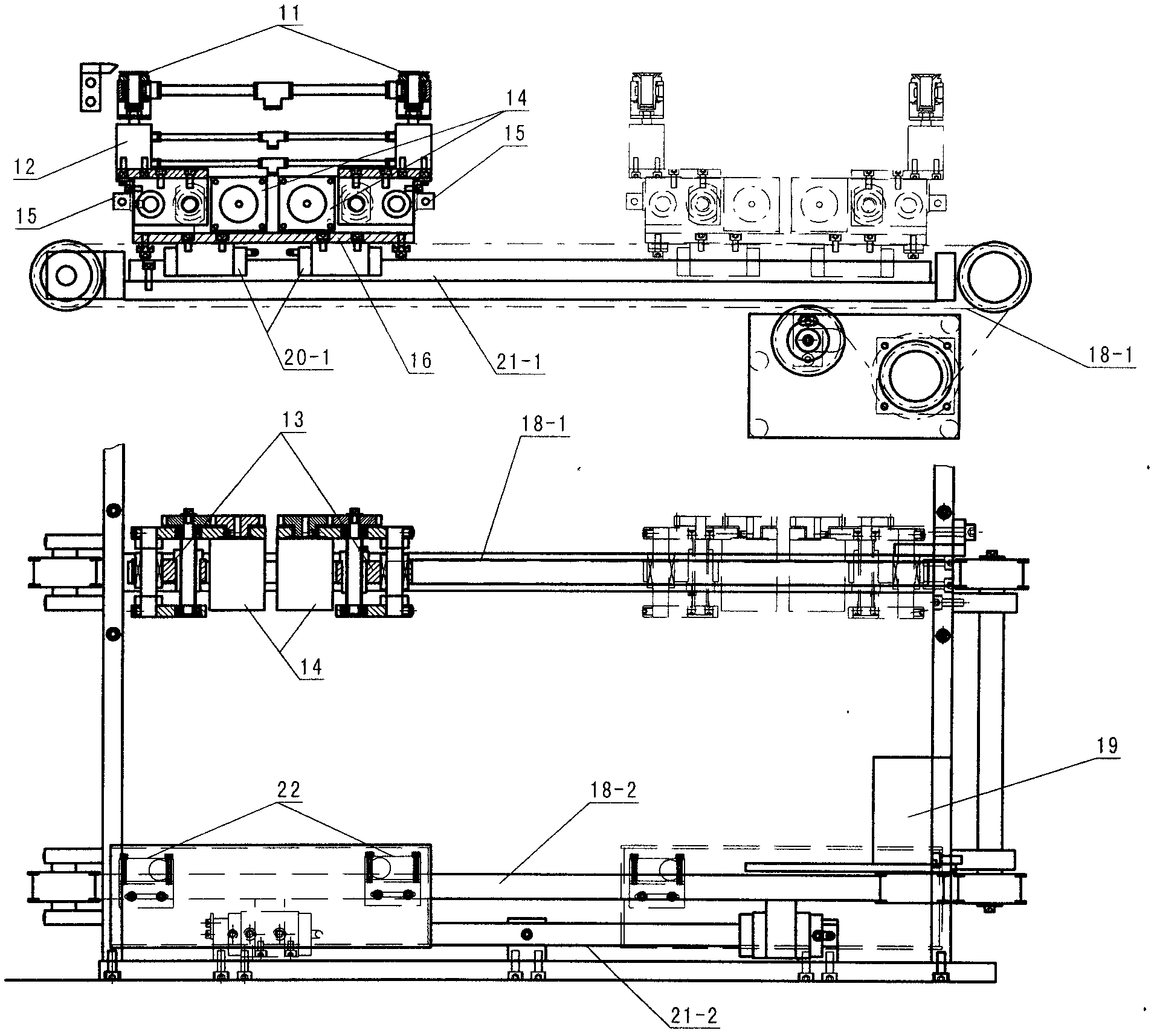

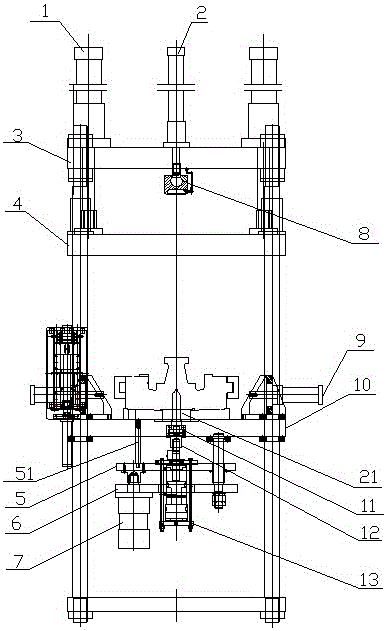

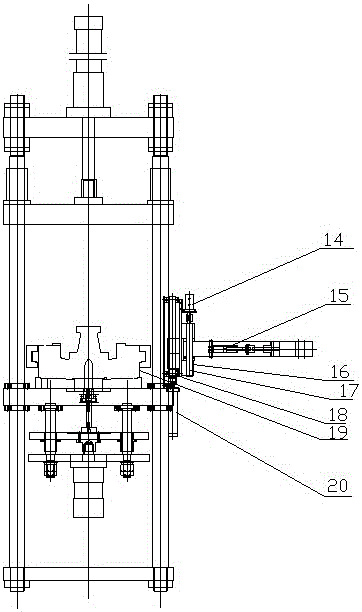

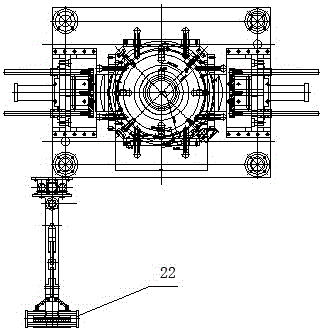

Continuous knotting test bench for multiple groups of knotters

PendingCN114112458AQuality improvementQuick and accurateStructural/machines measurementControl systemElectric machinery

The invention provides a continuous knotting test bench for multiple groups of knotters. The continuous knotting test bench comprises a rope pulling system I, a rope releasing device II, a knotter main shaft transmission system III, a motor driving system IV, a control system V, a rack VI and a rope bundling pre-tightening force adjusting device VII, the bundling rope pre-tightening force adjusting device VII is used for clamping and tightening a bundling rope, the control system V controls the motor driving system IV to enable a rope needle of the knotter main shaft transmission system III to send the bundling rope to the knotter, and the rope pulling system I enables the bundling rope to form a to-be-knotted rope loop. A motor driving system IV drives a knotter main shaft transmission system III to enable the knotter to complete the knotting action, and a rope releasing device II brushes off a knotted rope ring from a rope pulling system I; the continuous knotting process of multiple groups of knotters under the condition of bale rebound can be simulated, the knotting speed can be controlled by adjusting the rotating speed of the motor driving system, simultaneous continuous knotting of the multiple groups of knotters is automatically realized, the time consumed in the testing process is shortened, the testing efficiency and the knot quality are improved, and the failure rate is reduced.

Owner:JIANGSU UNIV

High precision cutting device with gear limit function

The invention relates to a high precision cutting device with a gear limit function. The device comprises a base, linear actuators are all fixedly and perpendicularly connected to the four corners ofthe upper end of the base, and the upper ends of two symmetrical linear actuators at front and back are fixedly connected with the same fixed block; grooves are formed in the two opposite side walls of the two fixed blocks, racks are fixedly arranged on the bottoms of the grooves, and a supporting rod is arranged between the two fixed blocks; the left and right ends of the supporting rod are bothfixedly connected with connecting blocks, the ends, away from the supporting rod, of the connecting blocks extend into the grooves, first motors are fixedly embedded in the grooves, and output shaftsof the first motors are fixedly connected with gears meshed with the racks. According to the device, the position of a cloth cutter can be conveniently adjusted, the cutting accuracy is greatly improved, and people can conveniently use the device.

Owner:浙江云杉服饰有限公司

Automatic tappet clearance adjusting device

InactiveUS7578276B2Quick and accurateIncrease pressure catch-up rateValve arrangementsMachines/enginesElectricityCombustion chamber

Owner:HONDA MOTOR CO LTD

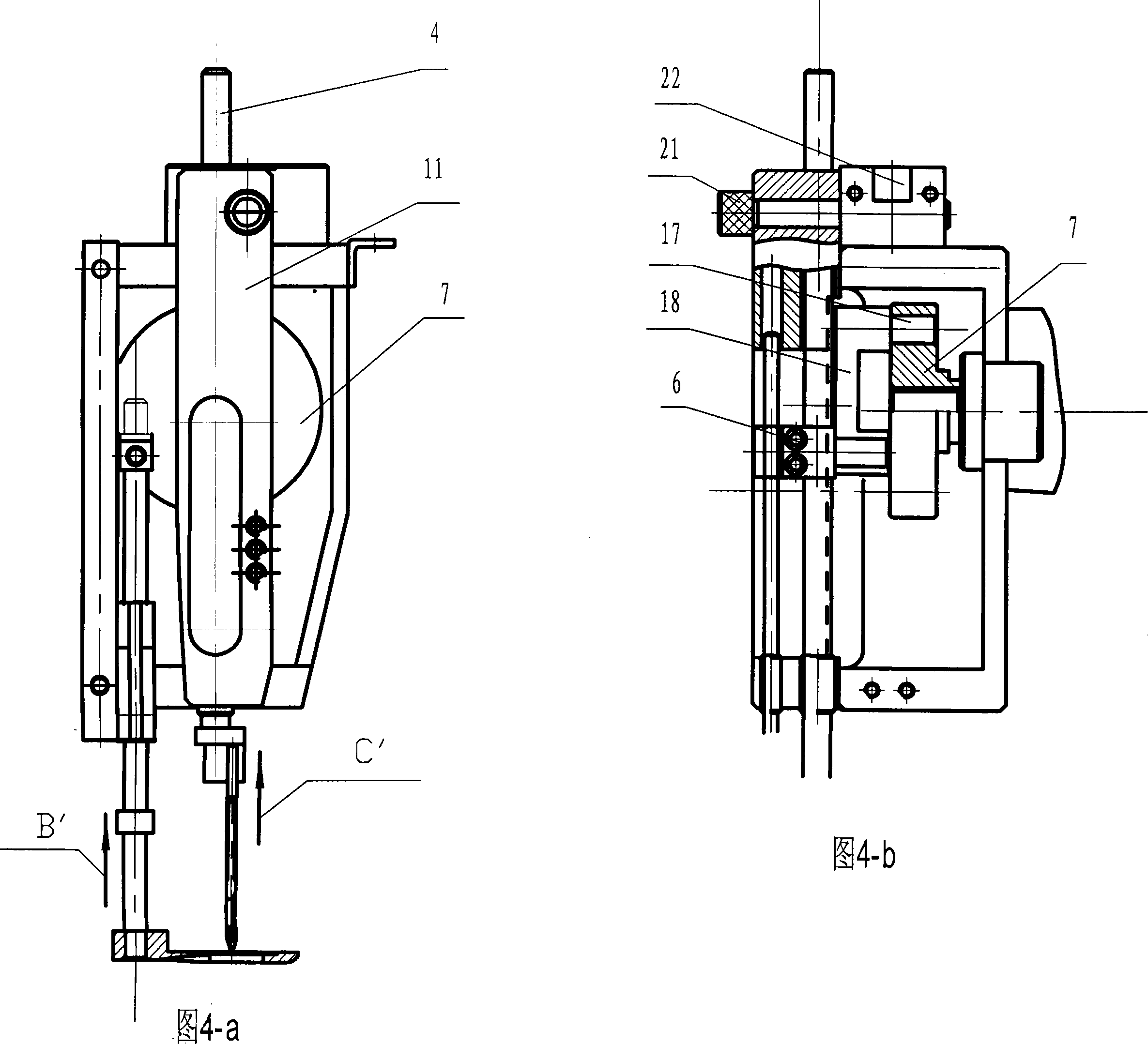

Automatic lifter of carpet tufting machine needle bar

An automatic lifter for carpet tufting machine needle bar consists of flywheel, link on eccentric pin, link block connected with another end of link, needle bar connected with link block vertically, pendulum driven by link block, needle bar fixing block arranged on top of link block, twisted-coil cant hook coupled below link block, whose middle is fixed with needle bar fixing block, transmission bent handle arranged on top of pendulum, one end contacts with upper end of twisted-coil cant hook, another end is fixed connected with medium link block and pressure bar by Connecting board, pressurebar lifter is made up of twisted-coil cant hook coupled below link block and transmission bent handle controlled by pressure bar; needle bar stops at summit instantly while twisted-coil cant hook is automatically uncoupled. It's fast, accurate and efficient, has better quality and less consumption.

Owner:王龙耀

Device for locking steel traveler of tyre builder

The wire ring locking device of the tire building machine, the sliding flange is set on the main shaft of the shaping drum, the outer positioning platform is fixedly connected with the inner positioning platform of the annular connecting sleeve, and a plurality of driving cylinders are evenly distributed on the outer side of the connecting sleeve, and the outer edge of the connecting sleeve is fixed. Position the chuck. The piston rods of each cylinder pass through the fixed push plate through the hole of the connecting sleeve to hinge a plurality of connecting rods and crank claws, and the turning points of the crank claws are hinged to the swivel seat on the connecting sleeve. After the carcass tube traveler reaches the positioning chuck, the driving cylinder simultaneously pushes the multiple crank claws of the push plate to swing outwards at the same time, and the opened pressure plate locks the traveler on the positioning chuck. The sliding flange sleeve moves inward for forming operations. After completion, each cylinder shrinks to drive each crank claw to swing inwardly, and the pressing plate is closed at the same time to disengage from the traveler. The sliding flange sleeve is moved outward, the traveler is separated from the positioning chuck, and the tire can be unloaded. The device replaces the capsule to realize the locking and positioning of the steel traveler, has high efficiency, strong reliability, long service life, less maintenance, and is beneficial to improve tire quality.

Owner:GUILIN RUBBER MACHINERY CO LTD

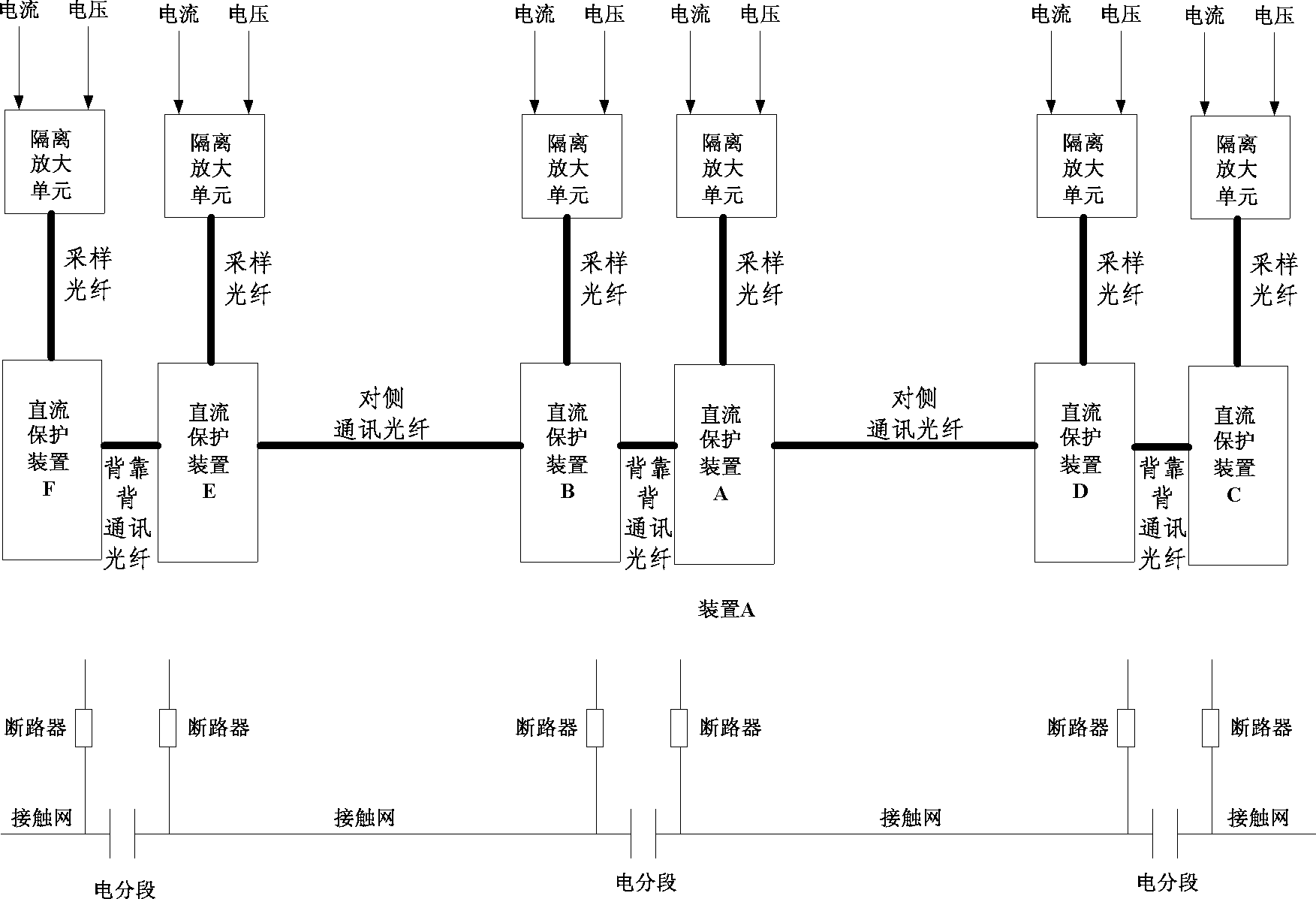

Direct-current protection system with multiple paths of optical fiber interfaces and direct-current protection method

ActiveCN102522732BAccurate and fast trippingQuick and accurateDc network circuit arrangementsEmergency protective circuit arrangementsInterference resistanceEngineering

The invention discloses a direct-current protection system with multiple paths of optical fiber interfaces and a direct-current protection method. Protection device action information and acquired current and voltage semaphores are mutually exchanged through an optical fiber, an opposite side direct-current protection device, a back direct-current protection device and an opposite device at the opposite side of the back direct-current protection device, so that intervals of operation and positions of failures of a train are determined, and the protection devices can rapidly and accurately carry out tripping and bilateral shunt tripping, and transmit information during region-crossing power supply. The direct-current protection system has the advantages of accurate and rapid action, simpleness and convenience, and strong interference resistance capacity.

Owner:NARI TECH CO LTD

Elevator safety level apparatus with multiple startup modes

InactiveCN101462665BAvoid the defect that it is not necessarily facing the floor doorDefects to avoid adverse effects from braking actionElevatorsSafety valveSteel rope

The invention relates to an elevator safety lever device capable of setting various starting modes. The safety lever device comprises safety levers, a lever sleeve, a reciprocating device, an electronic speed limiter, a motor, pier posts and so on, wherein the safety levers are arranged on the left and the right on or below an outer frame of an automobile; the pier posts are arranged on the shaft wall of an elevator; and the electronic speed limiter is arranged inside an elevator machine room. When an elevator is out of control and fallen down or pushed to the top at an excessive speed, the safety levers can be bounced out and stopped by the pier posts on both sides of the shaft wall; braking of the automobile can not be influenced even a guide rail, a steel rope, safety tongs and so on are stained with a large quantity of oil or humidified; and staffs are easy to go out because a motionless automobile door faces to a floor door. The device makes up for the blank in the aspect of using the safety lever device on the elevator, and is provided with various structural forms for people to select and set. The device can overcome the defect that the automobile door does not always face to the floor door when the safety tongs of the elevator brake, and can also overcome the defect that braking of the elevator is influenced because the steel rope, the guide rail and so on are stained with a large quantity of oil and too humidified.

Owner:白士良

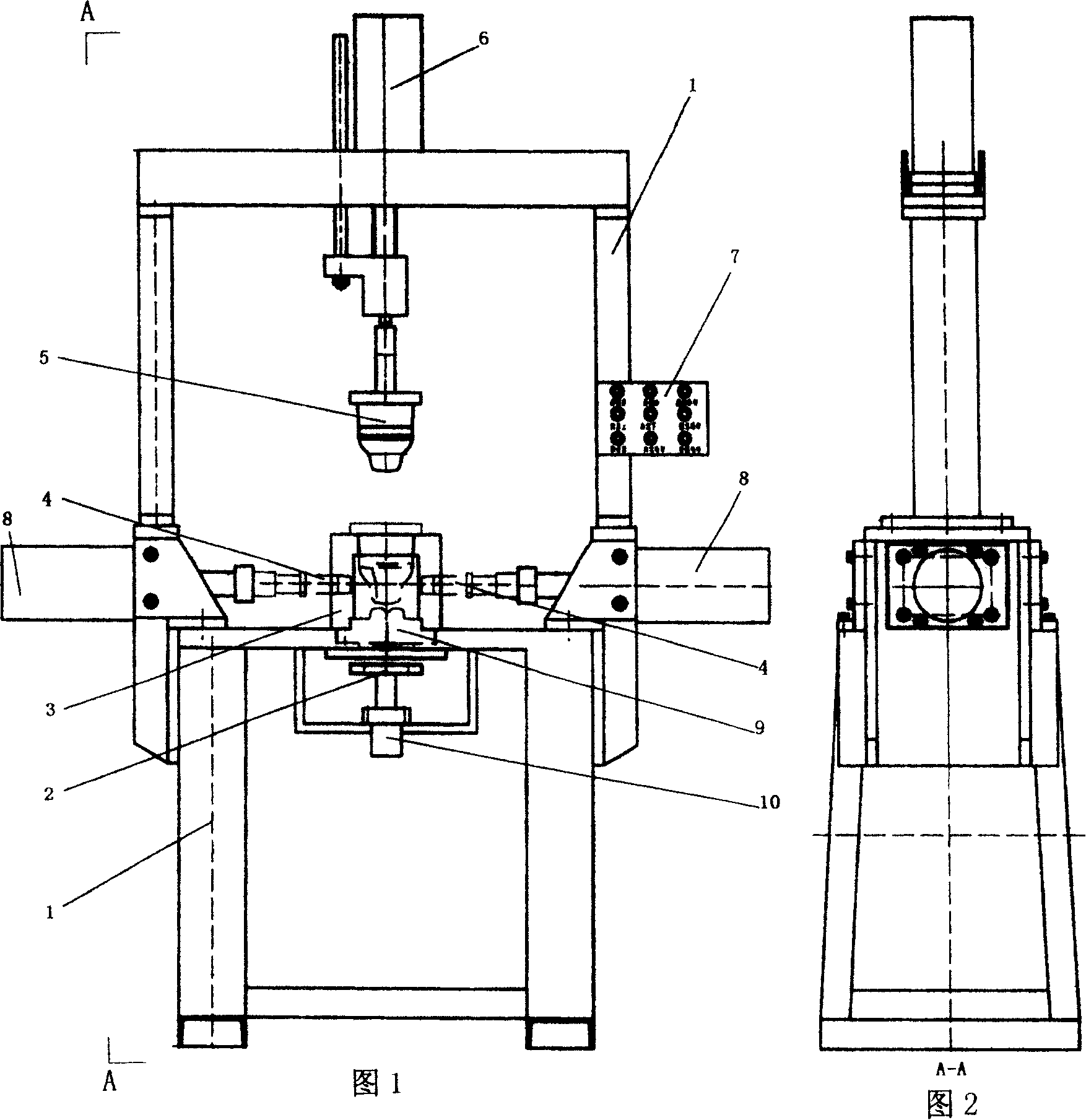

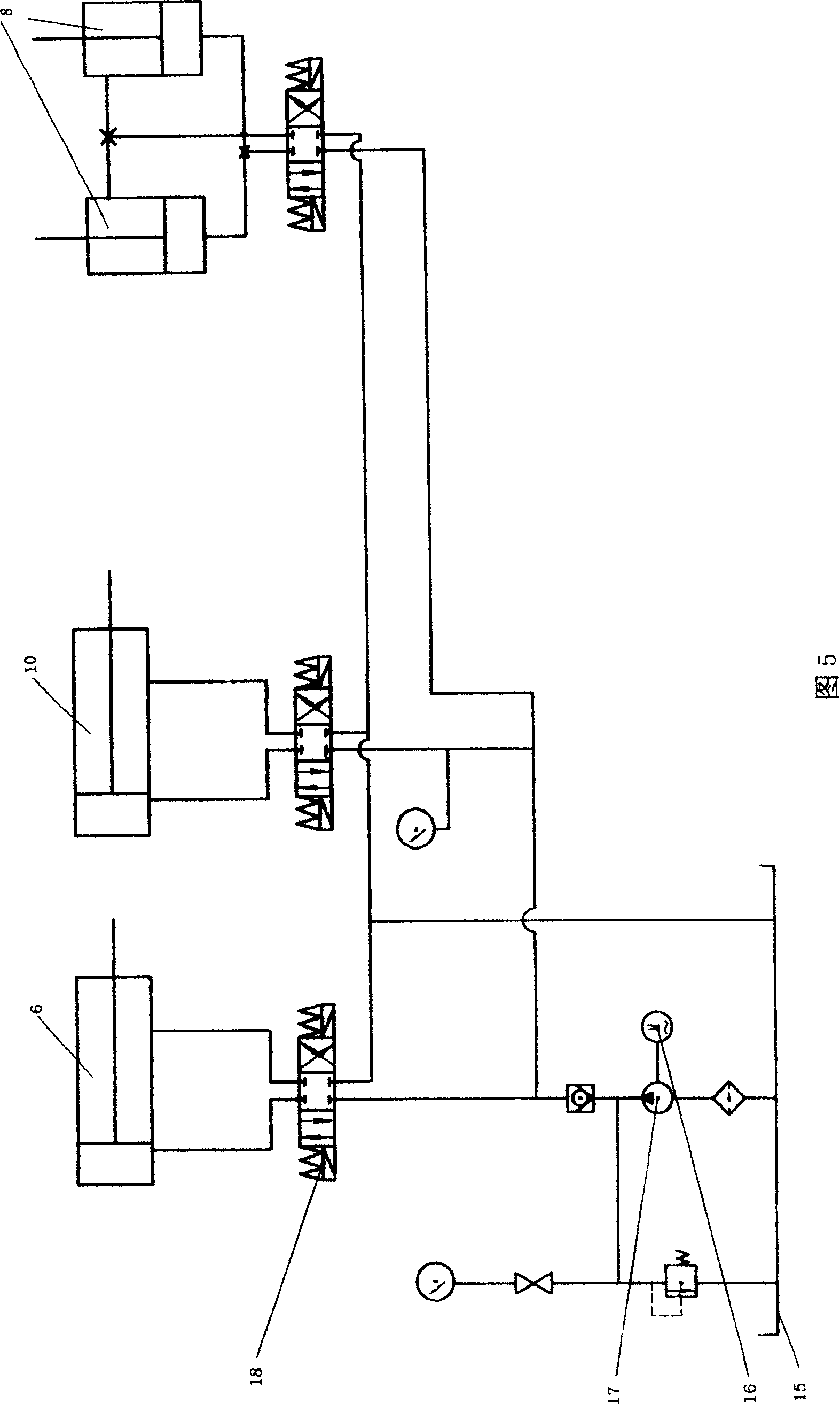

Piston blank casting machine

InactiveCN100381227CQuick and accurateImprove casting precisionMoulding machinesControl switchMaterials science

The piston blank casting machine includes one frame, one control switch box and one combined mold comprising outer mold and inner core. The opening and closing of the outer mold and the separation of the inner core are completed with one hydraulic system quickly and accurately to result in high casting precision and high production efficiency.

Owner:赵明军

A Thin Plate Heating Furnace Self-propelling Steel Rods

ActiveCN107299215BQuick and accurateImprove the working environment on siteFurnace typesHeat treatment furnacesThin slabWorking environment

The invention relates to a sheet heating furnace capable of automatically discharging steel pushing rods. The sheet heating furnace has a furnace body, wherein a furnace door sliding up and down is arranged in a front part of the furnace body; two steel pushing rod grooves arranged in parallel are formed in the bottom of the furnace body; front ends of the steel pushing rod grooves extend out a section from the furnace door; steel pushing rod driving devices are arranged at the front ends of the steel pushing rod grooves; two steel pushing rod outlet holes are formed in a rear end wall of the furnace body; steel pushing rod collecting boxes are arranged outside the two steel pushing rod outlet holes; a sheet outlet is formed in a tail side wall of the furnace body; a discharge door sliding up and down is arranged on the sheet outlet; a material table is arranged at the outer part of the sheet outlet; a sheet pulling device is arranged on the outer side of the material table; the sheet pulling device is provided with a pulling cylinder; an output end of the pulling cylinder is connected with a mounting base plate; two hooks are arranged on the mounting base plate side by side; the two hooks are arranged toward the sheet outlet. The sheet heating furnace provided by the invention is novel and delicate in structural design and simple and convenient to operate, and can greatly reduce work environment and work intensity of field operators.

Owner:湖北楠田工模具科技有限公司

Fully-automatic card conveying, detecting and locating device

ActiveCN102874620BRealize automatic deliveryImprove process precisionRegistering devicesMetal working apparatusControl systemPolyvinyl chloride

The invention relates to a conveying, detecting and locating device for a hard sequence card. The device is used on a fully automatic dividing and cutting machine for the hard card which is made of a polyvinyl chloride (PVC) material as a representative, belongs to the field of printing and packaging machinery, and comprises a conveyor belt, a side locating plate, a front locating plate, a nozzle assembly, a side detection switch, an induced-draught belt, a front detection switch and a control system. The device overcomes the defects of low efficiency, time and labor waste and low precision due to manual card conveying of the conventional card cutting machine, implements the automatic conveying, detection, location and adjustment for the hard sequence card, is fast and precise in action, and can obviously improve the working efficiency and effectively improve the process precision of conveying the card, so as to ensure the dividing and cutting qualities, avoid manual card conveying and location, and liberate the productivity. The device can also be used for the automatic conveying, detection, location and adjustment of the hard card made of a non-PVC material or a common paper card.

Owner:YUTIAN UANCHOR PACKAGING MACHINERY

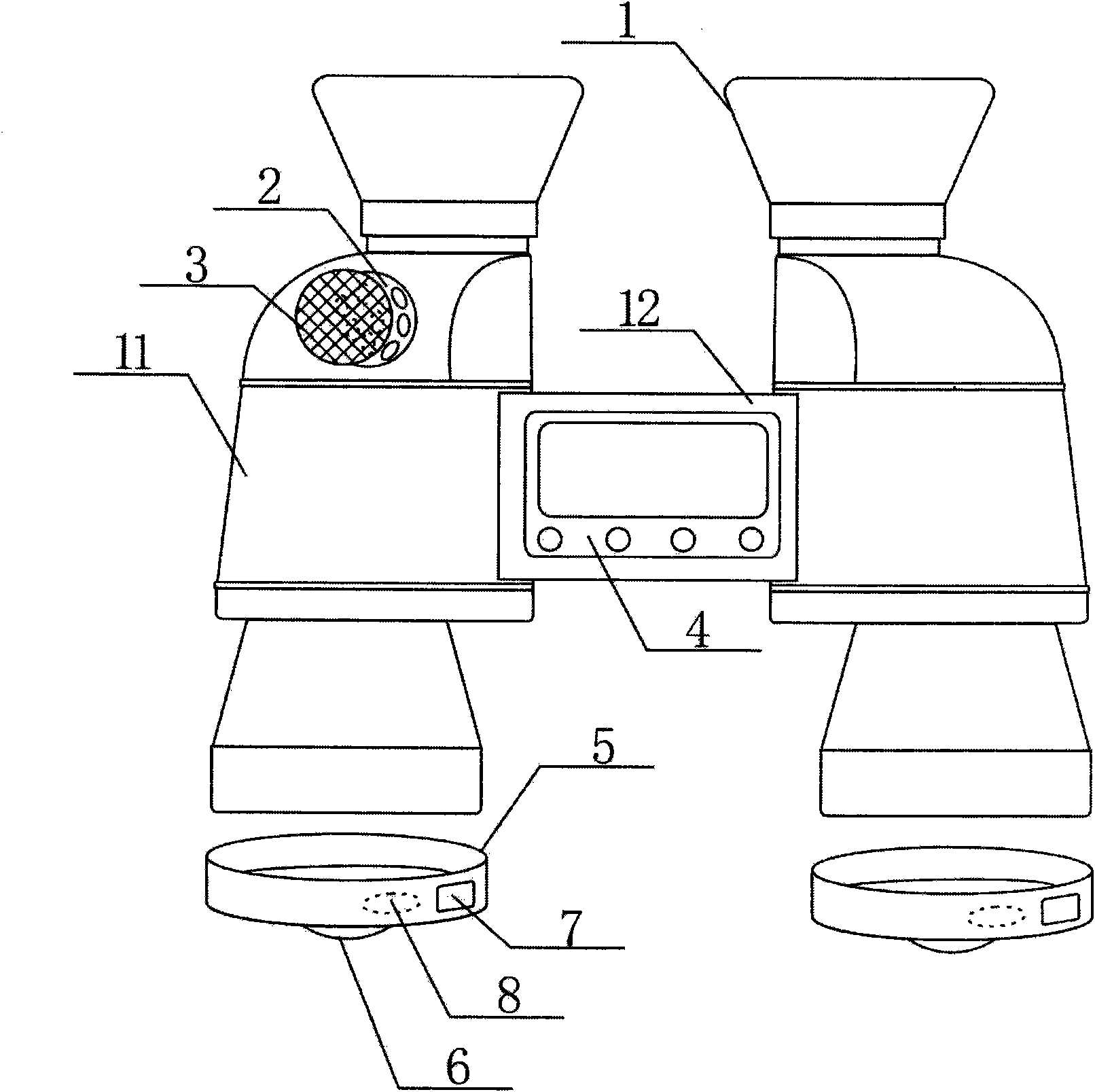

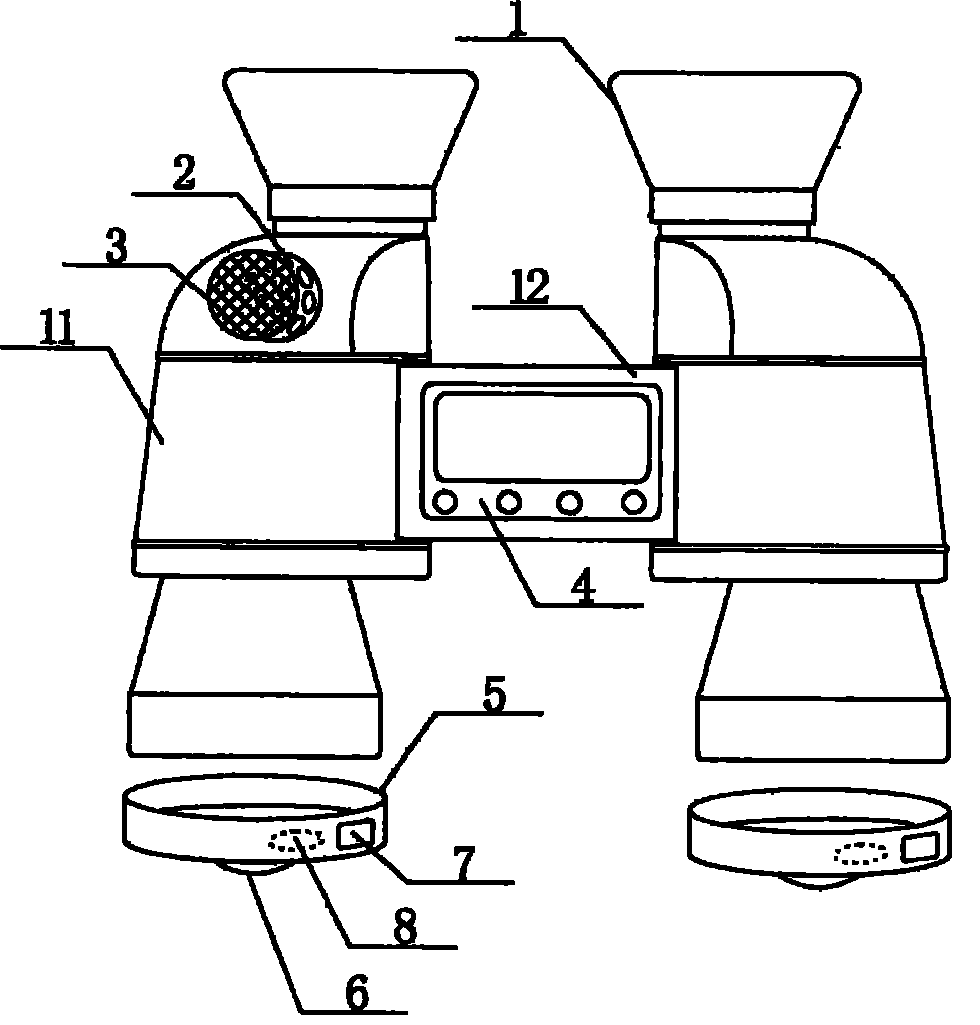

Telescope with GPS positioning function

InactiveCN101943795AEasy to useWith long-term visionLighting elementsTelescopesButton batteryEngineering

The invention discloses a telescope with a GPS positioning function, and relates to the telescope. The telescope comprises a binoculars body, wherein circular grooves and grid covers matched with the circular grooves are formed on lens cones of the binoculars; perfume is filled in the grooves; a GPS positioner is arranged on a connector for connecting the two lens cones; front ends of the two cylinders are in threaded connection with lens caps which are matched with the lens cones; an LED lamp and a control switch are arranged on the outer surface of each lens cap; and a button battery electrically connected with the LED lamp and the control switch is arranged on the inner surface of each lens cap. The telescope has the functions of viewing in long distance and observation of the traditional telescope, has the lighting function of a torch, can emit fragrance to ease emotion, relieve fatigue, and please metal and body. Furthermore, if a user is lost or encounters danger, the telescope can position of the user accurately and quickly, so that the rescue efficiency is improved. Therefore, the telescope facilitates the use of mountaineering enthusiasts, wild adventurers and the like.

Owner:曹勇

A high-pressure casting device for aluminum products and its casting method

The invention discloses a new high-pressure casting machine for aluminum products, which relates to the field of metal product casting. The traditional structure is improved, the operation is more convenient and accurate, and the casting efficiency is improved. The denseness of the product is increased by applying high pressure sequentially, and the The surface quality and mechanical properties of the product, on the premise of improving the product quality, reduce the weight of the product and save energy.

Owner:TAIAN XINCHUANG ALUMINUM PROD CO LTD

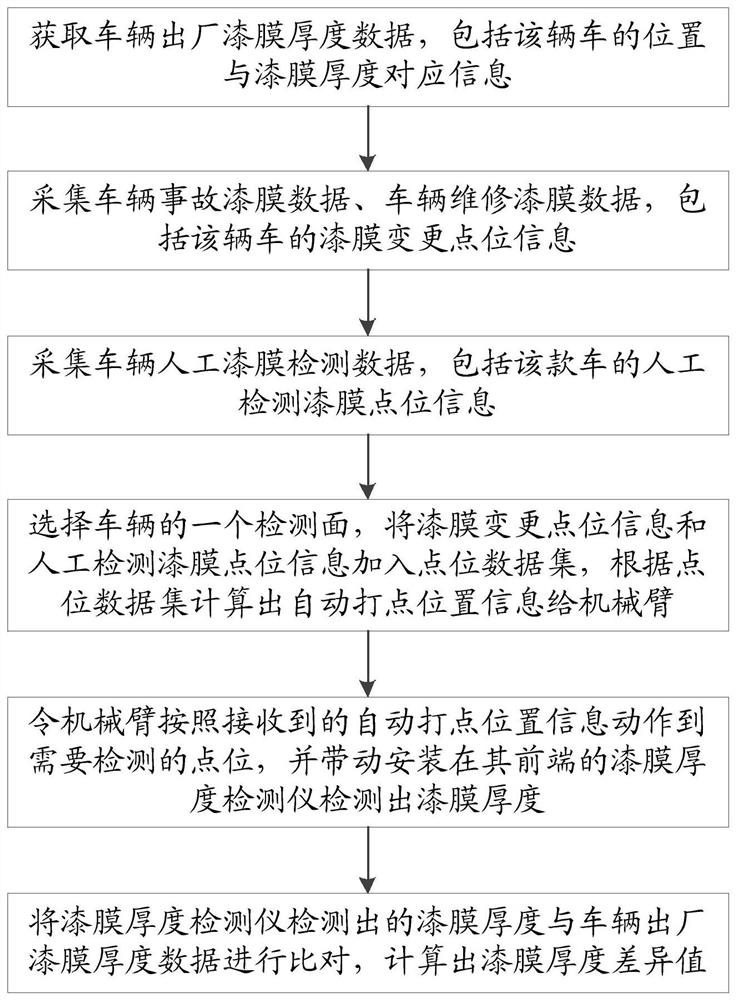

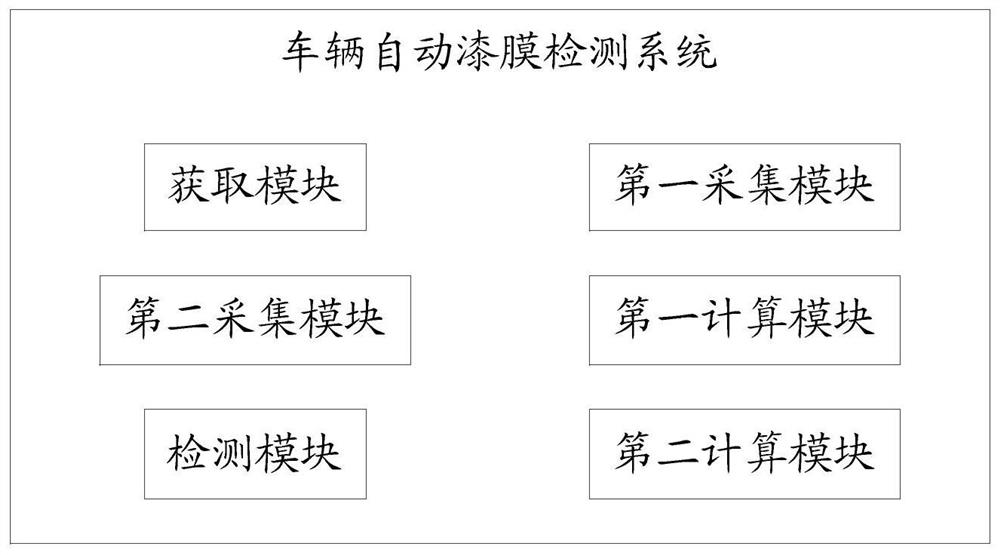

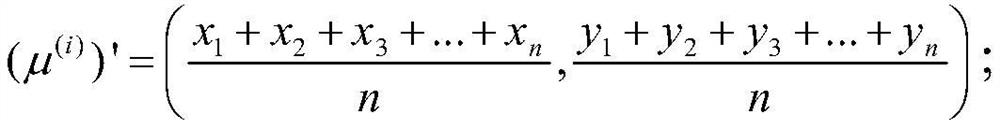

Vehicle automatic paint film detection method and system

Owner:HENGFENG INFORMATION TECH CO LTD

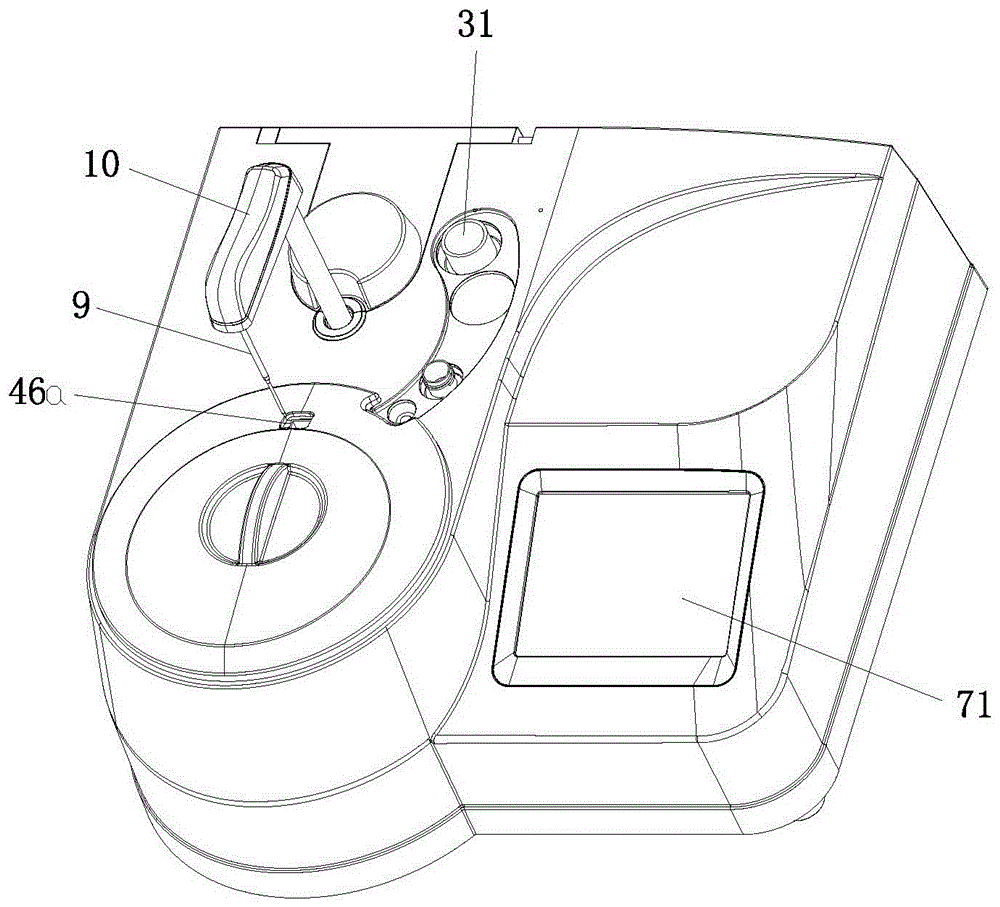

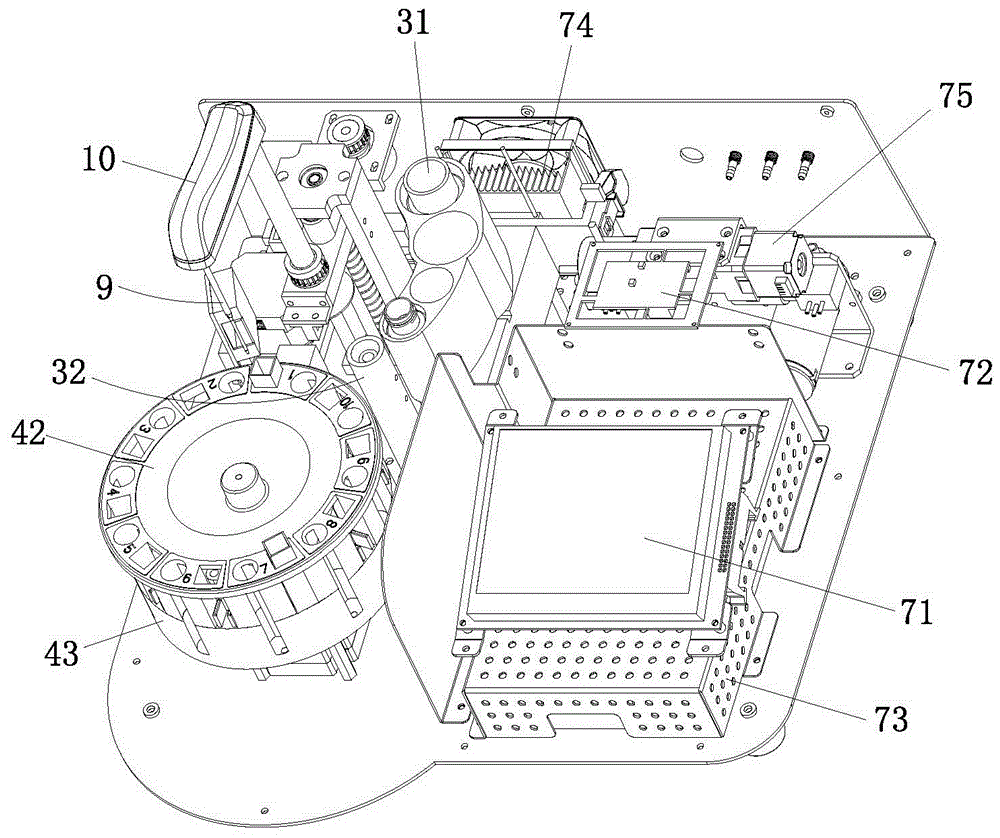

Fully automatic specific protein analyzer

The invention discloses a full-automatic particular protein analyzer which comprises a shell, a power system, a reagent cup base, a rotary sample disc, a sample adding probe mechanism, a fluid circuit system, a detection photoelectric system and a controller. The power system is used for providing power, the reagent cup base is used for containing a detection reagent, the rotary sample disc is used for containing a sample cup and a cuvette, the sample adding probe mechanism is used for adding samples, the fluid circuit system is used for providing cleaning fluid and positive and negative air pressure for a sample adding probe, the detection photoelectric system is used for detecting the turbidity of samples in the cuvette, the controller controls the power system, the detection photoelectric system and the fluid circuit system, the controller is further connected with a card reader and a displayer, the card reader reads operator information, the displayer displays parameters detected by the detection photoelectric system, and the sample adding probe adds the samples and the detection reagent into the cuvette through rotation and vertical movement for detection. According to the full-automatic particular protein analyzer, the accuracy and detection speed of protein analysis are greatly improved, and the operation intensity of workers is relieved.

Owner:SHENZHEN HUISONG TECH DEV

A method, device and storage medium for generating conference abstract based on conference records

ActiveCN112765344BQuick and accurateImprove efficiencySemantic analysisCharacter and pattern recognitionEngineeringConference note

The embodiment of the present invention discloses a method, a device and a storage medium for generating a conference summary based on conference records; the method may include: dividing sentences in the conference record corpus into at least one subtopic set according to a set clustering strategy; For each sub-topic set, a set multi-sentence compression scheme is used to generate a summary sentence corresponding to each sub-topic set; a conference abstract corresponding to the conference record is generated according to the abstract set formed by the summary sentences.

Owner:HARBIN INST OF TECH

A kind of fork type flexible weight double limit device

Owner:HENAN SINOKO CRANES

A kind of asphalt rotary compactor

ActiveCN106769333BEasy to brakeReduce lossPreparing sample for investigationDrive wheelElectric machinery

The invention discloses a pitch gyratory compactor, aims at solving the defects that an existing gyratory compactor is difficult to brake, and is technically characterized in that the pitch gyratory compactor comprises a bottom plate, a rotary table and a driving motor for driving the rotary table to rotate, wherein the rotary table is fixedly connected with a roller, the roller is rotationally connected with the bottom plate, a spindle of the driving motor penetrates through the bottom plate, and is fixedly provided with a driving wheel, the driving wheel and the roller are provided with a driving belt, used for realizing power transmission, in a sleeving manner, and the bottom plate is provided with a tension device for controlling the tightness of the driving belt. The pitch gyratory compactor is convenient to brake and also improves the detection efficiency for road samples, so that data about various properties of road surfaces can be quickly and accurately obtained, thereby providing effective reference value for road construction.

Owner:昆山市交通工程集团有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com