Piston blank casting machine

A casting machine and blank technology, applied in the field of machine tools, can solve the problems of difficulty in comprehensive guarantee, occupation of many man-hours, complicated procedures, etc., and achieve the effect of high casting precision and production efficiency, and fast and accurate action.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

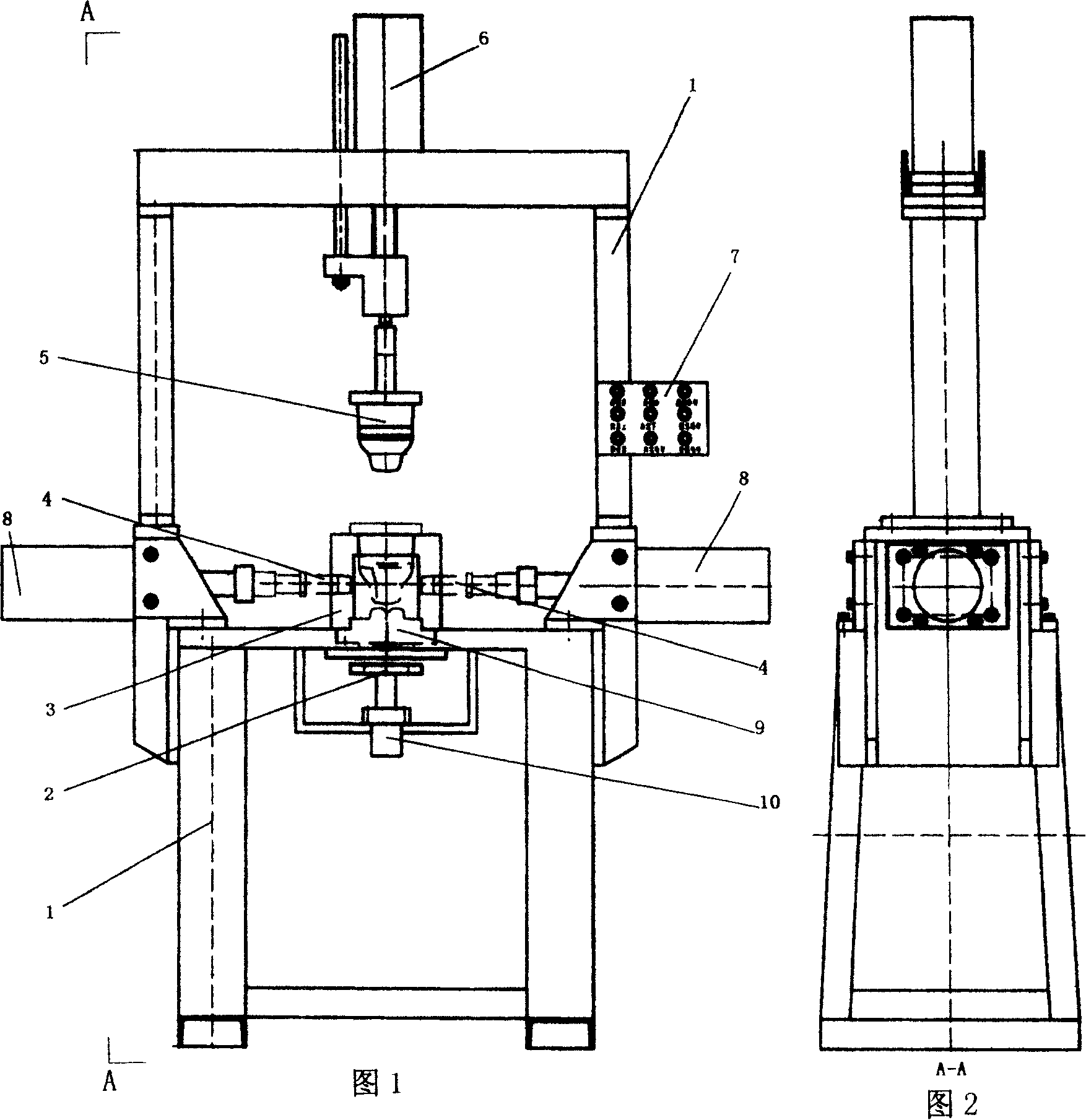

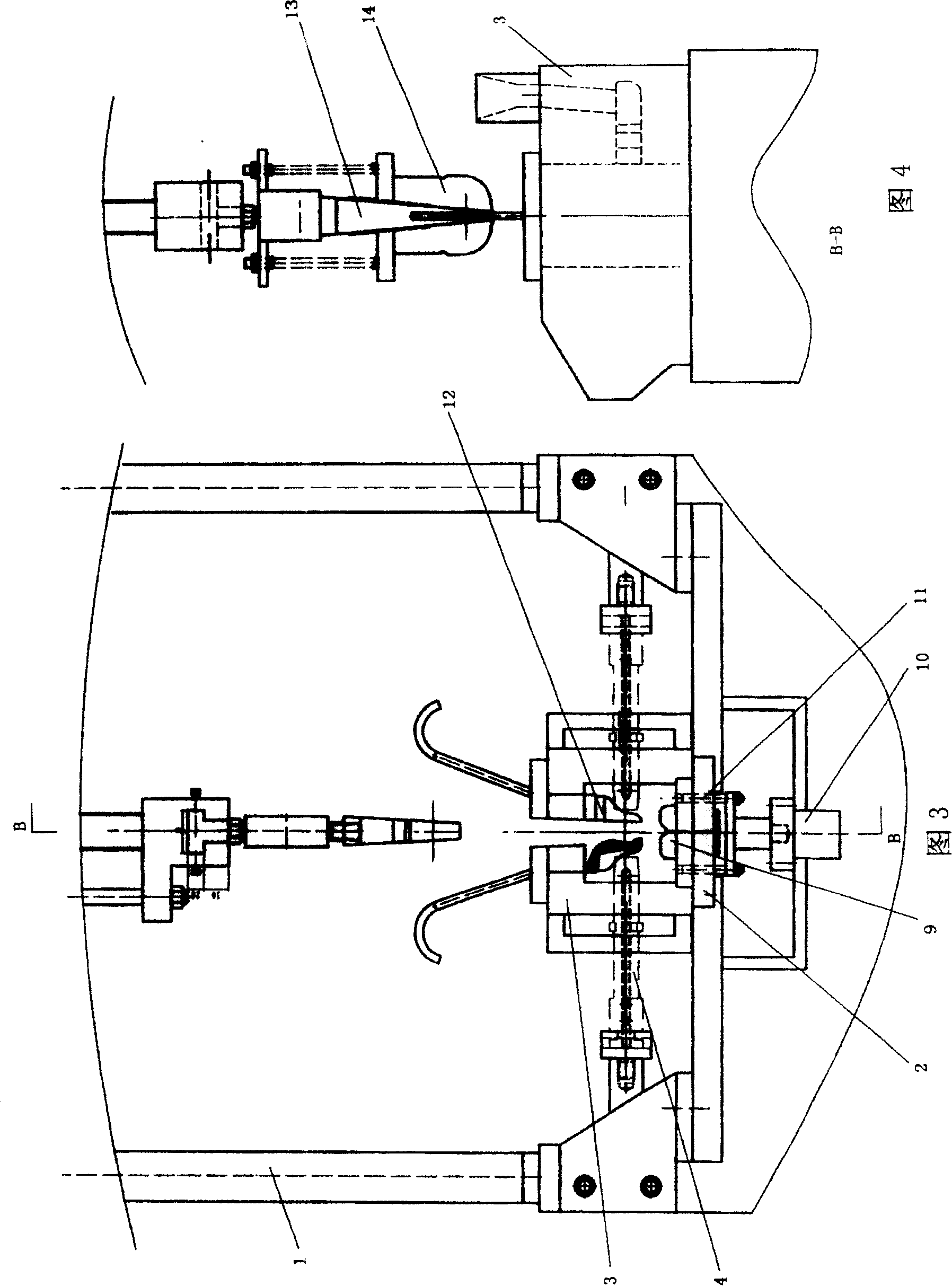

[0012] As shown in the accompanying drawings, the piston blank casting machine provided by the present invention has a frame frame 1 for supporting and installing a combination mold and a hydraulic device acting on the combination mold. The composite mold of the present invention is composed of an outer mold 3 and an inner core. The outer mold is composed of two assembled blocks on the left and right. The inner core refers to the two pin cores 4 on the left and right, the bottom core 9 at the bottom and the center core 5 at the top. .

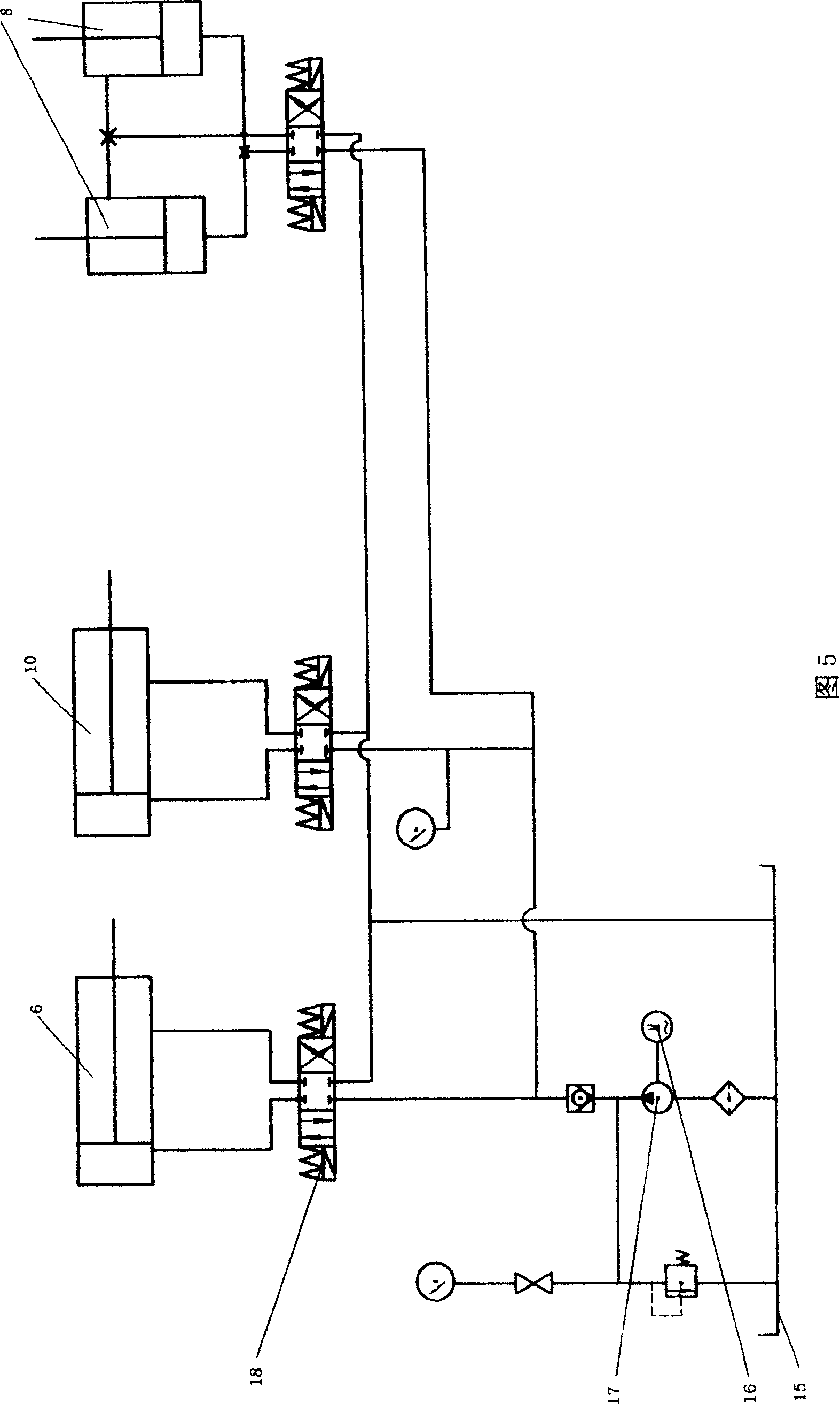

[0013] The present invention is characterized in that the above-mentioned outer mold and inner core are opened, closed and disengaged by a hydraulic system. As shown in Figure 1 and Figure 3, the left and right assembled blocks and the left and right pin cores 4 of the outer mold are respectively connected with the push rods of the left and right side hydraulic cylinders 8; The push rod of the cylinder 6 is connected; the lower bottom core 9 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com