Vehicle automatic paint film detection method and system

A detection method and paint film technology, applied to measuring devices, instruments, etc., can solve the problems of large manpower and working hours, poor reliability of detection data, etc., achieve labor saving, fast and accurate action, and realize automatic paint film detection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

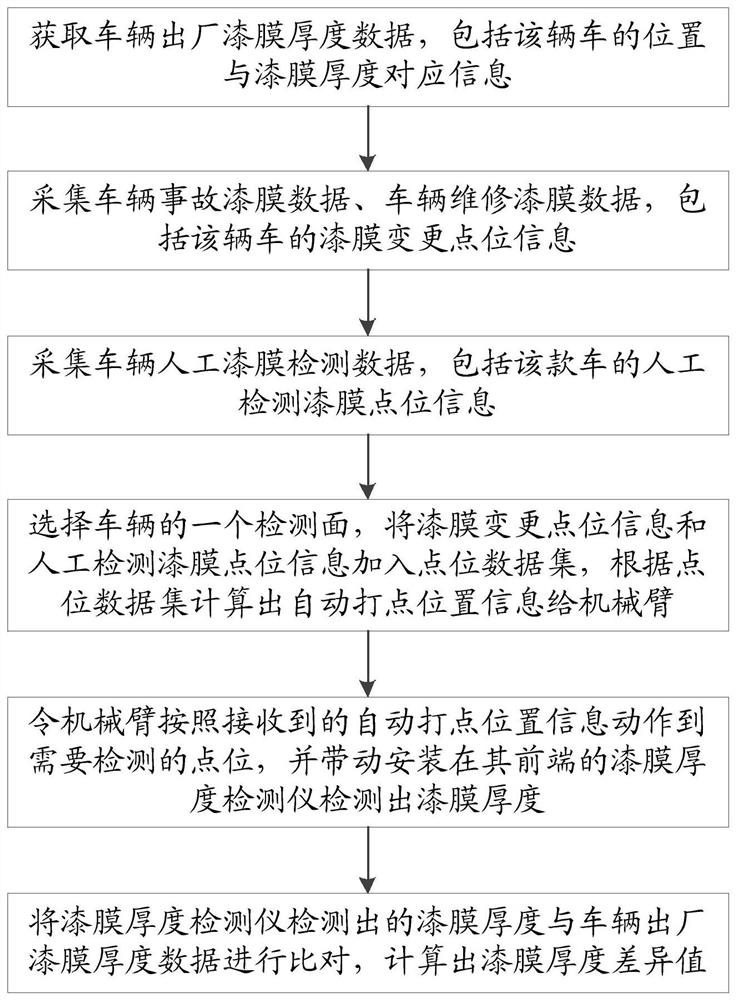

[0024] Please refer to figure 1 , the first embodiment provided by the present invention is:

[0025] A vehicle automatic paint film detection method, the method is:

[0026] Obtain the vehicle's factory paint film thickness data, including the information corresponding to the vehicle's location and paint film thickness;

[0027] Collect vehicle accident paint film data, vehicle maintenance paint film data, including the vehicle's paint film change point information;

[0028] Collect vehicle artificial paint film detection data, including the manually detected paint film point information of the vehicle;

[0029] Select a detection surface of the vehicle, add the paint film change point information and manual detection paint film point information to the point data set, and calculate the automatic dot position information according to the point data set to the robotic arm;

[0030] Make the robotic arm move to the point that needs to be detected according to the received au...

Embodiment 2

[0033] The second embodiment provided by the present invention is:

[0034] On the basis of the first embodiment, the paint film change point information and the manually detected paint film point information are added to the point data set, and the automatic dot position information is calculated according to the point data set to the robotic arm, specifically:

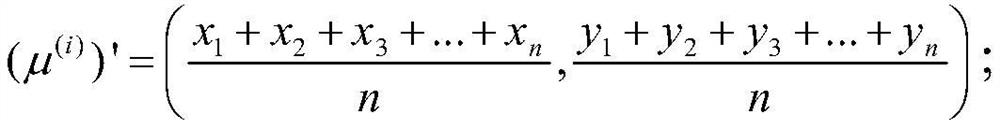

[0035] S1 adds the paint film change point information and the manually detected paint film point information as samples to the point data set D=x (1) , x (2) ,...,x (m) , set the number of detection points k, and randomly select k samples from the point data set D as the initial cluster center μ (1) , μ (2) , ..., μ (k) , set k cluster groups C 1 , C 2 ....C k , each cluster center corresponds to a cluster grouping;

[0036] S2 calculates the sample point x (j) and each cluster center μ (i) the distance:

[0037] set j = 1, 2, ..., m, i = 1, 2, ..., k;

[0038] Calculate distance

[0039] where x j ,...

Embodiment 3

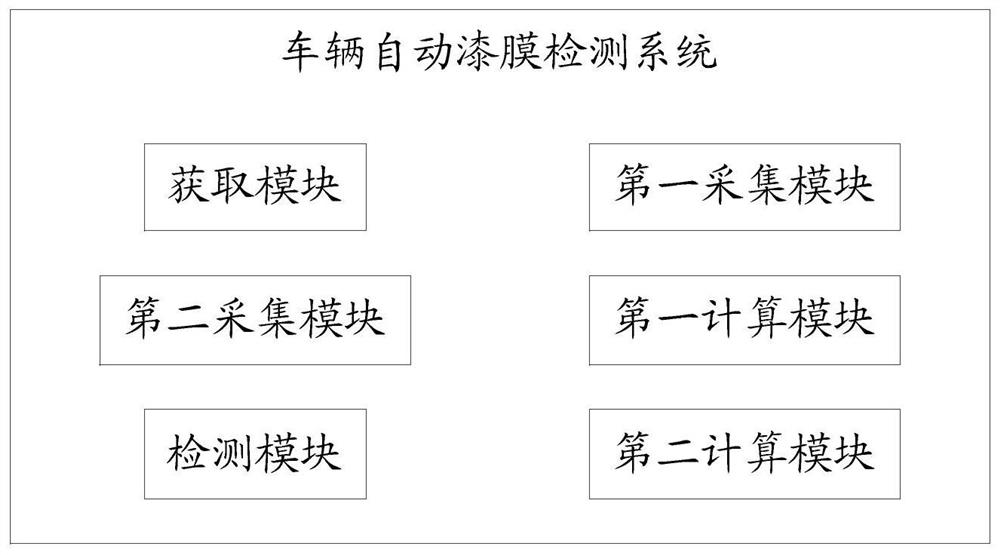

[0049] The third embodiment provided by the present invention is:

[0050] On the basis of Example 1, the paint film thickness detected by the paint film thickness detector is compared with the vehicle factory paint film thickness data, and the difference value of the paint film thickness is calculated. Specifically, k detection points are set. , i=1,2,...,k,Z i is the difference value of the paint film thickness at the i-th detection point, X i Detect the thickness of the paint film at the i-th detection point, Y i is the factory paint film thickness at the i-th detection point, then Z i =|X i -Y i |.

[0051] After the paint film thickness at the i-th detection point is detected, the paint film thickness difference Z is calculated based on the paint film thickness at the i-th detection point when leaving the factory. i , that is, the difference in the thickness of the paint film to be obtained. According to the difference in the thickness of the paint film at the k det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com