Laser weeding robot

A robot and laser technology, applied in the field of agricultural robots, can solve the problems of motion control accuracy limitation, work efficiency impact, and high control requirements, and achieve the effects of accurate and rapid action, reduced damage rate, and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

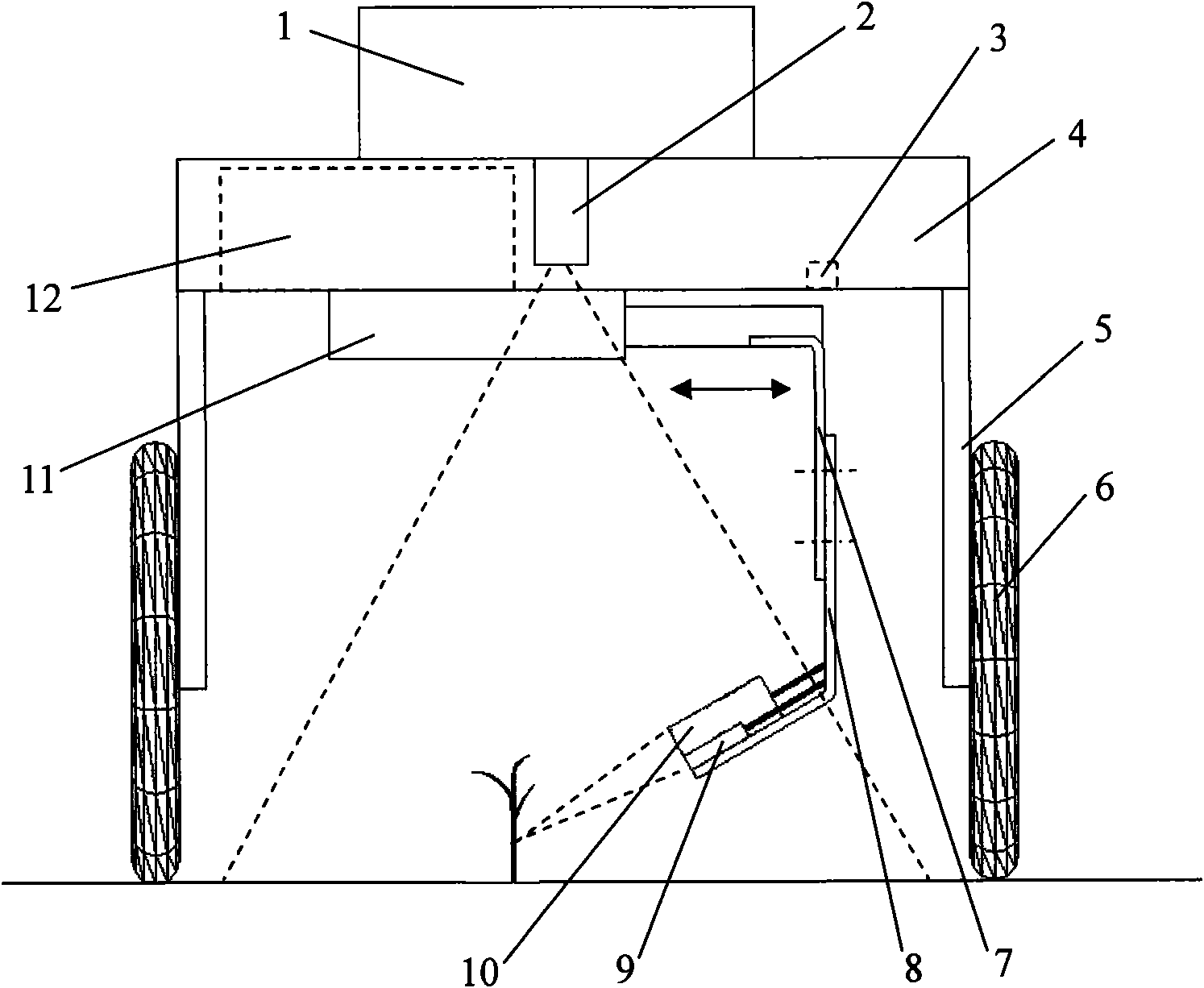

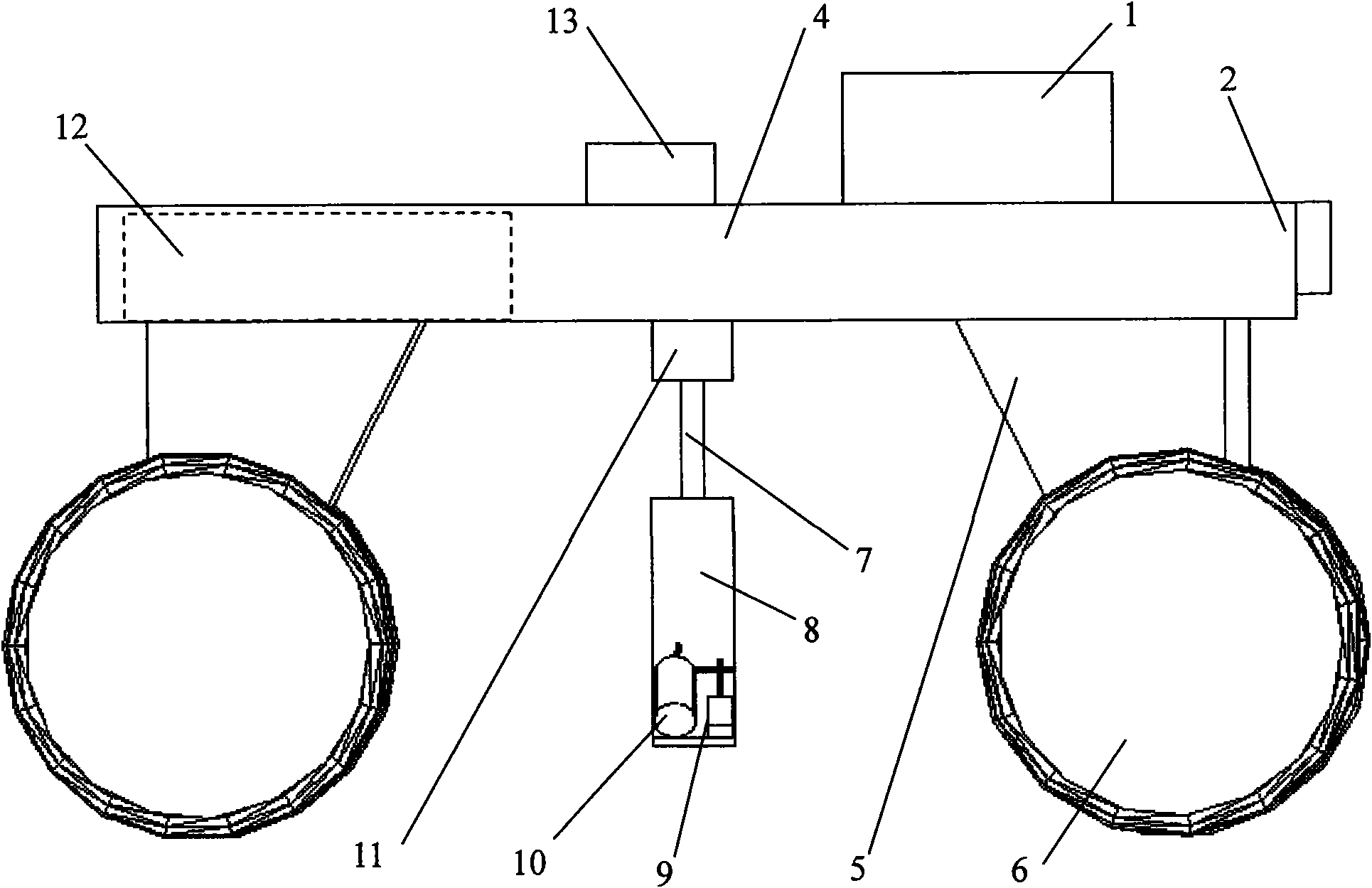

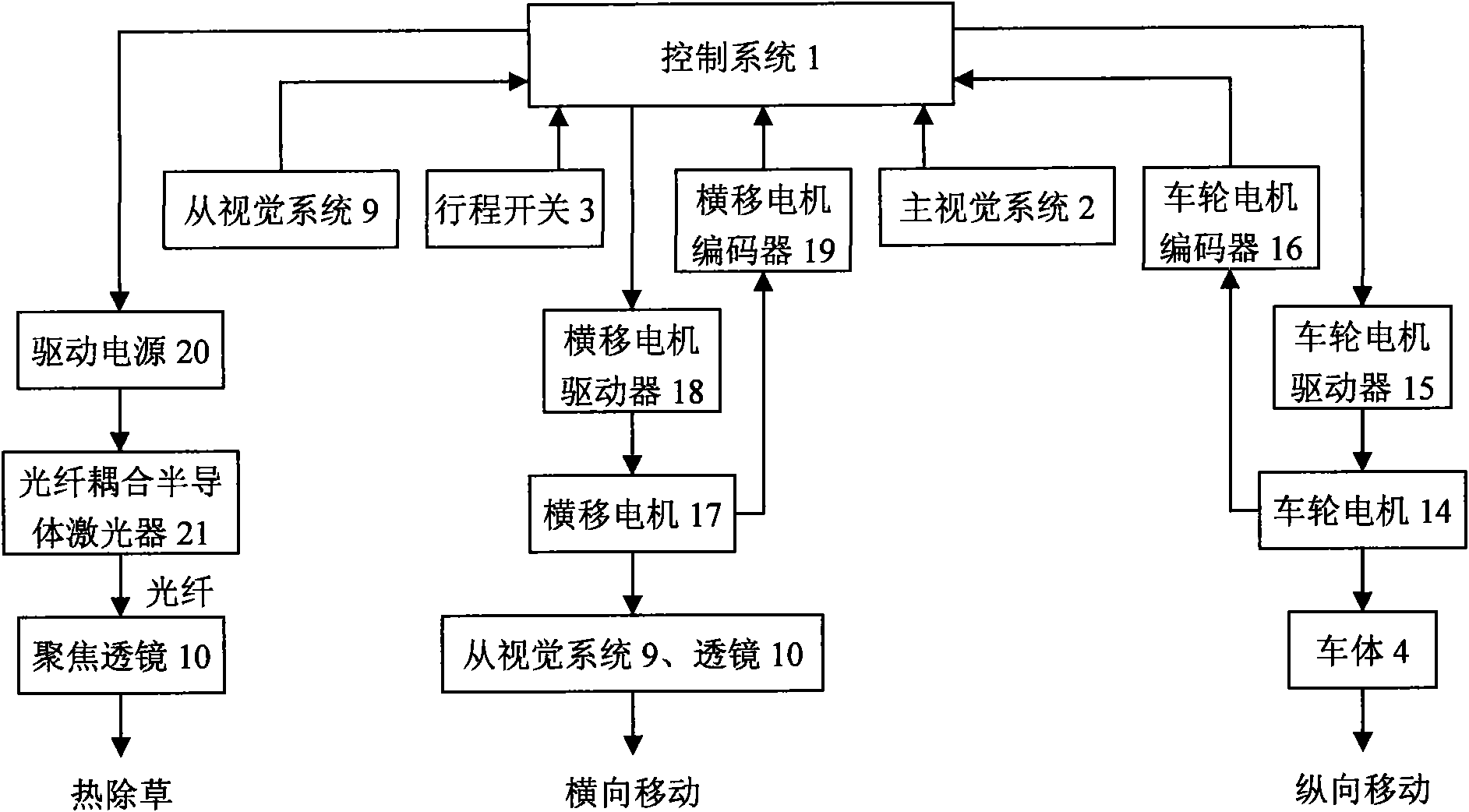

[0017] Such as Figure 1 ~ Figure 3 As shown, the laser weeding robot consists of an autonomous mobile trolley, a lateral movement device, a laser weeding device and a control system (1).

[0018] The control system (1) is composed of an industrial computer, a multi-axis motion control card and an input / output interface board.

[0019] The autonomous mobile car includes a main vision system (2), a car body (4), a frame (5), wheels (6), a battery pack (12), a wheel motor (14), a wheel motor driver (15), and a wheel motor Encoder (16). The main vision system (2) is installed at the head position of the car body (4), detects the information ahead to guide the autonomous mobile car to advance along the row direction of the crops; a battery pack (12) is installed under the car body (4) to provide power; the four wheels (6) are supported by the vehicle frame (5), and are respectively driven by a wheel motor (14); the wheel motor encoder (16) is installed on the axle of the wheel m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com