Automatic lifter of carpet tufting machine needle bar

A technology of automatic lifting device and tufting machine, applied in the field of carpet tufting machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

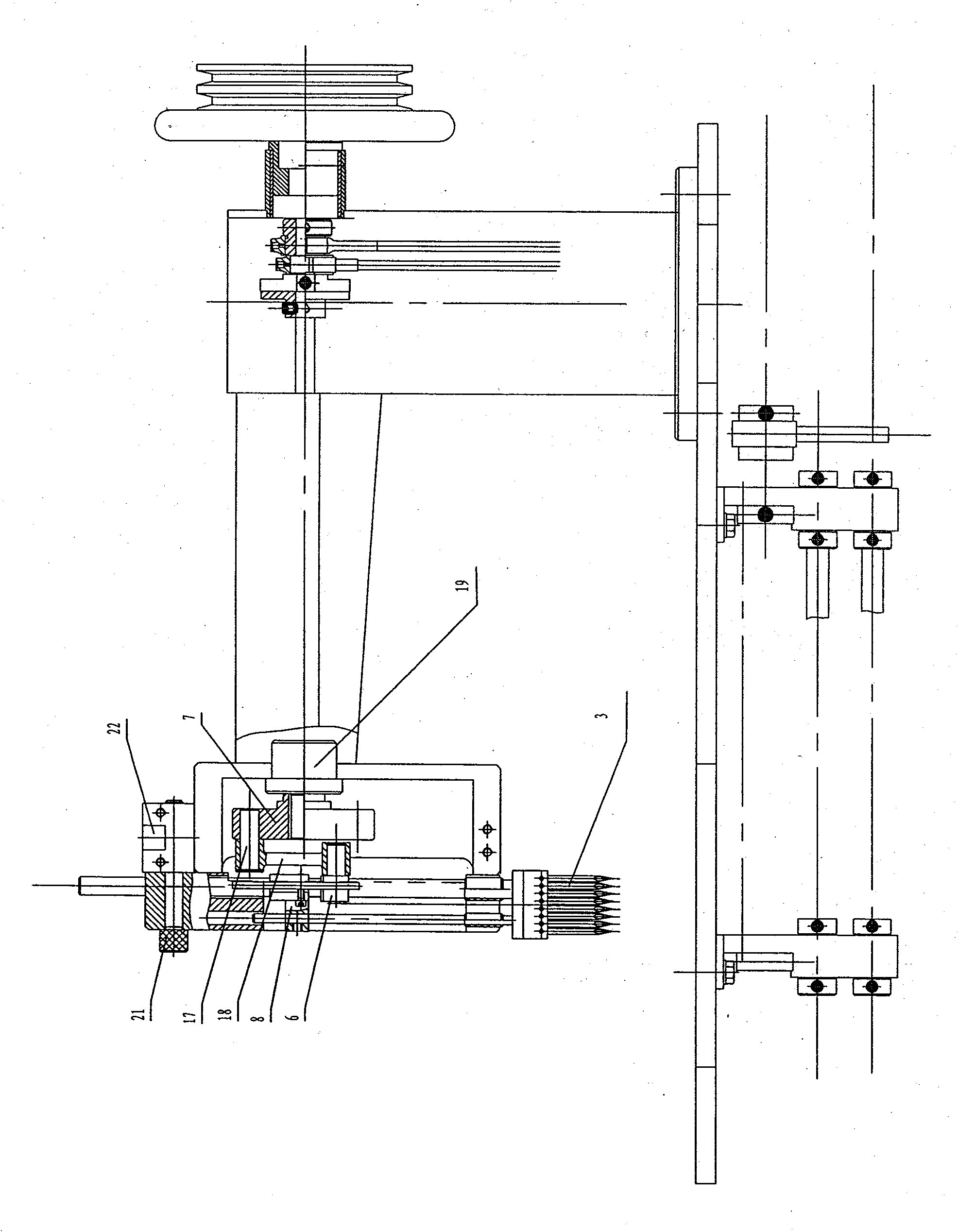

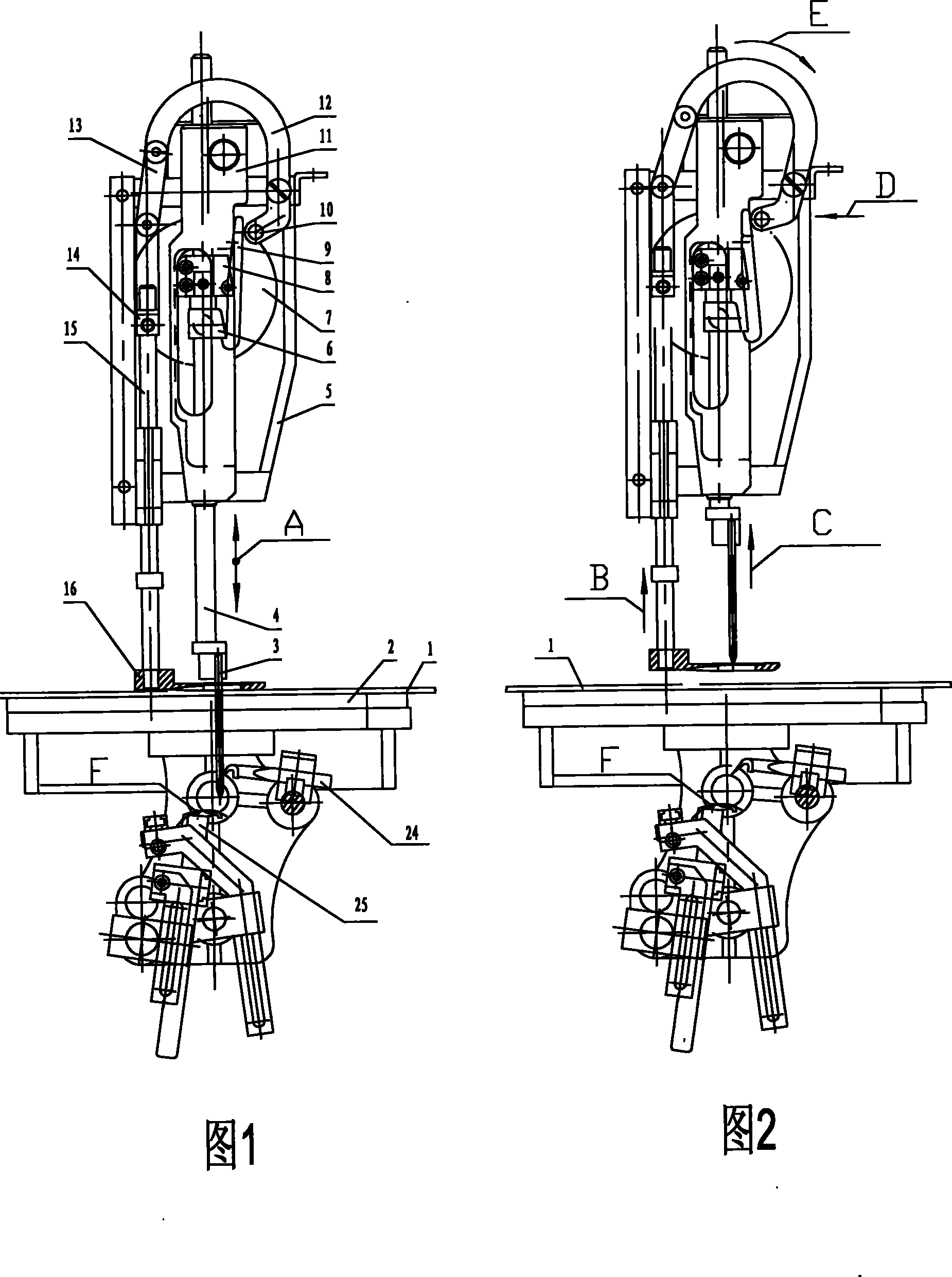

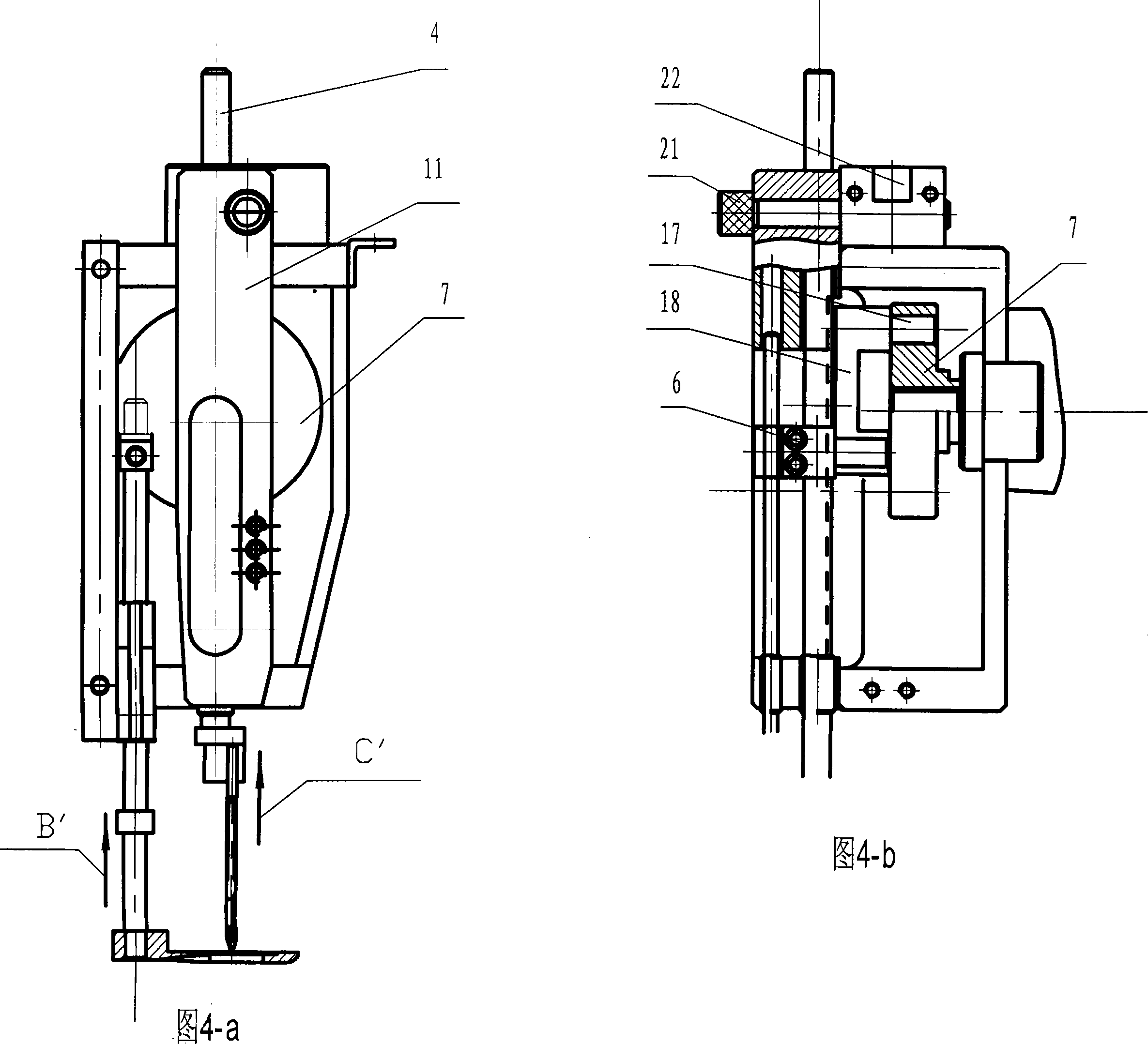

[0011] Carpet tufting head structure see figure 1 , figure 2 and image 3 As shown, it includes a machine head 5, a needle bar 4, a machine needle 3 and a platen 2, the carpet 1 is on the surface of the platen 2, and the lower part of the platen is a hook knife 24 and a straight knife 25. The inner side of the machine head 5 is provided with a transmission flywheel 7 driven by an electric motor 19, and an eccentric pin 17 is arranged on the transmission flywheel 7. One end of the eccentric pin 17 is embedded in the transmission flywheel 7, and the other end is vertically connected and fastened with a connecting rod 18. The connecting rod 18 The other end is fixedly connected with a connecting block 6 . The eccentric pin 17 on the transmission flywheel is parallel to the central axis of the transmission flywheel, and the eccentric pin 17 and the connecting rod 18 are vertically connected to form a crank connecting rod structure. A needle bar fixing block 8 is arranged above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com