A Thin Plate Heating Furnace Self-propelling Steel Rods

A technology for heating furnaces and steel rods, applied in heat treatment furnaces, furnaces, furnace types, etc., can solve problems such as harsh working environment, high working intensity, troublesome operation, etc., improve the on-site working environment, save manpower and material resources, and move quickly and accurately Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

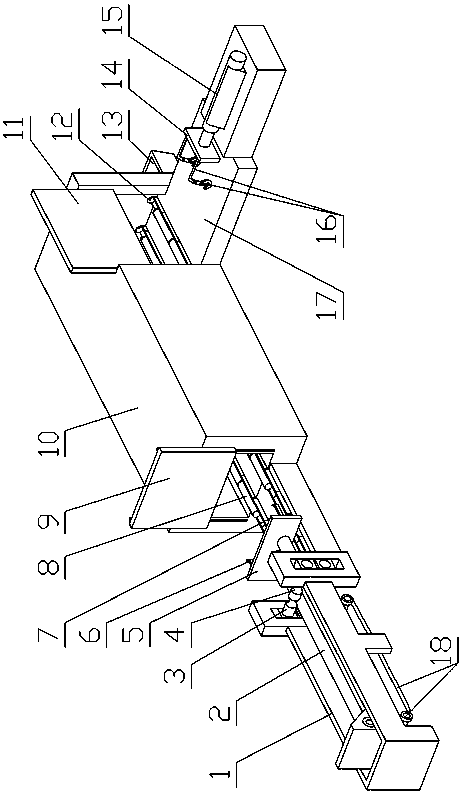

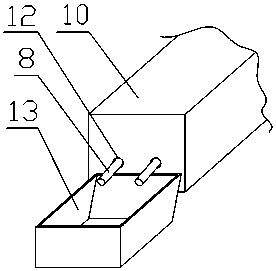

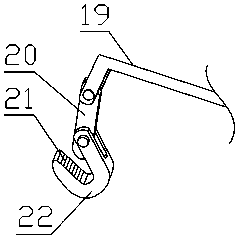

[0013] see Figure 1-Figure 3 , the present invention is a kind of thin-plate heating furnace that pushes steel bar automatically, has furnace body 10, and furnace body front part is provided with the furnace door 9 that slides up and down, is provided with two parallel furnace body length directions along the whole furnace body bottom. Arranged push steel bar groove 7, the front end of this push steel rod groove protrudes from the furnace door for a section, the front end of the push steel rod groove is provided with a push steel rod driving device, and the rear end wall of the body of furnace is provided with two push rods. Steel rod outlet hole 12, two push steel rod outlet holes are respectively docked with two push steel rod grooves, and the outside of the two push steel rod outlet holes is provided with a push steel rod collection box 13; There is a thin plate outlet, the thin plate outlet is provided with a discharge door 11 that slides up and down, the outside of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com