Pitch gyratory compactor

A technology of compactor and asphalt, which is applied in the field of auxiliary tooling for road material detection, can solve problems such as difficult braking and damage to the drive motor of the turntable, and achieves the effects of convenient power transmission, low energy loss, and improved detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

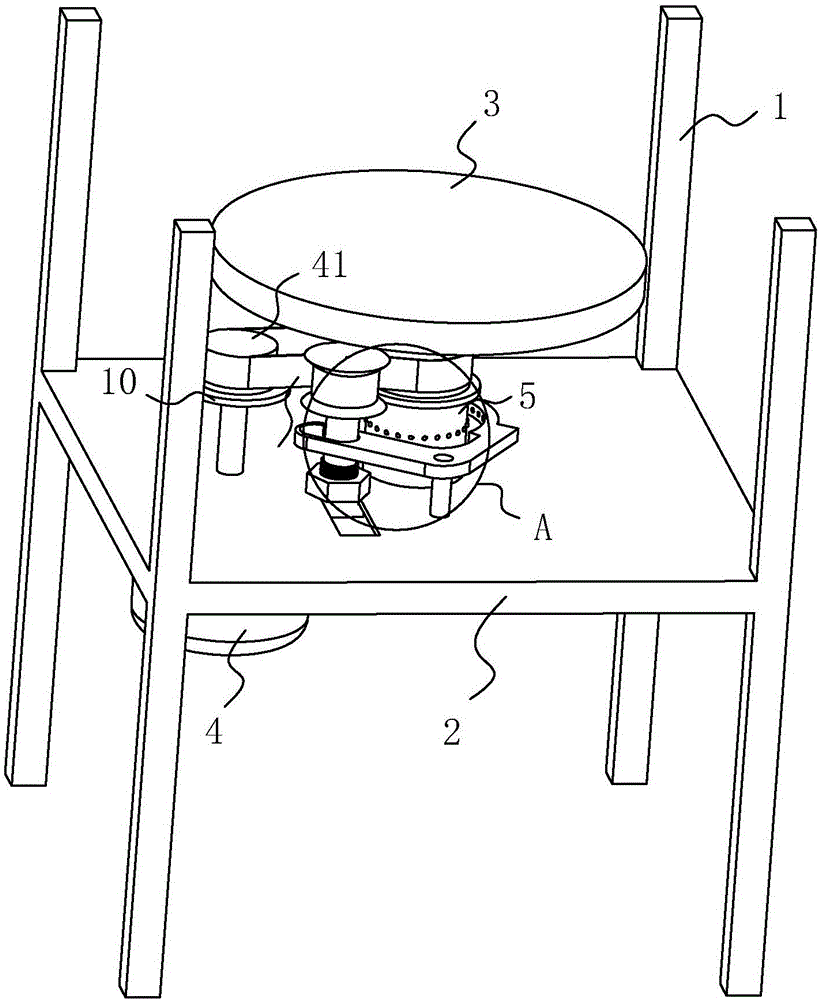

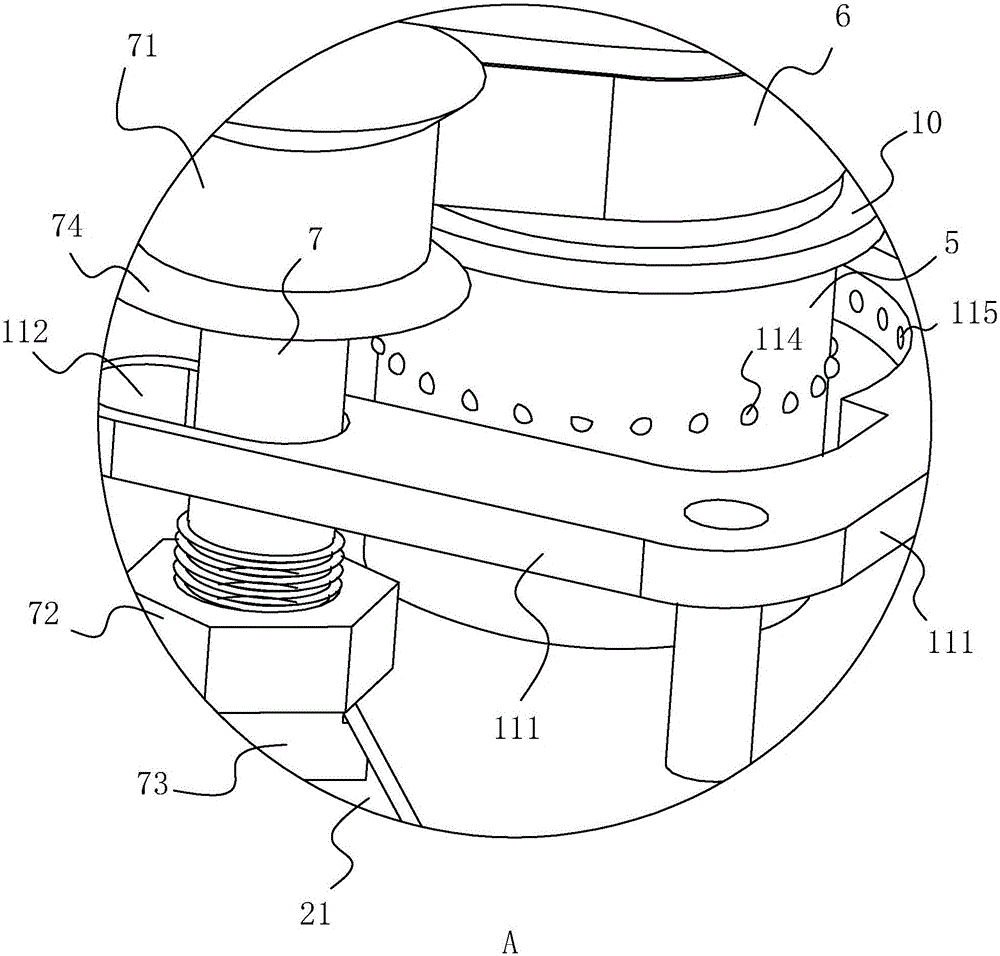

[0041] Embodiment one: a kind of asphalt rotary compactor, such as figure 1 As shown, the frame 1 is fixedly connected with a bottom plate 2, and the bottom plate 2 is rotatably connected with a rotating roller 5, and the end of the rotating roller 5 is sleeved with a turntable 3, and the bottom plate 2 is also fixedly connected with a driving motor 4, and the driving motor 4 passes Bolts are fixed on the lower surface of the base plate 2, and the rotating shaft of the drive motor 4 is provided with a transmission wheel 41, and a transmission belt 6 is sleeved between the transmission wheel 41 and the rotating roller 5, so that the transmission belt 6 is in a tight state. The driving force of the driving motor 4 can be transmitted to the rotating roller 5 to drive the rotating disk to rotate. Usually, the driving belt 6 can be a V-belt, so as to have a better transmission effect.

[0042] Such as figure 1 and figure 2 As shown, a tensioning device is provided on the base pl...

Embodiment 2

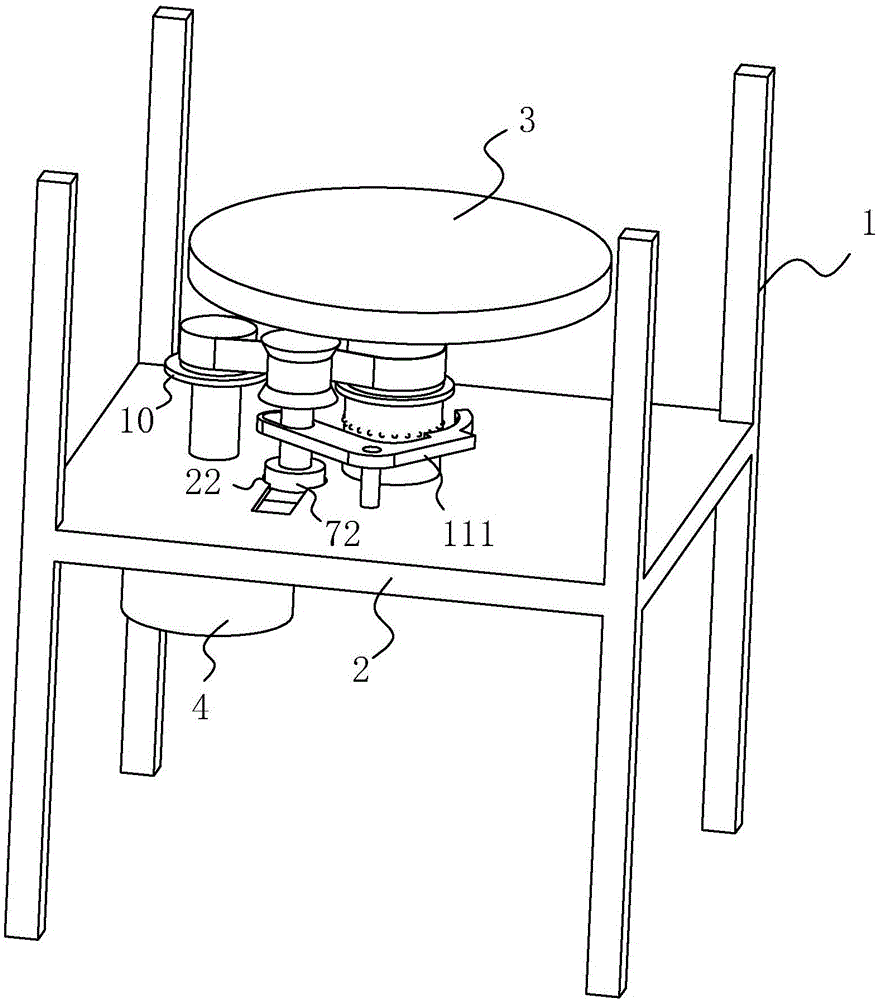

[0051] Embodiment two: a kind of asphalt rotary compactor, such as figure 2 As shown, the difference from Embodiment 1 is that the fixing piece 72 is slidably connected to the tension adjusting rod 7, and the bottom plate 2 is provided with a notch 22 matching with the fixing piece 72, and the fixing piece 72 is fitted into the notch 22. Inside.

[0052] When the transmission belt 6 is tensioned, slide the fixing part 72 to make it embed in the notch 22, and then the tension adjusting rod 7 can be fixed; Make drive belt 6 slack.

Embodiment 3

[0053] Embodiment three: a kind of asphalt rotary compactor, such as Figure 4 and Figure 5 As shown, the difference from Embodiment 1 is that the fixing member 72 is a fixing clip 8, and the fixing clip 8 includes two splints that are rotatably connected to the bottom plate 2, and the two splints can be rotated to a position that is relatively close to and away from each other. To realize the clamping and relaxation of the tension adjustment rod 7; the end of the fixed clip 8 is provided with a bayonet 81 that matches the tension adjustment rod 7, and when the fixed clip 8 clamps the tension adjustment rod 7, the tension adjustment rod 7 is placed In the bayonet 81, the tension adjustment rod 7 is restricted and cannot slide, so that the transmission belt 6 can realize more stable power transmission; the bottom plate 2 is connected with a pin block 9 in rotation, and the pin block 9 rotates in the vertical direction, and the pin block 9 9 is an L-shaped structure, which has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com